Volvo Truck Volvo VNL Fuse Box Diagram: Troubleshooting

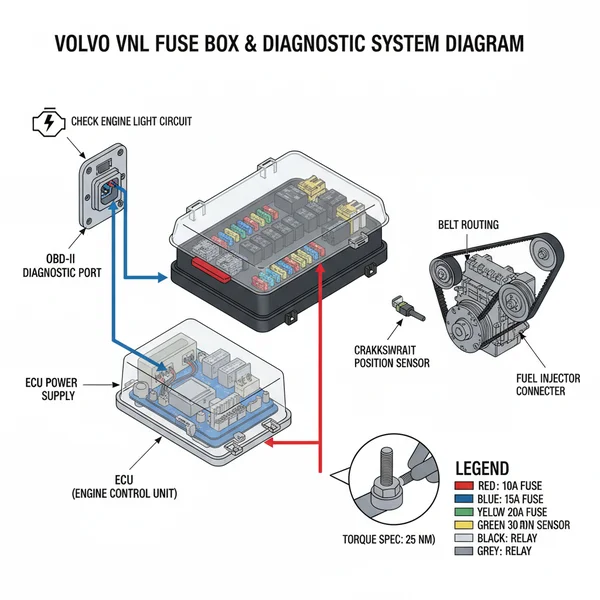

The Volvo VNL fuse box is primarily located in the center of the dashboard behind the access panel. This diagram labels critical fuses for the ECU, lighting, and power outlets. Using it allows drivers to resolve a check engine light or troubleshoot electrical failures before running a diagnostic code scanner.

📌 Key Takeaways

- The diagram identifies the specific location of fuses for the ECU and lighting systems.

- Most VNL models house the primary fuse panel in the center dashboard area.

- Matching the correct amperage is critical to prevent electrical fires or module damage.

- Fuses should be checked first whenever a check engine light or accessory failure occurs.

- Use this diagram alongside an OBD-II scanner for comprehensive electrical troubleshooting.

When you are operating a heavy-duty vehicle like a Volvo VNL, electrical reliability is the backbone of your productivity. Encountering a sudden failure in your lighting, wipers, or engine sensors can bring a profitable haul to a grinding halt. Having access to a comprehensive volvo truck volvo vnl fuse box diagram is not just a convenience; it is a critical diagnostic tool that bridges the gap between a minor inconvenience and an expensive service call. This guide provides a detailed look at the electrical architecture of your truck, helping you locate specific circuits and understand how power flows through your vehicle’s complex systems. By the end of this article, you will be equipped to identify blown fuses, troubleshoot relay failures, and maintain your electrical system with professional-level precision.

The electrical system of a Volvo VNL is centered around the Power Distribution Center (PDC), which acts as the hub for all electrical activity. Unlike smaller passenger vehicles, the Volvo VNL utilizes a sophisticated network of fuses, circuit breakers, and relays to manage the high-current demands of a commercial diesel engine and sleeper cab amenities. The volvo truck volvo vnl fuse box diagram typically reveals a layout divided into several logical zones. These zones include the primary ignition circuits, exterior lighting, interior comfort systems, and critical engine management components like the ECU (Engine Control Unit).

Each slot in the fuse box is assigned a specific alphanumeric code (such as F1, F2, or R1 for relays). The diagram is your key to translating these codes into functional components. For instance, you might find that a specific 15-amp fuse is responsible for the OBD-II diagnostic port, while a larger 40-amp circuit breaker manages the HVAC blower motor. Most VNL models feature a main fuse panel located inside the cab, usually situated behind a removable panel on the top of the dashboard on the passenger side. There is also an auxiliary power distribution module located in the engine compartment or near the battery box, which handles the high-amperage draws required for the starter and alternator circuits. Understanding this hierarchy is essential because a problem that appears to be a sensor failure might simply be a lack of power from the primary distribution block.

Most Volvo VNL trucks utilize a “Color-Amperage” standard. For example, Blue fuses are 15A, Yellow are 20A, and Green are 30A. Always verify the amperage stamped on top of the fuse against the volvo truck volvo vnl fuse box diagram to prevent circuit damage.

Interpreting the fuse box diagram and performing a physical inspection requires a systematic approach. If you are experiencing an electrical glitch, follow these steps to use the diagram effectively:

- Locate the Fuse Panel: In most Volvo VNL trucks, the main interior fuse panel is found under the dashboard cover on the passenger side. You may need a flat-head screwdriver or a Torx T25 driver to remove the mounting screws, though many modern versions use simple finger-twist fasteners.

- Reference the Diagram Legend: Turn the cover over or consult the manual to find the legend. Cross-reference the symptom you are experiencing (e.g., “Left High Beam”) with the corresponding fuse number on the volvo truck volvo vnl fuse box diagram.

- Perform a Visual Inspection: Use a fuse puller tool to remove the suspected fuse. Look at the metal bridge inside the plastic housing. If the bridge is broken or the plastic is charred, the fuse has blown.

- Use a Multimeter for Precision: Set your multimeter to the continuity setting or DC voltage. If the fuse is still in the panel, touch the probes to the small exposed metal pads on top of the fuse. A “beep” indicates continuity, while a lack of sound confirms the fuse is dead.

- Check for Diagnostic Codes: If the fuse is related to the engine or transmission, connect an OBD-II scanner. Often, a blown fuse will trigger a specific diagnostic code that points you directly to the circuit at fault.

- Verify the ECU Feed: If the truck will not start, locate the fuses labeled for the ECU or “Engine Management.” Without power to these fuses, the computer cannot initiate the start sequence.

- Replace with Correct Amperage: Never replace a fuse with one of a higher rating. If the diagram calls for a 10A fuse, only use a 10A fuse. Using a higher rating can lead to a fire or damage to expensive electronic modules.

- Test the Accessory Systems: After replacement, cycle the ignition and test the component. If the fuse blows again immediately, you have a short circuit that requires deeper investigation.

Never use a piece of wire or a “jumped” fuse to bypass a blown circuit. This bypasses the safety mechanism and can melt the wiring harness, potentially costing thousands of dollars in repairs or causing a vehicle fire.

When troubleshooting the electrical system, it is common to encounter “phantom” issues where a fuse appears intact, but the component fails to work. One of the most frequent problems is a faulty relay. Relays are electromagnetic switches that allow a low-current signal to control a high-current load. If your check engine light is illuminated and the fuse is fine, the relay responsible for the fuel pump or engine cooling fans may have failed internally.

Another common issue involves vibration-related wear. Because Volvo VNL trucks cover hundreds of thousands of miles, the constant vibration can cause fuses to wiggle loose or create “pitting” on the contact points within the fuse box. This leads to intermittent power loss. If you see a diagnostic code that keeps appearing and disappearing, inspect the underside of the fuse panel for loose terminal pins or signs of moisture intrusion, which can cause corrosion and high resistance.

If you are getting multiple unrelated sensor errors, check the main ground strap for the fuse box. A loose ground can cause “back-feeding,” where electricity tries to find a path to ground through other sensitive circuits, often confusing the ECU.

Maintaining the electrical health of your Volvo VNL goes beyond just replacing fuses. You should adopt a proactive maintenance schedule to ensure long-term reliability. Every time you perform an oil change or inspect the accessory belt, take five minutes to open the fuse box and look for signs of heat. Discolored plastic around a fuse slot is a warning sign of an overloaded circuit or a loose connection that is generating excess heat.

Furthermore, pay close attention to your charging system. An alternator that is overcharging or undercharging can put undue stress on your fuses and sensitive electronics. Check the tension on your accessory belt; if it slips, the voltage drops, and the amperage increases across your circuits to compensate for the power loss, which can blow fuses prematurely. While you are under the hood, ensure that sensors related to coolant flow and oil pressure have secure, clean connections at the harness level, as these are common sources of electrical noise that can trigger a false check engine light.

- ✓ Carry a complete kit of spare Mini and J-Case fuses in your glovebox.

- ✓ Use dielectric grease on relay pins to prevent corrosion in humid environments.

- ✓ Ensure battery terminal nuts are tightened to the proper torque spec to prevent voltage spikes.

- ✓ Clean the area around the fuse box cover before opening to prevent dust from entering the terminals.

- ✓ Document any recurring blown fuses to identify patterns for a professional mechanic.

In summary, the volvo truck volvo vnl fuse box diagram is an indispensable asset for any driver or fleet technician. By understanding the layout of the PDC, utilizing OBD-II tools for targeted diagnostics, and following strict safety protocols, you can resolve most electrical issues on the road. Remember that the electrical system is interconnected; a problem with the timing chain sensor or a coolant flow monitor might originate at a simple 10-amp fuse. Keep your connections tight, your fuses matched to the diagram, and your diagnostic tools ready, and your Volvo VNL will remain the reliable workhorse it was designed to be.

Step-by-Step Guide to Understanding the Volvo Truck Volvo Vnl Fuse Box Diagram: Troubleshooting

Identify the electrical symptoms, such as a check engine light or dead accessory, to narrow down the specific circuit needs.

Locate the fuse box panel, usually found in the center dash area or the engine compartment for high-voltage links.

Understand how the diagram’s grid system maps to the physical layout of the fuses and relays inside the truck.

Connect the diagnostic code from your OBD-II scanner to the related fuse listed on the diagram to check for power loss.

Verify that any replacement fuse matches the original amperage and that the mounting bolts meet the manufacturer’s torque spec.

Complete the repair by replacing the access cover and testing the component to ensure the circuit is fully operational again.

Frequently Asked Questions

What is Volvo Truck Volvo VNL fuse box diagram?

A Volvo VNL fuse box diagram is a visual map illustrating the location, amperage, and function of every fuse and relay in the truck’s electrical system. It identifies specific circuits for components like the ECU and interior lighting, helping technicians quickly isolate power failures without testing every single connection point manually.

How do you read Volvo Truck Volvo VNL fuse box diagram?

To read the diagram, match the numbered slots on the fuse panel with the corresponding legend in the manual or on the panel cover. Each number correlates to a specific component, such as the OBD-II port or headlamps, indicating the correct fuse type and amperage required for safe operation.

What are the parts of Volvo Truck Volvo VNL?

The main parts include the plastic housing, colored fuses of varying amperages, and mechanical relays. You will also find terminal connections for the ECU and diagnostic interfaces. Understanding these parts is essential when your check engine light illuminates and you need to verify if a simple fuse has blown.

Why is the fuse box important?

Fuses are critical because they protect expensive electronic modules like the ECU from power surges. Without them, a short circuit could cause permanent damage to the truck’s wiring or internal processors. They act as the first line of defense, blowing safely to prevent electrical fires or more costly component failures.

What is the difference between a fuse and a relay?

A fuse is a one-time sacrificial link that melts during an overcurrent event, while a relay is an electromagnetic switch used to control high-current circuits with low-current signals. Fuses protect the wiring, whereas relays manage the power flow to heavy-draw components like the starter motor or cooling fans.

How do I use Volvo Truck Volvo VNL fuse box diagram?

Use the diagram to identify which fuse controls the malfunctioning system before using an OBD-II scanner. Start by locating the fuse box on the dashboard, matching the symptom to the circuit number, and inspecting the fuse for a broken filament. This saves time during a roadside repair or maintenance.