5.7 Vortec Wiring Harness Diagram: Troubleshooting Guide

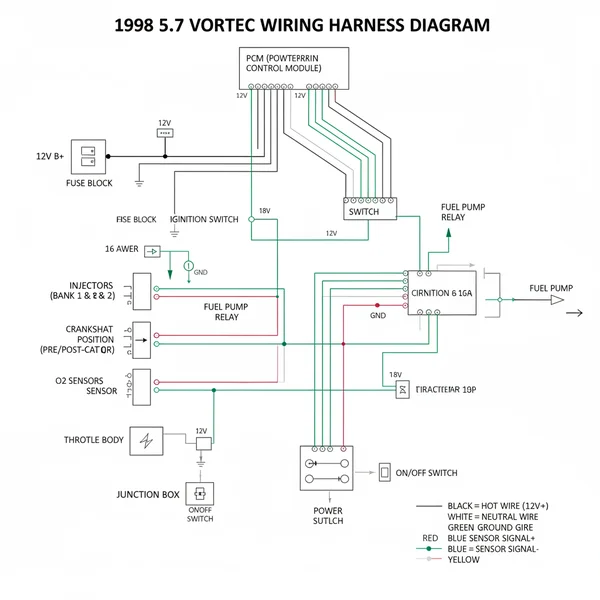

The 5.7 Vortec wiring harness diagram provides a visual map for the PCM, fuel injectors, and ignition system. It helps technicians identify the hot wire for power distribution, the ground wire for circuit completion, and the traveler wire signals that communicate critical sensor data for optimal engine performance and diagnostics.

📌 Key Takeaways

- Mapping the PCM connection to engine sensors

- Identifying the main fuse block power source

- Locating critical grounding points for signal stability

- Differentiating between power and data signal lines

- Troubleshooting no-start conditions using electrical paths

Finding the correct 1998 5.7 vortec wiring harness diagram is often the most challenging part of a restoration or engine swap project. Whether you are troubleshooting a stubborn misfire in your Chevrolet Silverado or transplanting the legendary L31 engine into a custom build, understanding how the wires interact with the Powertrain Control Module (PCM) is vital. This comprehensive guide breaks down the complex web of sensors, connectors, and power distributions that make up the 1998 5.7 Vortec electrical system. Having a precise diagram allows you to identify specific circuits, prevent accidental shorts, and ensure that every sensor—from the Mass Air Flow (MAF) to the oxygen sensors—receives the correct signal. By the end of this article, you will have a professional-grade understanding of how to read, interpret, and repair your Vortec harness.

Understanding the 1998 5.7 Vortec Wiring Layout

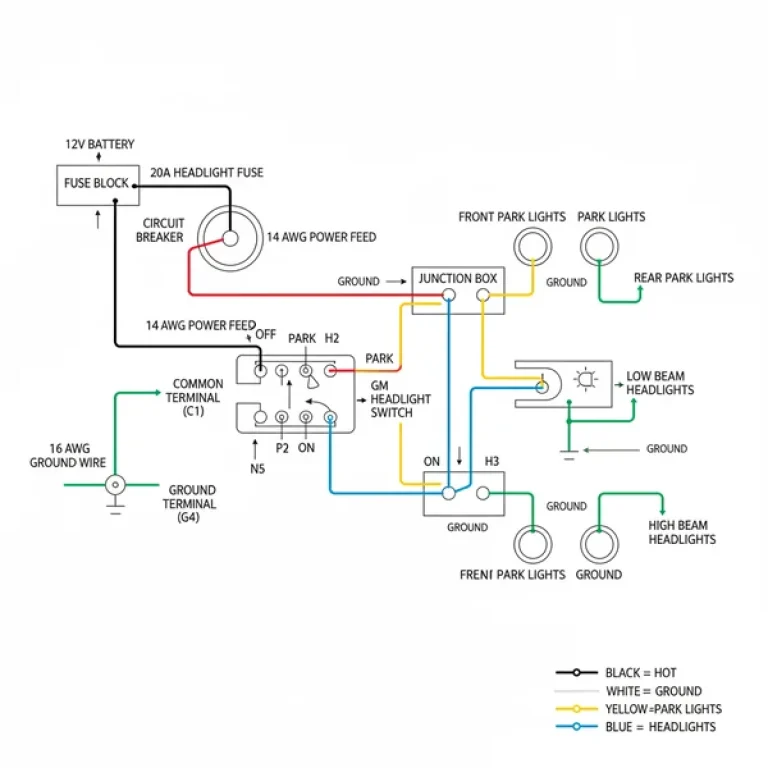

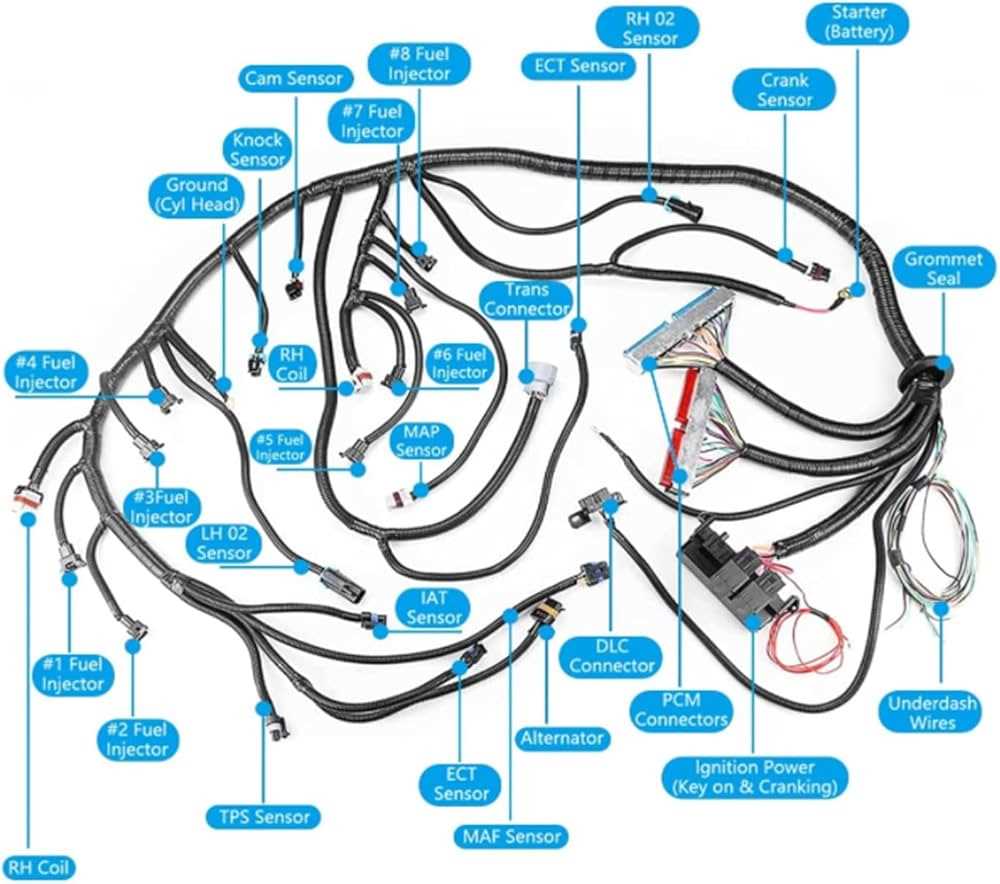

The 1998 5.7 Vortec wiring harness is a sophisticated network designed to support the Sequential Central Port Injection (SCPI) system. Unlike earlier TBI systems, this harness handles a significant amount of data to manage fuel trim and ignition timing with high precision. At the heart of the system is the PCM, which features two large 80-pin connectors, typically referred to as the “Blue” and “Black” (or clear) connectors. These serve as the common terminal for nearly every signal generated by the engine’s sensors.

When looking at the diagram, you will notice the layout is divided into several sub-harnesses. The primary branch feeds the ignition system, including the crankshaft position sensor (CKP) and the camshaft position sensor (CMP), which are critical for synchronization. A secondary branch handles the fuel delivery, connecting to the central injector pod located under the intake plenum. In many custom applications, users may add secondary lighting or accessories; in these cases, a traveler wire might be referenced when using three-way switching for interior or bed lights, although this is more common in residential-style auxiliary wiring.

Visualizing the diagram involves identifying the “Hot” circuits, usually represented by red or pink wires, which provide 12V power from the under-hood fuse block. The “Neutral” or return paths in this DC system are strictly ground-based, typically using black or black/white wires. Each sensor connector is color-coded to prevent confusion: for instance, the Engine Coolant Temperature (ECT) sensor usually features a yellow and black pair, while the Throttle Position Sensor (TPS) uses a 5-volt reference, signal, and ground.

The 1998 model year is unique because it was the final year of the classic C/K truck body style while utilizing the fully evolved Vortec engine management. This makes the 1998 5.7 vortec wiring harness diagram specific to this year, as 1999 saw the introduction of the LS-based 5.3L engines in many models.

Step-by-Step Guide to Interpreting and Installing the Harness

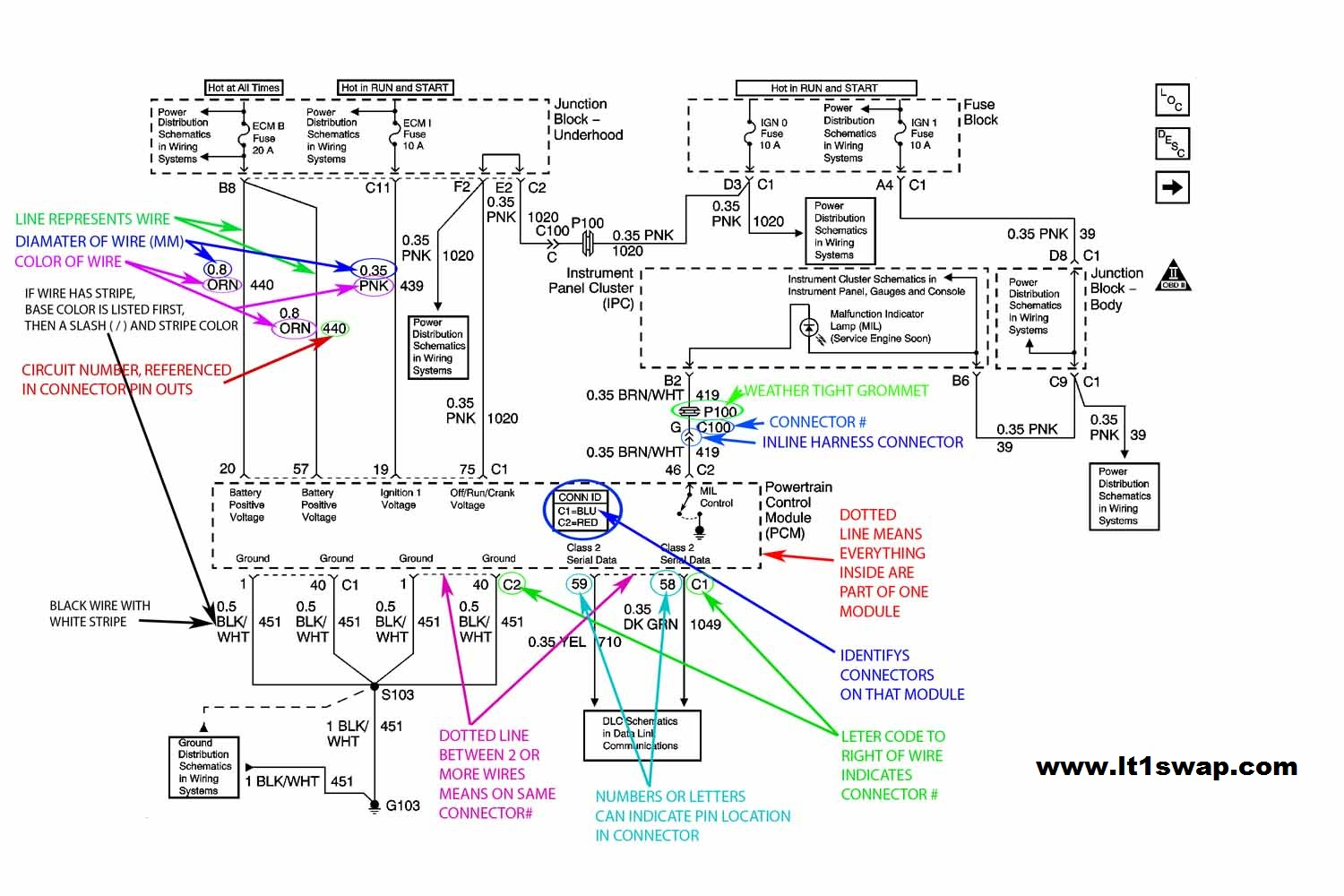

Interpreting an automotive wiring diagram can feel like reading a foreign language. However, by following a systematic approach, you can master the 1998 5.7 Vortec system without professional help.

- ✓ Step 1: Identify the Power Source (Hot Wire) – Begin by locating the main battery feed. In the 1998 Vortec system, the “hot wire” is usually a heavy-gauge red wire that connects to the starter solenoid or a power distribution block. Use a multimeter to verify 12 volts are present when the ignition is in the ‘On’ position.

- ✓ Step 2: Map the Grounding Points – Automotive systems rely on a solid ground wire to complete the circuit. Ensure the harness is grounded to the engine block, the frame, and the firewall. A common mistake is forgetting the ground strap at the rear of the cylinder head, which can cause phantom sensor readings.

- ✓ Step 3: Locate the Common Terminal/PCM Connectors – All sensor signals travel back to the PCM. Locate the blue and black connectors and verify that the pins are clean and free of corrosion. Refer to your pinout diagram to ensure that the correct wire gauge is used for signal wires (usually 18-22 gauge) versus power wires (10-14 gauge).

- ✓ Step 4: Check the 5-Volt Reference Circuit – Many sensors (TPS, MAP, MAF) share a 5-volt reference signal. If this circuit is shorted to ground, the entire engine will fail to start or run in “limp mode.” Check the voltage at the brass screw terminals of any aftermarket sensors or at the connector pins.

- ✓ Step 5: Trace the Traveler Wire for Accessories – If you are modifying the harness for a swap, you may need to run a “traveler wire” from a cabin switch to a relay in the engine bay. This allows you to control auxiliary fans or fuel pumps through the main harness loom safely.

- ✓ Step 6: Connect the Fuel Injector Harness – The 5.7 Vortec uses a unique 16-pin connector for the internal injector spider. Carefully seat this connector and ensure the locking tab clicks. This is a common point of failure for cylinder-specific misfires.

- ✓ Step 7: Final Continuity Testing – Before applying full power, use your diagram to perform a continuity test between the sensor ends and the PCM pins. This ensures no wires were pinched or crossed during installation.

Always disconnect the negative battery terminal before working on the wiring harness. Even a momentary short in a 5V reference wire can permanently damage the PCM internal circuitry.

Common Issues and Troubleshooting

The 1998 5.7 Vortec wiring harness is generally robust, but age and heat can take their toll. One of the most frequent problems users encounter is “heat soak” or brittle insulation near the exhaust manifolds. This often leads to exposed wires that can ground out against the block, causing intermittent stalling or blown fuses.

Another common issue involves the VATS (Vehicle Anti-Theft System). If your harness is from a donor vehicle, the PCM might be looking for a specific signal from the ignition cylinder. Without this, the engine will start for two seconds and then die. Using your 1998 5.7 vortec wiring harness diagram, you can identify the security signal wire to either bypass the system or integrate the correct resistance.

If you experience “ghost” codes for multiple sensors simultaneously, check the main ground wire at the thermostat housing. This is a common terminal for multiple sensor grounds, and corrosion here can wreak havoc on sensor voltage readings.

Watch for signs of “green crust” (corrosion) inside the connectors. This increases resistance, which drops the voltage and sends incorrect data to the PCM. If you see this, use a dedicated electrical contact cleaner and a small brass brush to restore conductivity.

Best Practices for Harness Maintenance and Repair

When repairing or modifying your 1998 5.7 Vortec harness, quality should be your top priority. Always use automotive-grade TXL wire, which is designed to withstand high engine bay temperatures. Standard primary wire from a hardware store often has a lower-quality insulation that can melt or crack over time.

- Use Proper Wire Gauge: Never downsize a wire. If the diagram specifies a 14-gauge wire for a fuel pump feed, using a 18-gauge wire will cause a voltage drop and potentially start a fire.

- Soldering vs. Crimping: While many DIYers prefer soldering, a high-quality “ratcheting” crimp with heat-shrink tubing is often more durable in high-vibration automotive environments.

- Labeling: As you disassemble or trace the harness, use masking tape or dedicated wire labels to mark every “hot wire” and “neutral” return. This saves hours of frustration during reassembly.

- Heat Shielding: Use split-loom tubing or braided sleeving to protect the harness. In areas near the headers, use reflective heat tape to ensure the internal wires stay within their operating temperature range.

Maintaining your electrical system is a cost-effective way to ensure your vehicle lasts another 100,000 miles. A well-organized harness not only looks professional but also makes future troubleshooting significantly easier. By referring back to your 1998 5.7 vortec wiring harness diagram regularly, you can keep your engine running at peak performance.

In conclusion, mastering the wiring of a 1998 5.7 Vortec is a rite of passage for many truck enthusiasts. By understanding the relationship between the power distribution, the sensor signals, and the grounding points, you take full control over your vehicle’s reliability. Whether you are identifying a traveler wire for a custom circuit or cleaning a common terminal to fix a sensor error, the technical knowledge gained here is invaluable. Keep your diagrams handy, use the right tools, and always prioritize electrical safety.

Frequently Asked Questions

What is a 5.7 Vortec wiring harness diagram?

This diagram is a schematic representation of the electrical system for the 5.7L Vortec engine. It details how the powertrain control module (PCM) connects to various sensors and actuators. It identifies every hot wire and ground wire, ensuring users can navigate the complex web of engine electronics without causing shorts or damage.

How do you read a 5.7 Vortec wiring harness diagram?

To read the diagram, start by locating the common terminal points or the PCM at the center. Follow the lines representing wires to their specific connectors, such as injectors or sensors. Pay attention to color codes and symbols that distinguish between a traveler wire for signals and standard power or neutral wire connections.

What are the parts of a 5.7 Vortec wiring harness?

The harness consists of the main trunk, branch connectors for sensors like the MAF or O2, and the fuse block interface. It includes power lines, a hot wire for constant 12V, a ground wire for chassis bonding, and specific pins for the common terminal on relays that power the fuel systems.

Why is a ground wire important?

The ground wire is critical because it provides the return path for electrical current to the battery. Without a solid ground, sensors may provide erratic readings, and components like the fuel pump might fail to activate. Ensuring a clean connection to the chassis prevents high resistance and potential electrical circuit interference.

What is the difference between a hot wire and traveler wire?

A hot wire provides constant 12V power to engine components from the battery. A traveler wire carries variable data signals between sensors and the PCM. Unlike AC systems with a neutral wire, automotive systems use the chassis as the return, but the diagram often labels specific low-side return paths for signal clarity.

How do I use a 5.7 Vortec wiring harness diagram?

Use the diagram to troubleshoot electrical faults by tracing continuity from the source to the component. Identify the common terminal on the relay or fuse box and use a multimeter to check for voltage on the hot wire. Verify the ground wire integrity to ensure the circuit completes properly for each sensor.