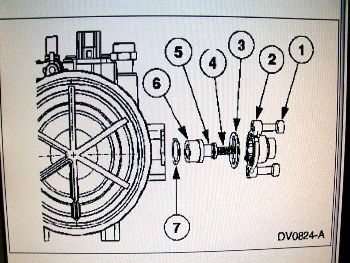

7.3 Powerstroke Fuel Pressure Regulator Diagram

The 7.3 Powerstroke fuel pressure regulator diagram can be found in the engine’s workshop manual. This diagram shows the location of the fuel pressure regulator and how it is connected to the engine’s fuel injectors. The fuel pressure regulator is responsible for maintaining the correct pressure in the fuel injectors so that they can deliver the correct amount of fuel to the engine.

If you’re looking for a powerstroke fuel pressure regulator diagram, then you’ve come to the right place. Here at 7.3 Powerstroke, we know everything there is to know about these engines, and we’re happy to share our knowledge with you.

The fuel pressure regulator is an important part of the powerstroke engine, and it’s responsible for regulating the pressure of the fuel that’s delivered to the injectors.

If the pressure isn’t regulated properly, then the injectors can’t do their job properly and the engine will run poorly.

There are a few different types of fuel pressure regulators available for the powerstroke engine, so it’s important to choose one that’s compatible with your particular engine. We carry all of the major brands and can help you find the perfect fit for your engine.

Once you have your new fuel pressure regulator installed, be sure to check it regularly to make sure that it’s working correctly. If you have any questions or need any assistance, our team of experts is always here to help.

Credit: www.accuratediesel.com

How Do You Check Fuel Pressure on a 7.3 Power Stroke?

If you have a 7.3 Power Stroke diesel engine, you may be wondering how to check the fuel pressure. While it’s not a difficult task, there are a few things you need to know before you get started.

To check the fuel pressure on your 7.3 Power Stroke, you’ll need a fuel pressure gauge.

You can purchase one at most auto parts stores or online. Once you have the gauge, connect it to the Schrader valve on the fuel rail. The Schrader valve is located on the passenger side of the engine, near the front of the cylinder head.

Start the engine and let it idle for a few minutes so that the gauge can register an accurate reading. The ideal fuel pressure for a 7.3 Power Stroke should be between 45 and 60 psi (pounds per square inch). If your gauge reads higher or lower than this range, it’s an indication that there may be an issue with your fuel system that needs to be addressed.

How Do You Prime the Fuel System on a 7.3 Powerstroke?

If you have a 7.3 Powerstroke, you may be wondering how to prime the fuel system. The good news is that it’s not difficult to do, and there are only a few steps involved. Here’s what you need to know:

1. Locate the fuel filter housing on your 7.3 Powerstroke. It will be located on the driver’s side of the engine, near the front of the vehicle.

2. Unscrew the cap from the fuel filter housing and remove the old filter element.

Be sure to dispose of it properly – don’t just leave it lying around!

3. Take a new filter element and insert it into the housing, making sure that it is seated correctly.

4. Screw the cap back onto the housing, being careful not to over-tighten it.

5..

How Much Fuel Pressure Does a 7.3 Powerstroke Need to Start?

In order to start a 7.3 Powerstroke, the fuel pressure needs to be at least 60 psi. This is because the engine uses a high-pressure oil pump to inject fuel into the cylinders. If the fuel pressure is too low, the engine will not start.

How Does a 7.3 Fuel Pump Work?

A fuel pump is a mechanical device that moves fuel from the tank to the carburetor or injectors in an internal combustion engine. The 7.3 fuel pump is no exception, and it uses a simple yet effective design to get the job done.

The 7.3 fuel pump consists of a housing, impeller, vanes, and check valve.

The housing is made up of two halves that are bolted together. Inside the housing is the impeller, which is connected to the drive shaft. The vanes are what move the fuel through the pump, and the check valve prevents fuel from flowing back into the tank.

To understand how the 7.3 fuel pump works, it’s helpful to think of it as a water pump. Just like a water pump needs water to function, a fuel pump needs gasoline or diesel fuel to operate. When you turn on the ignition switch, power is sent to thefuel pump through a relay or fuse panel.

This powers upthe electric motor inside thefuel pump, which starts spinningthe drive shaft connected tothe impeller blades inside themotor housing unit.

Asimple set of gears inside themotor connects tothedrive shaftand causesit toturn at high speeds—usually between 5,000 and 6,000rpm for most passenger carsand light trucks .This action causesa low pressurearea behind eachvane as it sweeps aroundin its circular patterninside themotor housingunit—thinkof thislike aperson spinningaround with theirarms outstretched tryingto hold ontoa beach ball .

Aslong as they keepspinning fastenough ,they can keepthat beachball closeby withoutdroppingit . Nowimaginethat sameperson holdingonto two beachballsinstead of just one while still spinningfast enough —this wouldbe more difficultbut still possiblebecause therewould be alower pressurearea createdbehind eachbeach ballas theywere swept around bythe person’sspinning motion .Now think aboutthree beach ballsinstead oftwo …or four…or even five…You getthe picture!

Byincreasing thenumberof vanesinside amechanicalpump ,you alsoincrease thenumberof lowpressureareascreatedbehindeach vane —which allowsfor greater volumeand flowratefrom thatpump (allother factorsbeing equal).

BAD FUEL PRESSUER REGULATOR ?? HOW TO INSTALL A FUEL PRESSURE REGULATOR FORD 7.3 DIESEL SUPERDUTY

7.3 Powerstroke Fuel Pressure Regulator Symptoms

If you own a 7.3 Powerstroke, it’s important to be aware of the fuel pressure regulator symptoms. This part is responsible for regulating the amount of fuel that is delivered to the injectors. If it isn’t working properly, it can cause all sorts of problems.

One symptom of a failing fuel pressure regulator is an illuminated check engine light. This is because the computer has detected an issue with the way the fuel system is functioning. Another symptom is hard starting.

This can be caused by too much or too little fuel being delivered to the injectors.

If you notice either of these symptoms, it’s important to have your 7.3 Powerstroke checked out by a qualified mechanic as soon as possible. Waiting too long could lead to more serious issues, like engine damage.

7.3 Powerstroke Fuel Pressure Regulator Replacement

If you have a 7.3 Powerstroke, it’s important to keep an eye on your fuel pressure regulator. Over time, the regulator can wear out and need to be replaced. Here’s what you need to know about replacing your fuel pressure regulator on a 7.3 Powerstroke:

1. The first step is to relieve the pressure in the fuel system by disconnecting the negative battery cable.

2. Next, remove the old fuel pressure regulator by disconnecting the two hoses that connect it to the fuel rail.

3. Install the new fuel pressure regulator by connecting the two hoses and then bolting it into place.

4. Reconnect the negative battery cable and start up your engine to check that everything is working properly.

Obs 7.3 Fuel Bowl Rebuild

If your 7.3 Powerstroke is anything like mine, then the fuel bowl has probably seen better days. After years of constant use, it’s not uncommon for the fuel bowl to become worn and need to be rebuilt. Luckily, this is a relatively easy process that anyone with basic mechanical skills can do.

The first step is to remove the old fuel bowl from the engine bay. Once it’s out, you’ll need to clean all of the parts and inspect them for wear. If any of the parts are damaged beyond repair, you’ll need to replace them before you can continue.

Once everything is cleaned and inspected, you can begin rebuilding the fuel bowl. Start by installing the new gasket onto the bottom of the bowl. Then, install the float valve into place and secure it with the retaining ring.

Next, install the inlet needle and seat into place and secure with another retaining ring.

Now you’re ready to reinstall the fuel bowl onto your 7.3 Powerstroke! Be sure to follow all manufacturer instructions when doing so, and make sure everything is tightened down securely before starting up your engine again.

With a little bit of time and effort, you’ve successfully rebuilt your 7.3’s fuel bowl – good as new!

1995 F250 7.3 Fuel System Diagram

If you’re looking for a 1995 F250 7.3 fuel system diagram, you’ve come to the right place. Here at FordF250.com, we have a comprehensive list of diagrams for all sorts of truck systems, including the fuel system.

The fuel system in your 7.3-powered truck is composed of several different parts, all working together to get gasoline to the engine.

Starting at the gas tank, there’s the fuel pump, which sends gas to the injectors via fuel lines. The injectors spray gasoline into the cylinders, where it mixes with air and is ignited by spark plugs to create power.

All of these parts are essential for your truck to run properly, so it’s important to know how they all work together.

That’s where our diagrams come in handy – they can help you understand how the fuel system works, and point out any potential problems areas. So whether you’re troubleshooting an issue or just doing some routine maintenance, be sure to check out our diagrams before you start wrenching!

Conclusion

If you’re looking for a 7.3 powerstroke fuel pressure regulator diagram, look no further! This helpful guide will show you everything you need to know about finding and installing the right fuel pressure regulator for your truck.

First, it’s important to understand what a fuel pressure regulator does and why it’s necessary.

A fuel pressure regulator is responsible for maintaining the correct amount of pressure in the fuel system. Too much or too little pressure can cause serious engine problems, so it’s crucial that the regulator is working properly.

Installing a new fuel pressure regulator is relatively simple, but there are a few things to keep in mind.

First, make sure to get the correct model for your truck. There are many different types of regulators available, so it’s important to choose one that will work with your specific vehicle. Second, follow the instructions carefully when installing the new regulator.

Incorrect installation can cause leaks or other problems, so it’s important to do it right the first time.

Once you have installed the new fuel pressure regulator, be sure to test it out before hitting the road. Start by turning on the ignition and letting the truck idle for a few minutes.

Then turn on all accessories such as headlights and wipers to make sure they’re working properly. Finally, take it for a test drive to ensure that everything is running smoothly.