Wiring Harness GM Power Seat Wiring Diagram: Repair Guide

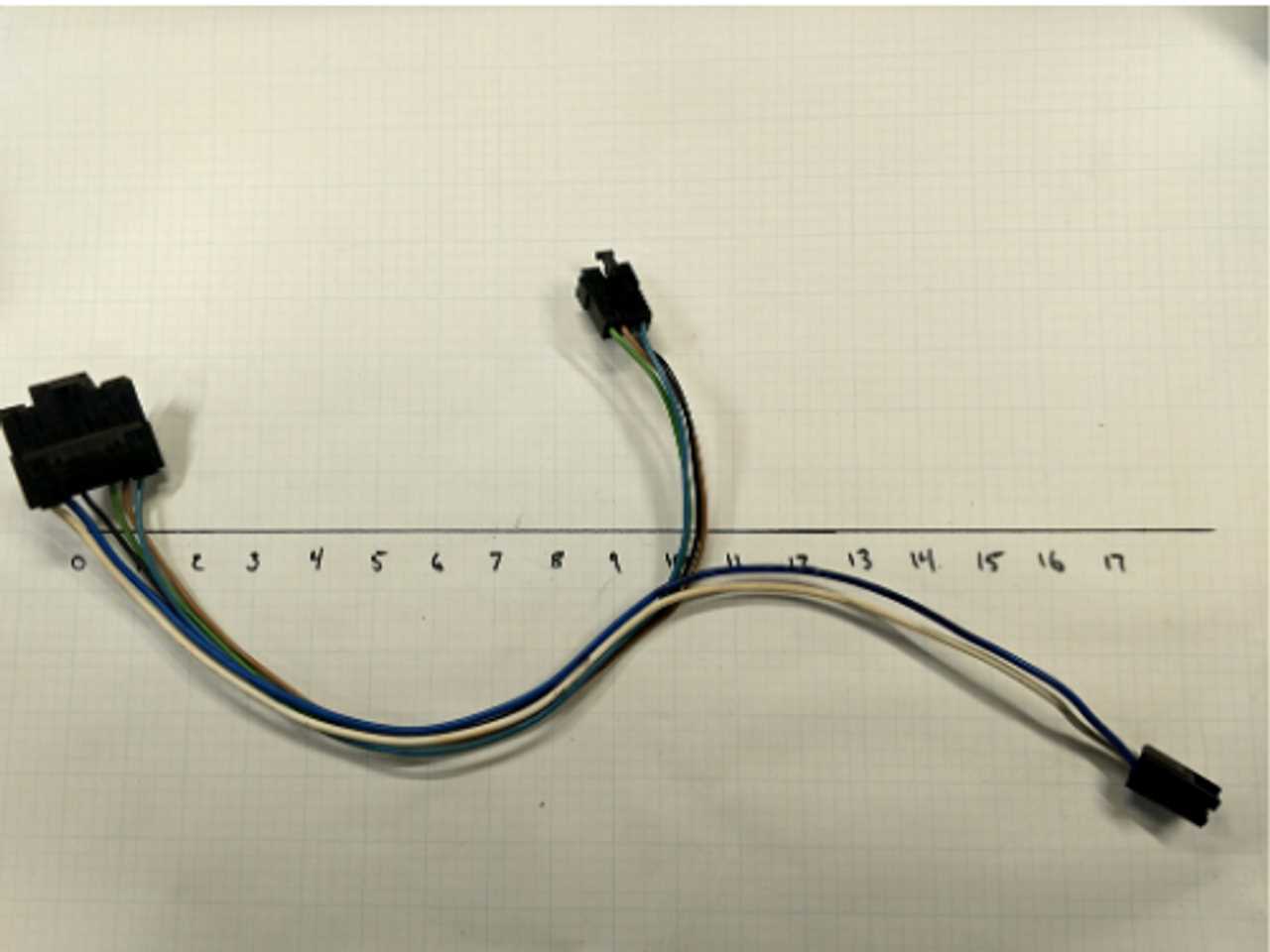

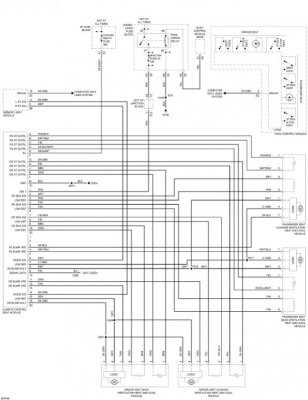

A GM power seat wiring diagram illustrates the electrical path from the fuse block to the seat motors. It identifies the 12V hot wire, the return ground wire, and the traveler wire connections that control seat movement. Understanding the common terminal and switch logic ensures accurate troubleshooting of power seat malfunctions.

📌 Key Takeaways

- Identify the 12V hot wire to ensure the system is receiving battery power

- Locate the common terminal to diagnose central switch failures

- Always check the ground wire for corrosion which often causes intermittent seat movement

- Use traveler wire identification to isolate specific motor malfunctions

- Consult this diagram when upgrading to power seats or fixing unresponsive controls

Navigating the electrical architecture of a vehicle requires a precise roadmap, especially when dealing with the comfort and convenience systems found in General Motors vehicles. If you are attempting a seat swap, repairing a broken recline motor, or troubleshooting a non-responsive lumbar support, understanding the wiring harness gm power seat wiring diagram is the first step toward a successful project. This comprehensive guide is designed to demystify the complex web of wires beneath your seat, providing you with the technical knowledge to identify every connection. By the end of this article, you will be able to trace power paths, understand the relationship between switches and motors, and safely integrate or repair your power seat system with professional-grade accuracy.

Understanding the GM Power Seat Circuitry

The standard GM power seat system is a marvel of simplified DC motor control, though it may look like a “nest” of wires at first glance. At its core, the system relies on a central wiring harness that connects the vehicle’s main power distribution block to the seat switch, and subsequently, to the various adjustment motors. In most GM configurations, the harness consists of a main power feed, a dedicated ground, and several pairs of “output” wires that lead to the individual motors for forward/backward movement, front tilt, rear tilt, and backrest recline.

A typical wiring harness gm power seat wiring diagram highlights the color-coded nature of these systems. Traditionally, GM utilizes a thick 12-gauge orange wire as the “hot wire” to provide a constant 12V supply from the fuse box. This is paired with a heavy-gauge black wire that serves as the primary ground wire, completing the circuit to the vehicle’s chassis. Unlike residential wiring that uses a neutral wire and a brass screw for grounding at the outlet, automotive systems use the metal frame of the car as a common return path. In more advanced memory seat modules, you may also encounter smaller signal wires that communicate with the Body Control Module (BCM) or memory seat module.

Most GM power seats operate on a 30-amp circuit. Always ensure that any replacement wiring or fuses match this specification to prevent overheating or potential fire hazards in the seat upholstery.

(SWITCH PANEL)

[POWER: ORANGE (12V)]

[GROUND: BLACK (GND)]

|

V

+———————–+

| COMMON TERMINAL |

+———–+———–+

| | |

[TRAVELER A] [TRAVELER B] [TRAVELER C]

(Motor 1) (Motor 2) (Motor 3)

| | |

+———–+———–+

|

[CHASSIS GROUND]

Step-by-Step Guide to Reading and Installing the Harness

Interpreting a wiring harness gm power seat wiring diagram requires a methodical approach. Follow these steps to ensure you are reading the diagram correctly and applying it to your vehicle safely. Before beginning, gather a digital multimeter, wire strippers, and high-quality electrical connectors.

- ✓ Step 1: Identify the Main Power Feed. Locate the thickest wire in the harness, usually orange. This is your hot wire. Use your multimeter to verify it shows 12V voltage when the ignition is in the ‘on’ or ‘accessory’ position. In some GM models, this is a constant hot, meaning it has power even with the key out.

- ✓ Step 2: Locate the Grounding Path. The black ground wire must be secured to a clean, unpainted metal surface on the floor pan. In a diagram, this is often shown as a series of decreasing parallel lines. Ensure this connection is tight, as a weak ground is the leading cause of “stuttering” seat motors.

- ✓ Step 3: Map the Common Terminal. On the back of the seat switch, you will find a common terminal where the main power enters. From here, the switch redirects current to different motors based on the direction you press. The diagram will show this central hub clearly.

- ✓ Step 4: Trace the Traveler Wires. Each motor has two wires leading to it. These act as traveler wire pairs. When you push the switch forward, one wire becomes “hot” and the other becomes “ground.” When you push backward, the switch reverses the polarity. Tracing these on your diagram helps you identify which motor controls which movement.

- ✓ Step 5: Verify Wire Gauge. Ensure the wire gauge matches the diagram’s specifications. High-draw motors require thicker wires (usually 12 or 14 AWG). Using wire that is too thin will cause a significant voltage drop, making the seats move slowly or not at all.

- ✓ Step 6: Test Pin Continuity. Before plugging in the harness, use your multimeter’s continuity setting to ensure that the pins in the connector match the layout in the wiring diagram. This prevents shorting out the switch module.

Always disconnect the vehicle’s negative battery terminal before working on the seat harness. Many GM seats are equipped with side-impact airbags; accidental deployment can cause severe injury and expensive damage.

Common Issues and Troubleshooting

Even with a perfect wiring harness gm power seat wiring diagram, issues can arise due to age, wear, or environmental factors. One of the most common problems is a “dead” seat where no motors function. This is often traced back to the 30A circuit breaker or fuse in the interior fuse block. If the fuse is intact, use your diagram to check for 12V at the common terminal of the switch. If power is present there but the seat doesn’t move, the switch itself may have oxidized internal contacts.

Another frequent issue involves “ghost” movements or seats that only move in one direction. This usually indicates a broken traveler wire inside the harness loom. Because the seat moves back and forth, the wires are constantly flexed. Over time, the copper strands inside the insulation can break. Your diagram will show you which pins correspond to that specific motor movement, allowing you to perform a continuity test from the switch to the motor plug. If you see “OL” (Open Line) on your meter, you have found a break in the circuit.

If your seat is stuck and you cannot access the mounting bolts, use a 12V cordless drill battery and two jumper wires. Use your diagram to find the horizontal motor pins and “jump” them directly to move the seat manually.

Tips and Best Practices for Seat Wiring

When working with a wiring harness gm power seat wiring diagram, quality should be your top priority. If you are extending wires for a custom project, never use residential hardware like a brass screw wire nut or masking tape. Automotive environments are subject to extreme vibrations and temperature swings. Always use automotive-grade TXL wire and heat-shrink butt connectors to ensure a weather-tight and vibration-resistant seal. This maintains the integrity of the voltage delivery to the motors.

Maintenance is equally important. Periodically inspect the harness where it emerges from the carpet. GM often uses a plastic “track” to guide the wires as the seat moves. If this track breaks, the harness can get caught in the seat gears, stripping the insulation and causing a short circuit. Applying a small amount of dielectric grease to the harness connectors can prevent corrosion, especially in regions where road salt is tracked into the vehicle. Finally, if you are performing a seat swap into a non-power vehicle, ensure you tap into a high-current “hot” lead. Tapping into a low-current “neutral” style circuit meant for interior lights will result in blown fuses and potentially melted wires. By following the diagram exactly and using the correct gauge wire, you ensure your GM power seats remain a reliable and comfortable feature of your vehicle for years to come.

In conclusion, mastering the wiring harness gm power seat wiring diagram is about more than just matching colors. It is about understanding the flow of electricity, the importance of solid grounding, and the mechanical limits of the wiring itself. Whether you are a DIY enthusiast or a professional technician, having a clear understanding of the hot wire, ground wire, and traveler logic will save you hours of frustration. Keep your diagrams handy, use the right tools, and always prioritize safety when working with your vehicle’s electrical system.

Frequently Asked Questions

What is GM power seat wiring diagram?

A GM power seat wiring diagram is a schematic representation of the electrical system governing seat adjustments. It shows how current flows from the battery through the hot wire to the switch and motors. This map is essential for locating faults in the wiring harness, connectors, or seat control modules.

How do you read GM power seat wiring diagram?

To read the diagram, start at the power source and follow the hot wire to the seat switch. Identify the common terminal where the circuit branches. Trace the traveler wire lines to the specific motors responsible for tilt, recline, or height adjustments, ensuring the ground wire path is complete.

What are the parts of GM power seat?

The system consists of the power seat switch, adjustment motors, a wiring harness, and a dedicated fuse. Inside the harness, you will find the hot wire for power, a ground wire for the circuit return, and several traveler wire sets that relay signals from the switch to the motors.

Why is common terminal important?

The common terminal acts as the central connection point within the seat switch assembly. It distributes current to the various traveler wire outputs based on the user’s input. If this terminal fails or becomes corroded, the entire seat may lose power or respond intermittently to the control switches.

What is the difference between traveler wire and hot wire?

The hot wire provides a constant 12-volt supply from the vehicle’s electrical system to the control switch. In contrast, a traveler wire only carries current when the switch is activated, sending power to a specific motor to move the seat forward, backward, up, or down.

How do I use GM power seat wiring diagram?

Use the diagram to perform continuity tests and voltage checks at specific points in the harness. By identifying the ground wire and hot wire locations, you can use a multimeter to verify if the seat is receiving power and if the switch is correctly routing electricity.