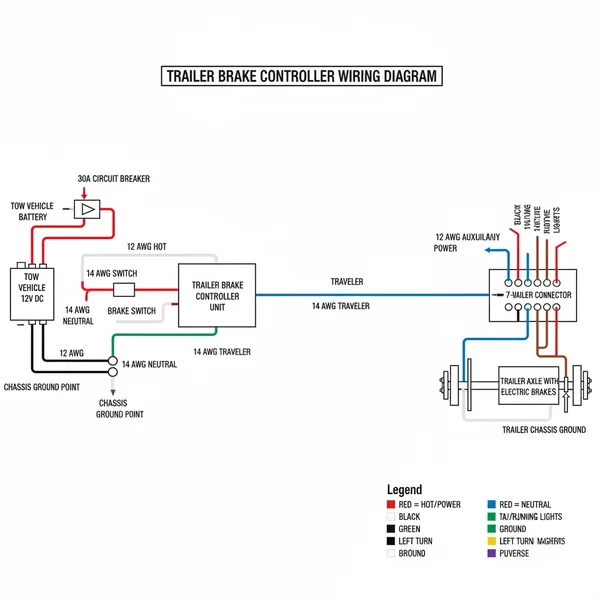

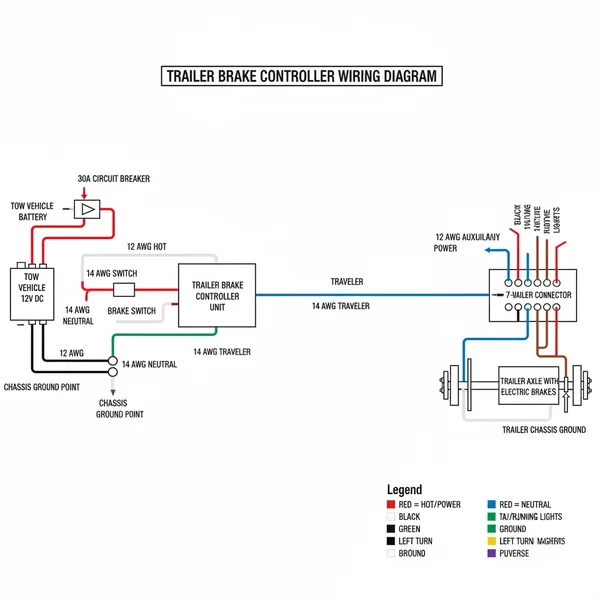

A trailer brake controller wiring diagram explains how to link your vehicle’s braking signal to the trailer’s electric brakes. It identifies the hot wire for battery power, the ground wire for circuit safety, and the traveler wire that sends the specific braking signal, ensuring synchronized stopping power between the truck and trailer.

📌 Key Takeaways

- The diagram serves as a blueprint for connecting the tow vehicle to trailer brakes

- The hot wire and ground wire are the most critical circuits to identify first

- Always use a circuit breaker on the power line to prevent electrical fires

- Color codes may vary by manufacturer, so always verify with a multimeter

- Use this diagram during initial installation or when troubleshooting signal loss

Understanding a trailer brake controller wiring diagram is the foundational step for any DIY enthusiast looking to improve their towing safety and vehicle control. Whether you are installing a proportional or a time-delayed unit, knowing how to map the electrical signals between your vehicle’s brake pedal and the trailer’s electromagnetic drums is essential. This guide provides a detailed breakdown of the wire colors, terminal connections, and voltage requirements necessary for a successful installation. By the end of this article, you will have a professional-grade understanding of how to interpret these schematics and execute a clean, reliable wiring job.

Interpreting Your Trailer Brake Controller Wiring Diagram

When you first look at a trailer brake controller wiring diagram, the array of lines and colors can seem overwhelming. However, most modern controllers follow a standardized four-wire color code that simplifies the process. The diagram serves as a blueprint, showing exactly how the controller interacts with the vehicle’s battery, the brake light switch, and the rear trailer plug.

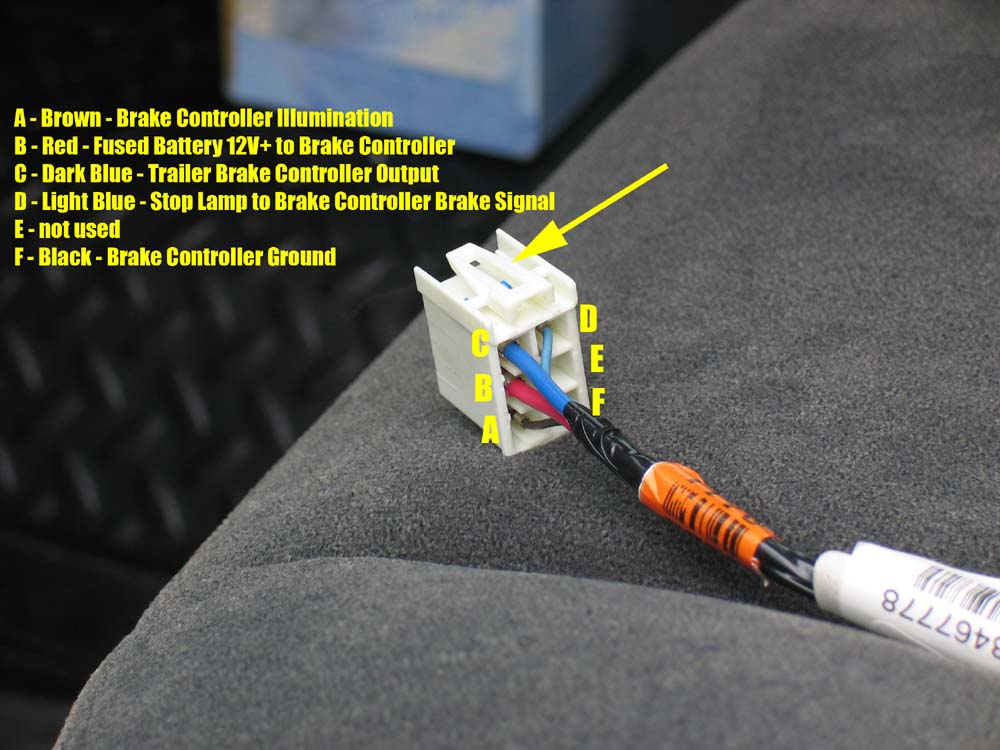

Most aftermarket brake controllers use a standard color scheme: Black (Power), White (Ground), Red (Signal), and Blue (Output). Always verify with your specific manufacturer’s manual as some European or specialty models may differ.

The diagram typically highlights four primary paths:

- ✓ The Power Circuit (Black Wire): This is the hot wire that delivers constant 12V power from the battery to the controller. It must be protected by a circuit breaker.

- ✓ The Ground Circuit (White Wire): This connects to the vehicle’s negative battery terminal or a clean chassis point, often secured via a brass screw to ensure a low-resistance path.

- ✓ The Stoplight Signal (Red Wire): This is the traveler wire that carries the signal from the cold side of the brake pedal switch. It tells the controller when you have pressed the pedal.

- ✓ The Brake Output (Blue Wire): This wire sends the modulated voltage back to the 7-way trailer connector to engage the trailer brakes.

While residential wiring uses a neutral wire to complete a circuit, in the world of DC automotive wiring, the vehicle’s frame serves as the return path. This makes the quality of your ground wire connection paramount. If you are using a distribution block, the common terminal serves as the central hub where multiple ground or power connections meet before heading to the main power source.

Step-by-Step Installation Guide

Properly executing a trailer brake controller wiring diagram requires a methodical approach. Before you begin, gather the necessary tools: a wire stripper/crimper, a digital multimeter or circuit tester, heat-shrink tubing, and a selection of ring terminals.

Always disconnect the vehicle’s negative battery cable before working on the electrical system to prevent short circuits and potential damage to the vehicle’s sensitive ECU.

Step 1: Mount the Controller

Select a location within reach of the driver but out of the way of the knees and airbag deployment zones. Use the provided bracket and ensure it is mounted level if your unit is a proportional controller, as internal sensors rely on gravity and inertia to function correctly.

Step 2: Establish the Ground Connection

Locate the white ground wire on the controller. For the most reliable connection, run this wire directly to the negative battery terminal. If that is not possible, find a factory ground location on the chassis. Use a brass screw and a star washer to bite through any paint, ensuring metal-to-metal contact. This prevents the “floating ground” issues common in trailer systems.

Step 3: Connect to the Hot Wire (12V Power)

The black wire provides the voltage necessary to actuate the brakes. You must use a dedicated circuit breaker (usually 20A or 30A depending on the number of trailer axles). Connect the black wire from the controller to the “AUX” post of the breaker and the “BAT” post of the breaker to the positive battery terminal. Use an appropriate wire gauge (typically 12 or 10 AWG) to prevent voltage drop over the length of the run.

Step 4: Locate the Brake Signal Traveler Wire

Use your circuit tester to find the wire on the brake pedal switch that only shows 12V when the pedal is depressed. This is often referred to as the “cold side” of the switch. Tap the red signal wire from your controller into this wire. Be careful not to tap into the “hot” side, or your trailer brakes will be permanently engaged.

Step 5: Run the Output Wire to the Trailer Plug

The blue wire is the workhorse of the system. Run this wire from the cab of the vehicle back to the 7-way trailer connector. It should be connected to the terminal labeled “Electric Brakes” (usually position 2 on a standard 7-way plug). Ensure this wire is protected by plastic loom where it passes through the firewall or along the frame rail.

Step 6: Final Terminal Inspection and Testing

Reconnect the battery. With the trailer disconnected, the controller should show a specific code (like “NC” for No Connection). Plug in your trailer. The display should change to show a connection or a “0.0” reading. Have an assistant check the trailer brake lights while you operate the manual override lever on the controller to ensure the trailer magnets are humming.

When running wires through the firewall, always use a rubber grommet. Vibration over time can cause the sharp metal edges of the firewall to cut through wire insulation, leading to a catastrophic short circuit.

Common Issues and Troubleshooting

Even with a perfect trailer brake controller wiring diagram, issues can arise due to environmental factors or wear and tear. One of the most common problems is a “Disconnected” error message. This is frequently caused by a corroded trailer plug. Inspect the common terminal inside the 7-way plug for green oxidation, which increases resistance and drops the voltage.

Another frequent headache is “Weak Brakes.” This often stems from using an inadequate wire gauge. If your blue output wire is too thin (e.g., 16 gauge instead of 12 gauge), the voltage will drop significantly by the time it reaches the trailer axles. Use a multimeter to check the voltage at the controller and compare it to the voltage at the rear plug; a difference of more than 0.5 volts indicates a wiring bottleneck.

If the controller stays on even when the vehicle is off, you likely tapped the red traveler wire into the wrong side of the brake switch. The red wire should only see voltage when the pedal is pressed. If it sees constant voltage, it will drain your battery and potentially overheat your trailer brake magnets.

Best Practices and Maintenance

To ensure your wiring job lasts for years, focus on the quality of your connections. While many DIYers use “T-Taps” or “Scotchlocks” for the signal wire, these are prone to failure due to vibration. Instead, use a soldered connection or a high-quality heat-shrink butt connector.

- ✓ Dielectric Grease: Apply a small amount to the terminals of your 7-way plug to prevent moisture from reaching the brass screw and copper wire interface.

- ✓ Circuit Protection: Never use a fuse in place of a manual-reset circuit breaker for the black power wire. Fuses blow and stay blown, leaving you with no brakes on a steep grade. A breaker will trip and reset, providing a margin of safety.

- ✓ Wire Management: Use UV-rated zip ties every 12 to 18 inches along the vehicle frame to prevent the blue and black wires from sagging or snagging on road debris.

In terms of cost-saving, purchasing a “plug-and-play” harness specific to your vehicle make and model can save hours of labor. These harnesses use the factory common terminal and existing connectors, eliminating the need to cut into the vehicle’s signal wires. If your vehicle did not come with a factory tow package, following a comprehensive trailer brake controller wiring diagram is the only way to ensure the system is built to handle the heavy electrical load of electric-over-hydraulic or electromagnetic brakes.

Maintaining your system involves a quick visual inspection before every trip. Ensure the brass screw ground is tight and that no wires are frayed. By adhering to these standards, you ensure that your trailer brake controller remains a reliable partner on the road, providing the precise voltage needed to keep you and your cargo safe. Regardless of the complexity of your setup, following a proper trailer brake controller wiring diagram will always lead to a more professional and safer result.

Frequently Asked Questions

What is trailer brake controller wiring diagram?

A trailer brake controller wiring diagram is a visual schematic that illustrates the electrical connections between a vehicle and a trailer’s braking system. It maps out the hot wire for power, the ground wire for the return path, and the specific signaling wires required to activate the trailer’s electromagnets safely.

How do you read trailer brake controller wiring diagram?

To read the diagram, start at the power source and follow the lines to the controller. Look for the common terminal where grounds meet, and trace the traveler wire to the rear plug. Solid lines represent physical wires, while symbols indicate components like fuses, breakers, and the brake pedal switch.

What are the parts of trailer brake controller wiring?

The main parts include the controller unit, a hot wire connected to the battery, a ground wire for the chassis, and a brake signal input. It also features a traveler wire that sends variable power to the trailer and a common terminal used to aggregate return paths in the harness.

Why is hot wire important?

The hot wire is the primary power source for the controller, connecting directly to the vehicle battery via a circuit breaker. It provides the high amperage needed to engage the electric trailer brakes. Without a properly fused hot wire, the controller cannot generate the force required to stop a heavy load.

What is the difference between traveler wire and neutral wire?

In trailer systems, the traveler wire carries the modulated braking signal from the controller to the trailer magnets. While DC systems don’t have a traditional AC neutral wire, the ground wire serves as the neutral return path for the current, completing the circuit back to the vehicle’s battery terminal.

How do I use trailer brake controller wiring diagram?

Use the diagram to identify which wire colors on your vehicle match the controller’s harness. It helps you locate the brake pedal switch signal and ensures you connect the traveler wire to the correct pin on the 7-way plug, preventing short circuits and ensuring the trailer brakes activate in sync.