Honda Pilot Serpentine Belt Diagram: Routing & Installation

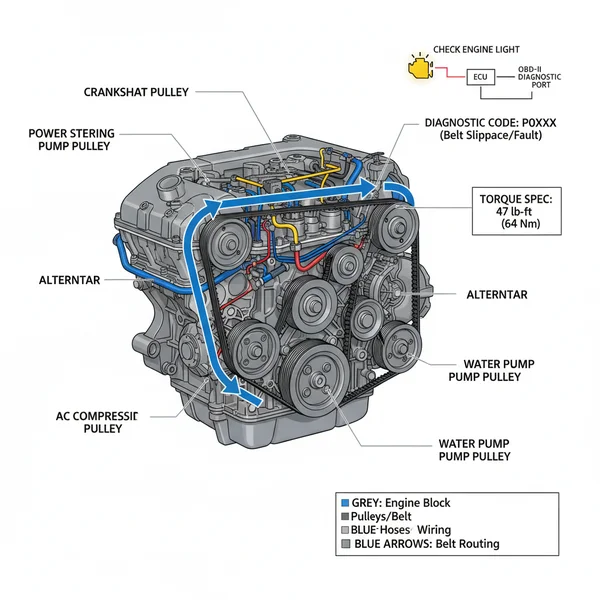

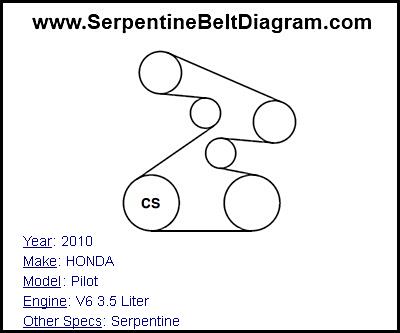

The serpentine belt routing for a Honda Pilot follows a precise path around the crankshaft, alternator, power steering pump, and A/C compressor. Using a tensioner tool to release pressure allows for easy removal. Ensuring correct alignment prevents diagnostic codes and potential damage to vital engine components and pulleys.

📌 Key Takeaways

- Visualize the specific path around the six main pulleys

- Identify the automatic tensioner pulley for belt release

- Ensure the belt is fully seated in all pulley grooves

- Correct installation prevents accessory failure and battery drain

- Use this diagram whenever replacing a worn or squealing belt

If you are performing maintenance on your 3.5L V6 engine, having a clear 2006 honda pilot serpentine belt diagram is an absolute necessity for ensuring your vehicle’s peripheral systems function correctly. The serpentine belt, often referred to as an accessory belt, is a single, continuous loop that provides power to several critical components, including the alternator, power steering pump, and air conditioning compressor. Replacing a worn belt or reinstalling one after a repair requires precise routing to avoid mechanical failure. This comprehensive guide will walk you through the routing layout, the tools required for the job, and the technical specifications needed to keep your Pilot running smoothly.

The 2006 Honda Pilot utilizes a spring-loaded automatic tensioner. Unlike older vehicles that require manual adjustment, this system maintains constant pressure on the belt to prevent slippage and ensure consistent power delivery to engine accessories.

Understanding the Accessory Drive Layout

The 2006 Honda Pilot features a J35 engine where the serpentine belt follows a specific serpentine path around six distinct pulleys. Understanding this “snake-like” configuration is vital because an incorrect installation can result in pulleys spinning in the wrong direction or the belt slipping off under load.

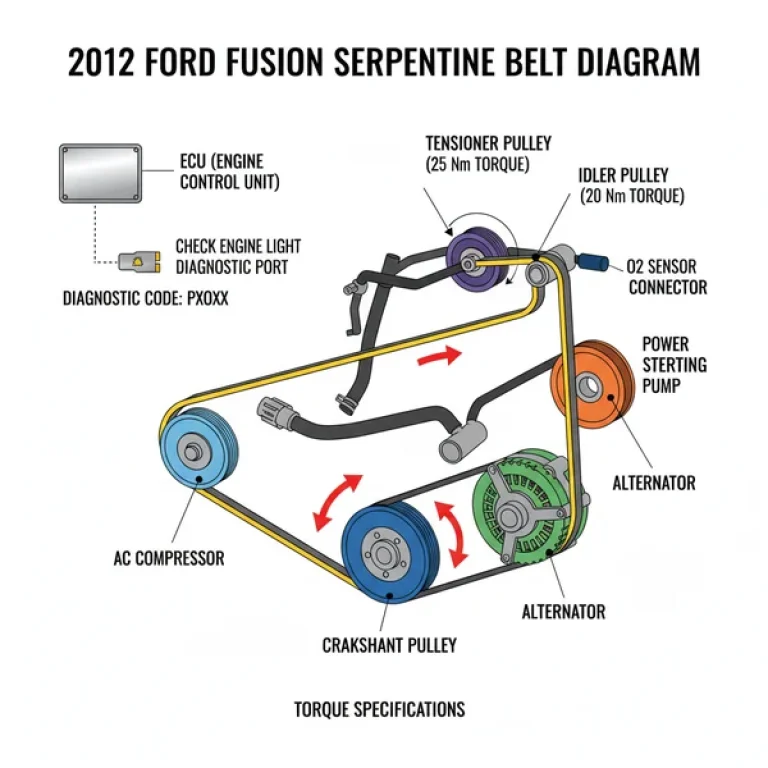

At the bottom center of the engine block sits the crankshaft pulley, which provides the primary rotational force. From the crankshaft, the belt travels upward to the power steering pump located at the top right (passenger side) of the engine bay. It then loops down under the idler pulley and across to the alternator, which is positioned at the top left. The belt then descends to the A/C compressor at the lower left of the engine. The final component in the loop is the automatic tensioner pulley, which sits between the alternator and the crankshaft.

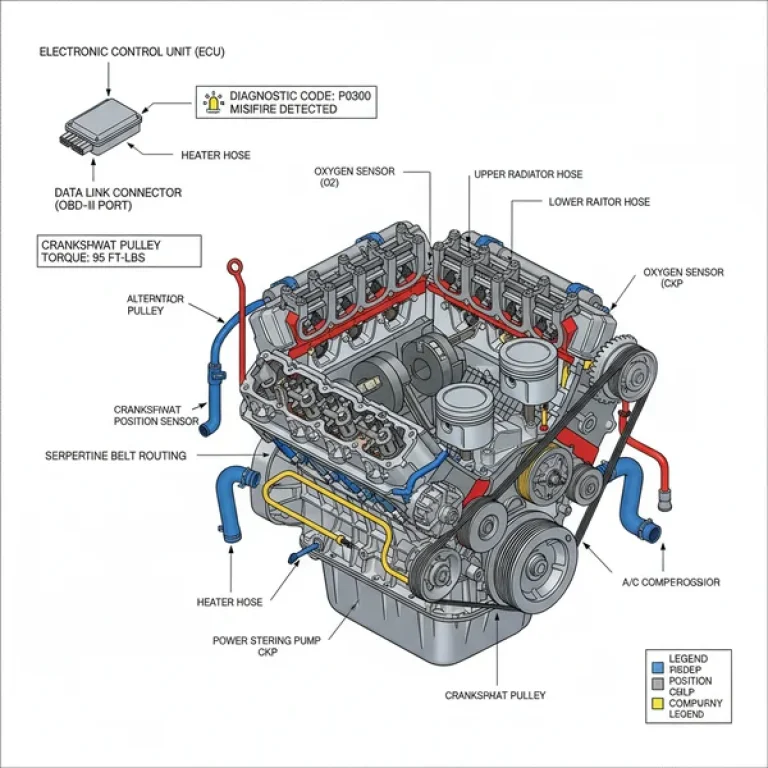

It is important to note that while the serpentine belt is visible and accessible, it is entirely separate from the internal timing belt (which some users mistakenly call a timing chain). The serpentine belt resides outside the engine covers, whereas the timing belt is protected behind plastic shrouds and synchronizes the camshafts and crankshaft. While the serpentine belt drives the alternator to keep the ECU (Engine Control Unit) powered, the internal timing system is responsible for the precise opening and closing of valves.

Visual representation of the 3.5L V6 pulley system: 1. Alternator (Top Left) | 2. Power Steering Pump (Top Right) | 3. Idler Pulley | 4. A/C Compressor (Bottom Left) | 5. Crankshaft Pulley (Bottom Center) | 6. Tensioner Pulley (Center Right)

Step-by-Step Installation and Interpretation Guide

Reading the diagram and translating it to the physical engine bay can be challenging due to the limited space between the engine and the passenger-side wheel well. Follow these steps to ensure a successful replacement or inspection.

- ✓ Step 1: Preparation and Safety – Ensure the engine is completely cool. Park the vehicle on a level surface and disconnect the negative battery terminal. This prevents any accidental starts and protects the ECU from electrical surges while you are working near the alternator.

- ✓ Step 2: Locate the Tensioner – The automatic tensioner is located towards the middle-front of the engine. It features a 14mm bolt head on the pulley itself. You will need a long-handled 14mm wrench or a dedicated serpentine belt tool to gain enough leverage.

- ✓ Step 3: Release Tension – Place your wrench on the tensioner bolt. Rotate the wrench clockwise (towards the rear of the vehicle) to compress the spring and release the tension on the belt. While holding the tensioner in this compressed position, slide the belt off the uppermost pulley (usually the power steering pump).

- ✓ Step 4: Remove and Inspect – Slowly release the tensioner and remove the old belt from the remaining pulleys. Inspect the pulleys for any play, roughness, or signs of bearing failure. If a pulley feels “gritty” when spun by hand, it may need replacement.

- ✓ Step 5: Route the New Belt – Using the 2006 honda pilot serpentine belt diagram as your reference, begin threading the new belt starting from the bottom. It is usually easiest to loop it around the crankshaft and A/C compressor first, then work your way up to the alternator and idler pulley.

- ✓ Step 6: Final Seating – Once again, rotate the tensioner clockwise to create slack. Slide the final loop of the belt over the power steering pump pulley. Before releasing the tensioner, double-check that the belt ribs are perfectly seated within the grooves of every pulley.

- ✓ Step 7: Verification – Release the tensioner slowly. Reconnect the battery and start the engine briefly. Observe the belt to ensure it is tracking straight and not oscillating wildly.

Never place your fingers between the belt and the pulleys. If the tensioner tool slips, the sudden snap can cause serious injury. Always use a tool with sufficient length to keep your hands clear of pinch points.

Common Issues and Troubleshooting

A malfunctioning serpentine belt system often presents clear symptoms before total failure. If the belt becomes loose or snaps, the alternator will stop charging the battery. This often triggers a check engine light or a battery warning light on the dashboard. In many cases, the ECU will detect a drop in system voltage and store a diagnostic code (such as P0562) which can be read via the OBD-II port.

Another common sign of belt trouble is a high-pitched squealing noise, especially during cold starts or when turning the steering wheel sharply. This usually indicates that the belt has stretched or the tensioner spring has weakened. If you notice a heavy steering feel, the belt may be slipping on the power steering pump. Furthermore, because the belt drives the accessories, a snap could lead to a loss of A/C. While the serpentine belt on this specific Honda engine does not directly drive the water pump (which is driven by the timing belt), a failed belt can still indirectly affect engine health by causing electrical failures that disrupt the cooling fans, eventually impacting coolant flow and engine temperature.

Tips and Best Practices for Maintenance

To ensure the longevity of your Honda Pilot’s drive system, experts recommend inspecting the belt every 30,000 miles and replacing it every 60,000 to 100,000 miles. When purchasing a replacement, opt for high-quality EPDM (Ethylene Propylene Diene Monomer) belts, which are resistant to heat and cracking.

When replacing the belt, always check the automatic tensioner’s indicator mark. Most Honda tensioners have a small notch and a range indicator cast into the housing. If the pointer is outside the indicated range when the belt is installed, the belt is either the wrong size or the tensioner has reached the end of its service life.

If you decide to replace the tensioner or idler pulley along with the belt, pay close attention to the torque spec for the mounting bolts. For the 2006 Pilot, the tensioner mounting bolt typically requires approximately 33 lb-ft of torque. Over-tightening can strip the threads in the aluminum engine block, while under-tightening can lead to vibration and pulley misalignment.

Lastly, always keep a copy of the 2006 honda pilot serpentine belt diagram in your glovebox or saved on your phone. If the belt snaps while you are on the road, having the diagram handy can make a roadside repair significantly faster and less stressful. By staying proactive with your accessory belt maintenance and understanding the nuances of the OBD-II system and ECU monitoring, you can prevent unexpected breakdowns and keep your Pilot’s vital systems performing at their peak. Maintaining proper tension ensures that everything from your power steering to your alternator operates efficiently, preserving the overall health of your vehicle for years to come.

Frequently Asked Questions

What is a serpentine belt diagram?

It is a visual map showing the specific path a single, continuous belt takes to power various engine accessories. For the Honda Pilot, this diagram ensures the belt wraps correctly around the alternator and power steering pump, preventing issues that might trigger a check engine light during operation.

How do you read a serpentine belt diagram?

Start by identifying the largest pulley, usually the crankshaft, and follow the lines representing the belt’s ribbed side. Pay close attention to whether the belt goes over or under the tensioner and idler pulleys to ensure the ECU receives correct data from the alternator and other sensors.

What are the parts of the serpentine system?

The system includes the crankshaft pulley, alternator, air conditioning compressor, power steering pump, and an automatic tensioner. If any component fails, it can throw a diagnostic code through the OBD-II system, signaling to the driver that there is a significant drop in electrical or mechanical performance in the vehicle.

Why is the tensioner important?

The tensioner maintains the exact pressure needed to prevent belt slippage. If the tensioner fails, the belt may slide, causing the alternator to undercharge. This can lead to the ECU detecting an error, resulting in a battery warning or a specific diagnostic code appearing during routine vehicle scans.

What is the difference between a serpentine belt and a timing belt?

A serpentine belt drives external accessories like the A/C and alternator, while a timing belt synchronizes the internal engine valves. While a snapped serpentine belt might trigger a check engine light, a broken timing belt often causes catastrophic engine failure that no standard OBD-II scanner can fix easily.

How do I use a serpentine belt diagram?

Refer to the diagram before removing the old belt to verify the routing. Once the new belt is positioned, use it to confirm every rib is seated in the pulley grooves. Finally, ensure the tensioner bolt is tightened to the manufacturer’s specific torque spec for maximum safety.