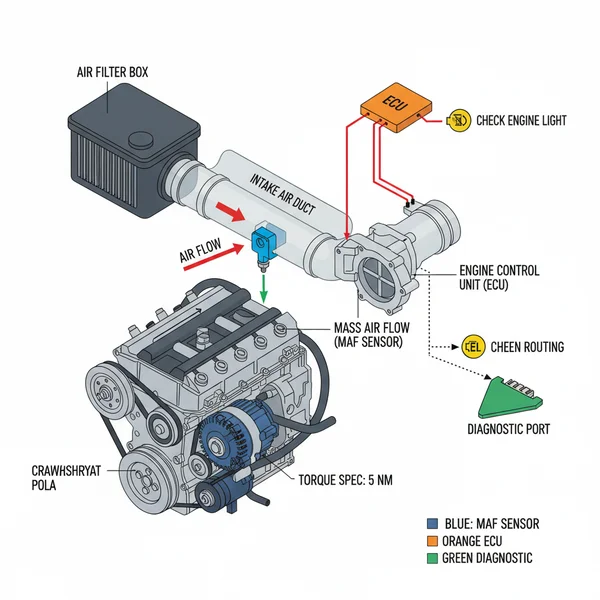

A mass air flow sensor diagram shows its location between the air filter box and the intake manifold. This critical sensor monitors air intake for the ECU to manage fuel injection. If faulty, it triggers a check engine light and a diagnostic code like P0101, requiring an OBD-II scanner for troubleshooting.

📌 Key Takeaways

- Pinpoint the MAF sensor between the air cleaner and throttle body

- Identify the electrical harness connecting the sensor to the ECU

- Ensure the engine is off and cool before touching sensitive components

- Use the diagram to identify potential air leaks in the intake tract

- Consult this map when clearing a check engine light or diagnostic code

Finding yourself staring at a glowing dashboard warning or experiencing a sudden loss of engine power can be a frustrating experience for any driver. If you have narrowed down your vehicle’s performance issues to the intake system, you are likely in search of a precise diagram mass air flow sensor location to help you identify this critical component. The Mass Air Flow (MAF) sensor is the primary gateway for air entering your engine, and having the correct visual guide is essential for accurate diagnostics. In this comprehensive guide, you will learn how to pinpoint the sensor, understand its relationship with other engine components, and master the steps required to maintain it effectively. By the end of this article, you will have the confidence to navigate your engine bay and resolve sensor-related issues without unnecessary stress or expense.

Understanding the Diagram Mass Air Flow Sensor Location

The primary purpose of a specialized diagram mass air flow sensor location is to provide a roadmap of the vehicle’s air induction system. When you look at an automotive intake diagram, you are viewing a layout of how ambient air travels from the outside environment into the combustion chamber. The MAF sensor is almost universally situated between the air filter box and the throttle body. This placement is strategic; the air must be filtered first to prevent debris from damaging the sensitive internal elements of the sensor, but it must be measured before it enters the intake manifold where it mixes with fuel.

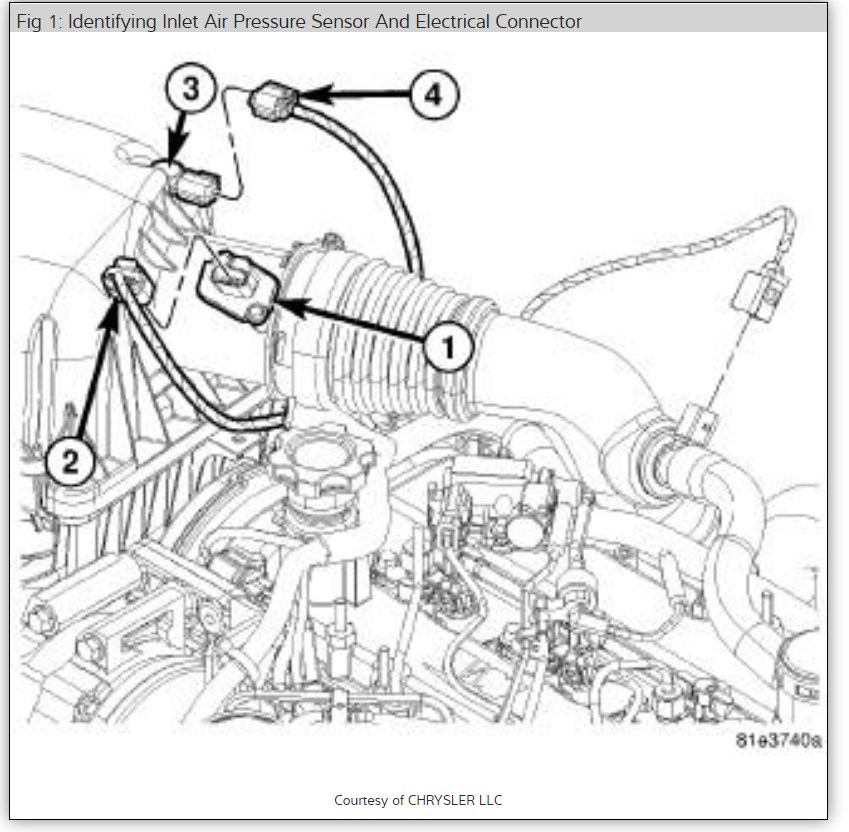

In a standard diagram, you will notice the sensor is typically housed within a plastic or aluminum tube that is part of the air intake ducting. The visual breakdown often includes the electrical harness connector, which links the sensor to the vehicle’s Engine Control Unit (ECU). The ECU relies on the data from this sensor to calculate the precise amount of fuel needed for efficient combustion. Depending on your specific vehicle make, the diagram might show a “drop-in” style sensor, which is a small probe held in by two screws, or a “housing-integrated” style where the sensor is permanently fixed inside a cylindrical section of the intake pipe.

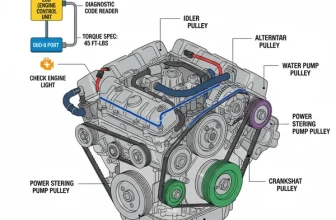

Variations in these diagrams occur based on engine configuration. For instance, in a naturally aspirated engine, the path is straightforward. However, in turbocharged or supercharged engines, the diagram might show the MAF sensor located before the turbo inlet to measure air before it is compressed. It is important to distinguish the air intake components from other engine systems shown in a general engine bay diagram, such as the accessory belt path or the routing for coolant flow. While these systems are physically close, the MAF sensor is strictly part of the electronic fuel injection and air management circuit.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing a car engine bay. The air filter box is highlighted on the left, leading to a corrugated rubber hose. In the middle of this hose, a rectangular sensor with a 5-pin wire harness is labeled “Mass Air Flow Sensor.” Arrows indicate the direction of airflow from the filter, past the sensor, and into the throttle body and intake manifold.]

The MAF sensor often works in tandem with an Intake Air Temperature (IAT) sensor. In many modern vehicles, these two components are integrated into a single unit to save space and simplify the wiring harness leading back to the ECU.

How to Find and Access the Sensor Using the Diagram

Interpreting a diagram mass air flow sensor location is the first step toward a successful DIY repair. To translate the 2D image into real-world action, follow these structured steps to ensure you find and handle the component correctly.

- ✓ Step 1: Open the hood and locate the air cleaner box, which is usually a large plastic housing on either the driver or passenger side.

- ✓ Step 2: Trace the thick, black rubber or plastic snorkel (the intake duct) that leads from the air box toward the center of the engine.

- ✓ Step 3: Look for an electrical connector plugged into the side of this duct. This is the MAF sensor.

- ✓ Step 4: Compare the physical orientation of the sensor to your diagram to identify the mounting screws or clips.

- ✓ Step 5: Carefully depress the locking tab on the electrical connector to unplug it.

- ✓ Step 6: Use the appropriate tool (usually a Phillips head or Torx bit) to remove the mounting fasteners.

Before you begin, gather the necessary tools. You will likely need a set of screwdrivers, a socket set for removing the intake duct clamps, and potentially a specialized “security” Torx bit if your manufacturer uses tamper-resistant screws. Always ensure the engine is cool to the touch before reaching into the bay.

Never attempt to clean or remove the sensor while the ignition is on. Disconnecting sensors with the battery connected can sometimes trigger a secondary diagnostic code or cause a small electrical surge that could harm the sensitive ECU internals.

When reassembling the unit, pay close attention to the torque spec of the mounting screws. These are often threaded into plastic, and over-tightening can easily strip the threads or crack the intake housing. A snug fit is usually sufficient to maintain the airtight seal required for the vacuum-sensitive intake system. Ensure that the rubber O-ring or gasket is seated perfectly; if air leaks in behind the sensor, the readings will be inaccurate, leading to lean-running conditions.

Common Issues and Diagnostic Troubleshooting

The most frequent reason people search for a diagram mass air flow sensor location is because their check engine light has illuminated. When the MAF sensor fails or becomes dirty, it sends incorrect data to the computer, resulting in a variety of drivability symptoms. Using an OBD-II scanner is the best way to confirm the issue. Common codes associated with this part include P0101 (Mass Air Flow Circuit Range/Performance), P0171 (System Too Lean), or P0174 (System Too Lean – Bank 2).

You may notice the following warning signs:

- ✓ Hesitation or “stumbling” during acceleration.

- ✓ A rough idle where the car feels like it might stall.

- ✓ A significant decrease in miles per gallon (MPG).

- ✓ Black smoke coming from the exhaust (indicating a rich fuel mixture).

If you encounter these symptoms, use your diagram to locate the sensor and inspect it for physical contamination. Often, oil from an over-serviced reusable air filter or dust that bypassed a cheap paper filter will coat the sensor’s “hot wire.” This insulation layer prevents the wire from cooling properly, leading to skewed voltage readings. If cleaning the sensor does not clear the diagnostic code, there may be an electrical fault in the wiring harness or an internal failure of the sensor’s thermistor. If you are uncomfortable testing voltages with a multimeter, this is the point where seeking professional help is recommended.

Tips and Best Practices for Maintenance

Maintaining your air intake system is far more cost-effective than replacing sensors frequently. By following a few expert recommendations, you can extend the life of your MAF sensor and keep your engine running at peak efficiency.

When cleaning the sensor, only use a dedicated “Mass Air Flow Sensor Cleaner” spray. Never use brake cleaner, carburetor cleaner, or WD-40, as these chemicals leave behind a residue that can permanently destroy the delicate sensing element.

First, always prioritize the quality of your air filter. The MAF sensor is highly sensitive to particulates. A high-quality OEM or reputable aftermarket filter acts as the primary shield for the sensor. Check the filter every 10,000 miles, especially if you drive in dusty environments. While you are in the engine bay, take a moment to inspect other related areas. Ensure the accessory belt is in good condition and that there are no leaks in the coolant flow lines near the intake, as steam or moisture can interfere with electrical connectors.

Furthermore, if your vehicle uses a timing chain, ensure your oil change intervals are strictly followed. Old oil can lead to increased blow-by gases being recirculated through the PCV system back into the intake, which eventually gums up the MAF sensor. When purchasing a replacement part, avoid the “bargain” sensors often found on discount marketplaces. The ECU requires extremely precise voltage-to-airflow mapping, and cheap sensors often have “noisy” signals that can lead to persistent check engine lights even if the part is brand new. Investing in an OEM or Tier-1 supplier part will save you time and frustration in the long run.

In conclusion, understanding the diagram mass air flow sensor location is more than just finding a part; it is about understanding how your engine breathes. By using the visual guide to locate the sensor, following safe removal procedures, and performing regular maintenance on your air filtration system, you can ensure your vehicle remains reliable and efficient for years to come. Whether you are clearing a P0101 code or simply performing a weekend tune-up, the knowledge of your intake anatomy is your most valuable tool.

Step-by-Step Guide to Understanding the Diagram Mass Air Flow Sensor Location: Finding Your Maf

Identify the air intake assembly located near the engine’s air filter box.

Locate the mass air flow sensor housing along the plastic intake tube.

Understand how the electrical harness connects the sensor directly to the ECU.

Apply the diagnostic code information by inspecting the sensor for debris or damage.

Verify that all mounting screws meet the manufacturer’s recommended torque spec after installation.

Complete the repair by using an OBD-II scanner to clear any remaining codes.

Frequently Asked Questions

What is diagram mass air flow sensor location?

This visual guide illustrates exactly where the MAF sensor sits within your engine’s air intake system. It typically shows the relationship between the air filter, the sensor housing, and the throttle body, helping you identify the specific part responsible for measuring air volume for the engine.

How do you read diagram mass air flow sensor location?

Start by identifying the air filter housing on one end and the intake manifold on the other. Trace the intake tubing between these two points; the diagram will highlight a small electronic component with a wire harness, which is the mass air flow sensor location for your vehicle.

What are the parts of diagram mass air flow sensor location?

The diagram includes the air filter box, the intake hose or bellows, the MAF sensor housing, the internal sensing element, and the electrical connector. It may also show the path to the ECU, which processes signals to manage the air-fuel ratio for efficient engine performance.

Why is the MAF sensor important?

The sensor measures the mass of air entering the engine, allowing the ECU to calculate the correct amount of fuel to inject. Without accurate readings, your car may suffer from poor fuel economy, rough idling, or a persistent check engine light that requires an OBD-II scan tool.

What is the difference between MAF and MAP sensors?

While both measure air, a MAF sensor sits in the intake stream to weigh incoming air volume, whereas a MAP sensor measures pressure inside the manifold. Our diagram specifically focuses on the MAF sensor location, which is usually found much closer to the external air filter housing.

How do I use diagram mass air flow sensor location?

Use the diagram to verify the correct orientation of the sensor during replacement. It helps you find mounting screws that require a specific torque spec and ensures the electrical connector is properly seated, preventing a diagnostic code from reappearing after you have completed your automotive repair.