Warn Winch Solenoid Wiring Diagram: Installation Guide

A Warn winch solenoid wiring diagram illustrates how to connect the hot wire from your battery to the solenoid pack and subsequently to the winch motor. It maps the traveler wire connections for remote operation and ensures the ground wire is properly secured for a complete, high-current electrical circuit.

📌 Key Takeaways

- Identifies correct cable routing between the battery, solenoid, and motor

- Highlights the importance of color-coding for motor field connections

- Ensures safe grounding to prevent electrical arcing or winch failure

- Clarifies how the remote control socket triggers the solenoid pack

- Essential for replacing old solenoids or upgrading to a contactor

When you are out on the trail and your recovery equipment fails, it is often due to a breakdown in the electrical system rather than a mechanical failure. Understanding a warn winch solenoid wiring diagram is the first step toward self-sufficiency in off-road recovery. This comprehensive guide is designed to help you navigate the complex web of high-current cables and control wires that make your winch function. You will learn the specific roles of each component, how to identify terminal markings, and the correct sequence for a safe installation. Whether you are replacing a faulty solenoid pack or building a custom control setup, having the correct diagram ensures that your winch delivers its maximum pulling power without risking an electrical fire or equipment damage.

Understanding the Warn Winch Solenoid Wiring Diagram Components

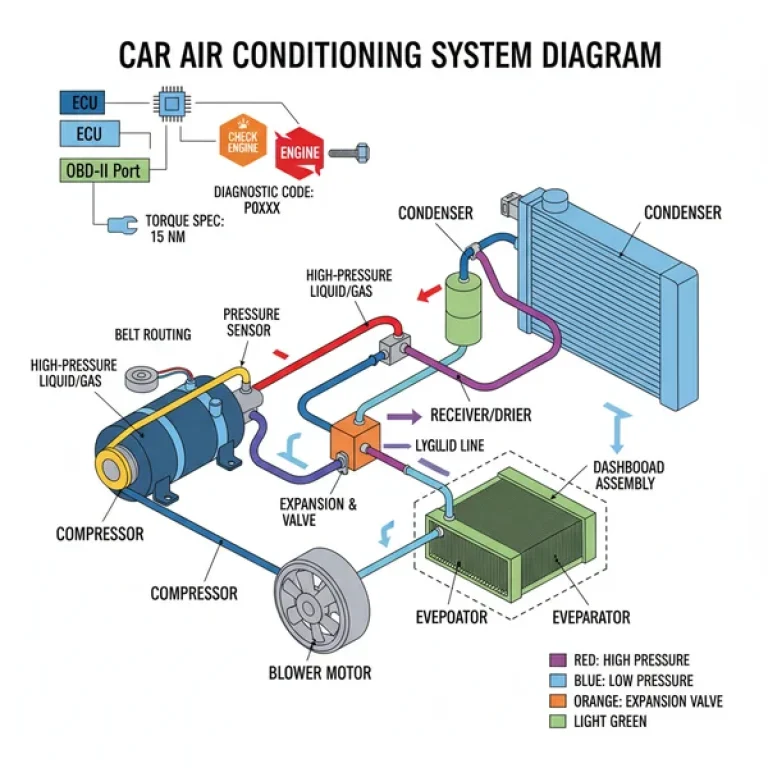

The solenoid is essentially a high-current relay. Because a winch motor draws several hundred amps under load, a standard dashboard switch cannot handle the power; instead, the switch triggers the solenoid, which then completes the circuit between the battery and the motor. In a standard Warn winch solenoid wiring diagram, you will typically see either a four-solenoid configuration (older models) or a modern Albright-style contactor.

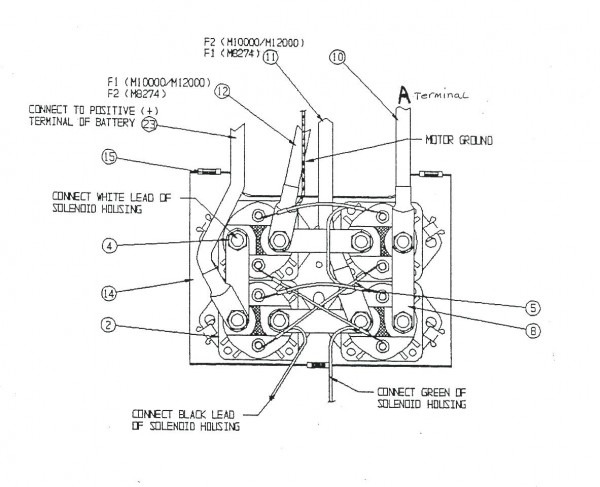

The primary components involve several heavy-gauge cables. The hot wire, usually a red 2-gauge or 4-gauge cable, runs directly from the positive terminal of the battery to the common terminal on the solenoid block. This terminal acts as the distribution hub for incoming power. From here, the solenoids route current to the motor’s field terminals, often labeled F1 and F2, and the armature terminal, labeled A.

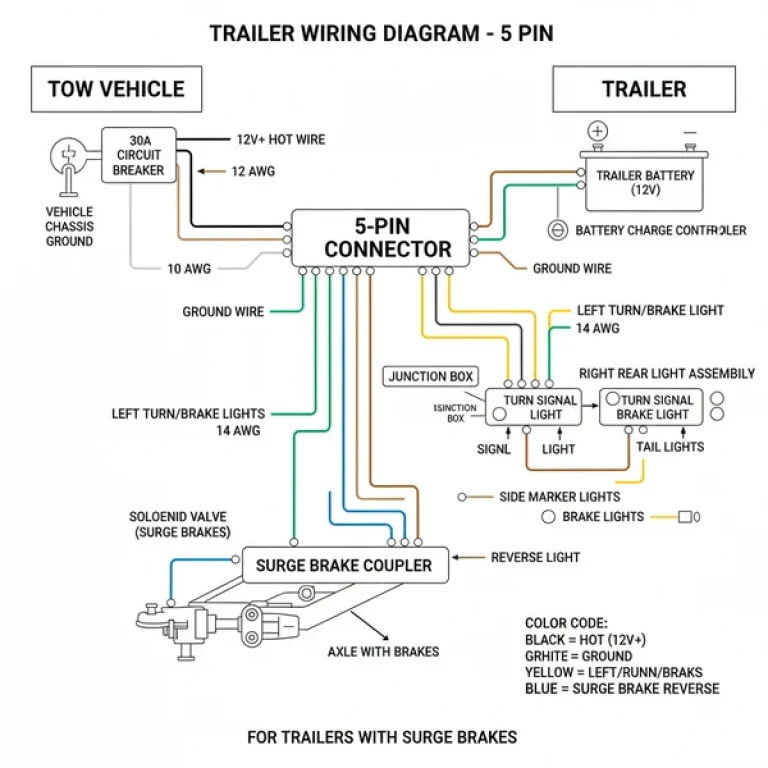

Visualizing the diagram requires looking at the color-coding and terminal positions. Most Warn systems use a specific color scheme: a yellow boot for F1, a blue boot for F2, and a red boot for the A terminal. The ground wire (black) connects the motor housing directly back to the negative battery terminal to ensure a low-resistance return path. Within the control circuit, you will find smaller diameter wires, often referred to as the traveler wire or trigger wires, which connect the remote control socket to the solenoid coils. These low-voltage signals tell the solenoids when to engage for “power in” or “power out” operations.

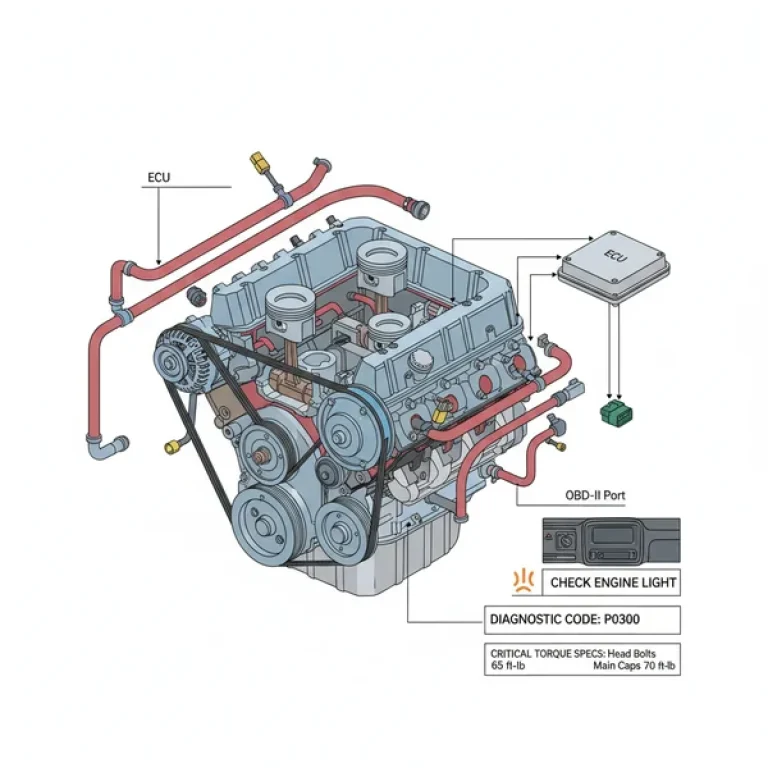

A visual representation of the battery connections, solenoid bridge, and motor terminal routing (F1, F2, A, and Ground).

Step-by-Step Installation and Wiring Guide

Reading a warn winch solenoid wiring diagram can feel overwhelming at first, but following a structured approach makes the process manageable and safe. Before you begin, ensure you have the correct gauge of wire for your winch’s capacity; 2-gauge is standard for most 8,000 to 12,000-lb winches.

Always use a dedicated ground wire that runs from the winch motor directly to the battery. Relying on the vehicle’s frame for a ground can lead to significant voltage drops and overheating.

Necessary Tools and Materials

- ✓ Insulated socket set and wrenches

- ✓ Wire crimpers and heat shrink tubing

- ✓ Multimeter to check voltage and continuity

- ✓ Dielectric grease to prevent corrosion

Execution Steps

1. Power Disconnection: Safety is paramount. Always disconnect the vehicle’s battery before touching any winch wiring. Remove the negative terminal first to prevent accidental shorting.

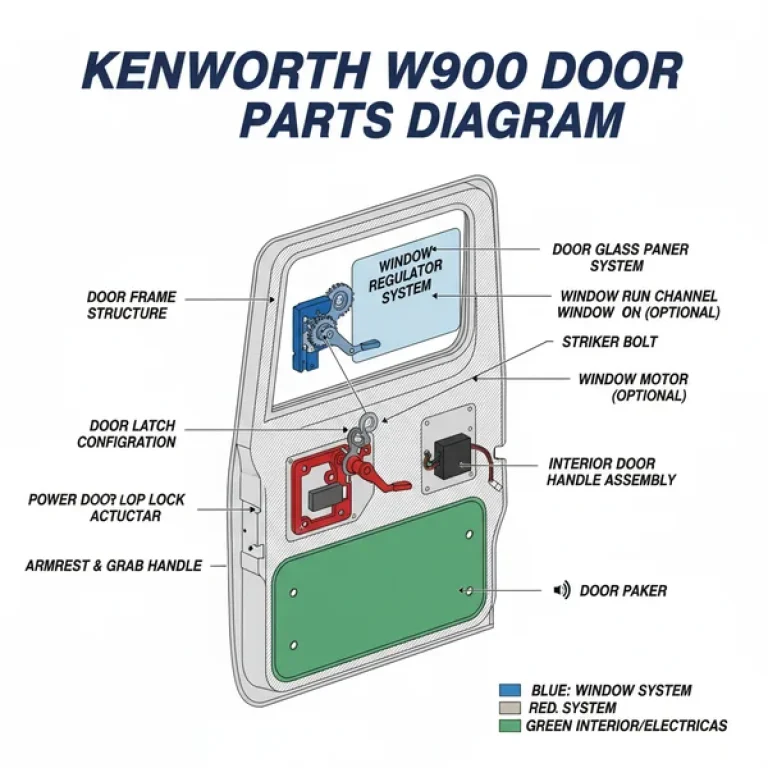

2. Mounting the Solenoid Box: Secure the solenoid pack in a location that is protected from extreme heat and excessive vibration. Ensure the brass screw terminals on the solenoids are facing a direction that allows for easy cable routing without sharp bends.

3. Connect the Motor Cables: Identify the F1, F2, and A terminals on the winch motor. Match these to the corresponding terminals on the solenoid pack as shown in your warn winch solenoid wiring diagram. Tighten the nuts firmly, but be careful not to strip the brass screw threads.

4. The Ground Connection: Run the heavy-duty ground wire from the motor’s bottom ground bolt to the negative battery terminal. This “neutral” path for the DC current must be as clean and direct as possible.

5. Wiring the Control Socket: The control socket allows the remote to communicate with the solenoids. Connect the traveler wire (usually green or black) to the small terminals on the solenoid coils. These wires carry the low-amp signal that triggers the high-amp bridge.

6. Main Power Feed: Connect the hot wire (red) to the common terminal on the solenoid pack. Do not connect this to the battery yet.

7. Verification: Double-check all connections against the diagram. Ensure no cables are touching the exhaust manifold or moving parts like the cooling fan.

8. Final Connection and Test: Reconnect the battery terminals. Using the remote, test the winch briefly in both directions. Watch for any sparks or unusual smells that might indicate a short.

Winch motors can pull over 400 amps. Using an undersized wire gauge or having a loose connection can cause the wires to melt or catch fire within seconds of operation.

Common Issues & Troubleshooting

Even with a perfect warn winch solenoid wiring diagram, issues can arise due to environmental factors or component wear. The most common symptom of a solenoid failure is a “clicking” sound when you press the remote button, but the motor fails to turn. This typically indicates that the solenoid coil is receiving power (the traveler wire is working), but the internal high-current contacts are pitted or corroded and cannot pass voltage to the motor.

Another frequent issue is the motor running in only one direction. This usually points to one specific solenoid in the pack being stuck or having a loose connection at the common terminal. Use your multimeter to check for 12V at the F1 and F2 terminals while the remote button is pressed. If voltage is present at the solenoid but not at the motor, the cable itself may have internal corrosion.

If the winch feels sluggish or slows down significantly under a light load, check your ground wire. A weak ground is the primary cause of winch overheating. Ensure the brass screw connections are not oxidized; a light sanding of the contact surfaces can often restore full functionality.

Tips & Best Practices for Winch Wiring

To ensure your winch remains reliable for years, maintenance and high-quality installation are key. Always use marine-grade heat shrink on all terminal ends to keep moisture out of the copper strands. Moisture can travel up inside the insulation, causing the wire to rot from the inside out, which increases resistance and lowers voltage.

Label your cables at both ends with a permanent marker or colored tape. If you ever have to disassemble the winch in the field, you won’t need to consult a diagram to remember which wire goes to F1 or F2.

When selecting replacement parts, prioritize high-quality solenoids with silver-alloy contacts. While cheap generic solenoids are available, they often fail under the sustained heat of a long recovery pull. Additionally, consider installing a master kill switch on the hot wire near the battery. This allows you to cut power to the entire winch system when not in use, preventing “phantom” battery drain and ensuring the winch cannot be tampered with or accidentally activated while driving.

Regularly inspect the common terminal for tightness. Off-road vibrations are notorious for loosening even the most secure nuts. A drop of blue thread-locker on the non-electrical threads can provide extra peace of mind. By following a detailed warn winch solenoid wiring diagram and adhering to these best practices, you ensure that your winch is a reliable lifeline when the trail gets tough. Proper wiring is not just about making the motor spin; it is about maximizing safety and efficiency in the most demanding environments.

Frequently Asked Questions

What is a Warn winch solenoid wiring diagram?

A Warn winch solenoid wiring diagram is a visual map showing the electrical paths for your recovery system. It details how the hot wire connects to the power source and how the common terminal bridges signals from the remote to the motor. This guide prevents incorrect wiring that could lead to motor damage.

How do you read a winch solenoid diagram?

To read the diagram, start at the battery and follow the thick cables to the solenoid terminals. Identify the small traveler wire connections that handle switching. Ensure you distinguish between the high-amperage motor leads and the low-amperage control wires, usually indicated by different line thicknesses or colors on the schematic.

What are the parts of a Warn solenoid system?

The system includes the solenoid pack (or contactor), a heavy-duty hot wire, a dedicated ground wire, and the winch motor itself. Internally, the remote control socket uses a common terminal to send power through a traveler wire to specific solenoids, which then engage the winch drum to rotate in or out.

Why is the ground wire important in winching?

The ground wire completes the high-current circuit back to the battery. Without a solid ground, the winch may lack pulling power or fail to operate entirely. In DC systems, this acts as the neutral wire return path, and a loose connection here can cause dangerous heat buildup and electrical fires.

What is the difference between 3-wire and 5-wire remotes?

The difference lies in how the traveler wire logic is handled. A 3-wire remote typically uses a common terminal for power and two wires for direction. A 5-wire system adds dedicated lines for grounding the remote and sometimes an indicator light, requiring a more complex wiring diagram to ensure proper solenoid activation.

How do I use a winch wiring diagram?

Use the diagram as a reference during installation or troubleshooting. Cross-reference the terminal labels on your solenoid, such as F1, F2, and A, with the diagram’s layout. Always verify that the hot wire is fused or disconnected while you are performing the initial wiring to ensure maximum safety during the process.