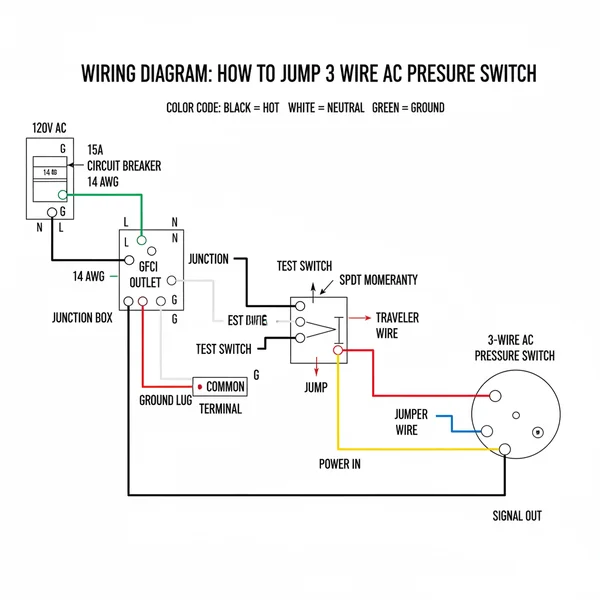

Wiring Diagram How to Jump 3 Wire AC Pressure Switch: Bypass

To jump a 3-wire AC pressure switch, identify the common terminal, hot wire, and signal traveler wire using a wiring diagram. Connect the power supply wire to the signal wire to bypass the sensor for testing. Always ensure the ground wire and neutral wire connections are secure to avoid short circuits.

📌 Key Takeaways

- The diagram identifies specific pinouts for power, signal, and ground paths.

- Finding the common terminal is essential for a successful jump and diagnosis.

- Never leave a switch jumped permanently as it risks terminal compressor damage.

- Use a multimeter to verify the hot wire before inserting any jumper tools.

- This diagram helps diagnose if the pressure switch or the refrigerant level is the fault.

Troubleshooting a non-functional automotive air conditioning system often leads a DIY mechanic to the pressure sensor. If your compressor clutch refuses to engage despite having a full charge of refrigerant, understanding the wiring diagram how to jump 3 wire ac pressure switch is the most efficient way to isolate the problem. Unlike older two-wire systems that act as simple “on-off” switches, the three-wire variant is a transducer that provides real-time pressure data to the vehicle’s computer. This article provides a comprehensive breakdown of the wiring architecture, a clear diagnostic diagram description, and the safety-conscious steps required to test your system without causing an electrical short.

A three-wire AC pressure switch operates on a 5-volt reference circuit. Attempting to jump this switch like a traditional two-wire switch (by simply bridging the terminals) can result in a blown ECU fuse or permanent damage to the engine control module. Always use a multimeter to verify wires before proceeding.

Understanding the 3-Wire AC Pressure Switch Diagram

The wiring diagram for a modern AC pressure transducer is significantly more complex than a basic thermal or high-pressure cutout. When you look at a schematic, you will see three distinct paths connecting the switch to the Engine Control Module (ECM) or Powertrain Control Module (PCM). These components are essential for the computer to modulate the cooling fans and the compressor clutch based on the internal pressure of the refrigerant lines.

In a standard diagram, the first component is the 5V Reference Wire. In residential electricity, you might refer to the energized lead as the hot wire, but in automotive electronics, this is a regulated 5-volt supply provided by the PCM. The second component is the ground wire, which completes the circuit. In household wiring, you often distinguish between a neutral wire and a ground, but in a vehicle, the ground usually returns directly to a common terminal on the PCM or the chassis frame. The third wire is the Signal Wire, sometimes referred to in general electrical schematics as a traveler wire because it carries the varying voltage data back to the control unit.

The visual breakdown of the connector usually shows three pins arranged in a triangular or linear fashion. While home outlets use a brass screw to denote the hot side, automotive connectors rely on pin numbers (1, 2, and 3) or wire colors. Typically, the wires are a thin gauge, ranging from 18 to 22, because they carry very little current. The diagram will show the internal resistance of the switch changing as pressure increases, which in turn changes the signal voltage sent back to the computer.

[DIAGRAM_PLACEHOLDER: A 3-wire AC Pressure Switch Schematic showing the 5V Reference (Red), Signal (Green/Blue), and Ground (Black) connecting to an ECU block. Labels highlight the 5V input, Ground return, and the Signal output.]

Step-by-Step Guide to Testing and Jumping the Switch

Jumping a 3-wire switch is a diagnostic procedure, not a permanent fix. Because the PCM expects a specific voltage range (usually between 0.5V and 4.5V), simply bridging the wires with a paperclip can trigger a “High Voltage” or “Low Voltage” error code, preventing the compressor from starting. Follow these steps to interpret the diagram and test the circuit correctly.

- ✓ Identify the Wires: Consult your specific vehicle’s wiring diagram how to jump 3 wire ac pressure switch to confirm colors. Use a multimeter set to DC volts. With the ignition ON, touch the black probe to a clean chassis ground and the red probe to each pin in the harness. One pin should read 5.0V (the reference), one should read 0V (the ground), and the third is your signal wire.

- ✓ Check for Ground: Switch your multimeter to the continuity setting. Touch one probe to the identified ground wire pin and the other to the negative battery terminal. A beep confirms the ground circuit is intact back to the common terminal.

- ✓ Simulate the Signal: To “jump” a 3-wire switch safely, you need to provide the signal wire with a voltage that tells the computer the pressure is within the “safe” range (usually around 2.0V to 2.5V). Professionals use a potentiometer, but for a quick test, some technicians use a resistor between the 5V reference and the signal wire to drop the voltage.

- ✓ Verify Compressor Engagement: Once the signal wire receives a simulated mid-range voltage, the PCM should ground the AC compressor relay. If the compressor clicks on, you have confirmed that the wiring and the PCM are functional, and the pressure switch itself is likely faulty or the system is low on refrigerant.

- ✓ Check Wire Integrity: If you don’t see 5V at the harness, inspect the thin gauge wiring for frays. Automotive wires are prone to vibration damage, especially near the connector where the insulation meets the plastic housing.

Never jump the 5V reference wire directly to the ground wire. This creates a dead short that can fry the internal traces of your engine computer. Unlike a residential hot wire that might just trip a breaker, automotive computer circuits are extremely sensitive to current spikes.

Common Issues & Troubleshooting

One of the most frequent problems users encounter is a “false positive” diagnosis. You might jump the switch and find the compressor works, assuming the switch is dead. However, the switch might be doing its job by reporting that the refrigerant is too low. If you replace the switch and the system still doesn’t work, the issue is likely a leak. Using the wiring diagram how to jump 3 wire ac pressure switch helps you differentiate between an electrical failure and a mechanical one.

Another common issue is corrosion within the harness connector. Unlike the secure connection of a brass screw on a light switch, automotive pins are subject to moisture and road salt. Look for green crust (oxidation) inside the plug. This oxidation increases resistance, causing the voltage signal to “drift,” which confuses the PCM into thinking the AC pressure is higher or lower than it actually is. If the gauge of the wire feels brittle or stiff, the copper inside may have corroded, requiring a pigtail replacement.

Tips & Best Practices for AC Electrical Work

When working with sensitive AC electronics, precision is your best friend. Always use a digital multimeter rather than a test light. A traditional test light can pull too much current through the 5V reference circuit, potentially damaging the PCM. When interpreting your wiring diagram how to jump 3 wire ac pressure switch, pay close attention to the terminal numbers stamped on the plastic connector; these are often tiny and require a flashlight to see clearly.

If you find that jumping the signal wire engages the compressor, check your refrigerant pressures with a manifold gauge set before buying a new switch. A switch that “fails” to engage the compressor is often just a messenger telling you your system is empty!

For long-term maintenance, always apply a small amount of dielectric grease to the weather seal of the pressure switch connector. This prevents moisture from entering and causing the voltage signal to fluctuate. If you need to replace the switch, opt for an Original Equipment Manufacturer (OEM) part. Aftermarket sensors often have slight variances in their internal resistance, which can lead to the AC cycling on and off too frequently. Finally, ensure the wire gauge of any repair pigtail matches the factory traveler wire or signal wire exactly to maintain the integrity of the resistance-based signal.

By following this guide and correctly utilizing the wiring diagram how to jump 3 wire ac pressure switch, you can save hundreds of dollars in shop diagnostic fees. Understanding the relationship between the hot wire (reference), the ground wire, and the signal path allows you to approach AC repair with the confidence of a professional technician.

Frequently Asked Questions

What is wiring diagram how to jump 3 wire ac pressure switch diagram?

This specific wiring diagram illustrates the electrical connections between the AC pressure switch, the compressor clutch, and the vehicle’s control module. It provides a visual roadmap for technicians to safely bypass the sensor by identifying the hot wire and the traveler wire, allowing for quick system diagnostic testing.

How do you read wiring diagram how to jump 3 wire ac pressure switch diagram?

Start by locating the pressure switch symbol and tracing the wires to their sources. Identify the common terminal where power enters and the signal path to the PCM. Look for color-coded labels indicating the ground wire and neutral wire configurations to ensure you are jumping the correct pins safely.

What are the parts of wiring diagram how to jump 3 wire ac pressure switch?

The primary parts include the common terminal for power input, the signal or traveler wire that communicates with the computer, and the ground wire. The diagram also shows the internal switch mechanism, the fuse or relay protecting the circuit, and the connection point for the AC compressor clutch.

Why is common terminal important?

The common terminal is the central hub where electrical current enters the switch assembly. Identifying it on a wiring diagram is critical because connecting the hot wire to the wrong pin can cause a major short circuit or damage the sensitive electronics in the vehicle’s engine control module.

What is the difference between traveler wire and hot wire?

The hot wire provides a constant voltage source from the battery or fuse box to the pressure switch. In contrast, the traveler wire or signal wire carries that voltage back to the control module only when the switch is closed, indicating that the system pressure is within safe limits.

How do I use wiring diagram how to jump 3 wire ac pressure switch diagram?

Use the diagram to identify which two pins need to be bridged to simulate a closed switch. Locate the hot wire and the traveler wire on the harness connector. Carefully insert a jumper wire between these two points while monitoring the AC compressor to see if it engages.