Bypass Heater Control Valve Diagram: Routing & Flow Guide

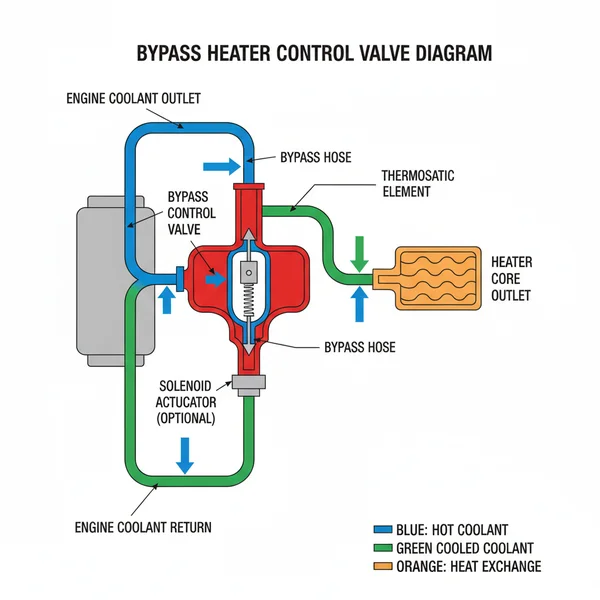

A bypass heater control valve diagram visualizes the flow of coolant between the engine and the heater core. This specific configuration utilizes a four-port valve to redirect fluid back to the engine when cabin heating is unnecessary, maintaining a stable cooling system structure and preventing pressure surges.

📌 Key Takeaways

- Visualizes coolant flow patterns in vehicle HVAC systems

- The four-port valve is the most critical component to identify

- Vacuum and electrical signal health is a vital safety consideration

- Use the diagram to trace leaks in complex hose networks

- Essential for troubleshooting cabin heat loss or engine overheating

Understanding the cooling and heating dynamics of your vehicle requires more than just a basic knowledge of the radiator and thermostat. When you are faced with temperature regulation issues inside the cabin, having a clear bypass heater control valve diagram is essential for diagnosing and repairing the system accurately. This specific component acts as a gatekeeper, directing the flow of hot coolant either into the heater core or back to the engine. Without a visual reference of the system’s configuration and layout, it is remarkably easy to cross vacuum lines or reverse the coolant hoses, leading to inefficient cooling or a total lack of heat. In this comprehensive guide, you will learn how to interpret the valve’s structure, understand its integration into the wider cooling loop, and follow a detailed process for testing or replacing the unit to ensure your vehicle remains comfortable in all seasons.

Deep Dive into the Bypass Heater Control Valve Diagram

A bypass heater control valve is a sophisticated piece of hardware designed to manage coolant flow based on the driver’s climate control settings. When you examine a standard diagram, the first thing you will notice is the four-port configuration, which is the most common layout in modern automotive design. The primary objective of this structure is to maintain a constant loop of coolant flow regardless of whether the heater is in use. This prevents “dead-heading” the water pump, a condition where fluid pressure builds up because it has nowhere to go.

The diagram typically illustrates the following key components: the inlet from the engine, the outlet to the heater core, the return from the heater core, and the bypass return to the engine. In the “Heat On” position, the diagram shows the valve internal passage opening to allow hot coolant to enter the heater core. In the “Heat Off” or “AC Max” position, the internal gate slides or rotates, blocking the path to the heater core and immediately re-routing that hot fluid back to the engine through the bypass port. This ensures that the heater core remains cool, allowing your air conditioning system to work at maximum efficiency without fighting against residual heat from the engine coolant.

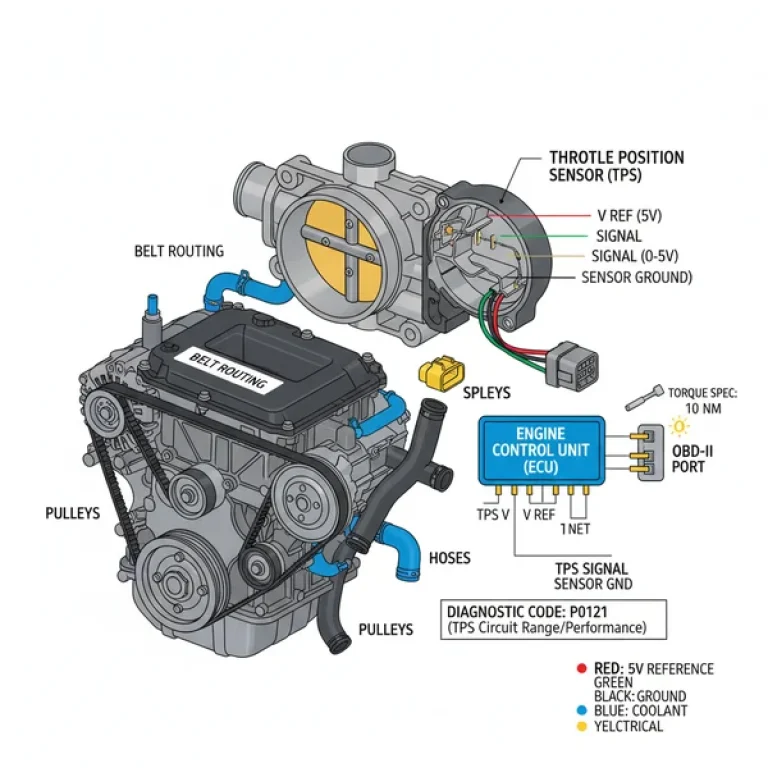

Visually, the diagram will often use color-coding to signify temperature differences. Red lines indicate high-pressure, high-temperature coolant flowing from the engine’s cylinder head or intake manifold. Blue or yellow lines might represent the return path or the bypassed flow. Furthermore, the diagram will highlight the actuation mechanism. Most older or heavy-duty systems use a vacuum-actuated diaphragm, while newer vehicles may feature an electronic solenoid. Understanding this specific configuration is vital because it tells you whether to look for a cracked vacuum line or a frayed electrical connector when the valve fails to switch positions.

[DIAGRAM_PLACEHOLDER: A detailed 4-port bypass heater control valve diagram showing the internal gate mechanism, vacuum actuator, and flow directions for both ‘Heat Mode’ and ‘Bypass Mode’. Labels include: Engine Inlet, Heater Core Feed, Heater Core Return, and Engine Bypass Return.]

Interpreting the Layout and Installation Guide

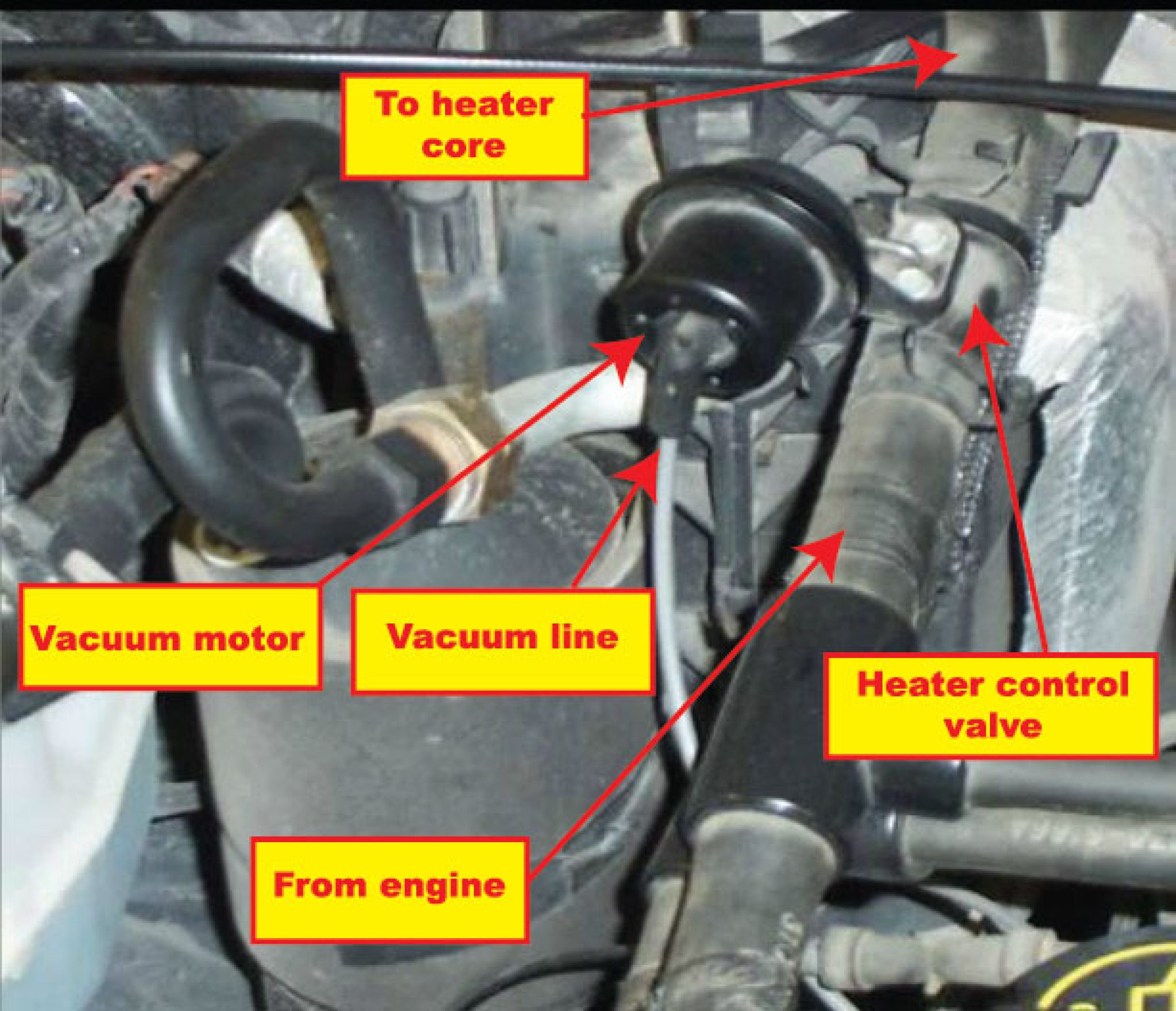

Reading a bypass heater control valve diagram is the first step toward a successful repair. To use the diagram effectively, you must first identify the orientation of the valve relative to the firewall. Usually, the valve is located in the engine bay, spliced into the two heater hoses that disappear into the dashboard.

Most bypass valves have directional arrows molded into the plastic or metal housing. These arrows must match the flow direction indicated on your system diagram to prevent overheating or valve chatter.

To begin your work using the diagram as a roadmap, gather the necessary tools. You will typically need hose clamp pliers (constant tension pliers are best), a drain pan to catch escaping coolant, a screwdriver set, and potentially a vacuum pump for testing.

Step 1: System Depressurization and Safety

Before touching any hoses, ensure the engine is completely cold. Opening a hot cooling system can cause severe burns. Once cool, remove the radiator cap to release any residual pressure. Consult your diagram to identify the lowest point in the heater hose circuit; you may want to drain a small amount of coolant from the radiator to prevent a mess when you disconnect the valve.

Step 2: Identifying the Hose Connections

Match the physical hoses in your engine bay to the ports shown on the diagram. Label each hose with masking tape: “To Core,” “From Core,” “Engine Supply,” and “Engine Return.” This prevents the common mistake of crossing the bypass and return lines, which can lead to air pockets forming in the system.

Step 3: Disconnecting the Actuator

If your diagram shows a vacuum-operated valve, carefully pull the small vacuum line off the top of the diaphragm. Inspect the line for cracks. If the diagram indicates an electrical connector, depress the locking tab and pull the plug away. Using your diagram, verify that the control signal (vacuum or electricity) is present when you toggle the dashboard controls.

Step 4: Removing the Old Valve

Loosen the clamps on all four ports. If the hoses are stuck, do not pry them with a sharp screwdriver as this can damage the rubber. Instead, use hose removal pliers or gently twist the hose with a pair of channel locks to break the seal. Once free, remove the old unit and compare it to the replacement and the diagram to ensure the port layout is identical.

Step 5: Installing the New Component

Slide the new valve into position according to the diagram’s orientation. Ensure the “Engine Inlet” port is receiving fluid from the engine block side. Tighten the clamps securely but avoid over-tightening if the valve body is plastic, as this can cause the port to crack over time.

Step 6: Reconnecting Controls and Bleeding the System

Reconnect the vacuum line or electrical plug. Refill the cooling system with the manufacturer-recommended coolant. This is the most critical step: you must “bleed” the air out. With the heater set to maximum, run the engine until it reaches operating temperature. Watch the diagram’s flow path and feel the hoses; the “To Core” hose should get hot, indicating the valve is opening and fluid is circulating correctly.

Common Issues and Troubleshooting

Even with a perfect bypass heater control valve diagram, mechanical components can fail. The most frequent issue is a stuck internal gate. If the gate is stuck in the bypass position, you will have no heat in the winter because the coolant never reaches the heater core. Conversely, if it is stuck in the open position, your air conditioning will feel lukewarm because the heater core is constantly radiating heat into the HVAC box.

A leaking heater control valve can spray hot coolant onto electrical components or exhaust manifolds, posing a fire risk or causing electrical shorts. Never ignore “sweet-smelling” steam coming from under the hood.

Use your diagram to perform a “touch test.” When the heat is on, both the inlet and outlet hoses going to the firewall should be hot. If the inlet is hot but the outlet is cold, the valve is likely blocked or not opening. Another common failure is a ruptured internal diaphragm. If you apply a vacuum to the actuator port and it doesn’t hold pressure, the valve is faulty and must be replaced. The diagram helps you locate these specific test points without guesswork.

Tips and Best Practices for Maintenance

To ensure the longevity of your heating system and the bypass valve itself, routine maintenance is paramount. The internal seals of the valve are sensitive to the pH levels of your coolant. Over time, coolant becomes acidic, which can eat away at the plastic housing or the rubber seals inside the valve.

- ✓ Flush Regularly: Perform a cooling system flush every 30,000 to 50,000 miles to remove sediment that can clog the valve’s small bypass passages.

- ✓ Check Vacuum Lines: If your vehicle uses vacuum actuation, inspect the thin plastic lines for brittleness. Heat cycles in the engine bay make these prone to snapping.

- ✓ Use Quality Clamps: When replacing the valve, consider using new stainless steel worm-gear clamps instead of reusing old spring-tension clamps that may have lost their “memory.”

- ✓ Match Specifications: Always buy a valve that matches the exact OEM configuration shown in your diagram. Even a slight difference in port diameter can cause flow restrictions.

If you are in a pinch and the valve fails in the ‘closed’ position during winter, you can temporarily bypass the valve by connecting the engine supply hose directly to the heater core inlet using a plastic coupler. This provides constant heat until you can replace the valve.

Investing time in studying a bypass heater control valve diagram pays off by reducing the time spent on trial-and-error repairs. By understanding how the fluid moves through the ports and identifying the role of each component, you can maintain a highly efficient cooling system. Whether you are dealing with a complex electronic unit or a simple vacuum-operated gate, the principles of flow and redirection remain the same. Keep your diagram handy during your next maintenance session, and you will find that managing your vehicle’s climate control system is a straightforward and rewarding task. Regular inspection of the valve’s structure and configuration will prevent unexpected leaks and ensure that whether you need freezing AC or blistering heat, your vehicle is ready to deliver.

Step-by-Step Guide to Understanding the Bypass Heater Control Valve Diagram: Routing & Flow Guide

Identify the main coolant inlet and outlet hoses coming from the engine block.

Locate the bypass heater control valve within the engine bay, usually near the firewall.

Understand how the actuator component, whether vacuum or electric, triggers the internal valve movement.

Connect the hoses to the correct ports as indicated by the specific diagram layout.

Verify that the vacuum line or electrical connector is securely attached to the actuator.

Complete the process by checking the system for leaks while the engine is running.

Frequently Asked Questions

What is a bypass heater control valve diagram?

This diagram provides a visual representation of the coolant circuit within a vehicle’s HVAC system. It specifically details how the bypass valve manages fluid distribution between the heater core and the engine. By showing the internal structure of the valve, it helps technicians understand the complex flow paths.

How do you read a bypass heater control valve diagram?

Start by identifying the primary coolant source from the engine. Follow the arrows indicating fluid direction through each port of the valve. Pay close attention to the layout of the vacuum or electrical lines, as these dictate how the internal configuration changes to either heat or bypass.

What are the parts of a bypass heater control valve?

The main parts include the valve body, four individual ports for coolant inlet and outlet, and an actuator component. Depending on the system, the actuator may be vacuum-operated or controlled by an electric motor. The internal gate or diaphragm is the moving part that redirects the flow.

Why is the bypass component important?

The bypass component is essential because it allows coolant to circulate through the engine block even when the heater is off. This prevents hot spots and thermal stress within the engine. Without this specific configuration, the cooling system could experience increased pressure and potential hose failures over time.

What is the difference between a standard and bypass valve?

A standard valve simply opens or closes the flow to the heater core, essentially acting like a dam. A bypass valve uses a more complex layout to redirect the flow back to the engine instead of stopping it entirely. This ensures the cooling system remains pressurized and balanced constantly.

How do I use a bypass heater control valve diagram?

Use this diagram to diagnose heating failures or coolant leaks by tracing the hose paths. Match the physical structure of your vehicle’s cooling system to the visual layout provided. It is an invaluable tool for identifying which hose connects to which port during a valve replacement procedure.