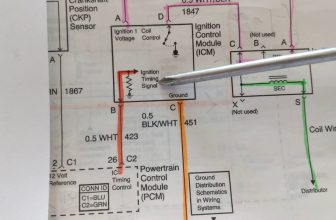

If you have a 5.7 Vortec engine and need a crank sensor wiring diagram, this post is for you. I’ll go over the basics of the crank sensor and what it does, then show you the diagram. The crank sensor is an important part of your engine’s ignition system.

It tells the computer when to fire the spark plugs. Without it, your engine won’t run. The sensor is located on the back of the engine, near the flywheel or harmonic balancer.

If you have a 5.7 Vortec engine, then you know that the crank sensor is an important part of the system. Without it, your engine will not run properly. If you are having trouble with your crank sensor, then you may need a new wiring diagram.

There are many different ways to wire a crank sensor, so it is important to find the right one for your engine. The best way to do this is to consult your owner’s manual or a mechanic who specializes in Vortec engines. They will be able to help you find the correct wiring diagram for your engine and ensure that it is installed correctly.

How Do You Test a Gm 3 Wire Crank Sensor With a Multimeter?

If you have a GM 3 wire crank sensor, you can test it with a multimeter. First, disconnect the negative battery cable. Next, remove the engine cover and locate the crankshaft position sensor.

It will be on the front of the engine, near the timing belt cover.

To test the sensor, connect your multimeter to the sensor’s ground wire and probe each of the other wires. The resistance should be between 700-1200 ohms for each wire.

If it is outside of that range, then the sensor is likely defective and needs to be replaced.

How Many Wires Does a Crank Sensor Have?

A crank sensor is a type of engine sensor that is used to monitor the position or rotational speed of the crankshaft. Crank sensors are commonly used in modern internal combustion engines and act as part of the engine control unit (ECU). The ECU uses signals from the crank sensor to determine when each cylinder should fire during the engine’s cycle.

Most crank sensors have either three or four wires. Three-wire sensors typically have a reference wire and two signal wires, while four-wire sensors usually have a ground wire in addition to the reference and signal wires.

Where Does the Crankshaft Sensor Plug Into?

The crankshaft sensor plugs into the engine block, usually near the crankshaft pulley. It monitors the position and rotational speed of the crankshaft and sends signals to the engine control unit (ECU). The ECU uses these signals to control ignition timing and fuel injection.

How Do You Reprogram a Crankshaft Position Sensor?

A crankshaft position sensor is a type of electronic sensor that helps to monitor the rotation of the crankshaft in an engine. This information is then used by the engine control unit (ECU) to help ensure that the engine is running at peak efficiency. In order to reprogram a crankshaft position sensor, it will first need to be disconnected from its power source.

Once this has been done, the ECU can be reprogrammed with new software that will take into account the changes in the crankshaft position sensor.

5.7 Vortec Crank Sensor Symptoms

If your 5.7 Vortec engine is having trouble starting, or if it’s running rough once it’s started, one possible cause is a faulty crank sensor. The crank sensor is responsible for sending information to the engine control unit (ECU) about the position of the crankshaft, so that the ECU can properly time the ignition and fuel injection. If the sensor isn’t working correctly, it can cause all sorts of problems.

Here are some common symptoms of a bad crank sensor on a 5.7 Vortec engine:

1. Engine won’t start: If your engine Crank Sensor Symptoms won’t even turn over, let alone start, then it’s likely that your crank sensor is to blame. This is because the ECU needs information from the sensor in order to properly timed the ignition sequence.

Without this information, the engine simply won’t run.

2. Engine runs rough: Even if your engine does manage to start with a bad crank sensor, it will probably run very roughly. This is because incorrect information from the sensor can lead to misfires and other issues with combustion timing.

As a result, you may notice that your engine shakes or vibrates more than usual when idling or under load.

3. Check Engine Light: One telltale sign of a problem with the crank sensor is an illuminated Check Engine Light on the dashboards of most vehicles equipped with OBD-II diagnostics . This light comes on when there’s any sort of problem with emissions-related components like sensors or catalytic converters .

So if you see this light along with some of the other symptoms listed here , it’s a good indication that your 5/7 Vortec’s crank sensor needs to be replaced . 4 Hard starting: If your 5/7 Vortec engine takes longer than usual to start up , especially after sitting for awhile , then a failing crankshaft position might be to blame .

Crank Sensor on 5.7 Vortec

A crank sensor is a type of position sensor used on automobiles, boats, and small engines to monitor the position or rotational speed of the crankshaft. Crank sensors are typically fitted into the engine block near the crankshaft. Most modern gasoline engines use a crankshaft-mounted magnetic sensor to determine ignition timing while diesel engines often have hall effect sensors located on either side of the flywheel.

.5.7 vortec

The 5.7 Vortec is a V8 engine produced by General Motors for use in full-size light-duty pickup trucks and vans. The 5.7 Vortec was introduced in 1996 as an upgraded version of the 5.0 L Vortec 5700 engine which was itself a successor to the Chevrolet Small Block engine family.

.

The main difference between the 5.0 L and 5.7 L engines is that the latter features cylinder heads with improved airflow, resulting in increased power output. The 5.7 L also has forged connecting rods and pistons, roller lifters, and higher compression ratios than its predecessor.

.

Because of its increased displacement, the 5.7 Vortec produces more torque than the smaller 5.0 L engine – 400 lb-ft at 3200 rpm versus 360 lb-ft at 2400 rpm respectively..

Additionally, the horsepower rating for the 5.7 Vortec is 260 hp at 4600 rpm while that of t he 5 . 0 L comes in at 205 hp at 4800 rpm..

Conclusion

The 5.7 Vortec Crank Sensor Wiring Diagram is a great way to keep your car running smoothly. This diagram can help you troubleshoot and fix any issues you may have with your car’s crank sensor.