Trailer Air Brake System Diagram: Essential Component Guide

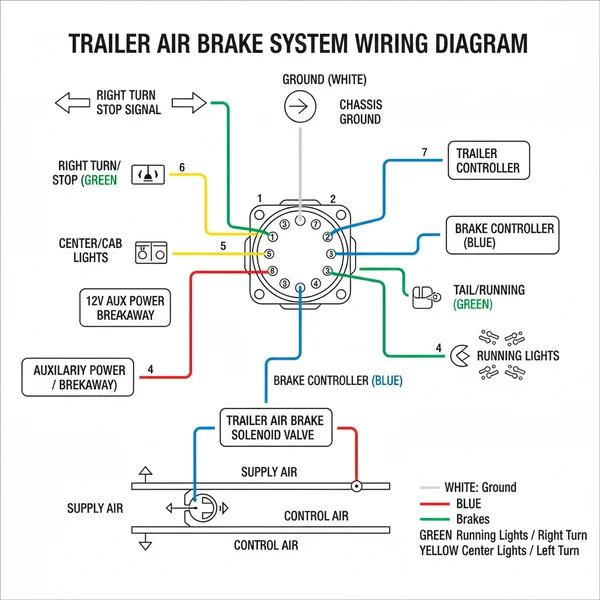

This diagram details the pneumatic and electrical layout of heavy-duty trailers. It visualizes how the brake controller regulates air pressure through service lines while managing electrical inputs for the RV blade connector, including turn signal lamps, running lights, and auxiliary power for consistent braking performance and lighting synchronization during transit.

📌 Key Takeaways

- Identifies the separation between service and emergency air lines

- Highlights the integration of the RV blade electrical connector

- Crucial for ensuring synchronous braking between tractor and trailer

- Assists in troubleshooting pneumatic leaks or electrical signal failures

- Necessary for DIY maintenance or professional heavy-duty repairs

Understanding the complexity of a heavy-duty towing setup can be daunting, especially when you are looking for a reliable trailer air brake system diagram to ensure your vehicle is road-legal and safe. Whether you are a fleet owner or a DIY enthusiast converting a large vehicle, having an accurate visual reference is the foundation of a successful installation. This guide provides a detailed breakdown of the pneumatic and electrical components required to synchronize your trailer with your tow vehicle. You will learn how the air lines, relay valves, and electrical connectors work in harmony to provide stopping power and lighting functionality.

A standard trailer air brake system relies on a dual-line setup: the Emergency (Supply) line and the Service (Control) line. These must be paired with a standardized electrical connector to power auxiliary lights and signals.

Decoding the Trailer Air Brake System Diagram

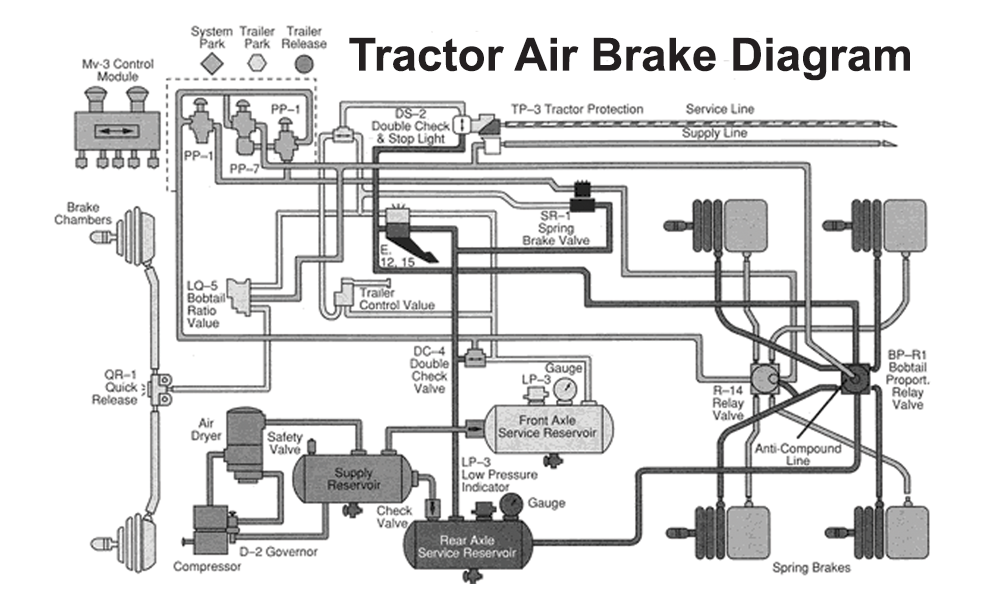

A comprehensive trailer air brake system diagram illustrates the flow of pressurized air from the tractor to the trailer’s brake chambers. The system is split into two primary circuits. The first is the supply line, often color-coded red, which fills the trailer’s air tanks and releases the spring-loaded emergency brakes. The second is the service line, color-coded blue, which transmits the signal from the foot pedal to the relay valve, telling the brakes how much pressure to apply.

In the diagram, you will see the “gladhand” connectors where the hoses attach to the trailer. Beyond the pneumatic lines, the diagram incorporates the electrical interface. While heavy-duty trailers use air for braking, they rely on a 7-way plug—often referred to in the recreational industry as an RV blade or flat connector—to manage electrical needs. This includes the ground pin for circuit completion, auxiliary power for interior lights or lift gates, and dedicated circuits for the running lights, turn signal, and brake lights.

The diagram also highlights the relay valve, which acts as the “brain” of the trailer brakes. It receives the small air signal from the service line and uses the high-pressure air stored in the trailer’s reservoir tanks to engage the brake chambers instantly. If the diagram includes an electric brake backup or a hybrid system, you will see a brake controller interface that manages the voltage sent to the magnets, though this is more common in medium-duty trailers than full air-brake setups.

Always use color-coded hoses and gladhand seals (Red for Emergency, Blue for Service). This prevents cross-connection, which can lead to the trailer brakes failing to release or failing to respond to the pedal.

Step-by-Step Guide to Interpreting and Installing the System

Reading a trailer air brake system diagram requires a methodical approach to ensure every hose and wire is in its proper place. Follow these steps to understand the flow and manage the installation or inspection process:

1. Identify the Supply and Service Inputs: Start at the front of the trailer (the nose). Locate the two gladhand connectors. The red gladhand is the supply line that provides constant air to the trailer’s air reservoir. The blue gladhand is the control line. In your diagram, trace the red line first as it is the “power” for the pneumatic system.

2. Map the Air Reservoir and Relay Valve: Follow the supply line to the air tank. From the tank, the line will lead to a relay valve. The relay valve is usually mounted directly to the air tank or a cross-member near the axles. This valve is the central hub that redirects air to the brake chambers when it receives a signal.

3. Trace the Service Signal: Now, look at the blue service line on the diagram. It should lead directly to the control port on the relay valve. It does not go into the tank; instead, it acts as a trigger. When you press the brake pedal in the cab, air flows through this line to open the relay valve.

4. Connect the Brake Chambers: From the relay valve, lines will branch out to the individual brake chambers on each wheel. Most modern trailers use “Spring Brake” chambers. These contain a heavy-duty spring that applies the brakes if air pressure is lost, acting as a failsafe parking brake.

5. Integrate the Electrical 7-Way Connector: Shift your focus to the electrical portion of the diagram. The 7-way RV blade or round pin connector must be wired according to standard color codes. Identify the ground pin (usually white) and ensure it is connected to a clean, unpainted part of the trailer frame.

6. Wire the Lighting Circuits: Trace the wires for the running lights (brown), left turn signal (yellow), and right turn signal (green). These ensure that when you use your vehicle’s controls, the trailer mirrors those actions. If your trailer has auxiliary power needs, such as a battery charger for a breakaway system, identify the auxiliary power pin (usually black or red).

7. Verify the Brake Controller Interface: If you are using a vehicle equipped with an electric brake controller for a hybrid trailer, ensure the blue wire (electric brake signal) is properly routed to the magnets. While air brakes use pneumatic pressure, some specialty trailers use an electric-over-hydraulic or electric-assist system that requires this specific signal.

8. Final Leak Test and Pressure Check: Once the physical installation matches the diagram, charge the system with air. Listen for leaks at the relay valve and gladhands. Use a soapy water solution on fittings to identify small “bubbles” that indicate a slow leak.

Never work on a trailer air brake system while the air tanks are pressurized. Always drain the tanks using the pull-cords or petcocks before loosening any fittings or valves.

Common Issues and Troubleshooting

Even with a perfect trailer air brake system diagram, mechanical and environmental factors can cause issues. One of the most common problems is “brake lag,” where the trailer brakes engage a fraction of a second after the tractor brakes. This is often caused by a faulty relay valve or a kink in the service line. By referencing your diagram, you can check every fitting between the gladhand and the brake chamber to ensure there are no obstructions.

Another frequent issue is the “frozen brake” syndrome, often caused by moisture in the air lines during cold weather. If the supply line is blocked by ice, the emergency brakes will not release. Referencing the diagram helps you locate the low points in the system where moisture collects. Additionally, electrical failures are common; if your running lights are dim, use the diagram to find the ground pin location. A loose or corroded ground is the culprit in nearly 80% of trailer electrical issues.

- ✓ Air Leaks: Check gladhand seals for cracks or debris.

- ✓ Brakes Not Releasing: Ensure the red supply line is reaching at least 60-90 PSI.

- ✓ Intermittent Lights: Inspect the 7-way flat connector for corrosion or bent pins.

Maintenance Tips and Best Practices

Maintaining your trailer air brake system is significantly easier when you treat it as a preventative task rather than a reactive one. The air brake system relies on clean, dry air. Therefore, the most important maintenance step is ensuring your tractor’s air dryer is functioning and that you regularly drain the trailer’s air tanks to remove accumulated water and oil.

When replacing components, always opt for high-quality, name-brand relay valves and brake chambers. Cheap components often have inconsistent spring tensions, which can lead to uneven braking across different axles. For the electrical side, use dielectric grease on your RV blade or flat connector pins. This prevents moisture from oxidizing the copper, ensuring your turn signal and brake lights remain bright and responsive.

If you are upgrading an older trailer, consider installing an ABS (Anti-lock Braking System) if it doesn’t already have one. A modern trailer air brake system diagram will include the ABS ECU (Electronic Control Unit) and wheel speed sensors. This addition significantly reduces the risk of tire flat-spotting and jackknifing during emergency stops. Lastly, always keep a physical copy of your specific trailer’s wiring and pneumatic diagram in the tool box; it is an invaluable resource when you are on the side of the road and need to identify a specific air line or wire color quickly. By following these best practices, you ensure your trailer remains a safe, reliable extension of your tow vehicle.

Frequently Asked Questions

What is a trailer air brake system diagram?

It is a visual representation of the compressed air lines and electrical circuits required to stop a heavy trailer safely. It maps the connection between the tow vehicle’s brake controller and the trailer’s actuators, ensuring pneumatic pressure and electrical signals for turn signal and running lights function correctly.

How do you read a trailer air brake system diagram?

Start by identifying the color-coded air lines, usually red for supply and blue for service. Follow the lines from the tractor interface to the air tanks and brake chambers. Also, trace electrical paths for the RV blade connector to see how auxiliary power and lights are distributed.

What are the parts of trailer air brake system?

Key parts include the air compressor, reservoirs, relay valves, and brake chambers. Electrically, the system involves the brake controller, RV blade plug, and wiring for running lights and turn signal lamps. These components work together to provide both stopping power and necessary signaling for highway safety and compliance.

Why is auxiliary power important?

Auxiliary power in a trailer system is critical for maintaining battery charge in trailers with independent power needs, such as refrigerated units or interior lighting. In a brake diagram, it ensures constant voltage is available for sensors or electronic stability controls that require power beyond the standard braking signal.

What is the difference between air and electric brakes?

Air brakes use pressurized air to actuate mechanical drums or discs, suitable for heavy-duty commercial use. Electric brakes rely on an electromagnetic actuator triggered by a brake controller. While air systems are more powerful, both require precise wiring for turn signal and running lights via an RV blade connection.

How do I use trailer air brake system diagram?

Use the diagram to troubleshoot leaks or wiring faults by tracing physical paths. It helps locate specific valves for maintenance or identify which pins on the RV blade connector correspond to the turn signal or auxiliary power, allowing for faster repairs and more accurate system upgrades or installations.