6.0 Powerstroke Engine Bay Diagram: Component Identification

A 6.0 Powerstroke engine bay diagram provides a visual map of critical components like the FICM, turbocharger, and cooling system. Using this guide helps you locate sensors for troubleshooting a check engine light or verifying a diagnostic code via the OBD-II port. It is an essential tool for accurate maintenance and performance tuning.

📌 Key Takeaways

- Identify high-pressure oil system components and electronic controllers.

- Locating the FICM (Fuel Injection Control Module) is vital for starting issues.

- Always check electrical connectors for signs of heat damage or fraying.

- Reference the diagram to ensure every bolt meets the correct torque spec.

- Use the layout to quickly access sensors when diagnosing performance drops.

Navigating the complex world of Ford’s 6.0L diesel engine can be a daunting task for even seasoned mechanics. Whether you are performing routine maintenance or diagnosing a performance issue, having a clear 6.0 powerstroke engine bay diagram is essential for success. This diagram serves as your visual roadmap, identifying the intricate web of sensors, fluid reservoirs, and mechanical components that make this V8 powerplant unique. By understanding the layout, you will learn how to identify critical parts like the FICM, turbocharger, and cooling system, ensuring you can tackle repairs with confidence and precision.

Understanding the 6.0 Powerstroke Engine Bay Diagram Layout

The 6.0 Powerstroke engine bay is notoriously crowded, designed to fit a high-output diesel engine into the engine compartments of Super Duty trucks and Excursions. A comprehensive 6.0 powerstroke engine bay diagram reveals a layout dominated by the large turbocharger assembly located at the rear-center of the engine. Surrounding this are the fuel injection control module (FICM) on the driver-side valve cover and the degas bottle (coolant reservoir) on the driver-side cowl.

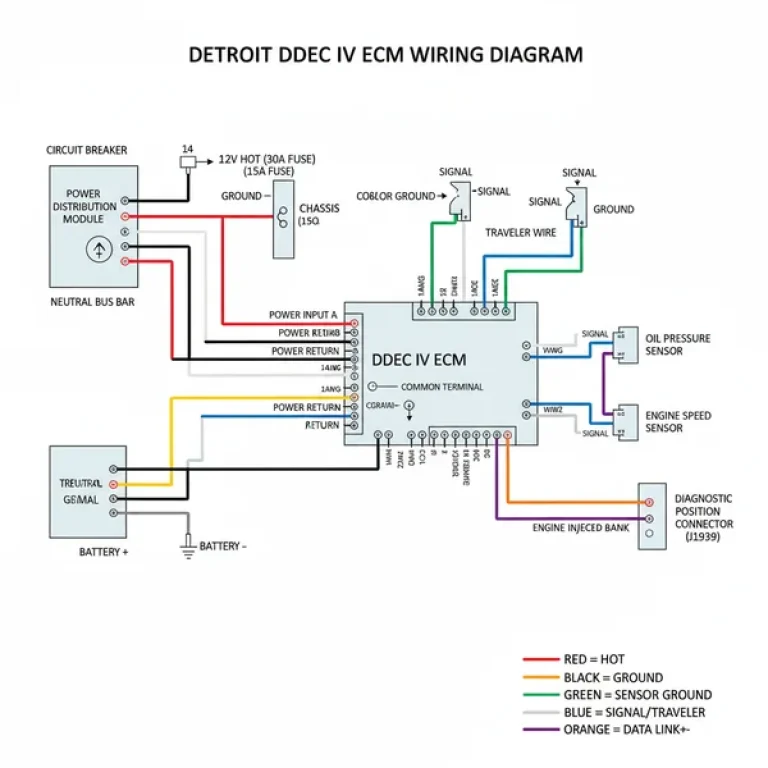

Key components are often color-coded in professional diagrams to help users distinguish between different systems. For instance, the air intake system is usually represented in black or blue, while the high-pressure oil system and fuel lines might be highlighted in yellow or red. The coolant flow paths are particularly important to follow, as they move from the radiator, through the oil cooler located in the valley of the engine, and then out toward the EGR cooler and heater core.

Unlike many gasoline engines, the 6.0 Powerstroke places its ECU (Engine Control Unit) in a protected location, typically near the driver-side fender or firewall, where it can manage the complex data coming from various sensors. Understanding these locations is vital because many components are stacked; for example, accessing the oil cooler requires removing the intake manifold and several upper-tier accessories.

The 6.0 Powerstroke uses a HEUI (Hydraulic Electronic Unit Injection) system. This means the engine bay contains both a low-pressure fuel system and a high-pressure oil system, both of which are critical for the engine to fire.

Step-by-Step Guide: How to Use the Engine Bay Diagram for Repairs

To effectively utilize a 6.0 powerstroke engine bay diagram, you must approach it systematically. Following these steps will help you translate the lines on the page into the heavy metal components under your hood.

- 1. Locate Your Starting Point: Open your hood and identify the largest, most recognizable components first. The degas bottle on the driver’s side and the large air filter housing on the passenger side are excellent landmarks to orient your diagram.

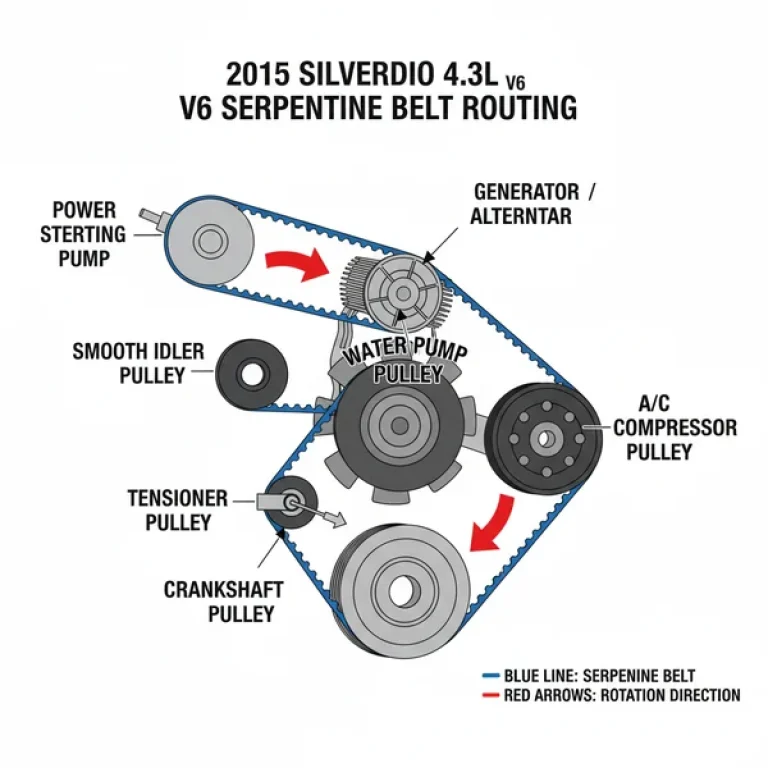

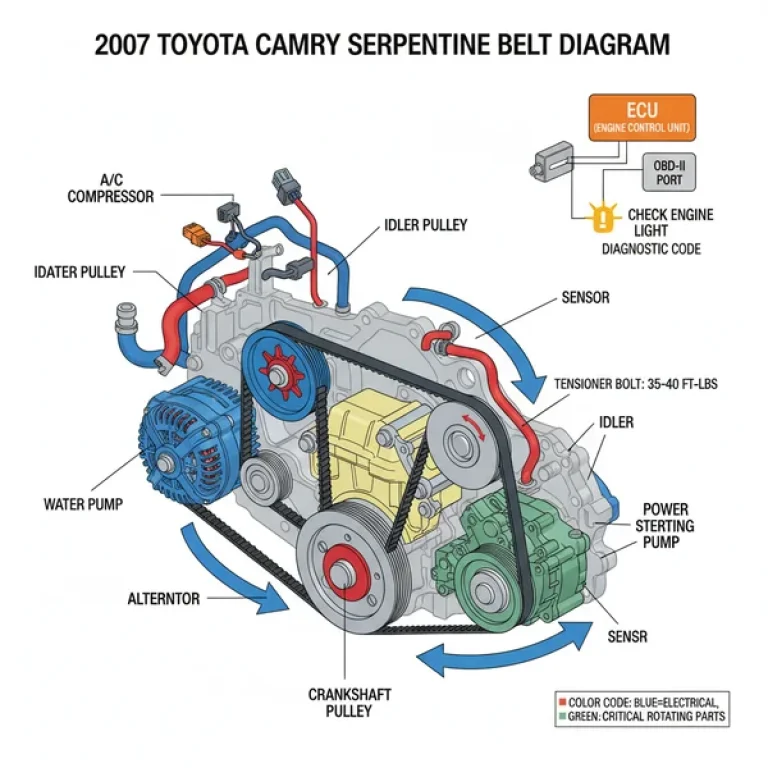

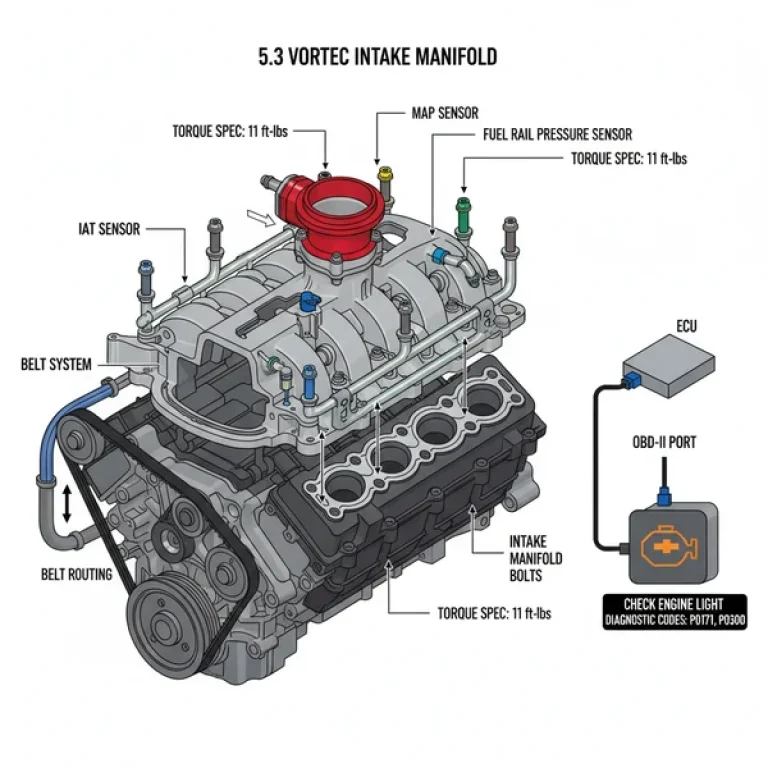

- 2. Identify the Accessory Drive: Locate the accessory belt (serpentine belt) at the front of the engine. The diagram will show the routing path over the alternator, water pump, AC compressor, and power steering pump. If you are replacing the belt, the diagram is your only guide to ensuring the correct tension and rotation.

- 3. Diagnostic Tool Connection: Before tearing into the engine, locate the OBD-II port under the dashboard. Use a scanner to pull any diagnostic code that may be stored. Once you have a code, refer back to the engine bay diagram to find the specific sensor (like the ICP or IPR sensor) associated with that fault.

- 4. Trace the Fluid Paths: For cooling issues, follow the coolant flow from the degas bottle down to the water pump. If you see white smoke, use the diagram to find the EGR cooler located behind the intake manifold, as this is a common failure point that allows coolant into the exhaust.

- 5. Observe Sensor Locations: The 6.0 is sensor-heavy. Use the diagram to find the EOT (Oil Temp) and ECT (Coolant Temp) sensors. Comparing these two values is the primary way to diagnose a clogging oil cooler.

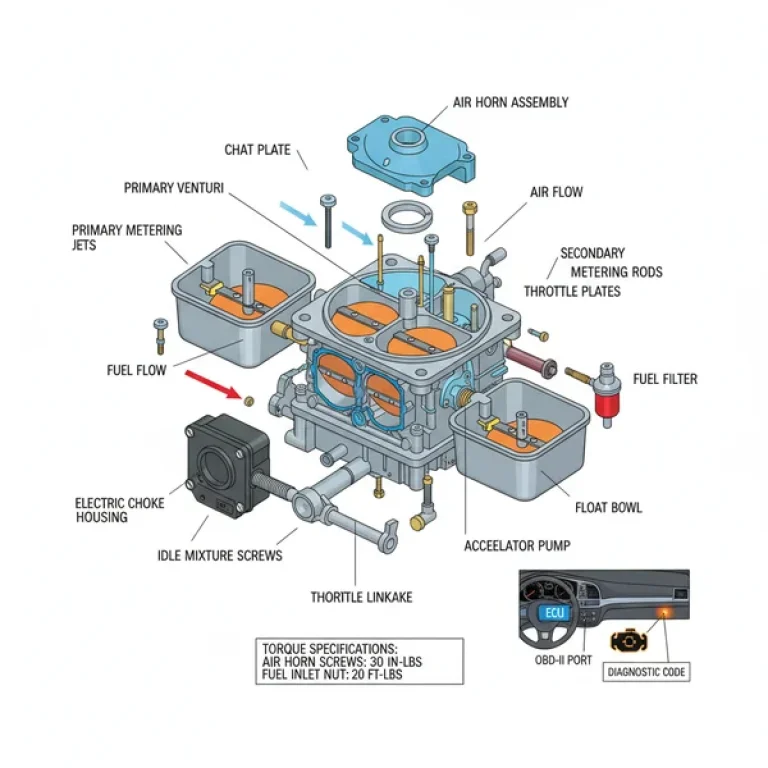

- 6. Apply Correct Torque Specs: When reassembling components found on the diagram, such as the fuel filter housing or intake bolts, always consult the manufacturer’s torque spec. Over-tightening bolts in the aluminum housings of this engine can lead to stripped threads and expensive repairs.

Always ensure the engine is completely cool before touching components like the turbocharger or EGR cooler. These parts operate at extremely high temperatures and can cause severe burns even hours after the engine has been turned off.

Common Issues & Troubleshooting with the 6.0 Powerstroke

When your check engine light illuminates, the 6.0 powerstroke engine bay diagram becomes your most valuable diagnostic tool. One of the most frequent issues involves the FICM (Fuel Injection Control Module). If the engine cranks but won’t start, or idles poorly when cold, the diagram helps you locate the FICM on the driver-side valve cover so you can test its voltage.

Another common problem is “stiction” in the injectors or a failure in the high-pressure oil system. By using the diagram to find the IPR (Injection Pressure Regulator) valve, you can inspect the screen for debris. Furthermore, although this engine uses a gear-driven system rather than a traditional timing chain, the diagram is essential for locating the Camshaft and Crankshaft position sensors which ensure the engine remains in sync. If these sensors fail, the engine will not start, and the OBD-II scanner will often throw a sync-related diagnostic code.

If you’re dealing with a “no-start” condition, use your diagram to find the secondary fuel filter on top of the engine. Unscrew the cap and see if it fills with fuel when the key is turned—this quickly tells you if your fuel pump is working.

Best Practices for Maintaining Your 6.0 Powerstroke

To keep your 6.0 Powerstroke running efficiently, adherence to a strict maintenance schedule is non-negotiable. The engine bay diagram highlights several areas that require frequent attention. First, only use OEM (Motorcraft) filters for both oil and fuel. Aftermarket filters often do not fit the housings correctly, leading to unfiltered oil or fuel bypassing the element, which can ruin your injectors or high-pressure oil pump.

- ✓ Monitor the “Delta”: Keep an eye on the difference between Oil Temp and Coolant Temp; a gap wider than 15 degrees at highway speeds indicates a clogging oil cooler.

- ✓ Battery Health: The ECU and FICM are extremely sensitive to low voltage. Ensure your batteries and alternator are in top shape to prevent module failure.

- ✓ Coolant Flush: Use only the recommended ELC (Extended Life Coolant) to prevent silicates from dropping out and clogging the narrow passages of the oil cooler.

- ✓ Inspect the accessory belt: Check for cracking or fraying every 15,000 miles to avoid being stranded.

By studying a detailed 6.0 powerstroke engine bay diagram and understanding how each component interacts, you transform a complex machine into a manageable project. Whether you are clearing a check engine light or performing a full “bulletproofing” of the cooling and oil systems, the diagram provides the clarity needed for a professional-grade repair. Proper identification, combined with the correct torque spec and high-quality parts, will ensure your 6.0 Powerstroke remains a reliable workhorse for years to come. Regardless of your experience level, keep a copy of the engine bay layout handy whenever you lift the hood to ensure every bolt and sensor is exactly where it needs to be.

Frequently Asked Questions

What is a 6.0 Powerstroke engine bay diagram?

A 6.0 Powerstroke engine bay diagram is a detailed visual schematic showing the location of the engine’s mechanical and electrical parts. It identifies the turbocharger, fuel filters, and cooling reservoir. This tool is essential for mechanics and owners to navigate the complex layout of the Ford Super Duty engine compartment efficiently.

How do you read a 6.0 Powerstroke engine bay diagram?

Start by orienting yourself with large components like the battery and coolant degas bottle. Follow the labeling or numbering system to identify sensors, wiring harnesses, and the ECU. These diagrams usually offer a top-down view, making it easier to trace fluid lines and electrical connections during complex repairs or routine checks.

What are the parts of a 6.0 Powerstroke?

Core parts include the Variable Geometry Turbo (VGT), Fuel Injection Control Module (FICM), High-Pressure Oil Pump (HPOP), and the Exhaust Gas Recirculation (EGR) cooler. The system also features dual batteries, a specialized cooling system, and various sensors that communicate with the ECU to manage performance and emissions across different loads.

Why is the ECU important?

The Engine Control Unit (ECU) acts as the brain of the vehicle, processing data from numerous sensors to optimize combustion. If you see a check engine light, the ECU has likely stored a diagnostic code. It manages fuel timing and boost pressure, ensuring the engine operates within safe parameters while driving.

What is the difference between OBD-II and FICM?

OBD-II is the universal diagnostic port used to scan for a diagnostic code when a check engine light appears. The FICM, or Fuel Injection Control Module, is a specific electronic component on the 6.0 Powerstroke that amplifies battery voltage to fire the fuel injectors, which is critical for starting.

How do I use a 6.0 Powerstroke engine bay diagram?

Use the diagram as a reference point when performing repairs or upgrades. It helps you find hidden sensors and ensure that every fastener is tightened to the manufacturer’s torque spec. By matching the diagram to the physical engine, you reduce the risk of damaging components or misidentifying vital connections.