Ford F150 Front Axle Diagram: Identify Key Components

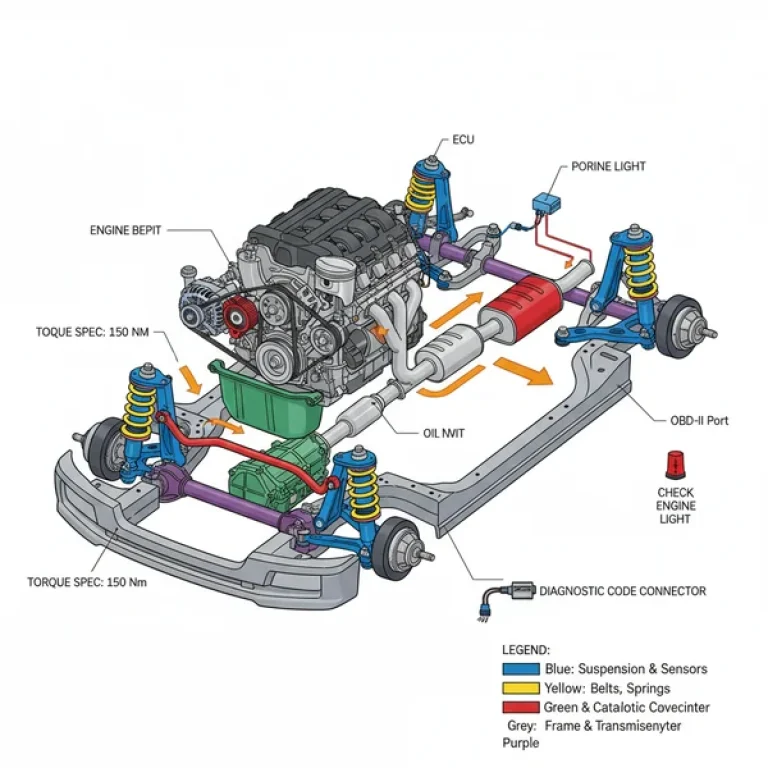

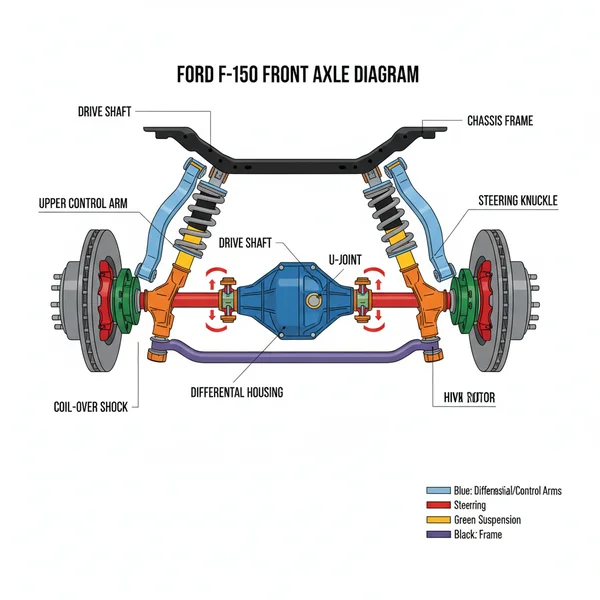

A Ford F150 front axle diagram illustrates the complex configuration of the front drivetrain system. It identifies key components like the differential, CV axles, hubs, and suspension mounts. Understanding this layout is essential for diagnosing four-wheel-drive engagement issues, replacing worn joints, or performing routine maintenance on your truck’s front-end structure.

📌 Key Takeaways

- Visualizes the spatial relationship between critical drivetrain parts

- Identifying the CV axle and vacuum hub locks is vital for 4WD

- Always verify specific torque specs when reassembling the axle system

- Use the layout to trace fluid leaks or mechanical play in joints

- Reference this diagram before starting any suspension or 4WD repair

Understanding the ford f150 front axle diagram is an essential step for any truck owner or mechanic aiming to maintain the vehicle’s legendary performance and off-road capability. Whether you are diagnosing a strange grinding noise, performing a routine inspection, or embarking on a complete suspension overhaul, having a clear visual and conceptual roadmap of the axle layout is vital. This diagram acts as a blueprint for the intricate mechanical system that transfers power from your engine to the front wheels. In this comprehensive guide, we will explore the core components of the front axle configuration, explain how to interpret technical layouts, and provide actionable advice for troubleshooting common drivetrain issues.

Most Ford F-150 models utilize an Independent Front Suspension (IFS) system. Unlike a solid axle, the IFS allows each front wheel to move independently, improving ride quality and handling while requiring a more complex series of CV axles and differential mounts.

Main Diagram Description and Component Breakdown

The front axle system of a Ford F-150 is a marvel of engineering designed to balance heavy-duty strength with precision handling. When viewing a ford f150 front axle diagram, the most prominent feature is the central front differential housing. This component is typically mounted to the vehicle’s frame and serves as the primary distribution point for torque coming from the transfer case via the front driveshaft.

Branching out from the differential are the half-shafts, commonly known as CV (Constant Velocity) axles. These shafts are responsible for delivering power to the wheels even as the suspension compresses or the wheels turn. The diagram will typically highlight the inner and outer CV joints, which are protected by flexible rubber or thermoplastic boots. These boots are critical because they retain the essential grease required to lubricate the high-friction joints while keeping out road debris and moisture.

Another unique element found in these diagrams is the Integrated Wheel End (IWE) system. In many 4WD configurations, the IWE acts as a vacuum-operated actuator that engages or disengages the front hubs from the axle shafts. This design allows the front wheels to spin freely when 4WD is not needed, reducing mechanical drag and improving fuel efficiency. The layout usually displays vacuum lines, a solenoid, and the actuator itself located behind the wheel hub assembly.

– Visual Representation of the Ford F-150 Front Axle System including Differential, CV Axles, IWE Actuators, and Hub Assemblies.

Finally, the diagram illustrates the connection points at the steering knuckle. This is where the axle shaft meets the wheel bearing and hub assembly. The layout ensures that all components—from the differential seals to the castle nuts—are aligned in a specific order to maintain structural integrity under the high stress of towing or off-roading.

Step-by-Step Guide: Interpreting the Layout and Installation

Correctly reading a ford f150 front axle diagram requires a systematic approach. By following these steps, you can use the diagram to guide you through an inspection or a component replacement, such as a CV axle or IWE actuator.

- ✓ Step 1: Identify the Central Axis – Start at the front differential. Locate where the driveshaft enters the carrier and where the two output flanges emerge to connect to the CV axles.

- ✓ Step 2: Trace the Power Flow – Follow the line from the differential through the inner CV joint, along the axle shaft, through the outer CV joint, and into the hub.

- ✓ Step 3: Locate the Vacuum System – Find the IWE solenoid (usually on the firewall) and trace the vacuum lines down to the actuators at the wheel ends.

- ✓ Step 4: Verify Fastener Locations – Use the diagram to identify critical bolts, such as the large axle nut (usually 30mm or 36mm) and the small IWE mounting bolts.

- ✓ Step 5: Inspect Seals and Boots – Look for the locations of the differential output seals and the CV boots on the diagram, then match them to the physical components on your truck to check for leaks.

Required Tools and Materials:

To work on the front axle system as depicted in the diagram, you will typically need a high-quality floor jack and heavy-duty jack stands. A comprehensive socket set (including 13mm, 18mm, 21mm, and axle nut sizes), a torque wrench capable of reaching 150 lb-ft, a vacuum pump for testing IWEs, and pliers for CV boot clamps are essential. Always have shop towels and high-temp axle grease on hand.

Never attempt to work on the front axle while the vehicle is supported only by a jack. Always use properly rated jack stands on a level, concrete surface. Additionally, ensure the vehicle is in “Park” with the parking brake engaged and rear wheels choked.

Safety Precautions:

When working with the front axle, be mindful of the weight of the components. The steering knuckle and hub assembly can be heavy and may fall if not supported during disassembly. Furthermore, take care not to over-extend the brake lines or ABS sensor wires; use bungee cords to hang the calipers out of the way rather than letting them dangle.

Common Issues and Troubleshooting with the Diagram

The ford f150 front axle diagram is an invaluable tool for diagnosing the “Achilles’ heels” of this specific truck’s drivetrain. One of the most frequent complaints among owners is a “marbles in a coffee can” grinding sound coming from the front wheels. By referencing the diagram, you can identify the IWE actuators as the likely culprit. This sound occurs when a vacuum leak prevents the actuator from fully disengaging, causing the gears to partially mesh while driving in 2WD.

Another common issue is CV joint failure. If you notice a rhythmic clicking sound while making sharp turns, the diagram helps you locate the outer CV joints. Inspect the rubber boots for tears; if the boot is split, grease has likely escaped and dirt has entered, leading to the premature wear of the internal bearings.

Differential leaks are also easily diagnosed using the layout. If you see fluid pooling near the center of the front crossmember, the diagram will point you to the pinion seal or the axle shaft seals where they exit the differential housing. Identifying these specific leak points early can prevent a “dry” differential, which would lead to catastrophic gear failure.

If you suspect an IWE issue, use a handheld vacuum pump to test the lines shown in the diagram. If the system holds vacuum, your solenoid or vacuum reservoir might be the problem rather than the expensive actuators themselves.

Tips and Best Practices for Long-Term Maintenance

To keep your front axle system operating smoothly for years to come, proactive maintenance is mandatory. The ford f150 front axle diagram serves as a reminder of the many moving parts that require attention.

First, prioritize regular fluid changes for the front differential. While many manufacturers claim “fill-for-life” intervals, heavy towing or water crossings can contaminate the gear oil. Changing the fluid every 50,000 to 75,000 miles is a cost-saving practice that prevents expensive gear set replacements. Always use the specific synthetic gear lubricant recommended in your owner’s manual, usually a 75W-85 or 75W-90 weight.

Second, perform a visual inspection of the CV boots every time you change your oil. A small tear in a $20 boot can quickly turn into a $300 axle replacement if ignored. If you catch a tear early, you can sometimes replace just the boot and repack the joint with fresh grease.

Third, when replacing components like wheel hubs or CV axles, resist the temptation to buy the cheapest aftermarket parts. The F-150 is a heavy vehicle, and the front axle takes significant abuse. Using high-quality OEM or reputable heavy-duty aftermarket components ensures that the tolerances match the original diagram specifications, preventing premature wear on related parts like the steering rack or transmission.

Finally, pay close attention to torque specifications. The axle nut is the primary fastener holding the hub and axle together; under-torquing it can lead to wheel bearing failure, while over-torquing can damage the CV joint. Always refer to a technical service manual for the exact foot-pounds required for your specific sub-model. By following these best practices and using a detailed ford f150 front axle diagram, you ensure your truck remains reliable whether on the highway or the trail.

Frequently Asked Questions

What is Ford F150 front axle diagram?

A Ford F150 front axle diagram is a visual representation showing the internal and external assembly of the front drivetrain system. It maps out how the differential, axles, and hubs interact within the suspension structure. This configuration guide helps owners identify specific parts for repair, maintenance, and parts ordering.

How do you read Ford F150 front axle diagram?

To read this diagram, start from the center differential and move outward toward the wheels. Identify major components through numbered callouts and follow the layout of the CV shafts. Look for lines indicating how parts connect, such as the mounting points between the axle housing and the frame or suspension.

What are the parts of Ford F150 front axle?

The main parts include the differential housing, ring and pinion gears, half-shafts (CV axles), and wheel hubs. Additional components in the system layout are the Integrated Vacuum Actuators (IWE), upper and lower control arms, and ball joints. These elements work together to provide power and steering stability.

Why is the CV axle component important?

The CV axle is a critical component because it transfers torque from the differential to the front wheels while allowing for suspension travel and steering angles. In the F150 front axle structure, worn CV boots or joints can lead to grease loss, clicking noises, and eventual drivetrain failure if ignored.

What is the difference between 2WD and 4WD layouts?

The 4WD layout includes a front differential, transfer case connections, and drive axles to power the front wheels. In contrast, a 2WD configuration lacks these driving components, featuring a simpler spindle or hollow beam structure. The 4WD system is significantly more complex due to the additional moving mechanical parts.

How do I use Ford F150 front axle diagram?

Use the diagram to locate specific bolts, seals, or bearings when performing repairs. It serves as a roadmap for disassembling the hub assembly or replacing the differential fluid. By following the illustrated configuration, you can ensure that every component is reinstalled in the correct order and orientation for safety.