How to wire a speed sensor? There are two wires coming out of the speed sensor. One is for the power and the other is for the signal.

To wire a speed sensor, you will need to connect the power wire to a 12V power source and connect the signal wire to an input on your vehicle’s computer. The exact location of the input will vary depending on your vehicle, but it is usually located near the ECU.

If you’re looking for a 2 wire speed sensor wiring diagram, you’ve come to the right place. Here at blog post, we’ve got all the information you need to know about this type of sensor, including how to wire it up correctly.

A 2 wire speed sensor is typically used in automotive applications where space is limited.

However, they can also be used in other applications such as industrial machinery or even home security systems. Regardless of where you plan on using yours, it’s important to know how to properly wire it up.

The first thing you’ll need to do is identify which wires are positive and negative.

The next step is to connect the wires to their respective terminals on the sensor. Make sure that the polarity is correct! If not, your sensor will not work properly.

Once everything is hooked up, give your system a test run and make sure everything is working as it should be. That’s all there is to wiring up a 2 wire speed sensor!

Credit: www.clublexus.com

How Does a Two Wire Speed Sensor Work?

A speed sensor monitors the rotational speed of a wheel or shaft and sends this information to a control unit. The two wire speed sensor is the most common type of speed sensor. It uses a magnet andHall effect sensor to generate an electrical pulse for each revolution of the target.

The frequency of these pulses is proportional to the rotational speed.

The magnet is attached to the target, such as a wheel or shaft, while the Hall effect sensor is mounted nearby. As the target rotates, the magnet passes by the sensor and generates a magnetic field.

This field causes a change in voltage across the sensor, which produces an electrical pulse. The frequency of these pulses is proportional to the rotational speed of the target.

The two wire speed sensor is simple and reliable, but has some limitations.

For example, it can only be used with ferrous (magnetic) targets; it will not work with non-ferrous targets such as aluminum wheels. In addition, because it relies on a mechanical connection between the magnet and target, it can be subject to wear and tear over time.

How Do You Test a 2-Wire Transmission Speed Sensor?

There are a few ways that you can test a 2-wire transmission speed sensor. The most common way is to use an oscilloscope. You will want to connect the ground lead of the oscilloscope to the ground terminal on the sensor, and then probe the signal wire with the oscilloscope’s positive lead.

If everything is working correctly, you should see a sine wave on the screen.

Another way to test a 2-wire transmission speed sensor is with a multimeter. Set your multimeter to AC voltage mode and touch the leads to the corresponding terminals on the sensor.

Again, you should see a sine wave if everything is working properly.

If you don’t have access to an oscilloscope or multimeter, you can still test your 2-wire transmission speed sensor by simply monitoring your engine’s RPMs. With the engine off, disconnect one of the wires from the sensor (it doesn’t matter which one).

Then start up your engine and let it idle. The RPMs should be significantly lower than normal since only one wire is now sending information to your ECU. If they’re not lower, or if they fluctuate erratically, then there may be an issue with your sensor.

How Do You Wire a 2 Proximity Sensor?

In order to wire a 2 proximity sensor, you will need the following materials:

-2 Proximity Sensors

-Jumper Wires

-Breadboard

First, take your breadboard and place the sensors on it. Make sure that they are in separate rows so that you can easily connect them with jumper wires later.

Next, use jumper wires to connect one of the power pins on each sensor (usually either VCC or GND) to the power rail on your breadboard. Now, connect the other power pin on each sensor to the other power rail on your breadboard. Finally, use jumper wires to connect the signal output pin on each sensor to a different input/output (I/O) pin on your microcontroller.

That’s it! You’ve now successfully wired a 2 proximity sensor setup.

How Do You Test a Speed Sensor?

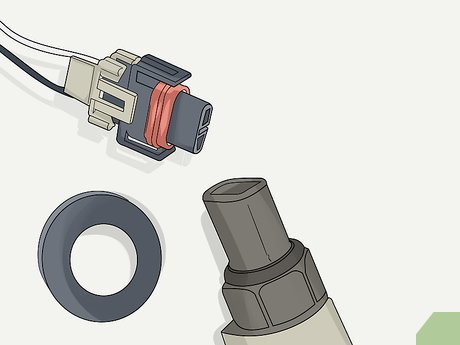

When testing a speed sensor, you will need to first check the wiring to the sensor. Make sure that there is no bare wire or frayed insulation. Next, check the connector at the sensor itself.

Make sure that it is clean and secure. If everything looks good so far, then you can proceed with the test.

To test the sensor, you will need a multimeter set to the resistance (ohm) setting.

With the multimeter probes touching the two terminals on the connector, you should see a reading of around 1-2 k ohms (1,000-2,000 ohms). This indicates that the sensor is working properly. If you see a reading of 0 ohms or infinity ohms, then this indicates an open circuit and the sensor is not working correctly.

How to Test a 2 Wire Speed Sensor

2 Wire Speed Sensor Voltage

Analog voltage speed sensors are the most commonly used type of speed sensor. They work by outputting a voltage that is proportional to the rotational speed of the shaft or pulley being monitored. The most common range for these sensors is 0-5 volts, with 2.5 volts corresponding to zero speed.

There are two main types of 2 wire analog voltage speed sensors: hall effect and magnetoresistive. Hall effect sensors use a magnetic field to generate their output signal, while magnetoresistive sensors use changes in resistance in response to a magnetic field. Both types of sensor have their advantages and disadvantages, but hall effect sensors are generally more accurate and durable than magnetoresistive sensors.

When choosing a 2 wire analog voltage speed sensor, it is important to consider the range of speeds that need to be measured and the accuracy required. For example, if only low speeds need to be measured, then a lower range sensor may be sufficient. However, if high accuracy is needed then a higher range sensor will be necessary.

Difference between 2-Wire And 3 Wire Sensor

There are many types of sensors available on the market, but two of the most common are 2-wire and 3-wire sensors. Both have their own advantages and disadvantages, so it’s important to know the difference before choosing a sensor for your application.

2-wire sensors are typically cheaper than 3-wire sensors, but they also have some drawbacks.

For one, they tend to be less accurate than 3-wire sensors. Additionally, 2-wire sensors can only be used with DC power sources, so if you’re using an AC power source, you’ll need to use a 3-wire sensor. Finally, 2-wire sensors require more wiring than 3-wire sensors.

3-wire sensors are more expensive than 2-wire sensors, but they offer greater accuracy and flexibility. Unlike 2-wire sensors, 3- wire sensors can be used with both AC and DC power sources. Additionally, 3 – wire sensor s often come with built – in amplifiers , which can improve signal quality.

However , three – wire sensor s also require more wiring than two – wire sensor s .

How to Test a 2 Wire Magnetic Speed Sensor

If you have a 2 wire magnetic speed sensor, there are a few tests you can run to make sure it’s working properly. First, check the power supply to the sensor to make sure it’s getting enough voltage. Next, check the ground connection to see if it’s secure.

Finally, test the signal output from the sensor to see if it’s sending a strong signal.

Conclusion

If you’re looking for a 2 wire speed sensor wiring diagram, then you’ve come to the right place. In this blog post, we’ll go over everything you need to know about wiring a 2 wire speed sensor, including what tools and materials you’ll need, and how to connect the wires correctly. We’ll also provide a troubleshooting guide in case you run into any problems along the way.

So let’s get started!