6 Pin CDI Box Wiring Diagram: Troubleshooting and Setup

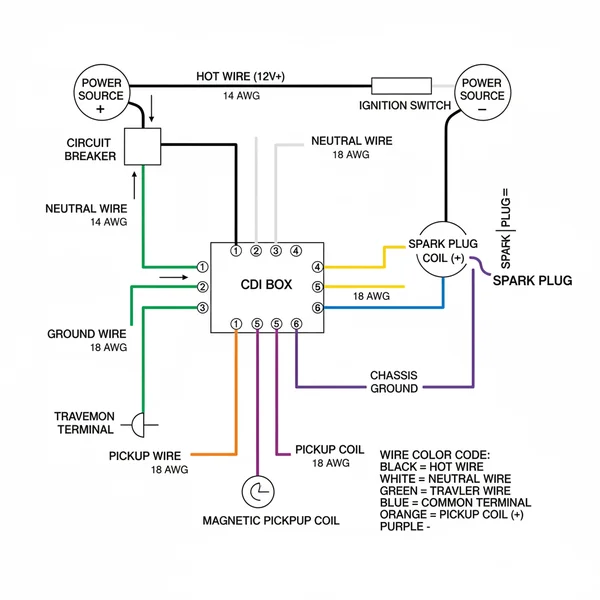

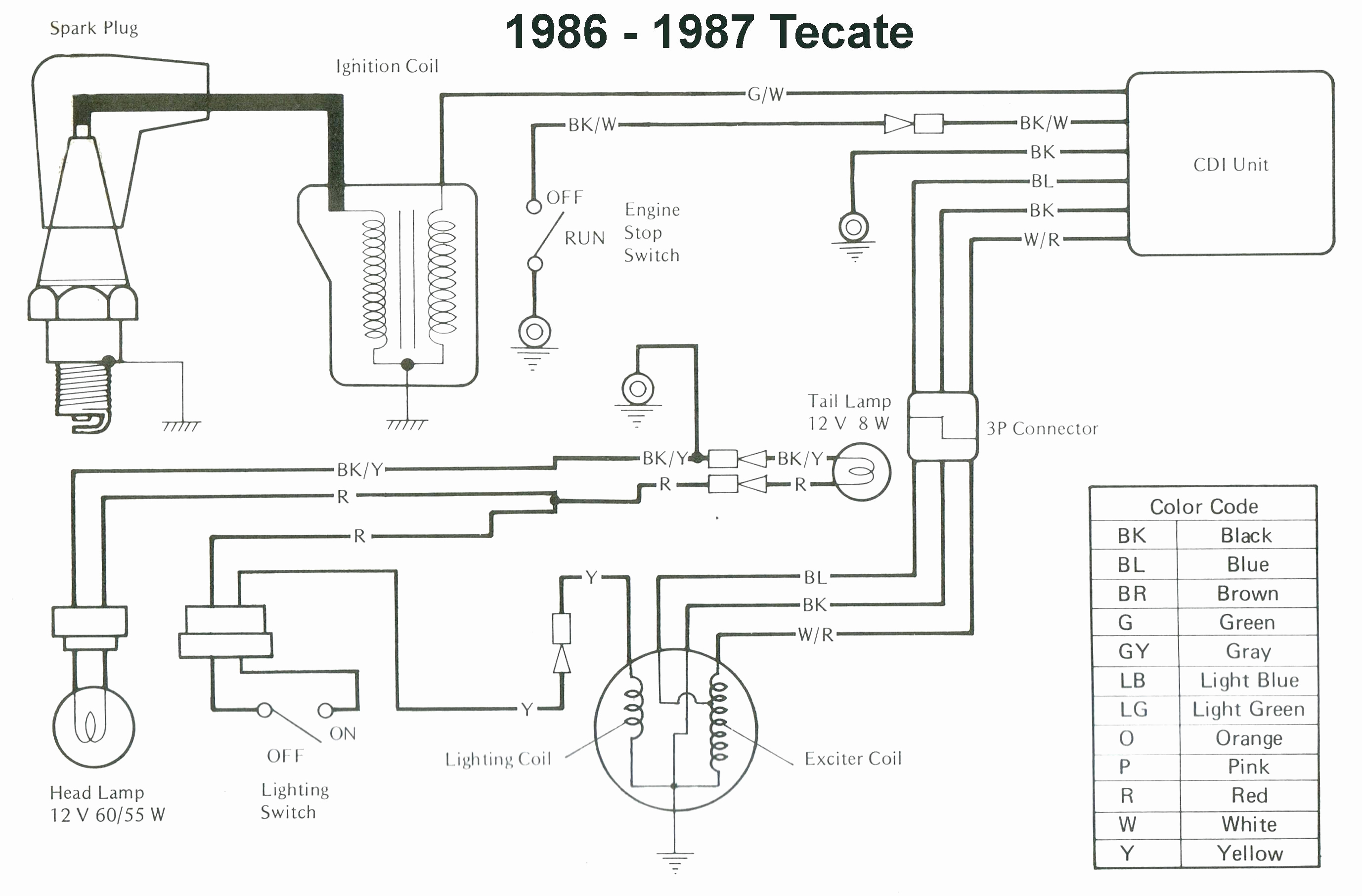

A 6 pin CDI wiring diagram maps the connections between the ignition coil, pickup sensor, power source, and kill switch. By identifying the hot wire for power and ensuring the traveler wire delivers the trigger signal, you can successfully wire the unit to a common terminal for reliable engine ignition.

📌 Key Takeaways

- Provides a visual map for connecting the ignition system to the engine harness

- The pickup sensor pin is the most critical trigger signal to identify correctly

- Ensuring a high-quality ground wire connection prevents CDI unit burnout

- Use the diagram to distinguish between AC-powered and DC-powered CDI systems

- Refer to this guide when diagnosing a complete loss of spark or engine misfires

Finding yourself stranded with a non-starting scooter, ATV, or dirt bike is often a result of a faulty ignition system, specifically the Capacitor Discharge Ignition (CDI) unit. Understanding a cdi box 6 pin cdi wiring diagram is the most effective way to diagnose and repair these common electrical issues. The CDI box acts as the “brain” of your engine’s spark timing, and having a precise map of its pins ensures you can differentiate between a failed box and a simple loose wire. This article will provide you with a comprehensive breakdown of the 6-pin configuration, explaining how each terminal interacts with your stator, ignition coil, and kill switch so you can restore your vehicle to peak performance.

Deep Dive into the 6-Pin CDI Component Layout

The 6-pin CDI is a staple in the world of small displacement engines, particularly those found in GY6-based machines. Unlike simpler 4-pin or 5-pin units, the 6-pin variation is typically divided into two distinct connector blocks: a 4-pin plug and a 2-pin plug. This physical separation helps prevent incorrect installation, but understanding the internal logic is crucial for troubleshooting. When viewing the diagram, you will notice that the components are color-coded to represent the flow of electricity from the source to the spark plug.

The primary elements involved include the AC ignition power source (often coming from the stator), the pulse or trigger signal that tells the box when to fire, and the output to the ignition coil. In many diagrams, you will see a specific ground wire designated to complete the circuit, ensuring that the high-voltage pulse has a return path. It is important to distinguish between AC-fired and DC-fired 6-pin boxes. While they look identical externally, their internal circuitry and the voltage they require differ significantly. An AC CDI draws power directly from the stator’s high-voltage windings, while a DC CDI relies on the 12V battery system.

Most 6-pin CDI units use a 4+2 plug configuration. The 4-pin block usually contains the trigger, ground, ignition coil, and kill switch wires, while the 2-pin block handles the power input from the stator or battery.

Step-by-Step Guide to Reading and Installing the CDI

Interpreting a wiring diagram might seem daunting, but by following a systematic approach, you can master the installation process. Before beginning, ensure you have the necessary tools, including a multimeter, wire strippers, and high-quality electrical tape or heat shrink tubing.

High voltage is present in the ignition system. Never touch the spark plug wire or CDI terminals while the engine is cranking or running, as it can deliver a painful or dangerous electrical shock.

- Identify the CDI Type: Use your multimeter to check the voltage at the power pin of your harness. If you see roughly 12V DC with the key on, you need a DC CDI. If you only see voltage while the engine is cranking, you require an AC-fired unit.

- Locate the Common Terminal: In any 6-pin CDI wiring diagram, the common terminal is usually the ground. Locate the green wire (standard for most Chinese engines) and ensure it has a solid connection to the engine frame. A weak ground is the leading cause of CDI failure.

- Trace the Traveler Wire: In ignition terms, the trigger wire (often blue with a white stripe) acts as a traveler wire, carrying the pulse signal from the pickup coil to the CDI. Connect this to the top-left pin on the 4-pin connector.

- Connect the Hot Wire: The hot wire in this context is the power feed. For AC units, this is usually black with a red stripe. For DC units, it may be solid red or black. Attach this to the appropriate pin on the 2-pin connector as shown in your specific diagram.

- Wire the Ignition Coil: Connect the output pin (often black with a yellow stripe) to the brass screw terminal on your ignition coil. This wire delivers the high-voltage pulse that creates the spark.

- Verify the Kill Switch: The kill switch wire (black with a white stripe) works by grounding the CDI when the switch is in the “off” position. Ensure this is not accidentally grounded, or the engine will never start.

- Check Wire Gauge and Insulation: Ensure all wires used are of the correct gauge (typically 16 or 18 AWG) to handle the current without overheating. Unlike a household neutral wire which carries current back to the source, small engine grounds must be extremely robust.

Always apply dielectric grease to the pins before plugging in the connectors. This prevents moisture ingress and corrosion, which are major enemies of sensitive CDI circuitry.

Common Issues and Troubleshooting

Even with a perfect cdi box 6 pin cdi wiring diagram, problems can arise. The most frequent issue users report is “no spark.” This is often misdiagnosed as a bad CDI when the actual culprit is a faulty stator or a pinched wire. By using the diagram to probe specific pins, you can isolate the fault.

For instance, if you are not receiving a signal on the traveler wire (trigger) while the engine is rotating, the pickup coil on the stator is likely dead. Conversely, if you have power and a trigger signal but no output to the ignition coil, the internal capacitor of the CDI has likely failed. Look for signs of “swelling” on the CDI casing or a burnt smell, both of which indicate internal short-circuiting.

Another common headache is intermittent stalling. This can happen if the ground wire is making poor contact with the frame. Vibration can cause a loose connection to break the circuit momentarily. If your engine runs for five minutes and then dies, it might be a thermal failure within the CDI; as it heats up, internal components expand and lose contact.

Tips and Best Practices for CDI Maintenance

To ensure your ignition system remains reliable, follow these maintenance recommendations. First, always prioritize wire quality. Using the correct gauge of wire is not just about fit; it’s about ensuring the voltage doesn’t drop over the length of the harness. Thin wires can create resistance, leading to a weak spark.

- ✓ Secure the Box: Use rubber mounting straps to isolate the CDI from engine vibrations, which can crack the internal solder joints.

- ✓ Clean the Brass Screw: Ensure the brass screw or terminal on the ignition coil is free of rust and tightened firmly to maintain a low-resistance path.

- ✓ Avoid “Racing” CDI Scams: Many cheap blue or orange “racing” CDIs actually advance the timing too far, which can damage your piston. Stick to reputable brands or OEM specifications.

- ✓ Systemic Checks: If you replace a CDI and it blows again immediately, check your voltage regulator. An over-charging stator can fry a new CDI in seconds.

When searching for replacement parts, remember that cost-saving shouldn’t come at the expense of quality. A high-quality 6-pin CDI might cost slightly more, but it will feature better potting compound (the resin inside that protects the components) and higher-grade capacitors. By combining the knowledge gained from a proper cdi box 6 pin cdi wiring diagram with consistent maintenance, you can ensure your vehicle starts reliably every time you turn the key. Whether you are dealing with a complex traveler wire issue or simply replacing a ground wire, understanding the flow of electricity is your best tool in the garage.

Frequently Asked Questions

What is a 6 pin CDI box wiring diagram?

A 6 pin CDI box wiring diagram is a schematic that illustrates the electrical connections required for an ignition system. It shows how the hot wire from the power source links to the ignition coil and trigger sensor. This diagram is essential for correctly routing signals to ensure the engine sparks consistently.

How do you read a 6 pin CDI wiring diagram?

To read the diagram, start by identifying the orientation of the 6-pin connector. Match each pin on the schematic to its corresponding terminal on the physical box. Look for labels like the traveler wire from the pickup coil or the common terminal for grounding to ensure proper circuit continuity.

What are the parts of a 6 pin CDI box?

The system includes the CDI unit, an ignition coil, a pickup/trigger sensor, and a stator or battery power source. The diagram details the hot wire for power input, a ground wire for stability, and the traveler wire that sends the ignition signal to the high-voltage coil for spark.

Why is the ground wire important?

The ground wire is critical because it completes the electrical circuit, allowing current to return to the source. Without a solid connection to the common terminal or frame, the CDI cannot discharge energy properly. This can lead to weak sparks, engine misfires, or permanent damage to the electronic unit.

What is the difference between AC and DC CDI boxes?

AC CDI boxes receive power directly from the stator’s high-voltage winding, whereas DC CDI boxes use a hot wire from the battery. While their 6-pin diagrams look similar, using the wrong type can prevent the engine from starting or cause the neutral wire return path to fail during operation.

How do I use a 6 pin CDI box wiring diagram?

Use the diagram to troubleshoot ignition failures by testing for voltage at the hot wire and continuity at the ground wire. Verify that the traveler wire from the sensor reaches the correct pin. It serves as a blueprint for replacing damaged harnesses or installing a new high-performance CDI.