4 Stroke Carburetor Hoses Diagram: Installation Guide

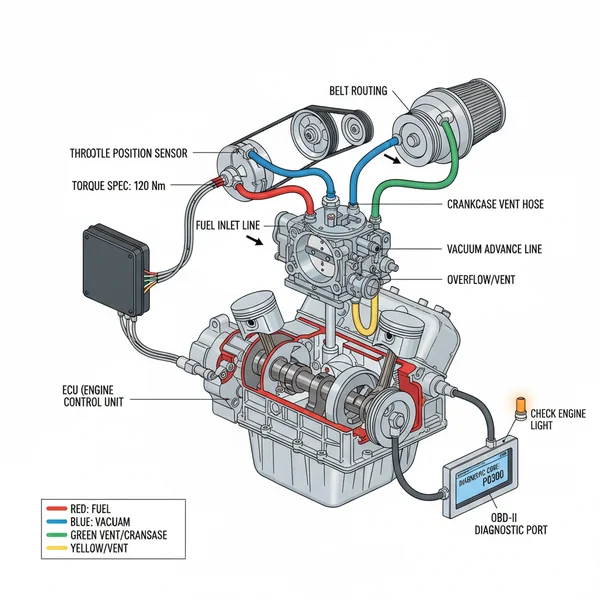

A 4 stroke carburetor hoses diagram illustrates the routing of fuel lines, vacuum hoses, and vent tubes essential for engine operation. Correct placement ensures proper air-fuel ratios, preventing a check engine light or diagnostic code on modern hybrids, while maintaining the specific torque spec for mounting bolts to avoid air leaks.

📌 Key Takeaways

- The diagram ensures precise routing of fuel, vacuum, and overflow lines.

- The fuel inlet is the most critical component to identify for supply.

- Always ensure airtight connections to prevent lean conditions and engine damage.

- Use the diagram to verify vacuum ports aren’t swapped with atmospheric vents.

- Refer to this schematic during rebuilds, cleaning, or when troubleshooting rough idles.

Finding yourself with a handful of loose rubber lines and a disassembled engine can be a daunting experience for any DIY mechanic. Whether you are rebuilding a vintage motorcycle, maintaining a lawnmower, or tuning up a small scooter, understanding a 4 stroke carburetor hoses diagram is the essential first step toward a smooth-running engine. This diagram serves as a roadmap for the fuel, air, and vacuum systems that allow your engine to breathe and combust efficiently. In this guide, we will break down the complex web of connections, explain the purpose of each hose, and provide the technical insights necessary to ensure your fuel system is routed with precision.

Understanding the 4 Stroke Carburetor Hoses Diagram

The 4 stroke carburetor hoses diagram typically illustrates three to five primary connections, depending on the complexity of the engine. Unlike modern fuel-injected systems that rely on an ECU (Engine Control Unit) and various sensors to manage fuel delivery, a carburetor uses mechanical vacuum and gravity to operate. Because there is no OBD-II port to plug into for a quick diagnostic code, your eyes and a reliable diagram are your primary tools for troubleshooting.

graph TD

A[Fuel Tank / Petcock] -->|Fuel Supply Hose| B(Carburetor Inlet)

C[Engine Intake Manifold] -->|Vacuum Hose| D(Fuel Pump or Vacuum Petcock)

B --> E{Carburetor Body}

E -->|Overflow/Drain| F[Bottom Drain Hose]

E -->|Air Vent| G[Atmospheric Vent Hose]

H[Coolant Bypass] -->|Coolant Flow| I(Carburetor Heater Port)

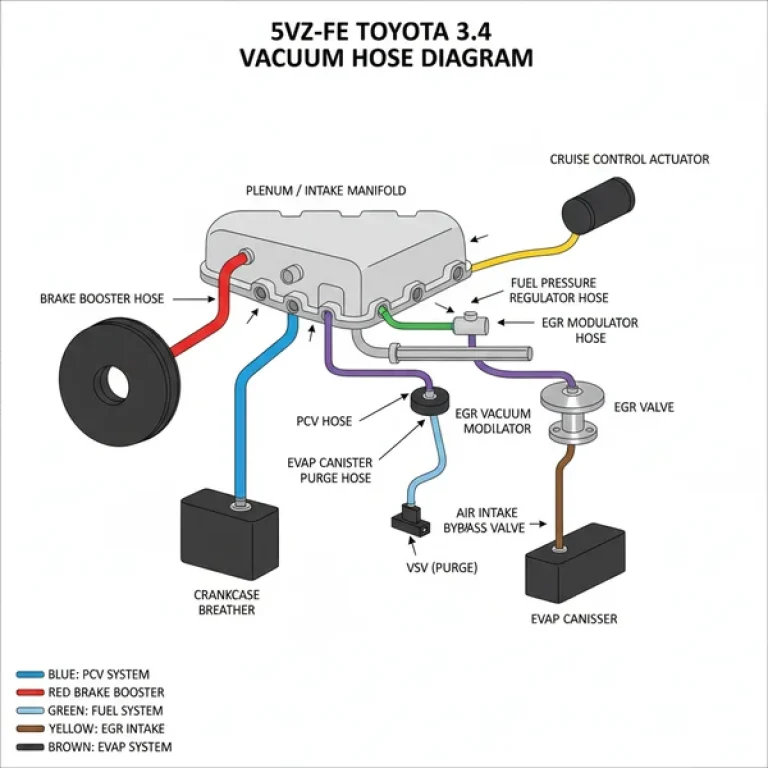

The key elements of the diagram include the fuel supply line, the vacuum line, the atmospheric vent line, and the overflow drain. The fuel supply line is usually the thickest hose, connecting the fuel tank or petcock directly to the carburetor’s inlet needle. The vacuum line is critical for engines using a vacuum-actuated fuel petcock or a fuel pump; it draws pulses from the intake stroke to “pull” fuel into the system. The atmospheric vent hose allows the float bowl to maintain equalized pressure, ensuring the fuel level remains consistent. Finally, the overflow hose, located at the bottom of the float bowl, acts as a safety release for excess fuel, preventing it from flooding the engine or the airbox.

Some high-performance or liquid-cooled 4-stroke engines may also feature hoses for coolant flow. These lines circulate warm engine coolant through the carburetor body to prevent icing in cold weather. While these aren’t part of the fuel delivery cycle itself, failing to route them correctly according to the diagram can lead to poor cold-weather performance or external leaks.

Most 4-stroke carburetors use different hose diameters for fuel and vacuum. Fuel lines are typically 1/4″ or 3/16″ (ID), while vacuum lines are thinner. Mixing these up can cause vacuum leaks or restricted fuel flow, neither of which will trigger a check engine light on older mechanical systems.

Step-by-Step Guide to Routing Your Carburetor Hoses

Correctly interpreting a 4 stroke carburetor hoses diagram requires a methodical approach. Follow these steps to ensure every line is secure and functional.

Step 1: Identify the Ports

Before attaching any hoses, clean the carburetor body with a dedicated cleaner. Locate the fuel inlet (usually a brass or plastic nipple), the vacuum port (often found near the engine-side flange), and the bowl vent (located higher up on the carb body). Referencing your diagram, label these ports mentally or with small pieces of masking tape.

Step 2: Inspect the Hoses and Clamps

Old rubber hoses tend to become brittle or “petrified” over time. Inspect your hoses for cracks or dry rot. If you are replacing them, ensure you use fuel-rated rubber or polyurethane lines. Vacuum lines must be reinforced or have thick enough walls to prevent collapsing under engine suction.

Step 3: Connect the Fuel Supply Line

Slide the fuel hose onto the carburetor inlet port. Secure it with a spring clamp or a worm-gear clamp. If your engine utilizes a fuel filter, ensure the arrow on the filter points toward the carburetor. This is the primary lifeline for the engine, so a secure, leak-free connection is non-negotiable.

Step 4: Route the Vacuum Line

Locate the vacuum source on the intake manifold or the carburetor body. Connect this to the vacuum-actuated petcock on the gas tank or the pulse fuel pump. Unlike modern cars where a diagnostic code would instantly flag a vacuum leak, a loose vacuum hose on a 4-stroke carb will simply result in an engine that refuses to start or dies immediately after starting.

Step 5: Install the Vent and Overflow Lines

Attach the vent hose to the upper port. This hose should be routed away from heat sources like the exhaust manifold and should generally point downward to prevent rainwater from entering the carb. Do the same for the drain hose at the bottom of the float bowl. Ensure these lines are not pinched by the frame or other engine components.

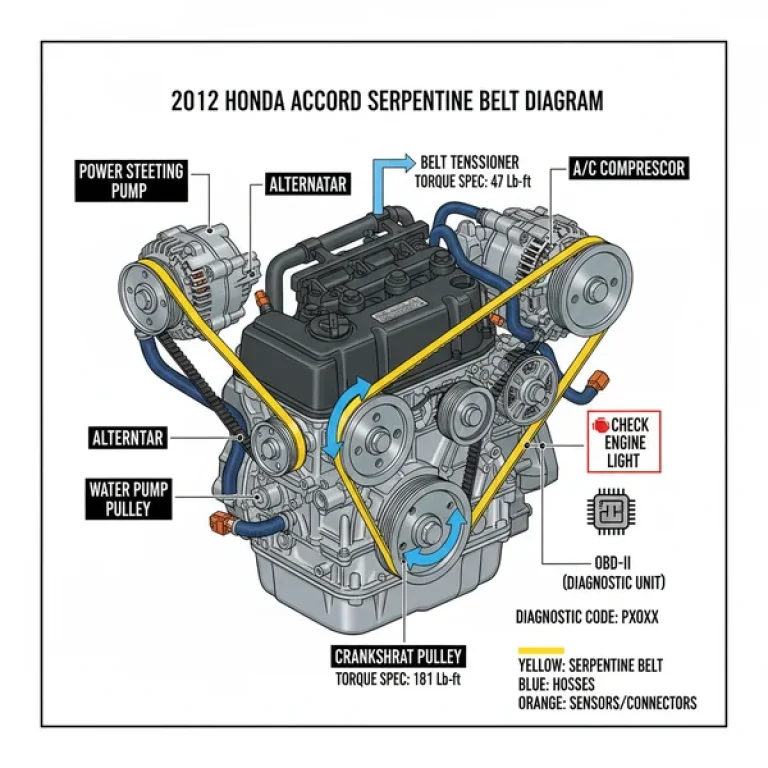

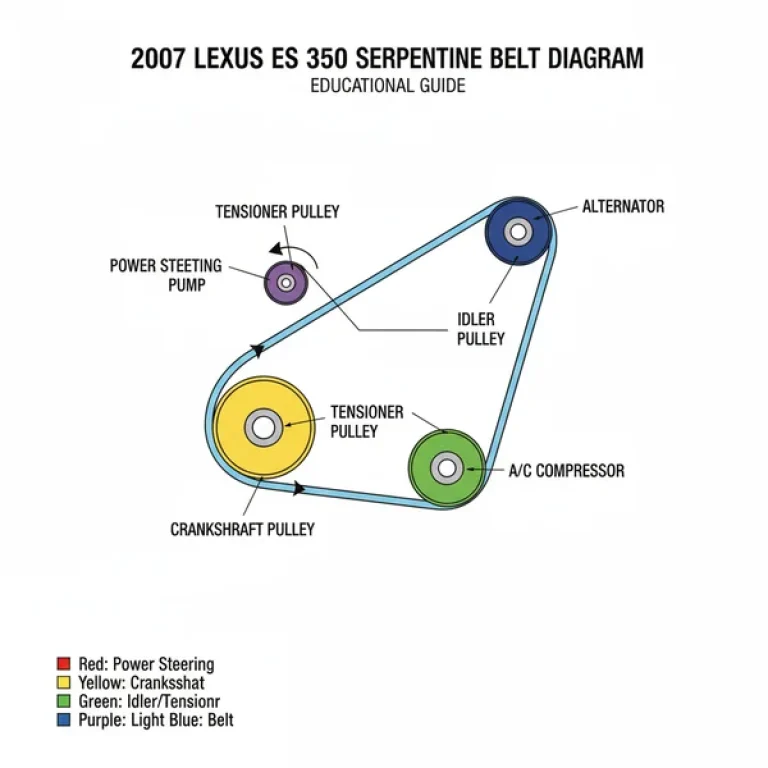

Step 6: Check for Interference

Ensure that the newly installed hoses do not interfere with the movement of the throttle linkage or the accessory belt if your engine is so equipped. For engines with a timing chain, ensure the hoses are clear of the tensioner access points. Check that the hoses have enough slack to account for engine vibrations but are not so loose that they can snag on moving parts.

Never cap off an atmospheric vent hose. If the float bowl cannot “breathe,” a vacuum will form inside the bowl, preventing fuel from entering the combustion chamber. This will cause the engine to sputter and stall as if it is out of gas.

Step 7: Final Fastening and Torque

If you had to remove the carburetor to access the ports, reinstall it now. Pay close attention to the torque spec for the mounting bolts. Over-tightening can warp the carburetor flange, leading to permanent vacuum leaks that no amount of hose adjustment can fix. Typical torque specs for small 4-stroke carburetors range between 8 to 12 Nm (check your service manual for specifics).

Common Issues & Troubleshooting

Even with a perfect 4 stroke carburetor hoses diagram, mechanical issues can arise. Because these systems lack an ECU to monitor performance, you must be your own diagnostic computer.

- ✓ Hard Starting: Often caused by a cracked vacuum line. If the vacuum petcock doesn’t receive a strong signal, it won’t open to allow fuel flow.

- ✓ Fuel Leaking from Drain Hose: This usually indicates a stuck float or a piece of debris in the needle valve, rather than a hose routing issue.

- ✓ Erratic Idling: Check for “false air” entering the system through a loose or cracked intake boot or a vacuum port that was left unplugged.

If you notice your engine is running lean (white spark plug tip), you likely have a vacuum leak. While a modern car would trigger a check engine light and store a diagnostic code like P0171, a 4-stroke engine requires a manual “smoke test” or spraying a little carb cleaner around the hoses to see if the RPMs change. If the RPMs rise when you spray a specific hose connection, you’ve found your leak.

When replacing hoses, use different colored zip ties or small colored rubber bands to mark which hose goes to which port. This makes future maintenance much faster and prevents the “where does this go?” headache during reassembly.

Tips & Best Practices for Carburetor Maintenance

To keep your fuel system operating at peak efficiency, maintenance should extend beyond just following a 4 stroke carburetor hoses diagram. High-quality components and proactive care are the keys to longevity.

First, always use high-quality, ethanol-free fuel if possible. Ethanol is hygroscopic (absorbs water) and can degrade rubber hoses from the inside out. Over time, this leads to “varnish” buildup in the carburetor jets. If you must use ethanol-blended fuel, consider installing a transparent inline fuel filter so you can visually inspect the coolant flow (in water-cooled models) and fuel clarity.

Second, pay attention to the routing path. Avoid sharp bends or “kinks” in the hoses. A kinked fuel line acts like a narrowed artery, restricting the flow needed during high-RPM operation. Similarly, ensure hoses are not touching the engine block or cylinder head directly unless they are specifically heat-shielded. Excess heat can cause the fuel to boil in the lines, leading to vapor lock.

Finally, keep an eye on your engine’s internal health. A stretched timing chain can cause improper intake valve timing, which reduces the vacuum signal sent to the carburetor. If your vacuum-operated hoses seem to be underperforming despite being new and correctly routed, the issue may lie deeper within the mechanical synchronization of the engine.

By keeping your 4 stroke carburetor hoses diagram handy and performing regular inspections, you ensure that your engine remains reliable and powerful. Whether you are navigating trails or mowing the lawn, a well-routed fuel system is the heartbeat of your machine. Regular maintenance, coupled with an understanding of how these mechanical components interact, will save you time and money, keeping you out of the repair shop and on the road.

Frequently Asked Questions

What is 4 stroke carburetor hoses diagram?

This schematic provides a visual layout of the various tubes connected to a small engine’s carburetor. It identifies the fuel supply line, vacuum pulse lines, and vent hoses. Understanding this layout is crucial for ensuring that the engine receives the correct fuel mixture and that pressure is properly regulated.

How do you read 4 stroke carburetor hoses diagram?

To read the diagram, start by locating the main carburetor body in the center. Identify the intake and outlet ports, then follow the lines representing hoses to their respective destinations, such as the fuel tank, air box, or charcoal canister, noting specific symbols for clamps and connectors.

What are the parts of 4 stroke carburetor hoses?

The primary parts include the fuel delivery hose, which carries gasoline from the tank, and the vacuum line that operates the fuel pump or spark advance. Additionally, vent hoses allow for atmospheric pressure balancing, while drain hoses prevent excess fuel from pooling inside the carburetor bowl during storage.

Why is the vacuum hose important?

The vacuum hose is critical because it utilizes engine suction to regulate fuel flow or timing. If this hose is cracked or disconnected, the ECU might struggle to manage the air-fuel ratio, potentially triggering a diagnostic code or check engine light on systems equipped with electronic monitoring or OBD-II.

What is the difference between a vent and vacuum hose?

A vent hose is open to the atmosphere to prevent pressure buildup, while a vacuum hose is a sealed line under negative pressure used to actuate components. Swapping these can cause engine stalling or flooding, as the carburetor won’t be able to draw fuel or vent gases correctly.

How do I use 4 stroke carburetor hoses diagram?

Use the diagram as a reference during reassembly after a cleaning or rebuild. Match each port on the physical carburetor to the corresponding line on the map. This ensures every hose is secured to its correct nipple, preventing leaks and ensuring the engine runs smoothly and efficiently.