4.3 Liter 4.3 Vortec Engine Diagram: Component Identification

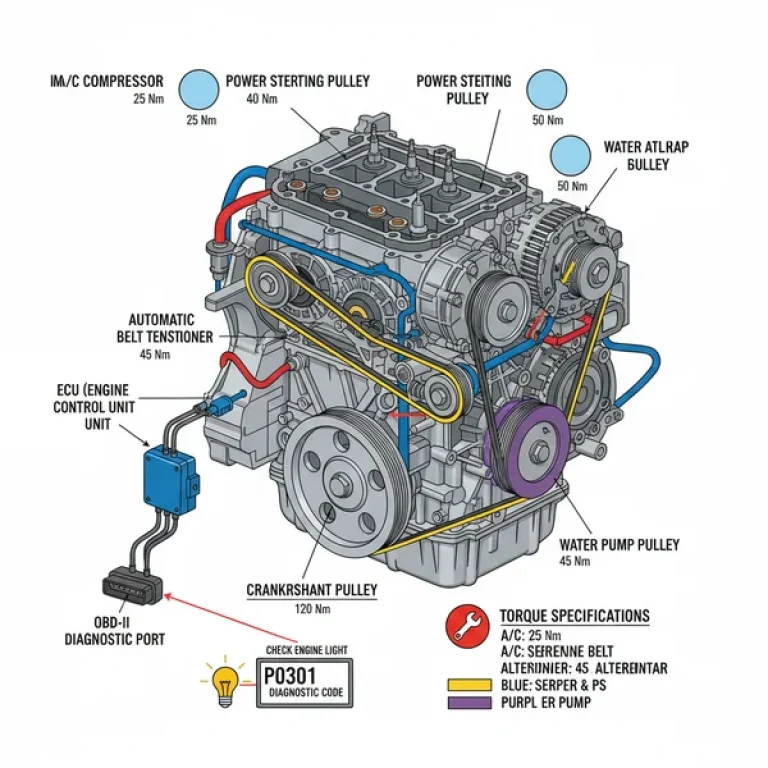

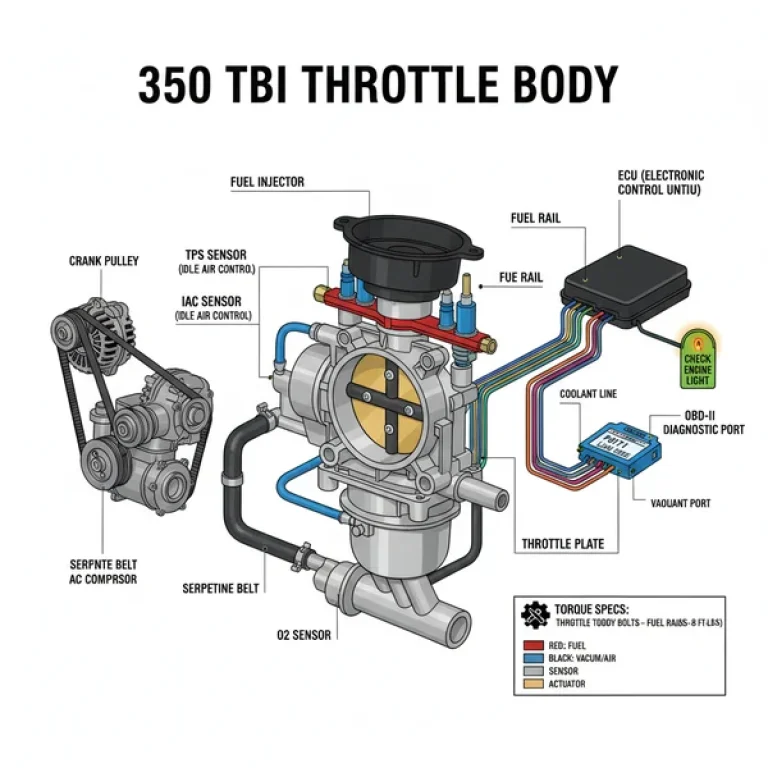

A 4.3 Liter 4.3 Vortec engine diagram illustrates the layout of internal components, vacuum lines, and electrical connections. It is essential for locating the ECU and sensors that trigger a check engine light. Using this visual guide helps mechanics interpret an OBD-II diagnostic code and apply the correct torque spec for assembly.

📌 Key Takeaways

- The diagram maps the V6 engine’s architecture for maintenance.

- Identifying sensor locations helps resolve fuel delivery issues.

- Always disconnect the battery before working on ECU connections.

- Use the diagram to verify the firing order for spark plugs.

- Refer to this guide when a diagnostic code indicates sensor failure.

Whether you are performing a routine tune-up or tackling a complex rebuild, having a clear and accurate 4.3 liter 4.3 vortec engine diagram is an indispensable asset. The Chevrolet/GMC 4.3L V6, often referred to as the “three-quarters of a 350,” has been a staple of the automotive world for decades due to its reliability and torque. Navigating the maze of vacuum lines, electrical connectors, and cooling passages requires more than just mechanical intuition; it requires a visual roadmap. This guide provides a detailed breakdown of the engine’s architecture, helping you identify critical components like the ECU interface, sensors, and mechanical drive systems. By the end of this article, you will have the knowledge needed to interpret technical schematics and apply them to your vehicle maintenance routine.

Understanding the 4.3 Liter Vortec Engine Layout

The 4.3 liter 4.3 vortec engine diagram typically illustrates a 90-degree V6 configuration. This layout is unique because it shares many design characteristics with the legendary Small Block Chevy V8. When looking at a primary diagram, you will notice the engine is divided into several functional zones: the top-end (intake and fuel delivery), the front-end (accessory drive and timing), and the lower block (oil pan and crankshaft).

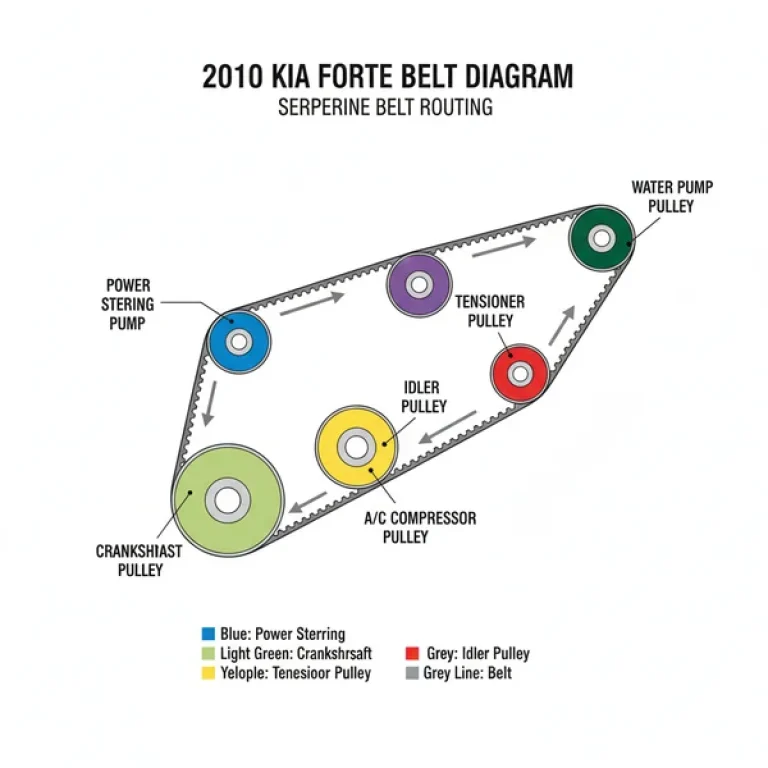

A key feature often highlighted in these diagrams is the Central Port Injection (CPI) or Sequential Central Port Injection (SCPI) system, frequently called the “spider” injector. The diagram shows how fuel lines enter the upper intake plenum and distribute to six individual poppet valves. Another vital area is the accessory belt routing. A correct schematic will trace the path of the serpentine belt as it winds around the alternator, power steering pump, air conditioning compressor, and the water pump.

Color-coding in modern diagrams often distinguishes between electrical circuits (highlighting the ECU and sensor wires), fluid paths (showing coolant flow from the radiator through the block), and mechanical components. For instance, the coolant flow is usually represented by blue or red arrows, indicating the path from the lower radiator hose, through the water pump, and out via the thermostat housing. Understanding these visual cues allows you to pinpoint exactly where a leak or electrical short might be occurring without unnecessary guesswork.

[DIAGRAM_PLACEHOLDER: A detailed 3D exploded view of a 4.3L Vortec V6 engine showing the intake manifold, accessory drive belt path, distributor location, and major sensor positions including the MAF and Crankshaft position sensors.]

How to Read and Apply the Engine Diagram

Interpreting an automotive diagram is a skill that bridges the gap between theory and hands-on repair. To get the most out of your 4.3 liter 4.3 vortec engine diagram, follow these structured steps to ensure accuracy and safety during your project.

Before beginning any work, always disconnect the negative battery terminal. The 4.3L Vortec uses a sensitive ECU that can be damaged by accidental electrical surges during sensor testing or replacement.

- 1. Orient the Diagram to the Vehicle: Always establish the “front” of the engine, which is the side with the cooling fan and accessory belt. Most diagrams are drawn from the perspective of someone standing at the front bumper looking into the engine bay.

- 2. Identify the Firing Order: For the 4.3L Vortec, the firing order is 1-6-5-4-3-2. Locate the distributor on your diagram; the number one cylinder is typically the front-most cylinder on the driver’s side (left side when facing the engine).

- 3. Trace the Accessory Belt Path: Use the diagram to verify the “ribbed” vs “smooth” side of the belt. The accessory belt must wrap around the pulleys correctly to ensure the water pump rotates in the proper direction for optimal coolant flow.

- 4. Locate Diagnostic Sensors: Find the Crankshaft Position Sensor (CKP) near the harmonic balancer and the Camshaft Position Sensor inside the distributor. These are common failure points that trigger a check engine light.

- 5. Verify Vacuum Line Routing: The 4.3L relies heavily on vacuum for the PCV system and brake booster. Follow the lines on the diagram from the intake manifold to their respective components to check for cracks or disconnections.

- 6. Match Wire Colors to the ECU: If you are troubleshooting an electrical issue, the diagram will specify wire colors leading to the ECU harness. Use a multimeter to probe these wires based on the pinout locations shown.

- 7. Cross-Reference Torque Specs: Once components are identified, look for the specific torque spec for bolts, especially for the intake manifold and cylinder heads, to prevent gasket failure.

Failure to follow the correct accessory belt routing can cause the engine to overheat rapidly or result in a loss of power steering. Always double-check the diagram before starting the engine after a belt change.

To perform these tasks, you will generally need a standard metric socket set, a torque wrench, a digital multimeter for electrical testing, and a scan tool to read any OBD-II diagnostic code.

Troubleshooting Common 4.3L Vortec Issues

The 4.3L Vortec is known for a few specific mechanical “quirks” that are much easier to diagnose when you have a diagram in hand. One of the most frequent issues is a random misfire, often accompanied by a P0300 diagnostic code. By consulting the diagram, you can trace the ignition system from the coil to the distributor and finally to the spark plugs. This helps you identify if the issue is a cracked distributor cap or a faulty wire.

Another common problem involves the “spider” fuel injectors located under the intake plenum. If you experience a hard start or poor fuel economy, the diagram will show you how to access the fuel pressure regulator and the injector bracket. Additionally, the check engine light often illuminates due to oxygen sensor failures or Mass Air Flow (MAF) sensor issues. The diagram allows you to see the exact orientation of these sensors in the exhaust stream and intake ducting.

If you notice a puddle of coolant under the front of the engine, use the coolant flow diagram to check the water pump weep hole or the bypass hose. Intake manifold gasket leaks are also notorious on this engine; the diagram will highlight the bolt pattern and the specific areas where the gasket is prone to failure, allowing for a more targeted repair approach.

Maintenance Tips and Best Practices

Maintaining a 4.3 liter Vortec engine requires attention to detail and high-quality parts. Because this engine is a high-mileage champion, preventative care is the best way to avoid costly shop visits.

When replacing the distributor cap and rotor, always use high-quality components with brass terminals. The 4.3L Vortec is very sensitive to ignition resistance, and cheap aluminum terminals can lead to premature misfires.

- ✓ Monitor the Timing Chain: While the timing chain on a 4.3L is robust, it can stretch over hundreds of thousands of miles. If you hear a rattling noise at the front of the engine, consult your diagram to locate the timing cover for inspection.

- ✓ Coolant Quality: Use the correct coolant specified for your vehicle. Mixing different types of coolant can lead to “sludging,” which restricts coolant flow and can clog the heater core or radiator.

- ✓ Grounding Points: Many ECU errors are actually caused by poor grounding. Use your 4.3 liter 4.3 vortec engine diagram to find the engine block and chassis ground straps. Clean these connections with a wire brush to ensure a strong electrical path.

- ✓ Oil Changes: Regular oil changes are vital for the hydraulic lifters and the balance shaft bearings found in later versions of this engine. Use a high-quality filter to maintain consistent oil pressure.

For those looking to save money, performing your own sensor replacements and belt changes using a 4.3 liter 4.3 vortec engine diagram can save hundreds of dollars in labor costs. Most sensors are easily accessible on the top or front of the engine, making this a very DIY-friendly platform. Always ensure you are using the correct torque spec for every bolt you remove; over-tightening a bolt into the aluminum intake manifold can lead to stripped threads and a much larger repair bill. By combining a high-quality diagram with a methodical approach to maintenance, you can keep your Vortec V6 running smoothly for years to come.

Step-by-Step Guide to Understanding the 4.3 Liter 4.3 Vortec Engine Diagram: Component Identification

Identify – Start with identifying the fuel injection type, such as CPI or SFI, on your 4.3 Vortec.

Locate – Locate the specific sensor or mechanical component related to your current OBD-II diagnostic code.

Understand – Understand how the electrical harness routes signals between individual engine sensors and the main ECU.

Apply – Apply the manufacturer-recommended torque spec to all fasteners to ensure a leak-free seal during reassembly.

Verify – Verify that all vacuum lines and electrical plugs are secure to prevent a check engine light.

Complete – Complete the repair process by clearing the system memory and performing a test drive to confirm the fix.

Frequently Asked Questions

What is 4.3 liter 4.3 vortec engine diagram?

A 4.3 liter 4.3 Vortec engine diagram is a detailed visual representation of GM’s reliable V6 powerplant. It highlights the cylinder arrangement, intake manifold, belt routing, and electrical sensors. This resource is vital for DIY mechanics attempting to fix a check engine light or performing routine maintenance on trucks and vans.

How do you read 4.3 liter 4.3 vortec engine diagram?

To read a 4.3 liter 4.3 Vortec engine diagram, start by orienting yourself with the front of the block. Follow the color-coded lines for electrical or vacuum circuits. Locate the ECU connection points and various sensors. Ensure you match the diagram labels to physical components like the distributor or fuel injectors.

What are the parts of 4.3 liter 4.3 vortec engine?

The primary parts include the engine block, cylinder heads, intake manifold, and the central sequential fuel injection system. Electrical components like the ECU, spark plugs, and oxygen sensors are also featured. The diagram clarifies the location of pulleys for the serpentine belt and the crucial OBD-II port linkage for diagnostics.

Why is torque spec important?

Following the correct torque spec is critical because it ensures that bolts are tightened with enough force to prevent leaks without stripping threads. In a 4.3 Vortec, precise tensioning of head bolts and intake manifold fasteners prevents vacuum leaks and internal coolant mixing, which could cause a permanent engine failure.

What is the difference between CPI and SFI 4.3 engines?

The main difference lies in the fuel injection design. Central Port Injection (CPI) uses a single injector with ‘spider’ tubes, while Sequential Fuel Injection (SFI) uses individual injectors for each cylinder. The diagram will show different fuel rail layouts and ECU wiring configurations depending on which specific V6 system is used.

How do I use 4.3 liter 4.3 vortec engine diagram?

Use the 4.3 liter 4.3 Vortec engine diagram as a reference during teardown and reassembly. When an OBD-II scanner reveals a specific diagnostic code, locate the corresponding sensor on the map. It helps verify wiring integrity between the sensor and the ECU, ensuring the check engine light stays off after repairs.