A sway bar bushing is a vital component of your vehicle’s suspension system. By keeping the sway bar securely in place, it helps to keep your car from rolling over on sharp turns and corners. If you notice that your car is handling oddly or that the ride is rougher than usual, it might be time to check your sway bar bushings for wear and tear.

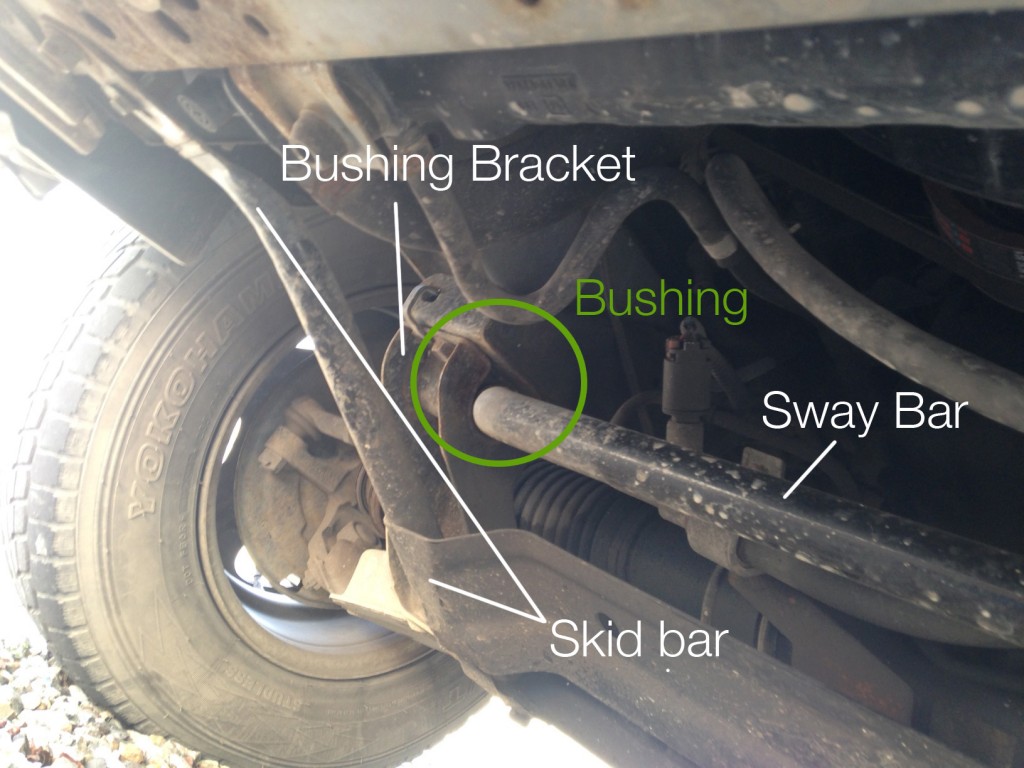

If you’re looking for a sway bar bushing diagram, you’ve come to the right place. We’ve got a great selection of diagrams to help you find the perfect fit for your vehicle.

Sway bar bushings are an important part of your suspension system, and they help keep your car stable while cornering.

Over time, however, they can wear out and need to be replaced. That’s where our diagrams come in handy – they’ll help you identify the right size and type of bushing for your car.

Once you’ve found the right bushing, simply follow the installation instructions included with the diagram.

In no time at all, you’ll have your car back on the road and handling like new!

Credit: machiine.com

How Do I Know If My Sway Bar Bushings are Worn?

If your car starts to feel like it’s “swaying” back and forth, or if you notice that the front end seems to be “floating” more than usual, then your sway bar bushings may be worn.

To check this, first take a look at your tires. If they seem to be wearing unevenly, with more wear on the inside or outside edges, then your suspension is likely not functioning properly.

This can cause all sorts of problems, including instability while driving and premature tire wear.

Next, check the connection points for your sway bar. If they’re loose or broken, then that’s definitely a sign that something is wrong.

Once you’ve confirmed that the problem is with your sway bar bushings, there are a few ways to go about fixing it.

The easiest way is to simply replace the bushings. You can do this yourself if you’re handy with tools, or you can take it to a mechanic or auto shop and have them do it for you.

Either way, replacing the bushings is relatively inexpensive and should solve the problem.

If you want to get a little bit more complicated (and save some money in the process), you can try greasing the old bushings instead of replacing them outright. This isn’t always effective, but it’s worth a shot if you’re feeling adventurous.

How Do You Press in Sway Bar Bushings?

Assuming you would like instructions on how to press in new sway bar bushings:

You will need:

-a bushing press (can be rented from most auto part stores)

-new bushings

-grease

-sockets and ratchets of various sizes

-an assistant (optional)

The first step is to remove the old bushings. This is done by placing the bushing press around the bushing and pushing until it pops out.

You may need to use a few different size sockets and ratchets to get the right fit for your particular vehicle. Once the old bushings are out, you can grease up the new ones and place them in the same spot. Again, use the press to push them in until they’re flush with the metal.

If you’re having trouble getting them started, have an assistant hold down one side while you work on pressing the other.

What is a Sway Bar Bushing?

A sway bar bushing is a device that helps to stabilize the suspension of a vehicle by reducing the amount of body roll during cornering. The bushing is mounted on the end of the sway bar and connects it to the chassis of the vehicle. The bushings are made from a variety of materials, including rubber, polyurethane, and metal.

Can You Drive With Broken Sway Bar Bushings?

If your car’s sway bar bushings are broken, you may be able to drive the car, but it is not advisable. The broken bushings can cause the sway bar to detach from the vehicle, which can lead to loss of control and a possible accident. If you must drive with broken sway bar bushings, be sure to go slowly and avoid sharp turns.

dont buy sway bar bushings ever again just do this and problem fixed any make/year/model

Sway Bar Bushing Replacement

Your car’s suspension system is responsible for keeping the vehicle level as it moves along the road. The system includes a number of parts, including the shocks, springs and sway bars. The sway bar connects the left and right sides of the suspension, and its job is to keep the body from rolling too much in a turn.

To do this, it uses bushings to attach itself to the suspension components.

Over time, these bushings can wear out or become damaged, which can affect the performance of your car’s suspension. If you notice that your car isn’t handling turns as well as it used to, or if you hear rattling from under the vehicle when going over bumps, it may be time to replace the sway bar bushings.

Replacing sway bar bushings is a fairly simple process that you can do at home with just a few tools. You’ll need a jack and jack stands to support the vehicle while you work, and a wrench or socket set to remove the old bushings and install new ones.

If you’re not comfortable working on your car’s suspension, you can take it to a mechanic or auto shop to have them handle the replacement for you.

Either way, replacing worn out or damaged sway bar bushings is an important part of maintaining your car’ssuspension system and keeping it performing at its best.

Sway Bar Bushing Symptoms

A sway bar bushing is a rubber or urethane bushing that connects the sway bar to the suspension. The main function of a sway bar bushing is to keep the sway bar from moving around too much and provide support for the suspension.

Sway bar bushings can wear out over time, causing various symptoms.

One symptom is that the vehicle may feel unstable when cornering. Another symptom is that the vehicle may have increased body roll due to the worn-out bushings. Additionally, noise may be produced from the worn-out bushings, which can be heard when driving over bumps.

If you suspect that your vehicle’s sway bar bushings are worn out, it’s important to have them replaced as soon as possible. Worn-out bushings can cause problems with handling and safety, so it’s best to get them fixed right away.

Sway Bar Bushing Replacement Cost

Are you noticing that your car is handling oddly? It may be time to replace your sway bar bushings! These little components play a big role in keeping your car stable while driving.

Depending on the severity of the damage, replacing these bushings can range in cost from $200-$600.

If you’re not sure whether or not your car needs new bushings, there are a few signs to look out for. You might notice that your car is making strange noises, or that it’s taking longer to stop than usual.

If you suspect that something is wrong with your sway bar bushings, it’s best to take it to a mechanic and have them take a look.

Replacing sway bar bushings is typically a pretty straightforward process. However, it’s always best to leave this kind of work to a professional if you’re not comfortable doing it yourself.

Once the old bushings are removed, new ones can be put in their place and secured with bolts. The whole process usually only takes a few hours from start to finish.

If you think your car might need new sway bar bushings, don’t wait too long to get them replaced.

Neglecting this repair could lead to more serious problems down the road!

Front Sway Bar Link Bushings

When it comes to your car, the front sway bar link bushing is an important part of the suspension system. This component helps to keep the vehicle stable when driving on uneven surfaces or making sharp turns. Over time, however, the bushing can become worn down, causing a number of problems.

If you notice that your car isn’t handling as well as it used to or that there’s a rattling noise coming from the front end, it could be a sign that your front sway bar link bushing needs to be replaced. With new bushings in place, you’ll enjoy a smoother ride and improved handling.

Conclusion

The diagram shows the locations of the sway bar bushings on a car. The bushings are located at the ends of the sway bar, and they connect the sway bar to the suspension. The bushings allow the sway bar to move freely, and they help to absorb shock when the car is driven over bumps.