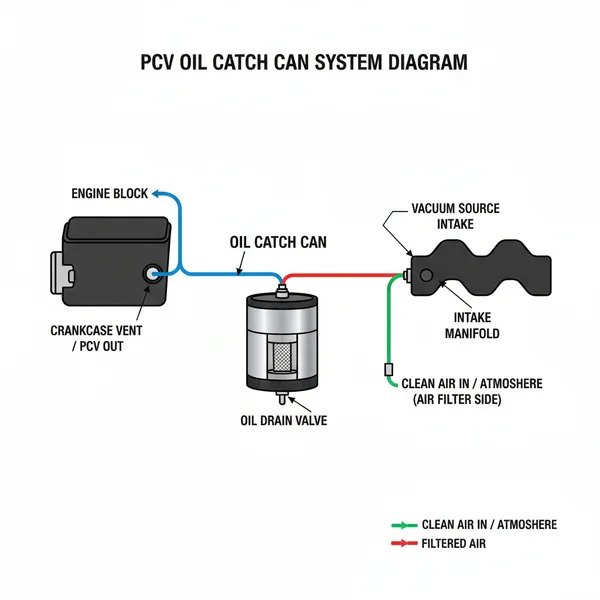

PCV Oil Catch Can Diagram: Installation and Flow Guide

A PCV oil catch can diagram illustrates the system configuration where a reservoir is spliced into the PCV line. This layout diverts blow-by gases from the crankcase through a filtering structure, trapping oil and moisture before the air returns to the intake manifold, preventing carbon buildup and protecting your engine.

📌 Key Takeaways

- Provides a visual map of the PCV system bypass and oil filtration path.

- The intake and outlet ports are the most vital components to identify for correct flow.

- Ensure all hoses are oil-resistant and clamps are tight to prevent vacuum leaks.

- Check the reservoir level regularly to avoid overflow into the intake manifold.

- Refer to this diagram during initial installation or when diagnosing vacuum leak issues.

Understanding the intricacies of your engine’s ventilation system is the first step toward maintaining long-term vehicle health and performance. If you are looking for a pcv oil catch can diagram, you likely recognize that the stock PCV (Positive Crankcase Ventilation) system, while functional, often introduces oil vapors and carbon deposits into your intake manifold. Having the correct diagram is essential because an incorrectly routed system can lead to vacuum leaks, pressure buildup, or even engine damage. This guide provides a detailed visual and conceptual breakdown of the system, explaining how each component interacts within the engine’s layout. By the end of this article, you will have a professional-grade understanding of how to interpret these diagrams and implement a catch can configuration that protects your intake valves from GDI (Gasoline Direct Injection) carbon buildup.

Understanding the PCV Oil Catch Can Diagram and Components

The primary purpose of a pcv oil catch can diagram is to illustrate the redirection of “blow-by” gases. In a standard factory configuration, these gases—consisting of unburned fuel and oil mist—are pulled from the crankcase and sent directly into the intake manifold to be burned off. While this is good for emissions, it is detrimental to engine cleanliness. A catch can acts as a filter, sitting in-line between the crankcase and the intake.

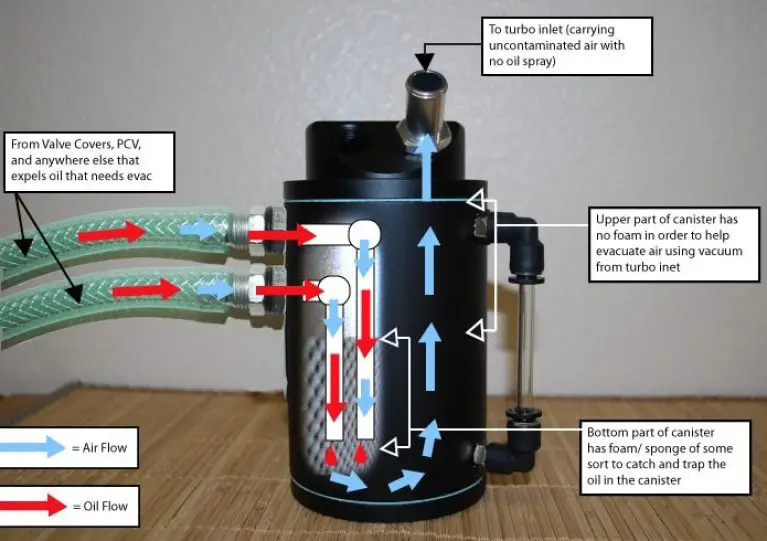

Most modern catch cans utilize an internal baffle structure. This internal layout forces the oil-laden air to change direction rapidly or pass through a mesh screen, causing the heavier oil particles to condense and drop to the bottom of the reservoir while the cleaned air continues to the engine.

When looking at a standard layout, the diagram typically highlights four main elements:

- ✓ The PCV Valve: This is the exit point from the valve cover or crankcase. It is a one-way valve that regulates the flow of gases based on engine vacuum.

- ✓ The Inlet Hose: This hose carries the “dirty” air from the PCV valve to the “In” port of the catch can.

- ✓ The Catch Can Reservoir: The central component where the separation occurs. It often contains a dipstick or sight glass to monitor oil levels.

- ✓ The Outlet Hose: This hose carries the filtered, “clean” air from the “Out” port of the catch can back to the intake manifold vacuum source.

In more complex configurations, such as those found in turbocharged or supercharged vehicles, the diagram may include additional check valves. These are necessary to prevent the intake manifold’s boost pressure from traveling backward through the catch can and pressurizing the crankcase, which could blow out oil seals.

[DIAGRAM_PLACEHOLDER: PCV OIL CATCH CAN LAYOUT]

Imagine a flow chart: [Crankcase/PCV Valve] -> (Inlet Hose) -> [Baffled Catch Can] -> (Outlet Hose) -> [Intake Manifold]

Step-by-Step Guide to Installation and Diagram Interpretation

Interpreting a pcv oil catch can diagram requires an understanding of air flow direction. Most diagrams use arrows to signify the path of the gases. Following these steps will help you translate the diagram into a physical installation on your vehicle.

1. Identify the PCV Line

Locate the existing rubber hose that runs from the PCV valve (usually on the valve cover) to the intake manifold. This is the line you will be “interrupting.” On the diagram, this is the single line that is removed to make room for the two new hoses.

2. Select a Mounting Location

The catch can must be mounted securely in the engine bay. The layout should ideally place the can in a cooler area, away from the exhaust manifold. Cooler temperatures help the oil vapor condense more efficiently inside the canister. Use the provided brackets to bolt it to a sturdy structure like the firewall or a strut tower.

3. Measure and Cut the Hoses

Based on the system configuration, measure the distance from the PCV valve to the can’s inlet, and from the can’s outlet to the intake manifold. Use oil-resistant reinforced hoses (such as SAE J30R7 or better). Avoid long loops or “U” shapes where oil can pool and block the airflow.

Never use standard heater hoses or vinyl tubing for a PCV system. The fuel vapors and heat will cause these hoses to collapse or melt over time, leading to a massive vacuum leak or engine damage.

4. Connect the Inlet and Outlet

Refer back to your diagram to ensure you don’t swap the ports. Most catch cans are directional. Connecting the intake manifold to the “In” port and the PCV valve to the “Out” port will bypass the internal baffles, rendering the system useless. Secure all connections with high-quality worm-gear or constant-tension clamps to ensure a vacuum-tight seal.

5. Final Inspection and Leak Test

Double-check the entire layout against the diagram. Start the engine and listen for any hissing sounds, which would indicate a vacuum leak. A vacuum leak can cause a rough idle or a lean-running condition, often triggering a “Check Engine” light (P0171 or P0174 codes).

Common Issues & Troubleshooting

Even with a perfect pcv oil catch can diagram, users may encounter issues if the physical installation doesn’t account for real-world variables.

- ✓ Vacuum Leaks: The most common issue. Ensure that the threads on the catch can fittings are sealed with PTFE tape or thread sealant.

- ✓ Hose Collapse: If the engine stumbles under load, check the hoses. If the hose isn’t vacuum-rated, the suction from the intake manifold can flatten it, cutting off crankcase ventilation.

- ✓ Oil Blow-By Overflow: If you notice oil dripping from the intake or the can is full within a few days, your engine may have excessive blow-by caused by worn piston rings, or the catch can is too small for your engine’s displacement.

The diagram helps solve these issues by providing a baseline for the “correct” state. If your car is throwing codes after installation, trace the flow on the diagram and compare it to your physical hose routing. A common mistake is forgetting a check valve on a turbocharged application, which allows 20+ PSI of boost to enter the catch can and blow oil out of the dipstick hole.

Tips & Best Practices for PCV System Maintenance

A catch can is not a “set it and forget it” modification. To keep your system running according to the specifications in your pcv oil catch can diagram, follow these maintenance tips:

Check your catch can every 1,000 miles initially to gauge how quickly it fills up. Every engine is different; some may need draining every oil change, while high-mileage engines might need it every two weeks.

Cold Weather Considerations

If you live in a climate where temperatures drop below freezing, be aware that catch cans collect a significant amount of water vapor (condensation). This water can freeze inside the can or the hoses, completely blocking the PCV system. If the system is blocked, crankcase pressure will build until it finds the weakest point—usually the rear main seal or the valve cover gasket. In winter, drain your catch can more frequently to prevent ice buildup.

Choose Quality Components

When purchasing a system, prioritize the internal structure. A simple empty can will not be nearly as effective as a baffled system. Look for catch cans that feature:

- ✓ Stainless steel wool or mesh filters

- ✓ Internal diverter plates

- ✓ An easy-to-access drain plug or valve

- ✓ High-quality AN fittings or barbed connectors

Cost-Saving Advice

While high-end kits can be expensive, you can often save money by purchasing a “universal” baffled catch can and sourcing your own high-quality hoses and clamps. This allows you to customize the layout to fit your specific engine bay configuration without paying the premium for a vehicle-specific bracket that might not be necessary.

In summary, a pcv oil catch can diagram is more than just a map; it is a blueprint for extending the life of your engine. By understanding the flow from the PCV valve through the baffled reservoir and back to the intake, you ensure that your engine breathes clean air. This reduces carbon buildup on valves, maintains fuel octane levels by preventing oil dilution, and keeps your intake tract pristine. Regular monitoring and following the proper installation configuration will result in a more efficient, smoother-running vehicle for years to come.

Frequently Asked Questions

What is a PCV oil catch can diagram?

A PCV oil catch can diagram is a visual representation of how an external reservoir integrates into the vehicle’s crankcase ventilation system. It shows the flow of blow-by gases from the PCV valve, through the catch can’s internal filtering structure, and back toward the intake manifold for clean combustion.

How do you read a PCV oil catch can diagram?

To read the diagram, follow the arrows indicating airflow direction from the engine crankcase. Identify the input line leading to the catch can component and the return line heading to the intake. The layout highlights where the oil is separated and stored within the reservoir during the process.

What are the parts of a PCV oil catch can?

The main parts include the reservoir body, an inlet port, an outlet port, internal baffling or filters, and a drain plug. High-quality configurations also feature a dipstick or sight glass to monitor oil levels and mounting brackets to secure the system within the engine bay safely.

Why is the internal baffle component important?

The internal baffle is a critical component because it provides a physical surface for oil vapor to condense. This structure forces the air to change direction or pass through mesh, slowing it down so heavy oil particles drop into the reservoir while cleaned air continues through the system.

What is the difference between vented and sealed catch cans?

A sealed catch can configuration maintains a closed loop, returning air to the intake manifold to maintain vacuum. A vented catch can uses a breather filter to release gases into the atmosphere. Most diagrams focus on sealed systems to ensure proper engine sensor readings and emissions compliance.

How do I use a PCV oil catch can diagram?

Use the diagram to plan your installation by identifying the correct hoses to intercept. It serves as a guide for mounting the reservoir in a cool location and ensures the flow direction is correct, preventing oil from being sucked directly back into the engine’s intake system.