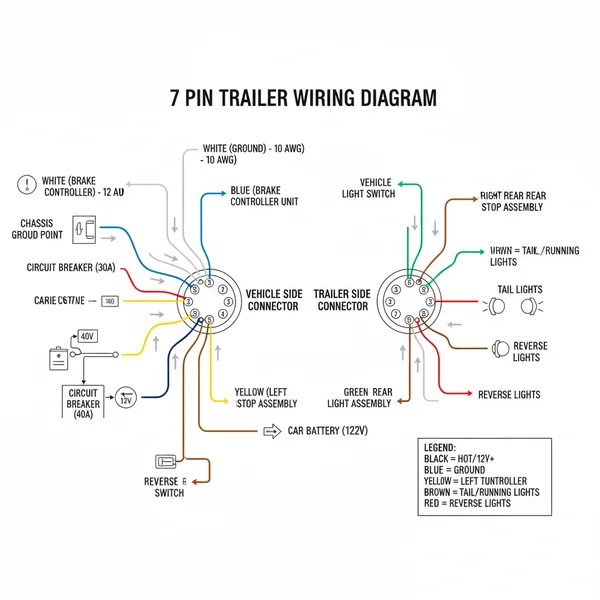

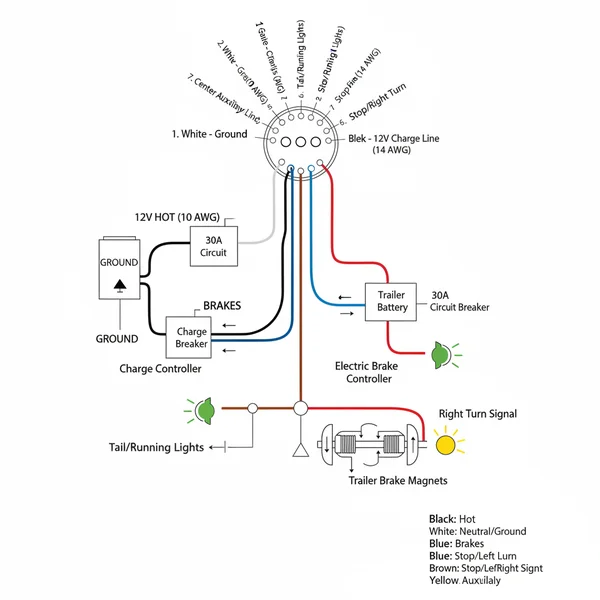

A 7-pin trailer wiring diagram illustrates connections for tail lights, turn signals, electric brakes, and a 12V auxiliary battery line. It ensures the trailer’s ground wire is properly bonded and that the hot wire provides consistent power. This setup is essential for heavy-duty towing, synchronizing vehicle signals with trailer braking and charging systems.

📌 Key Takeaways

- Synchronize lights, electric brakes, and battery charging between vehicle and trailer.

- The ground wire is the most critical connection for circuit completion and safety.

- Ensure the 12V hot wire is fused properly to prevent electrical fires.

- Use color-coded wires to match industry standards for easier maintenance.

- Reference this diagram when installing a brake controller or auxiliary battery.

When you are preparing for a long-distance haul or a weekend camping trip, ensuring your vehicle and trailer are communicating effectively is paramount for safety. A 7 pin trailer wiring diagram with brakes and battery provides the essential roadmap for connecting your tow vehicle’s electrical system to the trailer’s lights, electric brake magnets, and auxiliary power system. This comprehensive guide will walk you through the complexities of the 7-way connector, explaining how each wire functions to provide a seamless towing experience. By understanding this specific wiring configuration, you will learn how to properly route power to your trailer’s house battery and synchronize the electric brakes with your vehicle’s pedal. Whether you are replacing an old plug or building a trailer from scratch, having a clear diagram is the difference between a safe journey and a hazardous electrical failure.

A 7-way connector is the industry standard for trailers equipped with electric brakes and internal batteries. Unlike simpler 4-flat or 5-flat connectors, the 7-way plug supports auxiliary power and reverse lights, making it the preferred choice for RVs, horse trailers, and heavy-duty utility trailers.

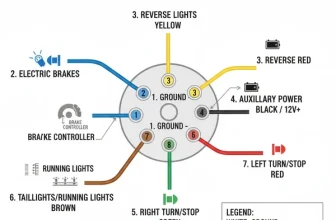

The 7-way trailer connector, often referred to as an RV-style plug, consists of seven distinct terminals arranged in a circular pattern around a central pin. Each terminal is assigned a specific color and function, though it is important to note that wire colors can occasionally vary by manufacturer. The main diagram shows the rear view of the plug (the side where you connect the wires) to ensure you are placing the correct wire into the corresponding brass screw terminal.

In a standard configuration, the central pin is typically reserved for backup or reverse lights. Moving clockwise from the top, you will find the 12V auxiliary power terminal, followed by the right turn and brake light signal. The bottom terminals include the electric brake output and the ground wire, which serves as the common terminal for the entire circuit. Finally, the remaining pins handle the left turn and brake signal as well as the tail or running lights. This layout ensures that high-current loads, such as the electric brakes and the battery charge line, are separated from sensitive signal wires to prevent interference.

[DIAGRAM_PLACEHOLDER: A 7-way round trailer connector diagram. Center: Reverse (Purple). 1:00 position: 12V Battery/Hot (Black). 3:00: Right Turn/Brake (Green). 5:00: Electric Brakes (Blue). 7:00: Ground/Common (White). 9:00: Left Turn/Brake (Yellow). 11:00: Tail/Running (Brown).]

Understanding the physical construction of the plug is just as important as the wiring logic. Most high-quality connectors utilize a brass screw for each connection point. Brass is preferred because it offers excellent conductivity and resists the corrosion commonly found in hitch environments. When viewing the diagram, always verify if you are looking at the “vehicle side” (socket) or the “trailer side” (plug), as they are mirror images of one another.

Never assume wire colors match the diagram perfectly without testing. Manufacturers sometimes deviate from standards. Always use a multimeter to verify the voltage and function of each wire before final installation.

To successfully implement the 7 pin trailer wiring diagram with brakes and battery, you must first understand the individual components and the specific demands they place on your vehicle’s electrical system. The most critical aspect of this setup is the integration of the electric brake controller and the 12V hot wire.

The electric brake circuit, usually represented by a blue wire, carries a modulated signal from the brake controller inside your cab to the electromagnets in the trailer’s hubs. This is not a simple on/off switch; the voltage varies based on how hard you press the vehicle’s brakes. This necessitates a thick wire gauge to handle the amperage without significant voltage drop. Similarly, the hot wire (usually black or red) provides a constant 12V stream to the trailer. This wire is used to charge the trailer’s onboard battery while the engine is running or to power interior lights and accessories.

The ground wire, often white, is the common terminal that returns all current back to the vehicle’s chassis. Because it carries the combined load of the lights, brakes, and battery charging, the ground wire must be the same gauge as, or larger than, the hot wire. If the ground is insufficient, you may experience “ghosting” in your lights, where one signal causes another to flicker weakly.

Installing or repairing a 7-way trailer plug requires precision and the right tools. Follow these steps to ensure a professional-grade connection.

- 1. Prepare Your Tools and Materials: You will need a high-quality 7-way plug, wire strippers, a crimping tool, a multimeter, and dielectric grease. Ensure you have the correct wire gauge for the application: 10-gauge for the ground, battery, and brake lines, and 14-gauge or 16-gauge for the signal lights.

- 2. Strip the Main Cable: Remove about 2 inches of the outer jacket from your trailer’s wiring harness. Be extremely careful not to nick the insulation of the internal traveler wires. Strip about 1/2 inch of insulation from each individual wire to reveal the copper strands.

- 3. Identify the Common Terminal: Locate the terminal labeled “GND” or “White” on the back of the plug. This is your ground wire. Loosen the brass screw, insert the white wire, and tighten it securely. A solid ground is the foundation of the entire system.

- 4. Wire the Lights: Connect the yellow wire to the left turn/brake terminal and the green wire to the right turn/brake terminal. The brown wire connects to the tail/running light terminal. These traveler wires carry the signals that keep you legal and visible on the road.

- 5. Connect the Power and Brakes: Attach the black wire to the 12V “Hot” or “Battery” terminal. This terminal provides the constant voltage needed for the trailer battery. Then, connect the blue wire to the “Electric Brake” terminal. Ensure these connections are exceptionally tight, as they carry the highest current.

- 6. The Auxiliary/Reverse Terminal: If your trailer has reverse lights, connect the purple wire to the center pin. If not, this pin can be left empty or used for another auxiliary function, though reverse lights are recommended for larger trailers.

- 7. Apply Protection and Assemble: Before closing the plug housing, apply a generous amount of dielectric grease to each brass screw and wire end. This prevents moisture from causing oxidation. Slide the plug housing over the connections and tighten the strain relief clamp to prevent the wires from pulling out.

- 8. Final Testing: Plug the trailer into your vehicle. Use a multimeter or a circuit tester to verify that each pin is receiving the correct voltage. Have a partner stand behind the trailer to confirm the left turn, right turn, brake, and tail lights are functioning correctly.

When wiring the hot wire and electric brake line, use heat-shrink terminals. These provide a secondary layer of protection against vibration and moisture, which are the leading causes of trailer wiring failure.

When dealing with a 7 pin trailer wiring diagram with brakes and battery, the physical properties of the wire are just as important as the connection points. Standard 12V DC systems are highly susceptible to voltage drop over long distances. If your trailer is 30 feet long and you use a thin wire gauge for the battery charge line, the voltage reaching the trailer battery may drop below 12.6V, meaning the battery will never actually charge.

For the battery and brake circuits, a 10-gauge wire is the industry recommendation. This thickness allows for the high amperage required by electric brake magnets (often 3-4 amps per magnet) without overheating the wire. For the signal lights, which use modern LED bulbs with very low draw, a 14-gauge or even 16-gauge wire is sufficient.

The term “neutral wire” is often used in AC household wiring, but in the DC world of trailers, the ground wire fulfills this role. It is the return path for all current. If you use a 10-gauge wire for your hot wire but only a 14-gauge wire for your ground, the ground will become a bottleneck, leading to heat buildup and potential melted connectors.

Trailer wiring is notorious for being temperamental, primarily because it is exposed to the elements. If your lights are dim or your brakes are grabbing unevenly, the 7-way diagram is your best diagnostic tool.

One of the most frequent problems is a “lost ground.” If the common terminal (the white wire) is loose or corroded, the electricity will try to find an alternative path to the vehicle’s frame. This often happens through the hitch ball, which creates an intermittent connection. The result is flickering lights that change rhythm when you hit a bump.

Another common issue is a blown fuse on the 12V hot wire. Many modern trucks have a dedicated fuse for the trailer’s auxiliary power. If your trailer battery isn’t charging, check the vehicle’s fuse block before taking the plug apart. Similarly, if the electric brakes aren’t responding, check the blue wire at the plug for voltage while someone manually slides the override on the brake controller. If you see 12V at the plug but the brakes don’t move, the issue lies within the trailer’s magnets or wiring.

If you find that your reverse lights stay on constantly, you likely have a short between the hot wire and the center pin. This can happen if stray strands of copper from the brass screw terminals touch each other inside the plug. Always ensure your wire strips are clean and no “whiskers” of copper are protruding.

To keep your 7-way system running for years, maintenance is key. The environment under a truck is harsh, involving road salt, rain, and constant vibration.

First, always use a mounting bracket for your vehicle’s 7-way socket. Letting the cable dangle puts unnecessary stress on the traveler wires and the plug housing. A secure mount prevents the cable from dragging on the pavement, which can strip the insulation and cause a dangerous short circuit.

Second, consider the quality of your components. Cheap plastic plugs can crack in cold weather, allowing moisture to seep into the brass screw area. Investing in a heavy-duty, rubberized or metal-housed plug can save you from a roadside repair later. When choosing wire, look for “marine grade” or “automotive grade” multi-strand copper wire. Avoid solid-core wire, as it will eventually snap due to the constant flexing of the trailer.

Third, perform an annual inspection. Once a year, open the plug and inspect the terminals for green corrosion. If you see it, clean the terminals with a wire brush and reapply dielectric grease. This simple ten-minute task can prevent a major electrical failure during a trip.

Finally, keep a 7-way circuit tester in your glove box. These small, inexpensive devices plug into your vehicle’s socket and have LEDs that indicate if each circuit is active. It allows you to quickly determine if a wiring problem is in the truck or the trailer, effectively cutting your troubleshooting time in half.

In conclusion, mastering the 7 pin trailer wiring diagram with brakes and battery is about more than just matching colors. It is about understanding how voltage travels through the system and ensuring that every connection, from the common terminal to the electric brake line, is secure and protected. By following the standard RV wiring conventions, using the correct gauge wire, and maintaining your connections with dielectric grease, you can ensure that your trailer remains a safe and functional extension of your vehicle. A properly wired trailer gives you the confidence to tackle any road, knowing that your brakes will respond and your batteries will be charged when you arrive at your destination.

Frequently Asked Questions

What is 7 pin trailer wiring diagram with brakes and battery diagram?

It is a schematic showing how to connect a vehicle to a trailer using a 7-way connector. This specific configuration supports standard lighting, electric trailer brakes, and a 12V power circuit for an onboard battery. It ensures all safety and power functions operate correctly while towing heavy loads.

How do you read 7 pin trailer wiring diagram with brakes and battery diagram?

To read the diagram, match the terminal numbers or colors to the corresponding pins on the plug. Identify the neutral wire or common terminal to establish the circuit return. Follow the lines to see how the hot wire connects to the battery and how the traveler wire facilitates switching.

What are the parts of 7 pin trailer wiring with brakes and battery?

The main parts include the 7-way plug and socket, electric brake controller, and color-coded wires. Key wires include the ground wire for circuit stability, the hot wire for auxiliary power, and the brake signal wire. A traveler wire may be used in specific auxiliary lighting or switching configurations.

Why is the ground wire important?

The ground wire is essential because it provides the return path for electrical current to the vehicle’s chassis. Without a solid ground connection at the common terminal, the lights may flicker, the electric brakes might fail to engage, and the auxiliary battery will not charge properly during transit.

What is the difference between 4-pin and 7-pin wiring?

A 4-pin connector only supports basic lighting like tail lights and turn signals. In contrast, a 7-pin connector adds circuits for electric brakes, a 12V hot wire for battery charging, and backup lights. This makes the 7-pin setup necessary for trailers with independent braking systems and power needs.

How do I use 7 pin trailer wiring diagram with brakes and battery diagram?

Use the diagram as a visual map during installation or repair. Start by identifying each wire’s function, then connect them to the appropriate terminals inside the plug. Ensure the hot wire is protected by a fuse and verify that the neutral wire is securely grounded before testing the system.