Ford Starter Solenoid Wiring Diagram: Step-By-Step Setup

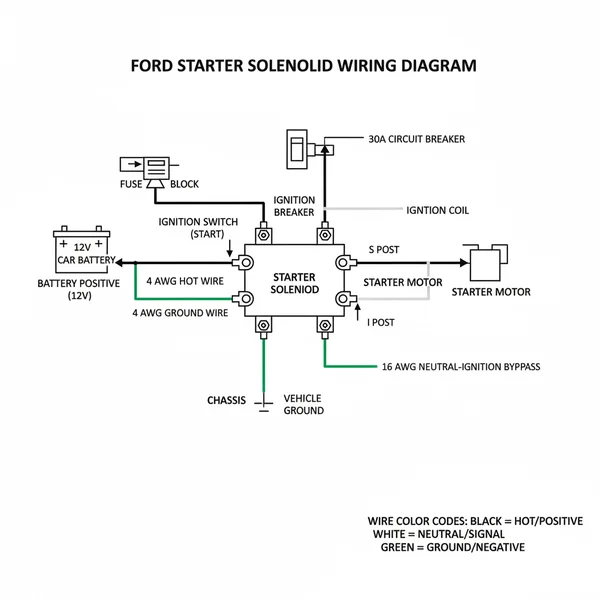

A Ford starter solenoid wiring diagram shows how to connect the battery to the starter motor. It details the hot wire from the battery, the ground wire for completing the circuit, and the ignition switch connection. This setup ensures high-current power flows only when the ignition activates the internal common terminal bridge.

📌 Key Takeaways

- Explains the path of high-current electricity from the battery to the starter motor.

- Identifies the large battery and starter posts plus the smaller ‘S’ ignition terminal.

- Ensures all connections are tight to prevent voltage drop or dangerous overheating.

- Essential for diagnosing ‘no-start’ conditions or replacing an old solenoid unit.

- Verifies the solenoid is properly grounded through its physical mounting bracket.

When you are facing a vehicle that refuses to turn over, having access to a reliable ford starter solenoid wiring diagram is the difference between a quick fix and an afternoon of frustration. Ford’s classic fender-mounted solenoid design is legendary for its simplicity, yet it remains one of the most misunderstood components in an automotive electrical system. Understanding this diagram is essential for ensuring that the high-amperage current from your battery reaches the starter motor safely and efficiently. In this guide, you will learn how to identify every terminal, choose the correct wire gauge, and master the installation process to get your engine roaring back to life.

Decoding the Ford Starter Solenoid Wiring Diagram

The ford starter solenoid wiring diagram serves as a map for the high-voltage highway of your vehicle’s starting circuit. At first glance, the solenoid appears as a small cylindrical unit with several threaded posts, often referred to as a “remote” solenoid because it sits on the inner fender rather than on the starter motor itself. The diagram identifies four primary connection points: the battery input, the starter output, the “S” terminal, and the “I” terminal.

The most prominent feature of the diagram is the heavy-duty hot wire that runs directly from the positive battery terminal to one of the large copper or brass posts on the solenoid. This is the primary power supply. On the opposite large post, a second heavy-gauge wire leads down to the starter motor. These large posts are designed to handle massive amounts of current, often exceeding 200 amps during the initial crank.

Between these large posts, you will find one or two smaller threaded studs. The “S” terminal, or start terminal, is where the traveler wire from the ignition switch connects. When you turn your key to the “start” position, a small 12V signal travels through this wire, creating an electromagnetic field inside the solenoid that pulls a heavy internal contactor into place. The “I” terminal, found on many older Ford diagrams, provides a momentary 12V boost to the ignition coil during cranking to help the engine fire up more easily.

|

[ SOLENOID BODY ]

/ | \

[ IGNITION SWITCH ] -> [ S ] | [ I ] -> [ COIL ]

\ | /

[ LARGE POST B ] ———–> [ STARTER MOTOR ]

|

[ CHASSIS GROUND ]

Figure 1: Conceptual Layout of a Classic Ford Starter Solenoid Circuit

Most Ford solenoids are grounded through their mounting bracket. If the bracket is bolted to a painted or rusty fender, the solenoid will not function correctly. Always ensure a clean, metal-to-metal contact point for the ground wire or mounting base.

Step-by-Step Installation and Wiring Guide

To successfully wire your solenoid using the diagram, follow these structured steps. This process ensures that you maintain the integrity of the electrical system while preventing common DIY mistakes.

Step 1: Disconnect the Battery

Before touching any part of the starter system, disconnect the negative battery cable. Since you will be working with a direct hot wire from the battery, any accidental contact between your wrench and the vehicle frame could cause a massive electrical arc, leading to burns or battery explosion.

Step 2: Mount the Solenoid

Attach the solenoid to the fender well or firewall using the integrated mounting bracket. Ensure the area is free of paint. The base of the solenoid acts as the common terminal for the ground circuit. Use a wire brush to clean the surface until the metal is shiny. Secure the unit using a high-quality brass screw or steel bolt with a lock washer to maintain a vibration-resistant connection.

Step 3: Connect the Main Hot Wire

Identify the positive cable coming from the battery. This cable should be a heavy gauge, typically 4-gauge or 2-gauge depending on the engine size. Attach this to the large post on the solenoid that is closest to the battery. If your vehicle has auxiliary power needs (like a fuse box feed), these wires often share this common terminal to receive constant 12V power.

Step 4: Route the Starter Cable

Take the heavy-gauge wire that leads to the starter motor and attach it to the opposite large post. It is crucial that these two large wires do not touch each other or any metal parts of the car. Ensure the rubber boots, if provided, are pulled tightly over the connections to prevent accidental shorts.

Step 5: Wire the Ignition Signal (S-Terminal)

Locate the traveler wire coming from your ignition switch or neutral wire safety switch. This is usually a thinner 14-gauge or 16-gauge wire. Connect this to the small post marked with an “S”. This wire only carries voltage when the key is turned to the “start” position. If your vehicle has an automatic transmission, this wire must pass through the neutral safety switch to prevent the car from starting in gear.

Step 6: Handle the Ignition Bypass (I-Terminal)

If your ford starter solenoid wiring diagram shows an “I” terminal and your vehicle uses a traditional distributor with a ballast resistor, connect the wire leading to the positive side of the coil here. If you have upgraded to a modern electronic ignition (like an HEI system), this terminal is often left vacant.

Step 7: Final Inspection and Reconnection

Double-check all nuts for tightness. A loose connection creates resistance, which generates heat and drops the voltage reaching the starter. Once confirmed, reconnect the negative battery cable.

Never use undersized wire for the main battery or starter connections. Using a thin gauge wire for high-amperage tasks can cause the insulation to melt and potentially start an engine bay fire.

Troubleshooting Common Solenoid Issues

Even with a perfect ford starter solenoid wiring diagram, components can fail or be installed incorrectly. The most frequent issue is the “rapid clicking” sound. This usually indicates that the solenoid is receiving enough voltage to move the internal plunger, but not enough to maintain the connection, often due to a weak battery or a corroded ground wire.

If you turn the key and hear nothing at all, use a multimeter to check the voltage at the “S” terminal while an assistant turns the key. If you see 12V but the solenoid doesn’t click, the solenoid internal coil is likely dead. If you don’t see 12V, the problem lies further up the line in the ignition switch or the neutral wire circuit.

Another common symptom is the starter “sticking” on. If the engine starts but the starter keeps spinning after you release the key, the internal contacts inside the solenoid may have welded themselves together due to excessive heat or low voltage. In this scenario, the diagram helps you quickly identify which hot wire to disconnect to prevent damage to the starter motor.

If you’re stranded and suspect a bad ignition switch, you can “jump” the solenoid by using a screwdriver to bridge the battery hot wire post to the small ‘S’ terminal. This bypasses the ignition switch entirely to test the solenoid’s health.

Best Practices and Maintenance Tips

To ensure your wiring stays reliable for years, focus on the quality of your connections. Automotive environments are harsh, involving vibration, moisture, and extreme temperature swings.

- ✓ Use Dielectric Grease: Apply a small amount of dielectric grease to the threaded posts before tightening the nuts. This prevents corrosion and moisture intrusion without interfering with electrical conductivity.

- ✓ Heat Shrink Terminals: When crimping new connectors onto your traveler wire or ground wire, use adhesive-lined heat shrink. This seals the wire strands against oxygen, preventing the “green crust” of oxidation that causes resistance.

- ✓ Check Wire Gauge: If you have upgraded to a high-torque mini-starter, verify if the manufacturer recommends a specific wire gauge. Often, these starters require more consistent voltage than original units.

- ✓ Secure the Harness: Use nylon zip ties or loom to secure the wires away from moving parts like the steering column or hot parts like the exhaust headers.

Maintaining the solenoid is relatively low-effort. Once a year, check the brass screw and mounting bolts to ensure they haven’t vibrated loose. If you live in a coastal area or a region where road salt is used, cleaning the terminals with a mixture of baking soda and water can neutralize any acid buildup and keep the ford starter solenoid wiring diagram’s intended path clear for current flow.

By following this comprehensive guide and keeping your ford starter solenoid wiring diagram handy, you empower yourself to handle one of the most vital parts of your vehicle’s electrical system. Whether you are restoring a classic Mustang or keeping a hardworking F-150 on the road, correct wiring ensures safety, reliability, and the peace of mind that comes with a first-time start every time you turn the key.

Frequently Asked Questions

What is Ford starter solenoid wiring diagram?

A Ford starter solenoid wiring diagram is a visual map showing electrical connections between the battery, ignition, and starter motor. It illustrates how low-current signals trigger a high-current bridge. This diagram is essential for troubleshooting starting failures and ensuring the hot wire and ground wire paths are correctly established for vehicle operation.

How do you read Ford starter solenoid wiring diagram?

To read this diagram, trace the path from the battery positive terminal to the common terminal on the solenoid. Look for the ignition signal line, often functioning like a traveler wire to trigger the internal switch. Lines ending at the chassis represent the ground wire, which is vital for completing the electrical circuit.

What are the parts of Ford starter solenoid?

The primary parts include the battery post (hot wire input), the starter motor post, and the ignition ‘S’ terminal. Internally, a plunger moves to bridge the common terminal. Understanding these parts helps you identify where power flows and where potential failures, like a broken neutral wire connection, might occur during cranking.

Why is common terminal important?

The common terminal acts as the central junction for high-voltage distribution in the starting system. It receives the hot wire from the battery and waits for an electrical signal to bridge the gap to the starter motor. Without this central component functioning correctly, the starter will not receive the amperage needed.

What is the difference between hot wire and ground wire?

In this automotive circuit, the hot wire carries the positive 12V current directly from the battery to the solenoid. The ground wire, or the solenoid’s metal casing, provides the return path to the battery’s negative terminal. Both are required to create a complete circuit, allowing the starter motor to engage.

How do I use Ford starter solenoid wiring diagram?

Use this diagram to perform a point-to-point check of your vehicle’s starting system. Start by verifying the hot wire connection at the solenoid, then check the neutral wire safety switch path. By following the diagram, you can use a multimeter to find where voltage is lost and fix issues.