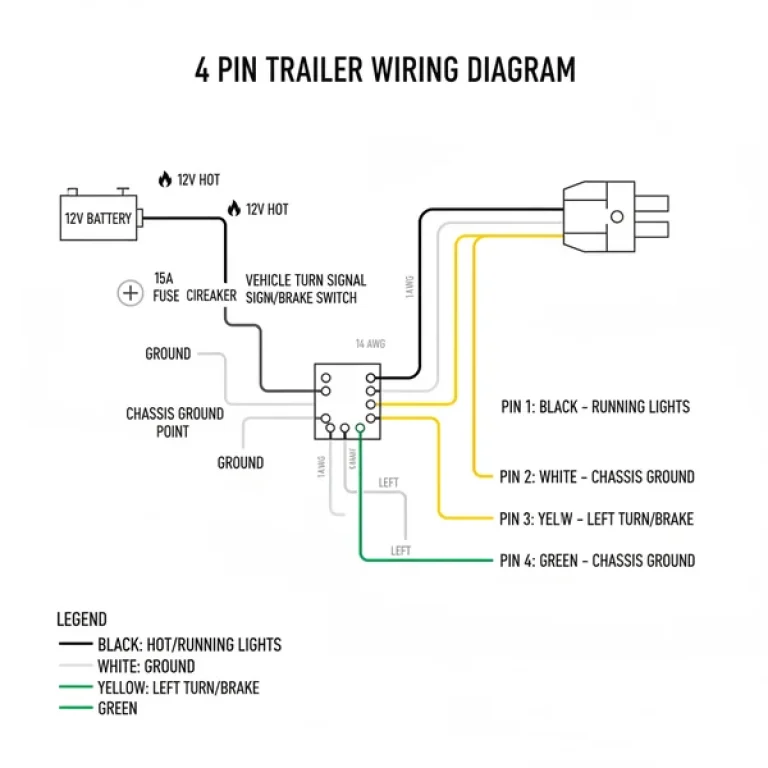

4 Wire Trailer Wiring Diagram: Easy Installation Guide

A 4 wire trailer wiring diagram illustrates connections for a standard flat-four plug, managing tail lights, turn signals, and brake lights. The white ground wire connects to the frame, while the brown hot wire controls running lights. Yellow and green wires act as a traveler wire system for left and right signals.

📌 Key Takeaways

- White wire always serves as the dedicated ground connection

- Brown wire powers all running and tail light functions

- Yellow and green wires handle independent left and right signals

- A secure common terminal connection prevents light flickering

- Standard color coding ensures compatibility across most trailer brands

Navigating the complexities of vehicle electronics can be daunting, but mastering a 4 wire trailer wiring diagram is an essential skill for any DIY enthusiast or trailer owner. This comprehensive guide is designed to provide you with a clear, visual, and technical understanding of how to connect your vehicle’s lighting system to your trailer effectively. By the end of this article, you will be able to identify each specific wire by its color code, understand the role of the ground wire, and ensure your trailer operates safely on the road. Whether you are installing a new harness or troubleshooting an old one, having the correct 4 wire trailer wiring diagram ensures that your brake lights, turn signals, and running lights function in perfect synchronization with your tow vehicle.

A standard 4-way flat connector is the most common interface for light-duty trailers. It carries four essential functions: ground, tail lights, left turn/brake, and right turn/brake. Understanding this configuration is the first step toward a safe towing experience.

Decoding the 4 Wire Trailer Wiring Diagram

The 4 wire trailer wiring diagram serves as the universal blueprint for light-duty towing. In this system, each of the four wires is color-coded to prevent confusion during installation. The four colors you will encounter are white, brown, yellow, and green. Unlike complex residential wiring that might involve a traveler wire or a common terminal on a 3-way switch, trailer wiring is a direct-current (DC) system that relies on a straightforward path from the battery to the lamps.

The white wire is arguably the most important element in the diagram; it represents the ground wire. In the world of 12V DC electronics, every circuit must return to the negative terminal of the battery to complete the loop. The brown wire is dedicated to the tail lights or “running lights,” which remain illuminated whenever your vehicle’s headlights are on. The yellow wire controls the left-side turn signal and brake light, while the green wire manages the right-side turn signal and brake light.

It is important to note that in a 4-way flat system, the turn signal and brake functions share the same wire for each side. This is achieved through the vehicle’s wiring harness, which pulses the voltage for turns and provides a steady 12V signal for braking. If your vehicle has separate bulbs for turn signals and brakes (common in many modern vehicles), you may require a tail light converter to properly adapt your vehicle’s output to the 4-wire trailer standard.

– 4 Wire Trailer Wiring Standard Configuration

Understanding Electrical Concepts: From Households to Trailers

While this guide focuses on trailers, many users often confuse trailer terms with residential electrical components. In a home’s AC system, you might deal with a neutral wire, a traveler wire, or a common terminal on a switch. However, in a 12V DC trailer system, these concepts shift slightly. For instance, the neutral wire in a home provides a return path for current, much like the white ground wire does in your trailer. However, a trailer’s ground wire is usually connected directly to the metal frame of the trailer to use it as a massive conductor.

Similarly, while you won’t find a brass screw on a plastic trailer plug, you will find them inside older metal junction boxes. The brass screw is traditionally used to identify the hot wire connection in AC outlets, but in the context of trailers, it is vital to remember that any wire carrying voltage (the brown, yellow, and green wires) acts as a hot wire when the corresponding light is activated. Keeping your gauge measurements consistent—usually 16 to 18 gauge for standard trailers—ensures that the voltage remains stable over the length of the vehicle without overheating the wires.

Step-by-Step Installation Guide

Installing or repairing your harness using a 4 wire trailer wiring diagram requires precision and the right tools. Follow these steps to ensure a professional-grade connection that withstands weather and vibration.

- ✓ Step 1: Preparation and Tool Gathering. Collect your tools, including a wire stripper, crimping tool, heat-shrink tubing, and a multimeter. Ensure your wire gauge matches the existing harness to maintain consistent electrical resistance.

- ✓ Step 2: Identify the Vehicle Wires. Using your multimeter, test the wires on your tow vehicle. Have an assistant press the brakes, activate the turn signals, and turn on the running lights while you probe for 12V voltage. This confirms which vehicle wire corresponds to the colors on your diagram.

- ✓ Step 3: Establish a Solid Ground. Secure the white ground wire to a clean, unpainted metal surface on the trailer frame. Use a self-tapping screw and a ring terminal. A poor ground is the cause of 90% of trailer lighting failures.

- ✓ Step 4: Connect the Tail Lights. Splice the brown wire from your plug to the wires running to both the left and right tail light assemblies. This wire provides the low-intensity “running” light function.

- ✓ Step 5: Connect the Signal Wires. Connect the yellow wire to the left side’s high-intensity filament and the green wire to the right side’s high-intensity filament. These handle both braking and turning.

- ✓ Step 6: Seal and Protect. Use heat-shrink tubing or liquid electrical tape on every connection. Trailers are constantly exposed to water, salt, and road debris, making waterproof seals non-negotiable.

- ✓ Step 7: Final Function Test. Plug the trailer into the vehicle and perform a “walk-around” test. Ensure the left turn signal doesn’t blink when you hit the right signal, and that the tail lights stay on when the headlights are engaged.

Always disconnect the vehicle’s battery or unplug the harness before cutting or splicing wires to avoid short circuits. Even 12V systems can cause sparks or damage sensitive vehicle computers if a hot wire touches the frame.

Deep Dive into Wire Gauge and Voltage Drop

When studying a 4 wire trailer wiring diagram, the physical properties of the wire are just as important as the colors. The “gauge” refers to the thickness of the copper conductor inside the insulation. For most standard utility trailers, 16-gauge wire is sufficient. However, if you are pulling a very long trailer, such as a boat trailer or a flatbed, you might encounter “voltage drop.” This occurs when the length of the wire creates enough resistance to lower the voltage reaching the lights, resulting in dim LEDs or flickering bulbs.

In these cases, upgrading to a 14-gauge wire for the ground wire and tail light circuit can help maintain a steady 12V signal. Since the ground wire carries the return current for all three other circuits combined, it is the most common bottleneck for electrical flow. Ensuring your ground has a clear path with minimal resistance is equivalent to ensuring a “common terminal” in a home switch box is properly tightened; without it, the circuit simply cannot complete its journey.

Common Issues & Troubleshooting

Even with a perfect 4 wire trailer wiring diagram, issues can arise due to environmental wear and tear. One of the most frequent problems is “feedback,” where turning on the left signal causes all the lights on the trailer to blink faintly. This is almost always a sign of a bad ground wire. If the current cannot return through the white wire, it will try to find a path through the other filaments, causing erratic behavior.

Another common issue involves the “hot wire” making contact with the trailer frame. This usually happens where the wire passes through a hole in the metal. If the insulation rubs away, it creates a short circuit that will immediately blow the fuse in your tow vehicle. If you find yourself constantly replacing fuses, check the entire length of your harness for pinched wires or exposed copper. Finally, if one side of the trailer is completely dark, use your multimeter to check the voltage at the vehicle’s plug. If the vehicle side is dead, the problem lies in the car’s fuses or the tail light converter rather than the trailer itself.

Apply a small amount of dielectric grease to the terminals of your 4-way plug. This specialized grease prevents corrosion and keeps moisture out, ensuring a clean connection every time you hitch up your trailer.

Tips & Best Practices for Long-Term Maintenance

Maintaining your trailer’s electrical system doesn’t have to be a chore. One of the best practices is to use tinned copper wire if you frequently tow near saltwater. Tinned wire resists the “green rot” corrosion that can travel up the inside of a wire’s insulation, effectively killing the conductor from the inside out. Furthermore, always secure your wiring harness with UV-resistant zip ties every 12 to 18 inches along the trailer frame. This prevents the wires from sagging and catching on road debris.

When it comes to component recommendations, always opt for LED lighting upgrades. LEDs pull significantly less amperage than traditional incandescent bulbs. This reduces the load on your vehicle’s electrical system and minimizes the heat generated at the connection points. Because they require less current, LEDs are also less susceptible to the negative effects of minor voltage drops. Finally, keep a spare 4-way flat extension in your glove box. If your main harness is damaged during a trip, an extension can often serve as a temporary bridge to get your lights working quickly so you can reach your destination safely.

Conclusion: Mastery of the 4-Wire System

A 4 wire trailer wiring diagram is more than just a map of colors; it is the key to ensuring your safety and the safety of everyone on the road. By understanding the relationship between the ground wire, the various signal wires, and the technical requirements of voltage and gauge, you transform a confusing mess of cables into a reliable lighting system. Remember that the white wire is your foundation, the brown wire is your visibility, and the green and yellow wires are your communication tools with other drivers. Whether you are dealing with a traveler wire in your home or a tail light harness on your boat trailer, the principles of solid connections and proper grounding remain universal. Keep your connections dry, your grounds clean, and your diagrams handy, and you will enjoy years of trouble-free towing.

- White: Ground (Connect to Frame)

- Brown: Tail & Running Lights

- Yellow: Left Turn & Brake

- Green: Right Turn & Brake

- Standard Gauge: 16 AWG

Frequently Asked Questions

What is 4 wire trailer wiring diagram?

It is a visual schematic showing how to connect a vehicle’s electrical system to a trailer using a four-pin connector. It typically identifies the white ground wire, the brown tail light lead, and the yellow and green signal wires. This diagram ensures that the trailer lights synchronize perfectly with the towing vehicle’s controls.

How do you read 4 wire trailer wiring diagram?

To read the diagram, match the color-coded lines to the pins on the connector. The white line represents the ground wire, while brown indicates the running lights. Green and yellow represent the right and left turn/brake signals. Treat these signal lines as a traveler wire set that carries power from the vehicle.

What are the parts of 4 wire trailer wiring?

The system consists of a four-pin flat plug, color-coded wiring, and the light fixtures. The primary components include the white ground wire for completing the circuit, the brown hot wire for tail lights, and the green and yellow wires for directional signals. Each wire leads to a specific common terminal or fixture.

Why is the ground wire important?

The ground wire is critical because it provides a return path for the electrical current back to the battery. Without a solid connection to a common terminal or the trailer frame, the lights will flicker, dim, or fail. It serves as the DC equivalent of a neutral wire in AC systems.

What is the difference between 4-wire and 5-wire setups?

A 4-wire setup handles basic tail, brake, and turn functions using one hot wire for running lights and two signal wires. A 5-wire system adds a blue wire, often used for hydraulic surge brakes to prevent engagement while reversing. The 4-wire version is the most common for standard utility trailers.

How do I use 4 wire trailer wiring diagram?

Use the diagram to identify which wire connects to each light function during installation. Start by grounding the white wire to the frame. Then, use the diagram to route each traveler wire to the appropriate left and right light housing. Always verify connections with a circuit tester to ensure power delivery.