6.7 Powerstroke Fuel System Diagram: Component Troubleshooting

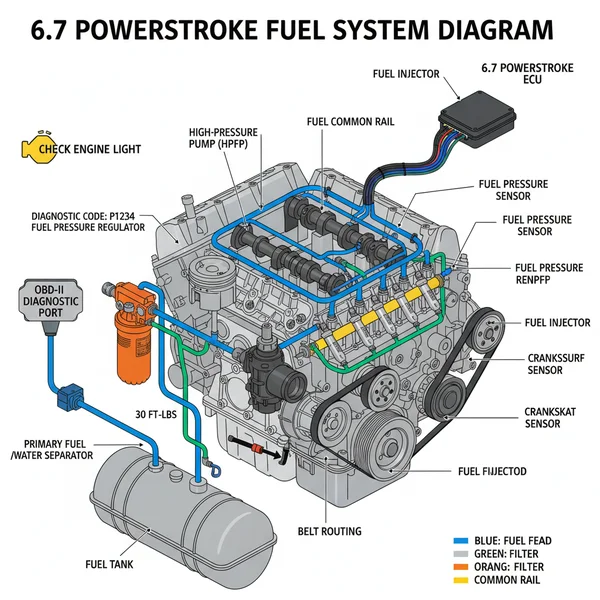

The 6.7 Powerstroke fuel system diagram illustrates the path from the fuel tank through the lift pump, filters, and high-pressure pump to the injectors. It helps identify critical sensors monitored by the ECU, allowing for faster troubleshooting when a check engine light appears or specific diagnostic codes are triggered.

📌 Key Takeaways

- Visualizes the high and low-pressure fuel flow paths

- Identifying the CP4 high-pressure pump is essential

- Never open high-pressure lines while the engine is running

- Trace leaks back to specific seals or fittings using the layout

- Ensure every filter is correctly serviced during routine maintenance

Understanding the intricate layout of the 6.7 Powerstroke fuel system diagram is essential for any Ford Super Duty owner or technician looking to maintain peak engine performance. Whether you are dealing with a sudden loss of power, a stubborn “no-start” condition, or simply performing routine maintenance, a clear visual guide helps you navigate the high-pressure common rail architecture. This article provides a comprehensive breakdown of fuel flow, component locations, and diagnostic procedures. You will learn how the low-pressure lift pump interacts with the high-pressure injection system, ensuring you have the knowledge to troubleshoot the 6.7 powerstroke fuel system diagram effectively and keep your truck on the road.

Main Diagram Description and Component Overview

The 6.7-liter Powerstroke diesel engine utilizes a sophisticated high-pressure common rail (HPCR) fuel system designed to provide precise fuel delivery for better efficiency and power. To read a 6.7 powerstroke fuel system diagram correctly, you must distinguish between the “low-pressure” side (suction and lift) and the “high-pressure” side (injection). The diagram typically illustrates the path of fuel starting from the fuel tank, moving through the frame-mounted Diesel Fuel Conditioning Module (DFCM), and up to the engine-mounted secondary filter.

The visual breakdown of this system usually employs color-coding to help the user identify different stages of fuel delivery. Blue lines often represent the low-pressure supply coming from the tank at approximately 55-70 PSI. Red lines indicate the high-pressure side, where the Bosch CP4.2 pump ramps pressures up to a staggering 30,000 PSI. Yellow or green lines represent the return circuit, which sends unused fuel back to the tank. Key components you will find on the diagram include the primary fuel filter/water separator, the secondary engine-mounted filter, the high-pressure fuel pump, the fuel rails, and the individual piezo-electric injectors.

Variations in the diagram may exist depending on the model year of your truck. While the core architecture remained consistent throughout the 6.7L production run, minor changes to line routing and connector styles occurred. Some diagrams may also include the fuel cooling circuit, which is vital because the high-pressure pump generates significant heat that must be dissipated before the fuel returns to the tank to prevent damage to the plastic tank components and the lift pump.

A detailed schematic showing the fuel path from the DFCM to the CP4.2 pump, highlighting the supply lines, return lines, and the high-pressure rails regulated by the ECU.

Step-by-Step Guide to Interpreting and Servicing the System

Interpreting a 6.7 powerstroke fuel system diagram requires a systematic approach. Follow these steps to understand the flow or to perform maintenance such as filter changes and system priming.

Step 1: Identify the Low-Pressure Source

Start your analysis at the fuel tank. The lift pump is located inside the frame-mounted DFCM. When the key is turned to the “on” position, the ECU (Engine Control Unit) sends a signal to activate this pump. The diagram shows fuel being drawn from the tank into the primary filter. This is the first line of defense against water and large particulates.

The low-pressure side must maintain a consistent pressure. If the pressure drops below 50 PSI, the high-pressure pump may experience cavitation, leading to catastrophic internal failure.

Step 2: Trace the Secondary Filtration

The fuel travels from the frame rail up to the top of the engine. Here, it enters the secondary fuel filter. This filter is a “final” stage that catches microscopic contaminants that could ruin the tight tolerances of the high-pressure pump and injectors. On your diagram, notice the small return line coming off this filter; it serves to bleed off air and return a small amount of fuel back to the tank.

Step 3: The High-Pressure Injection Pump

After the secondary filter, fuel enters the Bosch CP4.2 high-pressure pump. This pump is driven by the engine’s internal gears. While many older diesel engines used a timing chain for synchronization, the 6.7 Powerstroke uses a gear-driven setup to ensure the high-pressure pulses are perfectly timed with the piston strokes. Ensure the accessory belt is in good condition, as it drives the cooling system components that keep the pump area from overheating.

Step 4: Distribution via Fuel Rails

The diagram will show two fuel rails—one for each cylinder bank. The CP4.2 pump feeds these rails. The ECU monitors the fuel pressure through a sensor on the rail. If the pressure deviates from the target, it may trigger a check engine light. When installing or tightening these high-pressure lines, you must follow the exact torque spec provided by the manufacturer to prevent leaks or cracked fittings.

Step 5: Fuel Return and Cooling

Not all fuel delivered to the rails is injected. A significant portion is used to lubricate and cool the injectors and the high-pressure pump. This hot fuel travels through a return circuit. In many 6.7 configurations, this fuel passes through a specialized fuel-to-coolant heat exchanger. This exchanger relies on the coolant flow from the secondary cooling system to bring the fuel temperature down before it returns to the fuel tank.

Step 6: Priming the System

If you have opened the system (e.g., changed filters), you must purge the air. Do not attempt to start the engine immediately. Instead, cycle the ignition to the “on” position for 30 seconds, then off. Repeat this 6-10 times. This allows the lift pump to push air through the return lines and back to the tank, protecting the high-pressure pump from running dry.

Never crack a high-pressure fuel line while the engine is running or immediately after shutdown. The 30,000 PSI of pressure can cause serious injury or death through skin penetration.

Common Issues and Troubleshooting

When your truck exhibits symptoms like stalling or rough idling, the 6.7 powerstroke fuel system diagram becomes your primary diagnostic map. One of the most common issues is a clogged primary filter, which starves the high-pressure pump. You can diagnose this by connecting an OBD-II scanner to the vehicle and checking for a diagnostic code such as P0087 (Fuel Rail Pressure – Too Low).

If the check engine light illuminates, always start by checking the low-pressure supply. Use the diagram to locate the test ports on the secondary filter housing. If pressure is within spec but the truck won’t start, the issue may lie within the high-pressure pump or the volume control valve (VCV). Another frequent failure point is the contamination of the system with Water-in-Fuel (WIF). If the WIF light comes on, the diagram helps you locate the drain valve on the DFCM to purge the water before it reaches the expensive injectors.

Tips and Best Practices for Maintenance

To ensure the longevity of your fuel system, follow these professional recommendations. The 6.7 Powerstroke is a robust engine, but its fuel system is highly sensitive to debris and poor-quality diesel.

- ✓ Use OEM Filters Only: Always use Motorcraft filters. Aftermarket filters often have inferior micron ratings or fitment issues that can allow contaminants to bypass the media.

- ✓ Drain the Water Separator Monthly: Don’t wait for the dashboard light. Regularly draining a small amount of fuel from the DFCM can prevent long-term corrosion.

- ✓ Monitor the Cooling System: Since fuel temperature is regulated by the secondary cooling system, ensure your coolant flow is unobstructed and levels are topped off.

- ✓ Use Fuel Additives: High-quality lubricity additives can help protect the CP4.2 pump from the “dry” nature of modern Ultra-Low Sulfur Diesel (ULSD).

If you suspect a high-pressure pump failure, remove the VCV (Volume Control Valve) on top of the pump and inspect for metal shavings. If sparkles are present, the entire fuel system (including rails and injectors) likely needs replacement.

By following the 6.7 powerstroke fuel system diagram and maintaining a rigorous service schedule, you can avoid the most costly repairs associated with this platform. Understanding how the ECU manages pressure and how the physical components like the accessory belt and cooling circuits support the fuel system will make you a much more effective DIY mechanic or informed truck owner. Always keep your OBD-II scanner handy and refer back to your diagnostic codes to catch small problems before they become engine-ending catastrophes.

Frequently Asked Questions

What is a 6.7 Powerstroke fuel system diagram?

A visual map showing how diesel flows through the 6.7L engine. It details the connection between the primary and secondary filters, the lift pump, and the high-pressure fuel rails. Technicians use this layout to understand how the ECU manages pressure and where sensors are located for electronic monitoring.

How do you read a 6.7 Powerstroke fuel system diagram?

Start at the fuel tank and follow the flow arrows through the low-pressure lines to the filters. Continue to the high-pressure pump and fuel rails leading to the injectors. Look for labels indicating sensors that feed data to the OBD-II system, helping you interpret various engine performance metrics.

What are the parts of the 6.7 Powerstroke fuel system?

The system includes the fuel tank, lift pump, primary and secondary fuel filters, and the high-pressure CP4 pump. It also features common rails, fuel injectors, and return lines. Various sensors monitor pressure and temperature, sending real-time data to the vehicle’s ECU to ensure efficient and clean combustion.

Why is the fuel pressure sensor important?

The fuel pressure sensor is critical because it monitors the high-pressure rail’s status. If the pressure deviates from the setpoint, the ECU will trigger a check engine light. This sensor provides the specific diagnostic code needed to determine if the pump, injectors, or regulator are starting to fail.

What is the difference between the low and high-pressure sides?

The low-pressure side delivers fuel from the tank to the high-pressure pump using a lift pump and filters. The high-pressure side, managed by the CP4 pump, increases pressure significantly for direct injection. Distinguishing these helps when diagnosing a specific diagnostic code related to fuel delivery or pressure.

How do I use a 6.7 Powerstroke fuel system diagram?

Use the diagram to locate specific components during repairs or part replacements. It is invaluable for identifying the correct torque spec for fittings and locating sensors when a check engine light occurs. Referencing the map ensures you do not miss hidden connections or bypass critical filtration points.