If you’re looking for a 1999 Ford F250 7.3 Diesel Serpentine Belt Diagram, you’ve come to the right place. Here at serpentinebeltdiagrams.com, we have a wide variety of belt diagrams for many different makes and models of vehicles. Whether you need a diagram for your car, truck, SUV, or van, we’ve got you covered.

Finding the right diagram can be a bit tricky, but don’t worry – we’re here to help. First, take a look at the list of makes and models on our website to see if yours is listed. If it is, great!

Just click on the link and you’ll be taken to the page with the diagram. If your vehicle isn’t listed, don’t despair – we may still be able to help.

If you’re looking for a 1999 Ford F250 7.3 Diesel Serpentine Belt Diagram, look no further! This helpful diagram will show you exactly where to find the belt on your truck. Simply follow the path of the belt around the pulleys and you’ll be able to see how it all fits together.

Credit: www.thedieselstop.com

Q: How Do I Replace the Serpentine Belt on My 1999 Ford F250 7

3L Powerstroke?

A: Before you begin, make sure that the engine is cool to avoid being burned by the serpentine belt. Take off the negative battery cable to prevent an electrical shock.

Locate the tensioner pulley- it will have a spring-loaded arm with a square hole in the center. Use a ratchet and socket to rotate the tensioner clockwise until there’s enough slack in the belt to slip it off of the pulley. You can now remove the old serpentine belt.

Install the new serpentine belt by routing it around all of the pulleys except for the tensioner pulley. Once you have it in place, use your ratchet and socket to rotate the tensioner counterclockwise until there’s enough tension on the belt so that it won’t slip off of any of the pulleys. You can now put back on the negative battery cable and start up your engine- your new serpentine belt should be working properly!

3 Diesel

If you’re looking for an efficient and reliable engine, then a diesel is the way to go. Diesel engines are available in a variety of sizes and power output ratings, so you can find one that’s perfect for your needs. Here’s a look at three key benefits of owning a diesel engine:

1. Improved Fuel Efficiency

Diesel engines are more fuel-efficient than gasoline engines, thanks to their higher compression ratio. This means that they can convert more of the fuel’s energy into usable power, resulting in better fuel economy.

2. More torque and pulling power

Diesel engines also tend to produce more torque than gasoline engines, making them ideal for heavy-duty applications such as towing or hauling. And because they don’t rely on spark plugs to ignite the fuel, they can handle heavier loads without issue.

3. Longer lifespan

With proper maintenance, diesel engines can last twice as long as gasoline engines — up to 30 years or 1 million miles. That’s due in part to their tougher construction and simpler design, which includes fewer moving parts than a gasoline engine.

First, Locate the Tensioner Pulley And Release the Tension on the Old Belt

Next, remove the old belt from around all of the pulleys except for the tensioner. At this point, you may need to wiggle or pry the old belt off of the tensioner pulley. Be careful not to damage the spring on the back side of …

First, locate the tensioner pulley and release the tension on the old belt. Next, remove the old belt from around all of the pulleys except for the tensioner. At this point, you may need to wiggle or pry the old belt off of the tensioner pulley.

Next, Remove the Old Belt And Route the New One around All of the Pulleys Except for the Tensioner

If your car’s engine has an automatic belt tensioner, you can skip this step. But if it doesn’t, you’ll need to loosen the tensioner pulley before routing the new belt around all of the other pulleys. To do this, use a ratchet and socket to rotate the tensioner clockwise until there’s enough slack in the old belt to remove it.

Once the old belt is off, route the new one around all of the pulleys except for the tensioner.

Finally, Engage the Tensioner to Properly Tighten the New Belt

Assuming you are changing a serpentine belt:

First, find the tensioner. It will have a pulley on it and will usually be located near the bottom of the engine.

You may need to remove other components to get to it, such as an engine mount or power steering pump. Once you have found the tensioner, put a wrench on the bolt in the center of the pulley and rotate it clockwise to loosen the tension.

Next, thread the new belt around all of the pulleys except for the tensioner.

Make sure that you follow the routing diagram for your specific vehicle; if you don’t, the belt may not work correctly or could come off entirely while you are driving.

Once the new belt is in place, rotate the tensioner pulley counterclockwise until it is tight against the belt. You should be able to do this by hand; if not, use your wrench to finish tightening it.

Finally, check all of your work to make sure that everything is secure before starting your vehicle’s engine again.

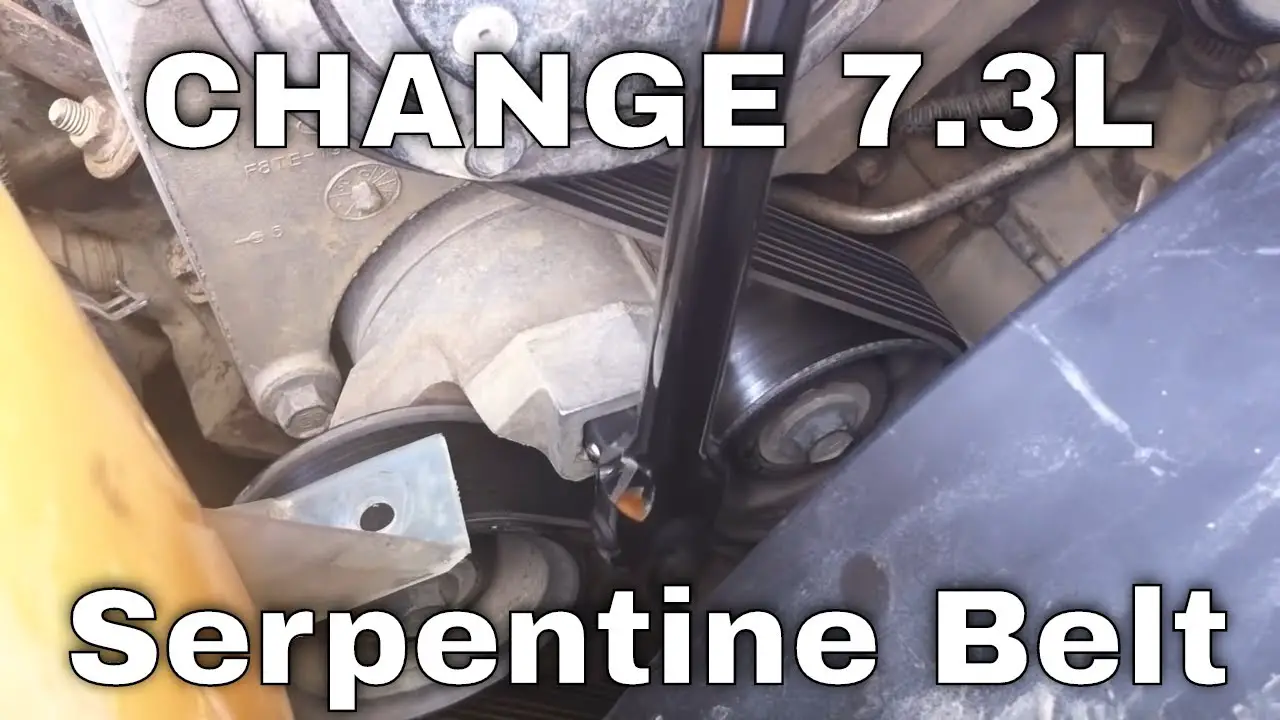

Ford F250 F350 7.3 Powerstroke Serpentine Belt change tutorial, PowerModz!

Conclusion

If you’re looking for a 1999 Ford F250 7.3 Diesel Serpentine Belt Diagram, you’ve come to the right place. Here at serpentinebeltdiagrams.com, we have a wide variety of diagrams for all sorts of vehicles, including this one.

This diagram shows the path that the serpentine belt takes on a 1999 Ford F250 7.3 diesel engine.

It is a pretty simple route, starting at the pulley on the crankshaft and going around various other pulleys before ending up back on the crankshaft. There are four main pulleys that the belt goes around, and each one serves a different purpose.

The first pulley is the tensioner pulley, which keeps the belt tight so it doesn’t slip off any of the other pulleys.

The second pulley is the idler pulley, which helps guide the belt around all of the other pulleys. The third and fourth pulleys are both located on the fan assembly, and they help drive both the fan and water pump.

Assuming everything is in good working order, this is a pretty straightforward process.

Just followthe diagram and you should have no trouble getting your serpentine belt replaced without any issues!