Roosa Master Injection Pump Diagram: Repair & Maintenance

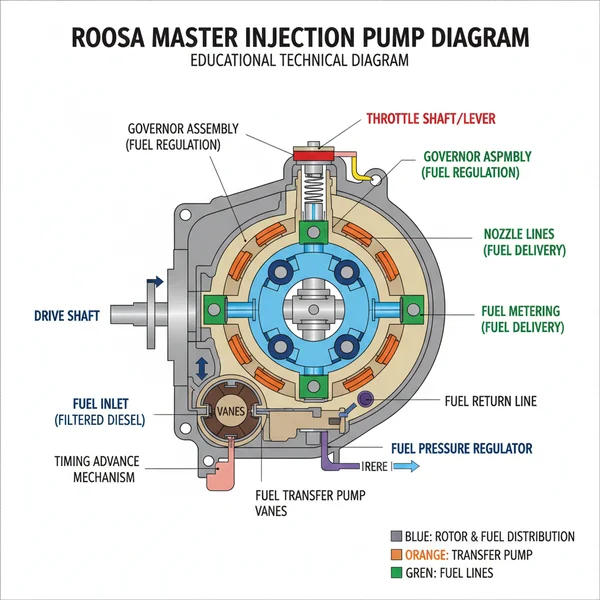

A Roosa Master injection pump diagram illustrates the internal structure and configuration of this rotary-style diesel fuel delivery system. It identifies critical elements like the transfer pump, metering valve, and rotor assembly, allowing technicians to trace fuel flow and diagnose delivery issues within the high-pressure fuel system efficiently.

📌 Key Takeaways

- Visualizing the fuel flow through the rotary distributor system

- Identifying the metering valve to regulate fuel quantity

- Ensuring proper timing alignment during pump installation

- Using the diagram to locate potential leak points in the housing

- Referencing the layout during complete pump teardown or rebuilds

Searching for a reliable roosa master injection pump diagram is often the first step in restoring the performance of a vintage diesel engine. Whether you are maintaining an old John Deere tractor, a Ford power unit, or a Case construction vehicle, understanding the internal layout of this iconic rotary distributor pump is essential for successful troubleshooting and repair. The Roosa Master, developed by Vernon Roosa and produced by Stanadyne, revolutionized diesel technology with its compact, fuel-lubricated design. This article provides a comprehensive breakdown of the pump’s internal configuration, helping you identify every critical component and understand the fuel flow system to ensure your engine runs smoothly and efficiently.

Understanding the Roosa Master Injection Pump Diagram

The roosa master injection pump diagram illustrates a sophisticated mechanical system designed to deliver precise amounts of fuel to engine cylinders at high pressure. Unlike inline pumps, the Roosa Master uses a rotary distributor design, meaning a single set of pumping plungers serves all cylinders. When looking at the diagram, the first thing you will notice is the drive shaft, which connects to the engine’s timing gear. This shaft turns the internal rotor, which is the heart of the pump’s structure.

The internal layout is typically divided into several functional zones. At the rear of the pump (opposite the drive end), you will find the vane-type transfer pump. This component is responsible for drawing fuel from the tank and pressurizing the internal pump cavity. Moving forward, the diagram shows the metering valve, a small but vital piece that regulates how much fuel enters the high-pressure chamber based on throttle position and governor input.

The center of the diagram highlights the hydraulic head and rotor assembly. Here, you will see the pumping plungers, which are pushed inward by stationary internal cams as the rotor turns. This action creates the high-pressure “shot” of fuel. The distributor portion of the rotor then aligns with the appropriate discharge port in the hydraulic head to send fuel to the correct injector. Color-coding in professional diagrams often uses blue for low-pressure supply fuel, yellow for regulated metering fuel, and red for high-pressure delivery fuel. Understanding this layout is crucial for identifying where leaks or pressure drops may occur within the system.

Most Roosa Master pumps, such as the DB and DB2 series, are fuel-lubricated. This means the diesel fuel itself acts as the lubricant for all internal moving parts, making fuel quality and filtration extremely important for the pump’s longevity.

How to Interpret and Use the System Configuration

Reading a roosa master injection pump diagram requires a systematic approach to follow the fuel’s journey from the inlet to the injectors. By breaking down the process into manageable steps, you can use the diagram to guide your mechanical work or diagnostic efforts.

Step 1: Identify the Fuel Inlet and Transfer Pump

Start at the back of the pump diagram. Locate the fuel inlet where the supply line connects. Directly behind this is the transfer pump. In the diagram, look for the vanes and the liner. This section handles the initial suction. If your engine won’t start, the diagram helps you locate the pressure regulating valve near the transfer pump, which might be stuck open.

Step 2: Trace the Path to the Metering Valve

Follow the internal passages from the transfer pump toward the top of the pump housing. The diagram will show fuel flowing into the metering valve. This valve is connected to the governor linkage. It is essential to understand this connection because if the engine is “hunting” (surging in RPM), the issue often lies in the mechanical link between the governor weights and this valve shown in your layout.

Step 3: Locate the Pumping Plungers and Cam Ring

In the center of the rotor, the diagram will show two or four small plungers. Surrounding them is the cam ring, which has internal “lobes.” As the rotor spins, the rollers on the plungers hit these lobes, forcing the plungers together. This is the exact moment of high-pressure injection. If the diagram shows wear patterns on these lobes, it indicates why your engine might be losing power under load.

Step 4: Understand the Governor Assembly

Look for the flyweights and the governor spring in the upper section of the diagram. The Roosa Master uses a mechanical centrifugal governor. The diagram explains how the outward movement of these weights opposes the spring tension to move the linkage. This configuration ensures the engine does not over-speed and maintains a steady idle.

Step 5: Identify the Advance Mechanism

Most modern versions of this pump include an automatic advance. On the diagram, this is usually located at the bottom of the pump housing. It uses internal fuel pressure to rotate the cam ring slightly, advancing the timing as engine speed increases. If the diagram shows a power screw or a piston in this area, that is your timing adjustment point.

Step 6: Trace the Return Line and Housing Pressure

Finally, look for the return line fitting, usually located on the top cover. The interior of the pump housing is filled with fuel under slight pressure. The diagram will show a small glass or plastic ball check valve in the return fitting. This maintains housing pressure, which is vital for the advance mechanism to function.

Never attempt to disassemble the hydraulic head or remove the rotor without a clean, dust-free environment. Even a microscopic speck of dirt can score the precision-lapped surfaces, leading to permanent pump failure.

Common Issues Solved by the Diagram

The roosa master injection pump diagram is an invaluable tool when dealing with common diesel engine failures. One of the most frequent problems with these pumps is the “flex ring” failure. Over decades, the rubber-like dampening ring inside the governor assembly can disintegrate. When this happens, small black fragments (often looking like coffee grounds) clog the return line check valve. By referring to the diagram, a user can quickly identify the location of the return fitting and the governor basket to verify if this disintegration has occurred.

Another common issue is air in the system. The diagram shows the various seals and “O” rings that maintain the vacuum and pressure. If the engine starts but dies shortly after, the diagram helps you locate the input shaft seals or the top cover gasket where air might be entering. Furthermore, if the engine lacks power, you can use the diagram to find the leaf spring adjustment on the plungers, which controls the maximum fuel delivery. Without the visual guide of a diagram, these internal components are nearly impossible to navigate for a DIY mechanic.

- ✓ Hard Starting: Often traced back to the transfer pump vanes or the metering valve sticking in the “off” position.

- ✓ Engine Runaway: Usually caused by a stuck governor linkage or broken governor weights shown in the upper structure.

- ✓ Smoke Issues: Can be linked to the timing advance piston being seized, identifiable in the lower section of the diagram.

Maintenance Tips and Best Practices

To keep your Roosa Master pump functioning according to its original design specifications, regular maintenance is mandatory. The configuration of these pumps makes them sensitive to fuel quality. Since the introduction of Ultra-Low Sulfur Diesel (ULSD), the natural lubricity of fuel has decreased.

Always use a high-quality diesel fuel additive that specifically mentions “lubricity” on the label. This protects the precision plungers and the distributor rotor from premature wear caused by dry modern fuels.

When performing a rebuild using your roosa master injection pump diagram, always purchase a complete seal kit. Standard kits usually include the upgraded “solid” governor flex ring, which replaces the old-style rubber ring that was prone to failure. This is a cost-saving measure that prevents you from having to pull the pump twice.

Additionally, always pay close attention to the torque specifications for the hydraulic head bolts and the drive shaft nut. Over-tightening can warp the housing, while under-tightening can lead to high-pressure leaks. Finally, ensure your fuel filters are changed at the recommended intervals. A Roosa Master pump is only as good as the fuel it receives; keeping water and sediment out of the transfer pump is the single most effective way to extend the life of the entire system.

By following the roosa master injection pump diagram and adhering to these best practices, you can ensure that your diesel engine remains a reliable workhorse for years to come. Whether you are performing a full restoration or a simple seal replacement, a clear understanding of the pump’s internal structure is your best tool for success.

Step-by-Step Guide to Understanding the Roosa Master Injection Pump Diagram: Repair & Maintenance

Identify the main pump housing and fuel inlet port to establish the flow direction.

Locate the transfer pump assembly at the rear of the unit to check for suction.

Understand how the metering valve interacts with the governor arm to control fuel delivery.

Connect the internal rotor alignment marks with the external timing indicators for accurate installation.

Verify that the cam ring and plungers are positioned correctly within the internal structure.

Complete the configuration by checking all seals and high-pressure outlet fittings against the diagram layout.

Frequently Asked Questions

What is Roosa Master injection pump diagram?

A Roosa Master injection pump diagram is a technical illustration showing the internal structure and component arrangement of a rotary diesel fuel pump. It details how the transfer pump, metering valve, and high-pressure plungers work together to deliver precise fuel amounts to injectors at the correct timing for combustion.

How do you read Roosa Master injection pump diagram?

To read this diagram, start by locating the fuel inlet to trace the path through the transfer pump. Follow the layout to the metering valve and then to the distributor rotor. Pay close attention to the labeling of mechanical linkages and hydraulic circuits that govern the pump’s configuration.

What are the parts of Roosa Master injection pump?

The primary parts include the drive shaft, transfer pump, pressure regulator, metering valve, and the rotating distributor head. The system also contains high-pressure plungers, a cam ring, and various seals. Understanding these components is essential for diagnosing performance issues or performing a comprehensive fuel system overhaul on diesel engines.

Why is the metering valve important?

The metering valve is a critical component that controls the volume of fuel entering the high-pressure pumping chamber. By adjusting its position based on governor input, it determines engine speed and power output. The diagram helps identify its location within the system layout for precise calibration and troubleshooting.

What is the difference between rotary and inline pumps?

Unlike inline pumps that have a separate plunger for each cylinder, a Roosa Master rotary pump uses a single distributor rotor to serve all cylinders. This compact structure simplifies the system configuration, making it lighter and more cost-effective, though it requires precise internal timing as shown in the diagram.

How do I use Roosa Master injection pump diagram?

Use the diagram as a visual reference during assembly or disassembly to ensure every internal component is correctly seated. It helps in identifying worn parts, understanding the hydraulic flow, and verifying that the governor linkages are properly connected to the metering valve for safe and efficient engine operation.