5.7 Chevy 350 Belt Diagram With AC: Easy Routing Guide

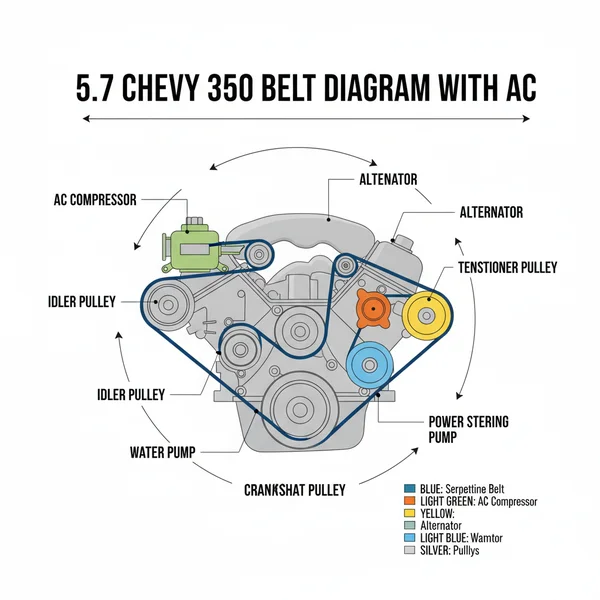

A 5.7 Chevy 350 belt diagram with AC illustrates the specific path the serpentine belt takes around the pulley system. It ensures every component, including the alternator, power steering pump, and AC compressor, receives power. Correct routing is essential for optimal engine performance and cooling system functionality in this classic V8 configuration.

📌 Key Takeaways

- Provides the exact routing path for the serpentine belt

- The automatic tensioner is the most critical component for belt removal

- Ensure the belt grooves match the pulley structure perfectly

- Sketch the layout before removal to avoid common installation errors

- Use this diagram during maintenance or when replacing a squealing belt

Navigating the engine bay of a classic Small Block engine can be a daunting task for even the most seasoned DIY mechanic without a clear visual aid. This guide provides a comprehensive 5.7 chevy 350 belt diagram with ac to help you understand the intricate routing and mechanical requirements of your vehicle’s serpentine system. Whether you are performing a routine maintenance check or replacing a snapped belt on the side of the road, having the correct diagram is essential for ensuring all engine accessories operate at peak efficiency. In the following sections, you will learn the exact component layout, the step-by-step process for installation, and professional troubleshooting tips to keep your Chevy running smoothly.

Understanding the Serpentine System Layout and Component Configuration

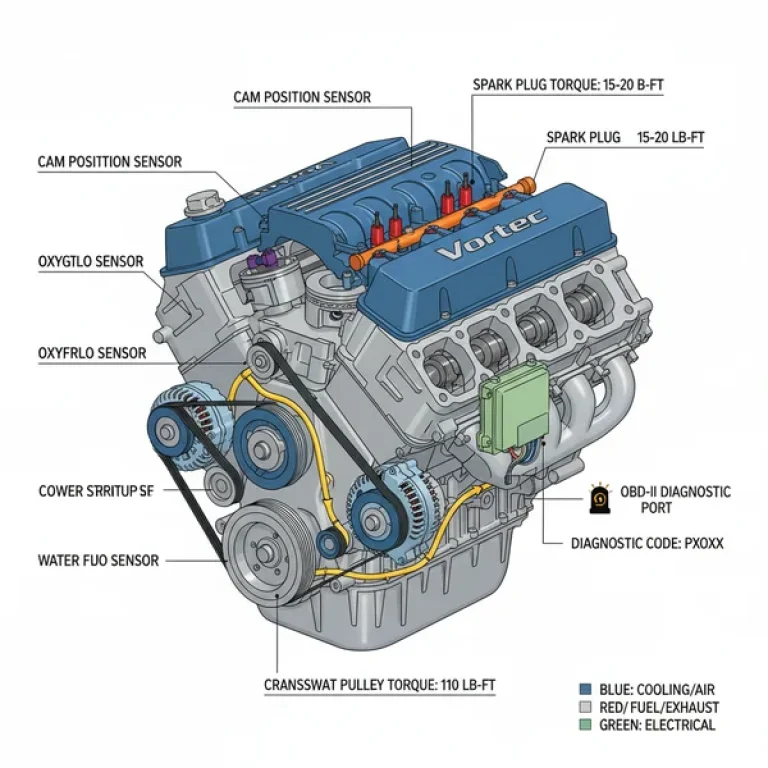

The serpentine belt system on a 5.7-liter Chevy 350 is a marvel of mechanical efficiency, using a single, continuous belt to drive multiple vital engine components. Unlike older V-belt systems that used separate belts for different accessories, the serpentine configuration simplifies maintenance but increases the complexity of the routing “layout.” When viewing the engine from the front, the system consists of a series of pulleys, each serving a specific “component” in the engine’s operation.

The “structure” of the belt path is designed to maximize the surface area contact between the belt and the pulleys, providing the necessary friction to turn heavy loads like the air conditioning compressor and the power steering pump. The primary driver of this entire “system” is the crankshaft pulley, located at the bottom center of the engine block. This pulley transfers the rotational energy of the engine to the belt.

From the crankshaft, the belt typically travels upward toward the water pump pulley, which is often located in the center of the configuration. The water pump is critical for maintaining engine temperature, and its pulley usually features a smooth surface because the backside of the belt (the flat side) often runs against it. After the water pump, the belt maneuvers toward the A/C compressor, which is generally mounted high on the driver or passenger side, depending on the specific bracketry used in your vehicle’s build.

Another essential element is the alternator, which is responsible for charging the battery and powering the electrical system. The alternator pulley is significantly smaller than the others, allowing it to spin at higher revolutions per minute (RPM) than the engine itself. Adjacent to this, you will find the power steering pump, which provides hydraulic pressure for easier handling. To maintain the proper “configuration” and tension, the system utilizes a spring-loaded tensioner pulley and, in many cases, a stationary idler pulley. These components ensure the belt does not slip or vibrate during high-speed operation.

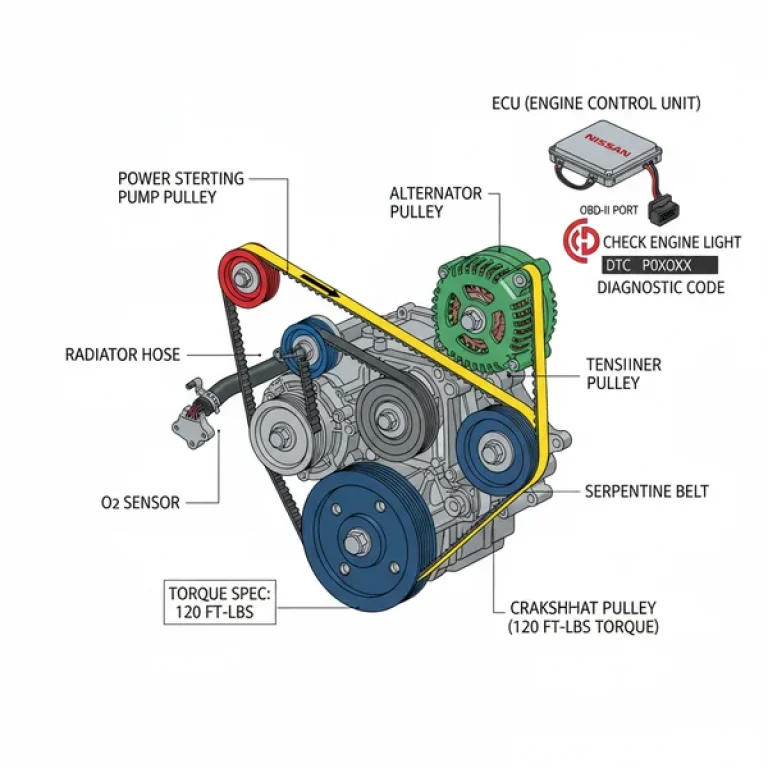

Visual Representation: 5.7 Chevy 350 Belt Diagram With AC showing Crankshaft, Alternator, A/C Compressor, Power Steering, Tensioner, and Idler Pulley positions.

Most 5.7 Chevy 350 engines utilize a 6-rib or 7-rib serpentine belt. When purchasing a replacement, ensure the rib count and the total length match your specific accessory bracket configuration, as variations in A/C compressor size can affect the required belt length.

Step-by-Step Guide: Interpreting the 5.7 Chevy 350 Belt Diagram With AC

Successfully installing or replacing a serpentine belt requires a methodical approach. By following the “structure” of the provided diagram, you can ensure that every pulley is engaged correctly and that the belt is oriented properly. Before you begin, gather a long-handled breaker bar or a dedicated belt tensioner tool, as the spring tension on a Small Block Chevy can be quite high.

Always ensure the engine is completely cool and the battery is disconnected before working near the belt. A sudden start or even residual heat can lead to severe injury when working with pulleys and high-tension springs.

Step 1: Locate the Routing Label

Check the underside of your hood or the fan shroud for a factory-printed routing diagram. If this label is missing or illegible, use the 5.7 chevy 350 belt diagram with ac provided in this guide. Take a moment to identify which pulleys are “grooved” and which are “smooth.” Grooved pulleys interact with the inside of the belt, while smooth pulleys interact with the flat backside.

Step 2: Position the Belt Around the Crankshaft

The most efficient way to start the installation is at the bottom of the engine. Drape the belt over the crankshaft pulley. This is the largest pulley and serves as the foundation for the rest of the routing. Ensure the ribs of the belt sit perfectly inside the grooves of the crankshaft pulley to prevent misalignment later in the process.

Step 3: Route Through the Lower Accessories

Follow the diagram upward. Typically, the belt will head toward the power steering pump. Loop the belt around the pump pulley, ensuring it stays tight. If your specific “layout” includes a low-mounted idler pulley, pass the belt over or under it as specified by your visual aid.

Step 4: Navigate the Water Pump and A/C Compressor

Bring the belt toward the center of the engine. In many 350 configurations, the flat side of the belt will press against the smooth water pump pulley. From there, pull the belt toward the A/C compressor. This is often the furthest point from the crankshaft, so ensure you have enough slack to reach the pulley without straining the belt prematurely.

Step 5: Wrap the Alternator

Pull the belt over the top of the alternator pulley. The alternator is usually positioned in a way that allows the belt to have nearly 180 degrees of wrap, which is essential for preventing the belt from slipping when the electrical load on the vehicle increases.

Step 6: Release the Tensioner

Insert your breaker bar or tensioner tool into the square drive or over the nut on the tensioner pulley. Rotate the tensioner (usually clockwise) to compress the internal spring. This will create the necessary slack to slip the final loop of the belt over the last pulley—often the alternator or a high-mounted idler.

Step 7: Final Inspection

Slowly release the tensioner tool so it applies pressure to the belt. Before starting the engine, visually inspect every single pulley. The belt must be perfectly centered on every “component.” If the belt is even one rib off-center, it will likely shred or jump off the pulleys within seconds of the engine starting.

If you are working alone, use a small piece of tape or a zip tie to loosely hold the belt in place on the crankshaft pulley while you route the top sections. This prevents the belt from falling off while you are reaching for the tensioner.

Common Issues & Troubleshooting

Even with a perfect “configuration,” serpentine systems can develop issues over time. The most frequent problem users encounter is a high-pitched squealing noise. This usually indicates either a glazing belt (where the rubber has become hard and slick) or a failing tensioner that can no longer provide adequate pressure.

If you notice the belt is fraying at the edges, this is a clear sign of a pulley misalignment. Using your 5.7 chevy 350 belt diagram with ac, check each “component” to see if a mounting bracket has bent or if a bearing in the alternator or power steering pump has failed, causing the pulley to tilt. A tilted pulley will force the belt to rub against the flanges, leading to rapid wear and eventual failure.

Another warning sign is a “chirping” sound at idle. This is often caused by a worn-out idler pulley bearing. To solve this, you can remove the belt and spin each pulley by hand. If a pulley feels gritty or makes noise when spun freely, it needs to be replaced immediately. If you experience a loss of power steering or your temperature gauge begins to rise rapidly, pull over and check the belt; these are the primary symptoms of a total belt snap.

Tips & Best Practices for System Maintenance

To ensure the longevity of your engine’s drive “system,” regular maintenance is key. Modern EPDM (Ethylene Propylene Diene Monomer) belts do not crack as easily as older neoprene belts, but they do lose material over time, much like a tire tread. Use a plastic belt wear gauge to check the depth of the grooves every 30,000 miles.

- ✓ Clean Your Pulleys: Before installing a new belt, use a wire brush and brake cleaner to remove any old rubber deposits or oil from the pulley grooves.

- ✓ Check the Tensioner: A tensioner should move smoothly without binding. If it sticks or requires excessive force to move, replace it along with the belt.

- ✓ Carry a Spare: Always keep an old, usable belt and the necessary tools in your trunk for emergency roadside repairs.

- ✓ Inspect for Leaks: Oil or coolant leaking onto the belt will cause it to swell and slip, significantly shortening its lifespan.

Quality components are worth the investment. When selecting a replacement, look for premium brands that offer reinforced internal cords. These belts stretch less and maintain a consistent “layout” even under heavy heat and high-performance conditions. Additionally, consider replacing the tensioner and idler pulleys every 100,000 miles as a preventative measure. These components are relatively inexpensive compared to the cost of a tow truck or engine repairs resulting from an overheat.

By following this comprehensive guide and keeping a copy of the 5.7 chevy 350 belt diagram with ac in your glove box, you can confidently manage the health of your vehicle’s accessory drive system. Proper routing and tension are the secrets to a reliable and powerful Small Block Chevy engine.

Frequently Asked Questions

What is a 5.7 Chevy 350 belt diagram with AC?

A 5.7 Chevy 350 belt diagram with AC is a visual map showing the serpentine belt’s path across the engine’s front. It details the specific layout for models equipped with air conditioning, ensuring the belt connects the crankshaft, alternator, water pump, and AC compressor in the correct sequence.

How do you read a 5.7 Chevy 350 belt diagram with AC?

To read the diagram, start at the crankshaft pulley and follow the lines indicating the belt’s path. Smooth circles usually represent pulleys contacting the back of the belt, while grooved circles indicate the ribbed side. This system ensures all components spin in the proper direction for engine health.

What are the parts of a 5.7 Chevy 350 belt system?

The core components of this system include the crankshaft pulley, alternator, power steering pump, water pump, and AC compressor. It also features an idler pulley and a spring-loaded tensioner. Together, they form a robust structure that powers essential vehicle accessories while maintaining consistent belt tension during operation.

Why is the tensioner component important?

The tensioner is a vital component because it maintains constant pressure on the serpentine belt. Without proper tension, the belt would slip, causing the system to lose power to the alternator or AC compressor. A failing tensioner can lead to belt failure, overheating, or loss of power steering assistance.

What is the difference between V-belts and serpentine configurations?

V-belts are older systems using multiple narrow belts for different components, whereas the serpentine configuration uses a single, wide, multi-ribbed belt. The serpentine layout is more efficient and easier to maintain, but a single failure can disable all engine accessories simultaneously, making the routing diagram essential for repairs.

How do I use a 5.7 Chevy 350 belt diagram with AC?

Use the diagram as a reference guide when installing a new belt or troubleshooting noise. Locate the tensioner to release pressure, then thread the belt around each component following the specified layout. Always verify that the belt is seated correctly in the grooves before starting the vehicle’s engine.