6.6 Duramax Coolant Flow Diagram: System Operation Guide

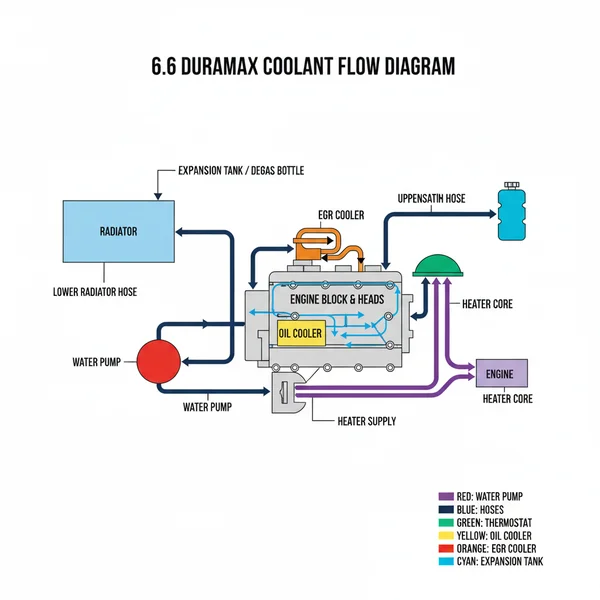

A 6.6 Duramax coolant flow diagram illustrates how antifreeze moves from the water pump through the engine block, cylinder heads, and radiator. This layout ensures heat is transferred away from critical engine parts, maintaining an optimal temperature configuration to prevent overheating and protect every internal engine component from thermal stress.

📌 Key Takeaways

- Provides a visual map of the path from the water pump to the radiator

- Identifies the dual-thermostat housing as the primary flow regulator

- Highlights the importance of maintaining a pressurized system configuration

- Assists in tracing leaks within the EGR and oil cooler lines

- Essential for diagnosing overheating or performing a system flush

Understanding the internal cooling mechanics of a heavy-duty diesel engine is essential for maintaining peak performance and longevity. For owners and mechanics working on GM’s legendary diesel platform, a 6.6 duramax coolant flow diagram serves as the ultimate roadmap for diagnostic and repair tasks. This diagram doesn’t just show where hoses go; it illustrates the complex thermal management system required to keep a high-compression, turbocharged engine from overheating under load. By mastering this layout, you will learn how coolant travels from the high-capacity water pump through the engine block, into the cylinder heads, and eventually back through the radiator, ensuring you can identify leaks, air locks, or component failures with professional precision.

Detailed Breakdown of the 6.6 Duramax Coolant Flow Diagram

The 6.6 duramax coolant flow diagram reveals a sophisticated pressurized system designed to handle extreme thermal loads. Unlike smaller gasoline engines, the Duramax utilizes a specific system configuration that prioritizes the cooling of the cylinder heads and the turbocharger, which are the highest-heat zones in the engine. The layout is centered around a gear-driven water pump located on the front passenger side of the engine, which is a departure from the belt-driven pumps found in many other vehicles.

Within the structure of this diagram, you will find several critical components that work in a synchronized loop. The flow begins at the water pump, which forces coolant into the engine block. From there, the fluid is distributed through internal galleries to the cylinder liners and then upward into the cylinder heads. A unique feature of the Duramax system is its dual-thermostat configuration. These thermostats are housed in a single manifold and are designed to open at slightly different temperatures (typically 180°F and 185°F) to provide a more graduated and stable transition of coolant flow to the radiator. This prevents “thermal shock” to the engine block when the system opens under heavy load.

Most 6.6 Duramax engines use a bypass circuit that allows coolant to circulate within the block and heads before the thermostats open. This ensures the engine reaches operating temperature quickly, reducing emissions and wear during cold starts.

The diagram also illustrates the auxiliary cooling paths. These include the heater core loop for cabin warmth, the EGR (Exhaust Gas Recirculation) cooler, and the oil cooler. In many configurations, the coolant also passes through the turbocharger housing to prevent oil coking after the engine is shut down. Understanding this layout is vital because a blockage in one of these smaller “branches” can lead to localized overheating even if the main radiator flow is clear.

Step-by-Step Guide: Interpreting and Using the Flow Diagram

Reading a 6.6 duramax coolant flow diagram requires a methodical approach. Whether you are flushing the system or replacing a water pump, follow these steps to interpret the system’s configuration correctly and perform maintenance safely.

Step 1: Identify the Direction of Flow

Start your analysis at the water pump. In any Duramax cooling system, the water pump is the “heart.” Look for the largest hose connecting the bottom of the radiator to the pump inlet. This is the suction side. The discharge side of the pump leads directly into the engine block. Tracing the arrows on the diagram from this point will show you how the fluid splits to cool both the left and right cylinder banks simultaneously.

Step 2: Locate the Dual Thermostat Housing

Follow the flow upward from the cylinder heads toward the top-front of the engine. Here, you will find the thermostat housing. In the diagram, note how the two thermostats act as a gatekeeper. When closed, they redirect coolant through the bypass pipe back to the water pump. When open, they allow coolant to exit toward the upper radiator hose. Understanding this “gatekeeper” function is essential for diagnosing a truck that takes too long to warm up or overheats instantly.

Step 3: Map the Auxiliary Loops

Modern diesel engines rely heavily on auxiliary cooling. Locate the EGR cooler on your diagram. Coolant is typically diverted from the main flow to pass through the EGR cooler to lower the temperature of exhaust gases before they re-enter the intake. Similarly, find the lines leading to the oil cooler (usually located near the oil filter base). If you notice oil in your coolant or vice versa, the diagram helps you identify these heat exchangers as potential failure points.

When refilling the system, always use the bleeder screw located on top of the thermostat housing. The 6.6 Duramax is prone to “air locking,” where a bubble of air gets trapped in the high point of the heads, preventing flow despite the pump working perfectly.

Step 4: Prepare the Necessary Tools

To work on this system based on the diagram, you will need a specific set of tools:

- ✓ Large drain pan (the system holds several gallons)

- ✓ Torque wrench (critical for the water pump and housing bolts)

- ✓ Cooling system pressure tester

- ✓ Long-reach hose clamp pliers

Step 5: Follow Safety Precautions

Never open the cooling system when the engine is hot. The Duramax system operates at high pressure, and the coolant can exceed 200°F. Wait at least one hour after driving before attempting to crack a seal or open the surge tank cap.

Common Issues & Troubleshooting Using the Diagram

The 6.6 duramax coolant flow diagram is your best friend when troubleshooting common diesel cooling issues. One of the most frequent problems is the failure of the water pump seal, often indicated by coolant leaking from the “weep hole” near the gear drive. By referencing the diagram, you can distinguish this from a simple hose leak.

Another common issue is an “overheating under load” scenario. If the diagram shows that the thermostats are the primary exit point to the radiator, and your truck stays cool at idle but spikes under a trailer load, it often points to a partially stuck thermostat or a clogged radiator core. Conversely, if you have no heat in the cabin, you can use the diagram to trace the heater core supply and return lines. Often, the quick-connect fittings on these lines become brittle and fail, or the core itself becomes plugged with debris, which is easily diagnosed by feeling the temperature difference between the two hoses identified in the layout.

Finally, the diagram is critical for spotting head gasket issues. If the system is over-pressurizing (indicated by a hard upper radiator hose shortly after startup), the diagram helps you understand that combustion gases are leaking into the coolant galleries in the head, bypassing the normal flow and pushing coolant out of the overflow tank.

Tips & Best Practices for Cooling System Maintenance

To keep your Duramax running cool, maintenance should be proactive rather than reactive. The 6.6 duramax coolant flow diagram highlights just how many components rely on clean fluid. Over time, the corrosion inhibitors in diesel coolant break down, leading to cavitation—a process where tiny bubbles collapse against the water pump impeller and cylinder liners, literally pitting the metal.

Always use the recommended OAT (Organic Acid Technology) coolant, commonly known as Dex-Cool, unless your specific aftermarket configuration dictates otherwise. Mixing different types of coolant can lead to “sludging,” where the fluid thickens into a gel that blocks the narrow passages in the EGR and oil coolers shown on your diagram.

- ✓ Inspect Hoses Every 50k Miles: The rubber components in the high-pressure zones of the Duramax can soften over time due to oil exposure and heat.

- ✓ Test the Cap: The surge tank cap is a pressure relief valve. If it fails to hold the correct PSI, the boiling point of your coolant drops, leading to mystery overheating.

- ✓ Clean the Radiator Fins: Because these trucks are often used for work, the space between the intercooler and radiator can collect dirt and bugs, obstructing the airflow required by the diagram’s heat exchange process.

In summary, the 6.6 duramax coolant flow diagram is more than just a technical drawing; it is a vital tool for ensuring your engine remains healthy for hundreds of thousands of miles. By understanding the system configuration, identifying each critical component, and following a regular maintenance schedule, you can prevent costly repairs and ensure your truck is always ready for the next heavy haul. Whether you are a DIY enthusiast or a professional technician, keeping the flow clear and the pressure steady is the key to Duramax reliability.

Frequently Asked Questions

What is 6.6 Duramax coolant flow diagram?

The 6.6 Duramax coolant flow diagram is a visual schematic showing the path fluid takes to regulate engine temperature. It highlights the internal structure of the cooling system, starting from the water pump and traveling through the block, heads, radiator, and heater core to maintain operational stability.

How do you read 6.6 Duramax coolant flow diagram?

To read the diagram, start at the water pump, which drives the fluid. Follow the arrows indicating direction through the engine block. Note where the flow splits toward the oil cooler and EGR cooler, and identify the thermostat location where fluid is directed back to the radiator.

What are the parts of 6.6 Duramax cooling?

The system includes the water pump, radiator, dual thermostats, oil cooler, heater core, and EGR cooler. It also features a complex layout of high-pressure hoses and a surge tank. Each component plays a vital role in ensuring the engine structure remains within a safe thermal operating range.

Why is the water pump component important?

The water pump is the central component that provides the mechanical force needed to circulate coolant. Without this pressure, the system cannot move heat away from the cylinder heads. A failure here disrupts the entire configuration, leading to rapid engine overheating and potential long-term structural damage to the block.

What is the difference between LLY and L5P flow?

While the basic flow structure remains similar across 6.6 Duramax generations, later models like the L5P feature a more complex EGR cooling layout and updated thermostat housing. The configuration of the oil cooler also evolved to handle higher heat loads produced by more modern, high-output engine calibrations.

How do I use 6.6 Duramax coolant flow diagram?

Use the diagram to identify potential leak points and to understand which hoses to disconnect during a flush. It is an invaluable tool for troubleshooting cold spots in the heater core or verifying that the thermostat component is opening correctly by checking temperature variations along the flow path.