If you’re looking for a serpentine belt diagram for a 6.7 Powerstroke, you’re in luck. There are a few different ways to find one, and we’ll show you how. The first place to check is your local auto parts store.

They should have a variety of diagrams available for different makes and models of vehicles. If they don’t have what you’re looking for, another option is to search online. A quick Google search will reveal a number of websites that offer free serpentine belt diagrams.

If you have a 6.7 Powerstroke, then you know that keeping up with maintenance is key to keeping your truck running smoothly. One important part of maintaining your 6.7 Powerstroke is making sure the serpentine belt is in good condition and properly tensioned. A loose or damaged serpentine belt can cause all sorts of problems, so it’s important to check it regularly and replace it if necessary.

If you’re not sure how to do this, don’t worry – we’ve got you covered. In this blog post, we’ll show you a diagram of the 6.7 Powerstroke serpentine belt so you can see exactly where it goes and what parts it covers. We’ll also give some tips on how to properly tension the belt and how to tell if it needs to be replaced.

Credit: www.thedieselstop.com

What is the Serpentine Belt Diagram for the 6

5 L diesel?

The serpentine belt routing diagram for the 6.5L diesel engine is as follows:

1. Start at the front of the engine on the left side and follow the belt to the tensioner.

2. From there, follow the belt to the left idler pulley.

3. Continue following the belt around to the right idler pulley.

4. Follow the belt around to the power steering pump pulley.

5. Continue following the belt to the crankshaft pulley (at bottom center of engine).

7 Powerstroke

The 7.3 Powerstroke was introduced in 1994 and quickly became one of the most popular engines available in Ford trucks. The 7.3L Powerstroke is a direct-injected, turbocharged diesel engine that was designed specifically for Ford Super Duty trucks. It’s one of the oldest designs still in production and has been incredibly reliable over the years.

The biggest reason for the 7.3 Powerstroke’s popularity is its reliability. These engines were built to last and they have a reputation for being nearly indestructible. They can handle a lot of abuse and still keep running strong.

Even with high mileage, many 7.3 Powerstrokes are still going strong today.

Another reason for their popularity is that they are relatively easy to work on compared to other diesel engines . There are plenty of aftermarket parts available and most mechanics are familiar with them.

This makes it easy to find someone who can work on your truck if you need repairs or upgrades .

If you’re looking for a dependable truck that will last for years to come, then a 7 . 3 Powerstroke should be at the top of your list .

These trucks have proven themselves time and time again , making them one of the best options out there .

How Do I Route the Serpentine Belt on the 6

0 Powerstroke?

If you have a 6.0 Powerstroke, you may be wondering how to route the serpentine belt. This can be a bit tricky, but with a few tips, you should be able to do it yourself.

First, take a look at the diagram that came with your truck. This will show you how the belt is supposed to be routed. If you don’t have the diagram, you can find it online or in a repair manual.

Next, make sure all of the pulleys are lined up correctly. The tensioner pulley should be at the top, followed by the idler pulley, then the water pump pulley. After that, line up the power steering pump pulley and finally the alternator pulley.

Now it’s time to start routing the belt. Start at the bottom of the tensioner pulley and work your way around clockwise until you reach the top again. Then continue on to each of the other pulleys until you’ve gone all the way around and back to where you started.

Once everything is lined up correctly, tighten down all ofthe bolts and check thatthe belt is tight by tryingto moveit side-to-side with your fingers. If it feels loose, try tighteningthe tensionerpulley a bit more until it’s snug but not too tight. And that’s it!

7 Powerstroke

When it comes to diesel engines, there is a lot of talk about the 7 Powerstroke. This engine was first introduced in the 2011 model year and it has been a popular choice ever since. There are a lot of things that make this engine so great, but here are 7 of the best reasons to choose a 7 Powerstroke engine:

1. Fuel economy – One of the biggest selling points of the 7 Powerstroke is its fuel economy. This engine is able to get up to 30 mpg on the highway, which is amazing for a diesel engine.

2. Towing power – If you need an engine that can tow heavy loads, then the 7 Powerstroke is definitely worth considering.

This engine has a max tow rating of 14,000 pounds, making it one of the most powerful diesels on the market.

3. Torque – Another big selling point of the 7 Powerstroke is its torque output. This engine produces an impressive 925 lb-ft of torque, which is sure to come in handy when hauling heavy loads or accelerating from a stop.

4. Reliability – When it comes to diesel engines, reliability is always a top concern. Thankfully, the 7 Powerstroke is built with durability in mind and it has proven to be a very reliable option over the years.

5. Resale value – If you’re looking for an engine that will hold its value down the road, then you can’t go wrong with the 7 Powerstroke .

Thanks to its popularity and demand , this engine typically commands top dollar when it comes time to sell . 6 . Warranty coverage – Another great benefit of choosing the7Power strokeis thatitcomeswitha5-year/100 , 000 – mile warranty .

This comprehensivecoverageis agreat wayto have somepeaceofmindwhen driving yourdiesel truck .

7 Overall performance – When you combine allof thesefactors together , it’s easyto see whythe7Power strokeis sucha popularchoice amongdieseltruck owners .

What are the Dimensions of the 6

5mm x284 cartridge?

The 6.5mm x284 cartridge is a high performance rifle cartridge that was developed in the early 1990s. It is based on the .308 Winchester case, which has been necked down to 6.5mm and blown out to create a longer, more powerful round.

The 6.5×284 has become a popular choice for long range target shooting and hunting applications. It is capable of reaching targets at extreme ranges with ease, and its accuracy and power make it a favorite among competitive shooters.

7 Powerstroke Serpentine Belt

If your 7.3L Powerstroke is like most, it’s probably been a while since you’ve given the serpentine belt any thought. After all, it’s not something that generally needs to be replaced very often. But, if you’re starting to hear some squealing from under the hood or you notice that the belt is looking a little worn, it might be time for a replacement.

Here’s everything you need to know about changing the serpentine belt on your 7.3L Powerstroke.

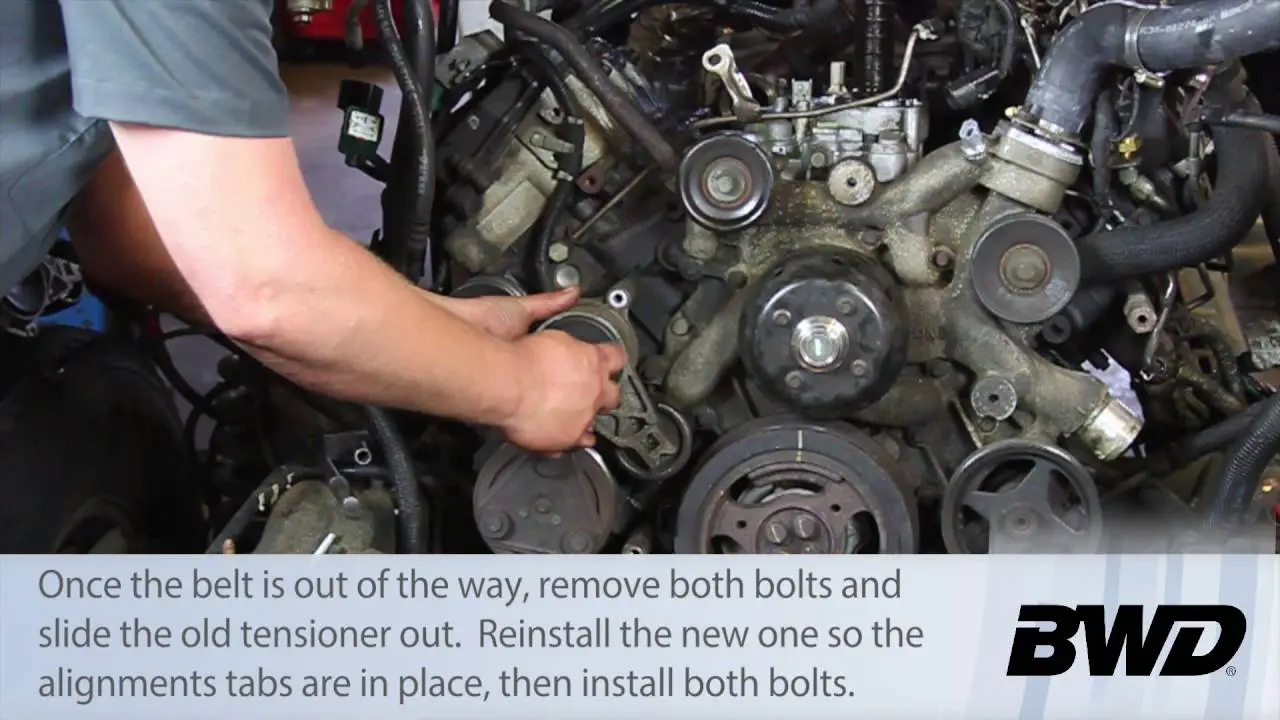

The first thing you’ll need to do is loosen the tension on the old belt by loosening the bolts on the tensioner pulley. Once the tension is released, you can remove the old belt and install the new one.

Be sure to route it correctly before tightening down the tensioner again.

One thing to keep in mind is that if your truck has an automatic transmission, there is an additional pulley on the back of the engine that also needs to be routed through with the new belt. This can be a little tricky, but if you take your time and make sure everything lines up correctly, you’ll get it installed without any issues.

Once everything is tight and in place, start up your engine and listen for any strange noises coming from under The hood- if everything sounds good, then congratulations! You’ve successfully changed your own serpentine belt!

What is the Part Number for the 6

8L SOHC 3-valve engine?

The part number for the 6.8L SOHC 3-valve engine is:

F7ZE-AA

This engine was used in the 1996 and 1997 model years of the Ford Explorer, as well as the Mercury Mountaineer. It was a V6 design with a displacement of 6.8 liters. Outputted power was 210 horsepower at 4,750 RPM with torque coming in at 315 lb-ft at 3,250 RPM.

7 Powerstroke Serpentine Belt

The serpentine belt on the 7.3L Powerstroke is a critical component to the engine. Without it, the engine will not be able to function. The belt helps to keep all of the pulleys in line and functioning properly.

Over time, the belt can become worn and damaged, which can cause it to break. If this happens, it is important to replace the belt as soon as possible to avoid any further damage to the engine.

How Do I Install the Serpentine Belt on the 6

4 Powerstroke?

Assuming you have all of the necessary tools, follow these steps to install the serpentine belt on the 6.4 Powerstroke:

1. Park your vehicle on a level surface and set the emergency brake.

Pop the hood and prop it open.

2. Locate the tensioner pulley near the center of the engine compartment. The tensioner pulley is usually silver and has a square or hexagonal shaft sticking out of it.

You’ll also see a belt routed around other pulleys in the engine bay; this is the serpentine belt.

3. Place a socket and ratchet on the tensioner pulley’s shaft and rotate it clockwise to relieve tension on the serpentine belt. This will make it easier to remove the old belt and install the new one later on.

4. Slide off the old serpentine belt from around all of the pulleys except for either end of the crankshaft pulley (the large, round Pulley at each end of engine). At this point, you can dispose of your old Serpentine Belt..

5. To route your new Serpentine Belt, start by threading it around either side of your Crankshaft Pulley (the big round one at either end). Then continue routing it around all other corresponding accessory Pulleys in a zigzag pattern until you reach back to your Tensioner Pulley..

Don’t forget that most Serpentine Belts will have an arrow or some type of indicator showing which direction they should be installed! After ensuring that your new Belt is properly routed, apply pressure to move The Tensioner clockwise again so that you can slip The Belt over its grooves..

You may need someone else to help hold The Tensioner while you do this step.. Now start up your Engine and check for properbelt operation & alignment before moving forward!

6.7 Ford Diesel BELT replacement

Conclusion

If your 6.7 Powerstroke is anything like mine, then you’re constantly looking for ways to keep it running smoothly. One of the most important things you can do is keep an eye on the serpentine belt. This blog post will show you a diagram of the serpentine belt so you can see how it works and what parts are involved.