LML Duramax Coolant Hose Diagram: Complete Layout Guide

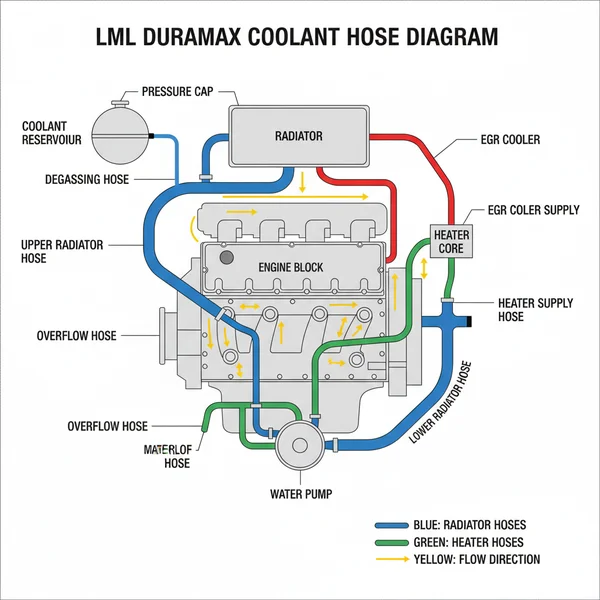

An LML Duramax coolant hose diagram illustrates the intricate system of upper and lower radiator hoses, heater core lines, and EGR cooler connections. This visual layout helps identify every component in the cooling configuration, ensuring you understand the fluid structure for effective troubleshooting, leak detection, or hose replacement tasks.

📌 Key Takeaways

- Visualizing the coolant flow path through the engine and radiator

- Identifying the quick-disconnect fittings on the heater core lines

- Ensuring all clamps are seated correctly to prevent high-pressure leaks

- Using the diagram to trace leaks back to specific worn hoses

- Referencing the layout during routine maintenance or full coolant flushes

The cooling system of the LML Duramax engine is a sophisticated network designed to manage the intense thermal loads produced by heavy-duty towing and high-performance driving. When you are faced with a mysterious puddle of orange fluid under your truck or a rising temperature gauge, having a reliable lml duramax coolant hose diagram becomes your most valuable tool. This comprehensive guide is designed to help truck owners identify every component within the cooling structure, understand the complex layout of the pressurized lines, and gain the confidence to perform repairs or upgrades. By the end of this article, you will have a complete understanding of how coolant flows through your 6.6L engine and how to maintain the system for long-term reliability.

The LML Duramax utilizes a dual-thermostat design and a pressurized surge tank. Unlike older cooling systems that use a simple overflow bottle, every hose in this configuration is critical to maintaining the pressure required to prevent localized boiling within the cylinder heads.

Understanding the LML Duramax Coolant Hose Configuration

The architecture of the LML cooling system is significantly more complex than its predecessors due to the integration of the Exhaust Gas Recirculation (EGR) cooler and the heavy-duty oil cooler. An accurate lml duramax coolant hose diagram reveals a “spider” layout where hoses radiate from the central water pump and thermostat housing to various peripheral components.

The system can be broken down into three primary circuits: the main radiator circuit, the heater/bypass circuit, and the auxiliary cooling circuit. The main radiator circuit involves the massive upper and lower radiator hoses. The upper hose connects the thermostat housing to the top of the radiator, while the lower hose returns cooled fluid from the bottom of the radiator to the water pump inlet.

The auxiliary circuit is where most DIY mechanics find the diagram useful. This includes the intricate hoses feeding the EGR cooler, which is located on the passenger side of the engine valley. There are also smaller diameter hoses that lead to the turbocharger for cooling the center bearing housing and the oil cooler located on the lower driver side of the engine block. The surge tank (reservoir) acts as the highest point in the system, connected by a small air bleed hose that runs to the top of the radiator and the thermostat housing to ensure air pockets are purged during operation.

[DIAGRAM: LML DURAMAX COOLANT HOSE LAYOUT]

| |

+—(Heater Hoses)-> [Heater Core]

| |

+—(Surge Hose)—> [Surge Tank]

Visual representation of the primary coolant flow and hose connections.

Step-by-Step Guide to Interpreting and Replacing Hoses

Interpreting an lml duramax coolant hose diagram is the first step toward a successful repair. Follow these steps to navigate the system and replace components safely:

1. Identify the Leak Source

Before consulting the diagram, perform a pressure test. Many leaks on the LML occur at the quick-connect fittings rather than the rubber hose itself. Use the diagram to trace the path from the leak point back to the nearest junction to determine if you need a specific molded hose or a generic length of heater hose.

2. Gather Necessary Tools and Materials

To work on this system, you will need:

- ✓ Constant tension hose clamp pliers (locking style)

- ✓ Clean 5-gallon buckets for coolant capture

- ✓ A pick set for removing O-rings and quick-connect clips

- ✓ Pre-mixed Dex-Cool or concentrate with distilled water

3. Drain the Cooling System

Locate the drain petcock on the bottom passenger side of the radiator. Note that the LML system holds approximately 6 to 7 gallons of coolant. Ensure the engine is completely cool before opening the surge tank cap to avoid steam burns.

4. Map the Hose Routing

Using your diagram, locate the specific hose you are replacing. For example, if you are replacing the heater core supply hose, identify the connection at the rear of the engine block and the firewall. Many LML hoses are “clocked” or indexed to fit around other components like the air intake and wiring harnesses. Take photos of the original routing before removal.

Never attempt to remove a coolant hose while the engine is hot. The LML system operates at 15 PSI, and the coolant can reach temperatures well over 200°F. Wait at least two hours after driving before beginning work.

5. Removing and Installing Hoses

Most factory LML hoses use constant tension spring clamps. Use your specialized pliers to compress the clamp and slide it back onto the hose. If the hose is stuck to the metal fitting, use a hose pick to break the seal gently. When installing the new hose, ensure it is pushed past the bead on the metal pipe before releasing the clamp.

6. The Bleeding Process

This is the most critical step. The LML is prone to air pockets, especially in the EGR cooler and heater core. Locate the bleeder screw on the top of the thermostat housing. With the surge tank full, open this screw until a steady stream of coolant emerges without bubbles. Tighten the screw and run the engine with the heater on full blast until the upper radiator hose feels hot, indicating the thermostats have opened.

Common Issues and Troubleshooting

Even with a perfect lml duramax coolant hose diagram, certain issues are endemic to this engine series. One frequent problem is the “soft hose” syndrome, where the lower radiator hose collapses under high RPM because the internal spring has rusted away or the hose wall has weakened. This restricts flow and causes rapid overheating.

Another common failure point is the plastic “Y” and “T” connectors used in the heater core and surge tank lines. Over hundreds of heat cycles, these plastic components become brittle and can crack without warning. If you notice crusty orange residue around a plastic junction, replace it immediately. The EGR cooler hoses are also susceptible to heat damage due to their proximity to the exhaust manifold; look for blistering or hardening of the rubber in this area.

If you are experiencing a slow coolant loss but see no leaks, check the surge tank cap. These caps are designed to vent pressure at 15 PSI. If the spring inside the cap weakens, coolant will evaporate as steam through the vent, leaving no visible liquid trail.

Tips and Best Practices for Long-Term Maintenance

To keep your LML Duramax cooling system in peak condition, follow these professional recommendations:

Quality Component Selection

When replacing hoses identified on your diagram, prioritize high-quality materials. While EPDM rubber is the factory standard, many enthusiasts upgrade to silicone hose kits. Silicone hoses offer superior heat resistance and do not harden over time, though they require specialized T-bolt clamps to prevent leaks, as standard worm-gear clamps can cut into the softer silicone material.

Maintenance Schedule

Do not ignore the coolant condition. Dex-Cool is rated for 5 years or 150,000 miles, but in high-load diesel applications, it is wise to test the pH and freeze point every two years. Acidic coolant will eat away at the aluminum radiator cores and the delicate fins inside the EGR cooler from the inside out.

Pressure Testing

Every time you perform an oil change, give the main hoses a “squeeze test.” They should feel firm but pliable. If a hose feels “crunchy” (indicating internal scale buildup) or excessively soft, it is time for a replacement. Keeping a spare set of the most common hoses—the upper radiator hose and the heater core supply—in your truck can save you from a costly tow during a road trip.

Cost-Saving Advice

You can save significantly by bundling repairs. If you are already removing the fan shroud to access the water pump or thermostats, that is the ideal time to replace all the primary hoses. The labor overlap is nearly 80%, meaning you only pay for the parts rather than paying for the same disassembly twice in a year.

By understanding the layout of the lml duramax coolant hose diagram and following a disciplined maintenance routine, you can ensure your engine remains cool under pressure. Whether you are performing a simple repair or a full system overhaul, the structure and configuration of these hoses are the lifelines of your Duramax engine. Keep them inspected, use the right tools, and always prioritize safety when working with the pressurized cooling system.

Frequently Asked Questions

What is an LML Duramax coolant hose diagram?

An LML Duramax coolant hose diagram is a visual representation of the cooling system’s internal configuration. It maps out the path of every hose, pipe, and component responsible for regulating engine temperature. This structure includes the radiator, thermostat housing, water pump, and EGR cooler lines for easy identification.

How do you read an LML Duramax coolant hose diagram?

To read the diagram, start at the radiator and follow the flow through the upper hose toward the thermostat. Identify each component by its label or icon. Note the layout of branching lines to the heater core and expansion tank to understand how the entire system connects.

What are the parts of an LML Duramax cooling system?

The system consists of the radiator, water pump, thermostat housing, and expansion tank. Key hose components include the large diameter upper and lower radiator hoses, smaller bypass lines, heater core supply and return hoses, and specific cooling lines for the EGR and turbocharger systems for heat management.

Why is the LML water pump hose important?

The water pump hose is a critical component because it acts as the primary conduit for circulating coolant throughout the engine block. If this part of the configuration fails, the cooling system loses pressure, leading to rapid overheating and potential damage to the Duramax engine’s head gaskets.

What is the difference between upper and lower hoses?

The upper radiator hose carries hot coolant from the engine to the radiator for cooling, while the lower hose returns the cooled fluid back to the water pump. The lower hose is often reinforced with a spring structure to prevent collapsing under the suction created by the pump’s rotation.

How do I use an LML Duramax coolant hose diagram?

Use the diagram to identify the exact location of a leak or to plan a component replacement. By studying the layout, you can determine which hoses need to be removed to access deeper parts, ensuring you have the correct configuration of tools and parts before starting work.