Ford 3G Alternator Wiring Diagram

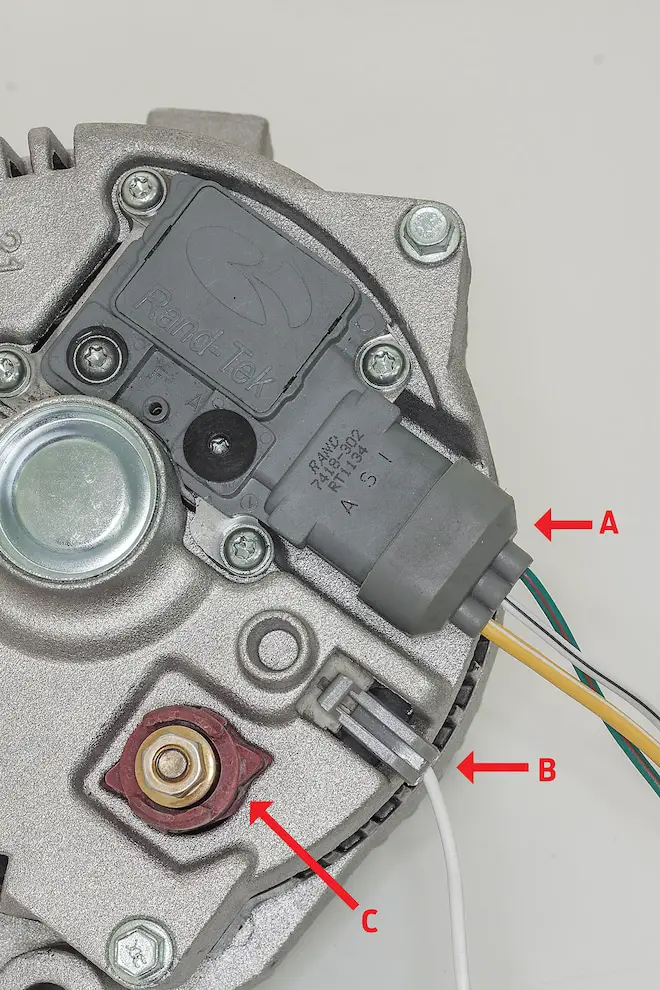

The 3G alternator is a high output alternator that is often used as an upgrade on Ford vehicles. The wiring diagram for this alternator is shown below. This particular model has an external regulator, which means that the voltage regulator is not built into the alternator itself.

This makes it easy to install and wire up, but it also means that if the regulator fails, you will need to replace the entire unit.

If you’re looking for a Ford 3G alternator wiring diagram, you might be out of luck. While there are a few diagrams available online, they’re often inaccurate or incomplete. And even if you could find a accurate diagram, it would be nearly impossible to follow without any prior experience with electrical wiring.

Fortunately, there’s an easier way to wire up your 3G alternator. The team at Painless Wiring has created a comprehensive wiring kit that includes everything you need to properly wire up your alternator. The kit comes with detailed instructions and color-coded wiring diagrams, so even if you’ve never done this before, you’ll be able to install it quickly and easily.

Don’t waste your time searching for a Ford 3G alternator wiring diagram – just get the Painless Wiring kit and be done with it!

Credit: www.supermotors.net

How Do You Wire a Ford 3G Alternator?

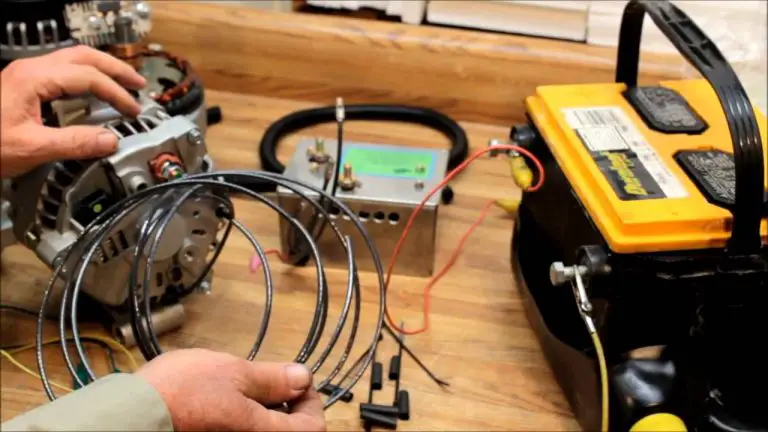

If you’re having trouble wiring your Ford 3G alternator, you’ve come to the right place. This guide will show you how to wire your alternator in just a few easy steps.

First, disconnect the battery negative cable.

Next, remove the drive belt and pulley from the alternator. Then, disconnect the electrical connector from the back of the alternator.

Now it’s time to remove the old alternator.

Remove the bolts that hold it in place and carefully pull it out. Be careful not to damage any of the surrounding components while doing this.

Now it’s time to install the new alternator.

First, connect the electrical connector to the back ofthe new alternator. Next, bolt it into place using the same bolts that held your old one in place. Finally, reattach your drive belt and pulley system.

Once everything is reconnected, start up your engine and check to make sure that everything is working properly. If all looks good, congratulations! You’ve successfully installed your new Ford 3G Alternator!

Where Do the Wires Go on a 3 Wire Alternator?

On a 3 wire alternator, the wires go to the battery, ignition switch, and regulator. The battery provides power to the alternator when the engine is not running. The ignition switch turns on the alternator when the engine is started.

The regulator controls the output of the alternator to keep it from overcharging the battery.

How Do You Wire a 3 Wire Alternator on a Ford Tractor?

Assuming you are referring to a 3 wire alternator on a Ford tractor with an external regulator:

The first step is to identify the three wires on the alternator. There should be a large battery cable attached to the back of the alternator, as well as two smaller gauge wires.

One of these smaller gauge wires will be labeled “BATT” or “BAT.” The other wire will typically be black.

Next, connect the large battery cable to the terminal on the back of the alternator marked with either “BATT” or “BAT.”

Then, take the black wire and attach it to one of the remaining terminals. Finally, attach the remaining small gauge wire to the last empty terminal.

If your tractor has an internal regulator, things will be slightly different.

In this case, you’ll need to identify four wires instead of three. Two of these wires will be attached to terminals marked “BATT” or “BAT.” The other two wires will be labeled “IGN” and “START.”

To wire an internally regulated alternator, start by attaching one of the “BATT” or “BAT” terminals to your battery’s positive post. Next, connect one of the IGNITION terminals (marked IGN) directly to your ignition switch’s B+ terminal. Finally, join together both START terminals (one from Alternator & Starter Solenoid and one from Ignition Switch).

How Many Amps is a 3G Alternator?

On average, a 3G alternator produces about 100 amps of power. This can vary depending on the make and model of the alternator, as well as any aftermarket modifications that have been made to it. It is important to note that the output of an alternator can also be affected by factors such as temperature and engine speed.

3G Large Case High Output Alternator with Wiring Harness

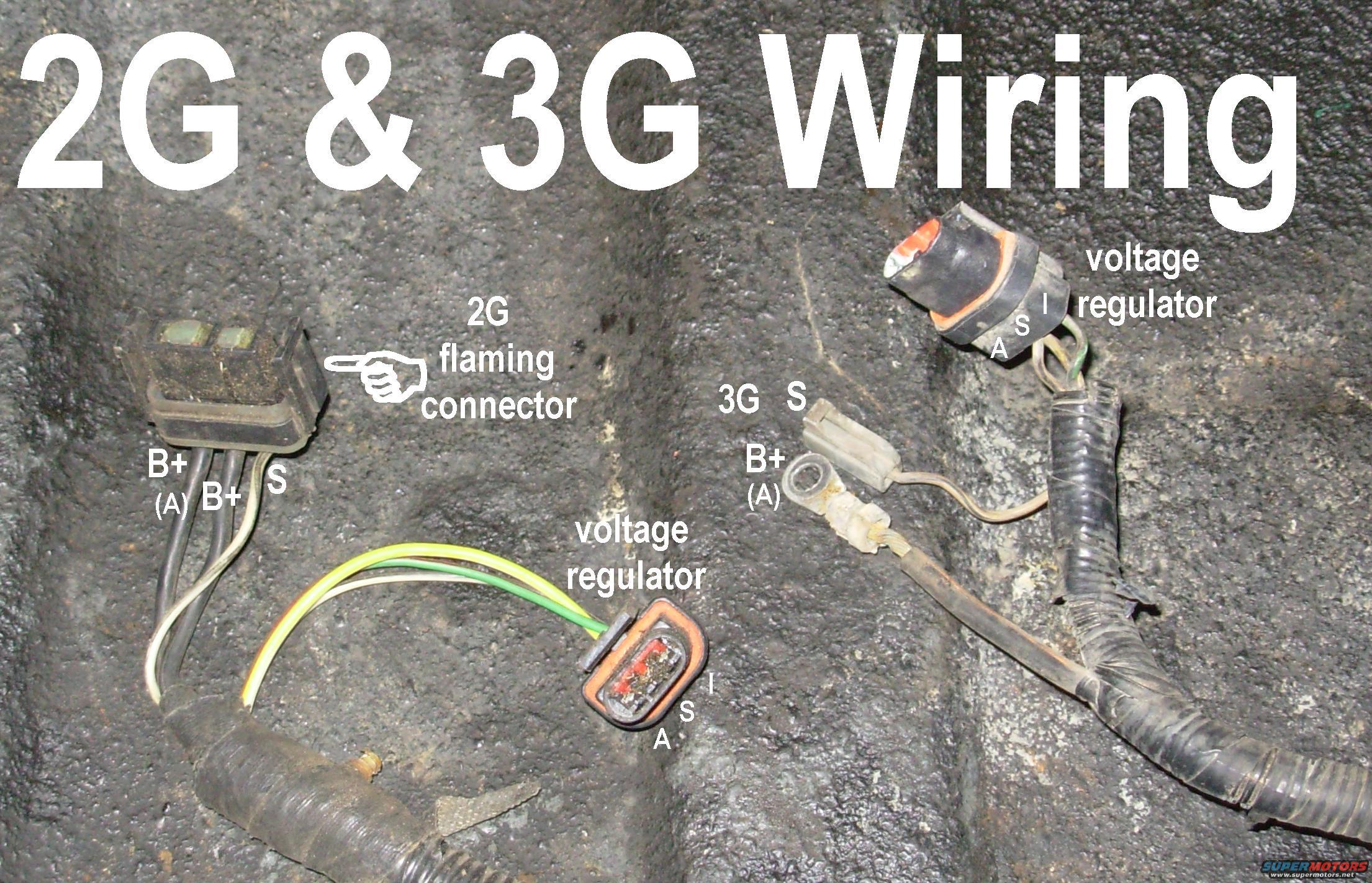

Ford 2G to 3G Alternator Wiring

If you are looking to upgrade your Ford Alternator from a 2G to a 3G, there are a few things you need to know. The first is that the 3G alternators were not available until 1985, so if your car is older than that, you’ll need to find an aftermarket option. The second is that the wiring for these two alternators is different, so you’ll need to wire it up correctly in order to get it working properly.

The biggest difference between the 2G and 3G alternators is the amperage output. The 2G produces around 60 amps, while the 3G can output up to 130 amps. This increased output is what allows the 3G to power all of the modern electronics in today’s cars.

If you are running any kind of audio system, GPS, or other electronic accessories, upgrading to a 3G will give you the power you need without overloading your electrical system.

Wiring the new alternator is fairly simple; just follow the diagram on the back of the unit. However, there are a few things to keep in mind.

First, make sure that all of your connections are tight and secure; loose wires can cause problems down the road. Second, pay attention to which way the battery terminal is facing; if it’s not pointing in the right direction, your car may not start properly (or at all). Finally, be sure to double-check all of your work before starting up your car – no one wants fried electronics!

Upgrading your Ford Alternator from a 2G to a 3G is a great way to improve both performance and reliability. With just a few hours of work (and some basic wiring knowledge), you can give your car the power it needs to keep up with today’s technology demands!

Wiring 3G Alternator

If you’re looking to wire a 3G alternator, there are a few things you need to know. First, the 3G has three wires: the big battery cable, the little ignition wire, and the output wire. Second, when wiring the alternator, make sure that the big battery cable is on the bottom and the output wire is on top.

Finally, be sure to connect the ground wire to a good clean chassis ground. With these tips in mind, wiring a 3G alternator should be a breeze!

Ford 1G to 3G Alternator Conversion

In the early 2000s, the Ford Motor Company released a new generation of alternators for their vehicles. These newer alternators were more powerful and efficient than the older ones that they replaced. However, many Ford owners found that these new alternators did not fit into the existing mounts on their cars and trucks.

This meant that they had to either purchase a new mounting bracket or find an aftermarket solution.

Fortunately, there are now kits available that allow you to convert your old 1G or 2G alternator to the newer 3G style. This conversion is not difficult to do, and it can be completed in a few hours with basic hand tools.

The kit includes everything you need to make the switch, including a new pulley, belt, and instructions.

If you’re looking for a way to improve the charging system on your Ford vehicle without spending a lot of money, then this 1G-to-3G alternator conversion kit is definitely worth considering.

Ford 1G to 3G Alternator Wiring Harness

If you are a Ford owner, chances are you have had to deal with a faulty alternator at some point. Alternators are vital to your car’s electrical system, and when they go bad, it can be a major inconvenience. If you have ever wondered how to wire a 1G to 3G alternator conversion harness, this article is for you.

The first thing you need to know is that there are two different types of alternators used in Ford vehicles – the 1G and the 3G. The 1G was used in vehicles up until about 2006, while the 3G started being used in 2007 and newer models. Both types of alternators serve the same purpose, but they use different wiring harnesses.

1G to 3G Alternator Wiring Harness Conversion:

What You Need:

-A 3-wire pigtail (available at most auto parts stores)

-Wire strippers/cutters

-Electrical tape or heat shrink tubing

-Screwdriver

-Needlenose pliers (optional)

Instructions:

1. Start by disconnecting the negative battery terminal to avoid any shocks while working on your car’s electrical system.

2. Locate the three wires coming from your old 1G alternator’s wiring harness – these will be labeled “S,” “I,” and “L.” Using your wire strippers or cutters, carefully remove about ½ inch of insulation from each wire so that you can access the bare copper wire inside. If necessary, use needlenose pliers to twist the wires so that they lay flat against each other.

3. Take your 3-wire pigtail and strip about ½ inch of insulation off of each wire as well. Match up each wire from the pigtail (which should be labeled “B,” “+,” and “-“) with its corresponding wire from the old 1 G harness (“S,””I,””L”). Once they are matched up, twist them together clockwise until tight – make sure not overlap any of the wires so that they don’t short out when reconnected to power.

4a) If using electrical tape: Wrap each connection point several times with tape, making sure that there are no gaps or spaces where exposed wires could touch and cause a short circuit.* Be sure to cover all three connection points – B+to S , Ito + ,and Lto – .

Conclusion

If you’re looking for a Ford 3G Alternator Wiring Diagram, you’ve come to the right place. Here at EasyEngineering, we make it our mission to provide the best possible information and resources to help you repair and maintain your vehicle.

One of the most common problems with older vehicles is that the alternator wiring can become brittle and break over time.

This is usually caused by age and exposure to heat and moisture. Fortunately, there are a few things you can do to prevent this from happening, or at least delay it for as long as possible.

The first thing you should do is inspect the wiring regularly for any signs of wear or damage.

If you see anything that looks questionable, replace it immediately. It’s also a good idea to keep some spare wire on hand in case of an emergency.

If your vehicle is equipped with an external voltage regulator, make sure that it’s in good working order.

These regulators can often go bad after years of use, so it’s important to test them periodically. Many auto parts stores sell replacement regulators, so if yours goes bad, don’t hesitate to get a new one.

Most importantly, always follow the manufacturer’s instructions when working on your vehicle’s electrical system.

If you’re not sure about something, ask a professional mechanic or technician for assistance.