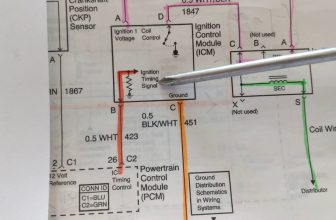

The Chevy 5.3 knock sensor wiring diagram can be found in the service manual. It shows how to connect the two sensors to the ECU. The knock sensor is used to detect engine knock and send a signal to the ECU so it can adjust the timing accordingly.

If you’re working on a Chevy 5.3 engine and need a knock sensor wiring diagram, you’re in luck. This helpful guide will show you everything you need to know about the knock sensor and how to wire it up correctly.

The knock sensor is responsible for detecting knocking or pinging sounds in the engine.

These sounds are caused by the engine’s pistons moving up and down at high speeds, and they can be damaging to the engine if left unchecked. The knock sensor sends a signal to the computer when it detects these sounds, which then adjusts the timing of the ignition to prevent further damage.

Wiring the knock sensor is relatively simple – just follow the diagram and connect the correct wires to the corresponding terminals.

Make sure that all connections are tight and secure before starting the engine, as loose wires can cause problems with the sensor’s operation. If everything is hooked up correctly, your Chevy 5.3 should be running smoothly without any knocks or pings!

How Do You Test a Knock Sensor Wiring?

A knock sensor is a piezoelectric sensor that produces a voltage when it is vibrated by engine knocking. The voltage is amplified and used to trigger the ignition timing to be retarded, which reduces the knocking.

The knock sensor is usually mounted on or near the engine block, cylinder head or intake manifold.

It must be located so that it can sense knocking in any of the cylinders.

To test the knock sensor wiring, you will need a multimeter and an assistant. Have your assistant start the engine and let it idle.

While the engine is idling, use the multimeter to check for continuity between the positive terminal of the knock sensor and ground. There should be no continuity. If there is continuity, then there is a short circuit in the knock sensor wiring and it needs to be repaired or replaced.

How Many Wires Does a Knock Sensor Have?

A knock sensor is a type of sensor that is used to detect knocking in an internal combustion engine. Knocking is a type of abnormal combustion that can cause engine damage. The knock sensor is mounted on the engine block and produces a small voltage when it detects knocking.

This voltage is sent to the engine control unit, which then adjusts the ignition timing to prevent knocking.

Most knock sensors have two wires, but some newer models may have three or four wires. The extra wires are used for additional features, such as monitoring the health of the knock sensor itself.

Where Does Knock Sensor Connect To?

If your car has a knocking noise, it could be due to a faulty knock sensor. The knock sensor is designed to detect engine knocking and send a signal to the computer to adjust the ignition timing. This can help prevent engine damage from occurring.

The knock sensor is usually located on the engine block, near the cylinder head. It will be connected to the engine with a wiring harness. In some cases, it may also be mounted on the firewall or fender well.

How Does a 2 Wire Knock Sensor Work?

A knock sensor is a type of sensor that is used to detect knocking in an internal combustion engine. Knock sensors are usually mounted on the engine block, cylinder head, or intake manifold. When the knock sensor detects knocking, it sends a signal to the engine control unit (ECU).

The ECU then adjusts the ignition timing to prevent further knocking.

Knocking occurs when the air/fuel mixture in the cylinders detonates too early. This can cause damage to the engine.

Knock sensors help prevent this by detecting knocking and then adjusting the ignition timing accordingly.

There are two types of knock sensors: piezoelectric and piezo-resistive. Piezoelectric knock sensors generate a voltage when they vibrate.

Piezo-resistive knock sensors change resistance when they vibrate. Both types of knock sensors work similarly and accomplish the same goal.

Chevy 5.3 Knock Sensor Bypass

The Chevy 5.3 knock sensor bypass is a relatively simple procedure that can be completed in less than an hour. This will allow you to avoid the expensive replacement of the knock sensor, and potentially save you hundreds of dollars.

The knock sensor is located on the side of the engine block, near the oil filter housing.

It is responsible for monitoring engine noise levels and sending a signal to the computer when knocking is detected. If the knock sensor fails, it can cause engine damage or decreased performance.

To bypass the knock sensor, you will need to disconnect the electrical connector and plug it into a spare wire harness.

Then, route the wire harness around the side of the engine block and connect it to the same location on the other side. This will effectively bypass the knocked sensor entirely.

Once everything is reconnected, start up your engine and test drive it to see if there are any negative effects from bypassing the knock sensor.

In most cases, there will be no change at all in terms of performance or fuel economy. However, if you do experience any issues, simply reverse the process and reconnect your original knock sensor.

Chevy 5.3 Knock Sensor Wiring Harness

If you have a Chevy 5.3 engine, then you may have a knock sensor wiring harness issue. This can be a difficult problem to diagnose, but there are a few things that you can look for to help you troubleshoot the issue.

First, you’ll want to check the wiring harness itself for any loose or damaged wires.

If there are any damaged wires, they will need to be repaired or replaced before proceeding.

Next, check the connection between the knock sensor and the ECU (engine control unit). Make sure that this connection is tight and secure.

Finally, test the knock sensor itself with an multimeter. You should see a reading of around 2-3 volts when the engine is idling smoothly. If you see a higher voltage reading, then this could indicate that the knock sensor is faulty and needs to be replaced.

Knock Sensor Connector

A knock sensor connector is a device that helps to regulate the timing of an engine by sensing when knocking or pinging sounds occur in the engine. This is done by using a piezoelectric crystal that produces a voltage when it is vibrated. The knock sensor connector then sends this information to the ECU so that it can adjust the ignition timing accordingly.

Knock sensors are important because they help to prevent engine damage caused by pre-ignition and also improve fuel economy.

Silverado Knock Sensor Ground

The Silverado knock sensor ground is a very important part of the truck. It helps to protect the engine from damage by keeping the oil pressure at a certain level. If the oil pressure gets too low, it can cause the engine to knock and this will damage the engine.

The knock sensor ground is located on the side of the engine near the oil filter.

Conclusion

If you’re working on a Chevy 5.3 engine and need a wiring diagram for the knock sensor, you can find one here. This diagram will show you how to wire up the sensor so that it works properly.