Front Suspension Dodge Ram 2500 Front End Diagram: Repair Guide

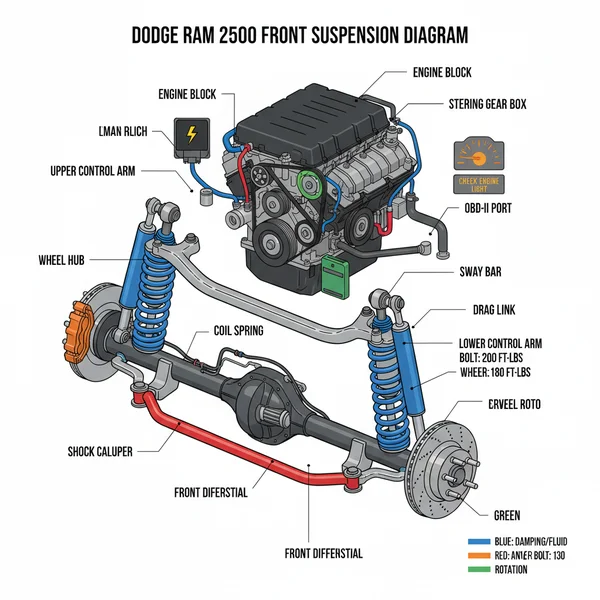

The Dodge Ram 2500 front suspension diagram illustrates a heavy-duty solid axle configuration featuring radius arms, a track bar, and a drag link steering setup. This visual guide helps owners identify wear-prone components like ball joints and steering stabilizers, ensuring precise reassembly and accurate alignment for heavy-duty towing and off-road performance.

📌 Key Takeaways

- Identifies the relationship between the solid axle and steering linkage

- Highlights the track bar as the primary component for preventing death wobble

- Always use a calibrated wrench to meet the specific torque spec for safety

- Helps locate wheel speed sensors that communicate with the truck’s ECU

- Essential for troubleshooting front-end play or uneven tire wear patterns

Owning a heavy-duty truck means dealing with significant weight and demanding towing requirements, which places immense stress on your steering and chassis components. Navigating the complexities of a front suspension dodge ram 2500 front end diagram is an essential skill for any owner looking to maintain vehicle stability, eliminate “death wobble,” or perform a comprehensive rebuild. This guide provides a detailed breakdown of the intricate mechanical linkages and dampened components that keep your heavy-duty pickup tracking straight. By understanding the relationship between the radius arms, track bar, and steering linkage, you will gain the knowledge necessary to diagnose wear and perform repairs with confidence. Whether you are a DIY enthusiast or preparing for a professional consultation, this article covers everything from component identification to the critical torque specs required for a safe and reliable front end.

Detailed Breakdown of the Front End Diagram

The front suspension of a heavy-duty truck is a masterpiece of robust engineering, designed to support a heavy Cummins turbo-diesel or Hemi engine while managing off-road articulation and highway stability. When looking at a front suspension dodge ram 2500 front end diagram, the layout typically features a solid front axle supported by a sophisticated multi-link or radius arm system. The core of this system is the track bar, which runs laterally from the frame to the axle. This specific component is responsible for centering the axle under the truck; even a minor amount of play in its bushings can lead to significant steering wandering.

The steering geometry itself usually follows a “T-style” or “Haltenberger” setup. In a T-style configuration, the tie rod connects both steering knuckles directly, while the drag link connects the pitman arm to the passenger-side knuckle. The diagram will also highlight the upper and lower ball joints, which serve as the pivot points for the steering knuckles. These are high-wear items because they carry the vertical load of the vehicle while allowing for horizontal rotation.

Modern iterations of this suspension also integrate electronic components. While the primary hardware is mechanical, sensors communicate with the ECU (Engine Control Unit) to manage stability control and anti-lock braking. If you see a check engine light or a stability control warning on your dashboard, it may be related to the steering angle sensor located within this assembly. Furthermore, the diagram will detail the placement of the steering stabilizer (damper), which is a horizontal shock absorber designed to minimize the feedback felt through the steering wheel when hitting bumps.

Most heavy-duty trucks utilize a solid front axle for durability. Unlike independent front suspensions found on light-duty trucks, the solid axle relies heavily on the track bar and radius arms to maintain alignment and prevent lateral movement.

Step-by-Step Guide to Interpreting and Servicing the Front Suspension

Reading a suspension diagram is the first step; applying that knowledge to physical maintenance is where the real work begins. Follow these steps to interpret your diagram and conduct a thorough inspection or part replacement.

Step 1: Identify the Steering Configuration

Consult your front suspension dodge ram 2500 front end diagram to determine if you have a factory Y-style or an upgraded T-style steering linkage. Locate the pitman arm, drag link, tie rod, and steering stabilizer. Understanding this layout is crucial because adjusting one component, such as the drag link, will directly affect your steering wheel centering.

Step 2: Perform a “Dry Park” Test

With the vehicle on the ground and the engine running, have an assistant turn the steering wheel back and forth rapidly between the 10 o’clock and 2 o’clock positions. While they do this, crawl underneath (safely) and use your diagram to locate each joint. Look for any “pop” or lateral movement in the track bar ends, tie rod ends, and drag link sockets. Any visible play indicates a part that needs immediate replacement.

Step 3: Inspect Ball Joints and Wheel Bearings

Jack up the front of the truck and support it securely on heavy-duty jack stands. Place a long pry bar under the tire and lift upward. Use your diagram to locate the upper and lower ball joints and watch for vertical movement. To check wheel bearings, grab the tire at the 12 and 6 o’clock positions and shake it; any rocking motion suggests the hub assembly is failing.

Step 4: Check Dampening and Control Components

Examine the coil springs and shocks for signs of damage or leakage. While you are in this area, it is wise to perform a peripheral inspection. Look upward toward the engine bay; check the condition of the accessory belt and look for any signs of oil or fluid leaks from the front of the engine, which could indicate issues with the timing chain cover or water pump. Ensuring proper coolant flow is essential, as leaks onto suspension bushings can cause the rubber to swell and fail prematurely.

Step 5: Apply Precise Torque Specifications

Suspension components are subject to extreme vibrations. When replacing parts identified in your diagram, always use a calibrated torque wrench. For example, track bar bolts often require over 200 lb-ft of torque. Failing to hit the correct torque spec is a leading cause of recurring “death wobble” issues.

Step 6: Calibrate and Clear Codes

After replacing steering components, your steering wheel may be off-center. This can trigger a diagnostic code in the steering angle sensor, which communicates with the ECU. Use an OBD-II scanner to check for any stored codes. If the check engine light or traction control light is illuminated, you may need to perform a “zero-point calibration” after a professional alignment is completed.

Never attempt to service suspension components without properly rated jack stands. The front end of a 2500-series truck can weigh over 4,000 lbs. Additionally, always replace high-stress bolts if the service manual designates them as “one-time use” or torque-to-yield fasteners.

Common Issues and Troubleshooting

The most notorious issue associated with this front end is the “death wobble”—a violent shaking of the front wheels after hitting a bump at highway speeds. By using the front suspension dodge ram 2500 front end diagram, you can methodically isolate the cause. Usually, the culprit is the track bar bushing or a loose steering stabilizer. However, it can also be a combination of worn ball joints and improper caster settings.

Another common symptom is “steering wander,” where the truck feels like it is floating across the lane. This often points to play in the steering gear box or worn tie rod ends. If you notice uneven tire wear (such as cupping or “feathering”), your shocks are likely worn out, or your toe-in alignment is out of specification. Troubleshooting these issues early can prevent a cascading failure where one worn part accelerates the wear on every other component in the system.

- ✓ Violent Shaking: Inspect track bar and steering stabilizer.

- ✓ Wandering Steering: Check steering gear box and tie rods.

- ✓ Clunking Noises: Inspect ball joints and control arm bushings.

- ✓ Dashboard Lights: Use OBD-II scanner to check steering angle sensor codes.

Tips and Best Practices for Maintenance

To maximize the lifespan of your front suspension, regular maintenance is non-negotiable. If your replacement parts feature grease zerks, ensure you lubricate them at every oil change. Using a high-quality synthetic grease will prevent moisture intrusion and reduce friction in the ball joints and tie rod ends.

When it comes to replacement parts, consider upgrading to heavy-duty aftermarket components. Many factory parts use rubber bushings that deflect under load; polyurethane or heavy-duty spherical bearings can offer much tighter steering response. Furthermore, if you are performing a front-end rebuild, take the opportunity to inspect the engine’s lower half. Check the accessory belt for cracking and ensure the coolant flow remains unobstructed by debris in the radiator fins. A well-maintained engine bay prevents leaks that can degrade the rubber components of your suspension.

Always get a professional alignment after replacing any steering component. Even if you measured the threads during installation, a fraction of an inch can cause rapid tire wear and trigger electronic stability errors that require an OBD-II reset.

Lastly, keep a record of your torque settings. Because these trucks are often used for heavy hauling, the constant cycling of the suspension can cause bolts to slightly back out over time. Re-checking the torque on your track bar and radius arms every 10,000 miles is a proactive way to ensure your front suspension remains tight and safe. By combining the visual aid of a front suspension dodge ram 2500 front end diagram with consistent mechanical oversight, you can enjoy a smooth, controlled ride for hundreds of thousands of miles.

Frequently Asked Questions

What is a Dodge Ram 2500 front end diagram?

This diagram is a visual schematic detailing the heavy-duty components of the Ram 2500’s steering and suspension system. It identifies the solid axle housing, coil springs, shocks, and steering linkage. Mechanics use it to ensure all parts are correctly oriented and to verify the sequence of washers and bushings.

How do you read a Dodge Ram 2500 front end diagram?

To read the diagram, start by identifying the center axle and branching out to the control arms or radius arms. Look for dashed lines indicating how bolts pass through components. Match the numbered callouts to a parts list to confirm specific hardware sizes and the required torque spec.

What are the parts of a Dodge Ram 2500 suspension?

Major components include upper and lower ball joints, the track bar, drag link, tie rod ends, and steering stabilizer. On newer models, you will also see wheel speed sensors that communicate with the ECU. These parts work together to provide steering control and maintain the vehicle’s heavy load capacity.

Why is the track bar important?

The track bar is critical because it laterally locates the front axle under the frame. If the track bar bushings fail, it often causes a violent shaking known as ‘death wobble.’ Proper installation ensures the axle remains centered, preventing steering wandering and protecting other vital steering box components.

What is the difference between 4WD and 2WD diagrams?

A 4WD diagram features a solid front axle with a differential, whereas a 2WD diagram typically shows an independent front suspension (IFS) with upper and lower A-arms. The 4WD version is significantly more complex, requiring specific attention to the U-joints and the front driveshaft connection points during maintenance.

How do I use a Dodge Ram 2500 front end diagram?

Use the diagram as a blueprint for disassembly and reassembly during a front-end rebuild. It helps you identify where sensors might trigger a check engine light if disconnected. Referencing it alongside an OBD-II scanner helps troubleshoot issues when a specific diagnostic code points toward wheel speed sensor faults.