350 TBI 5.7 TBI Vacuum Diagram: Routing and Repair Guide

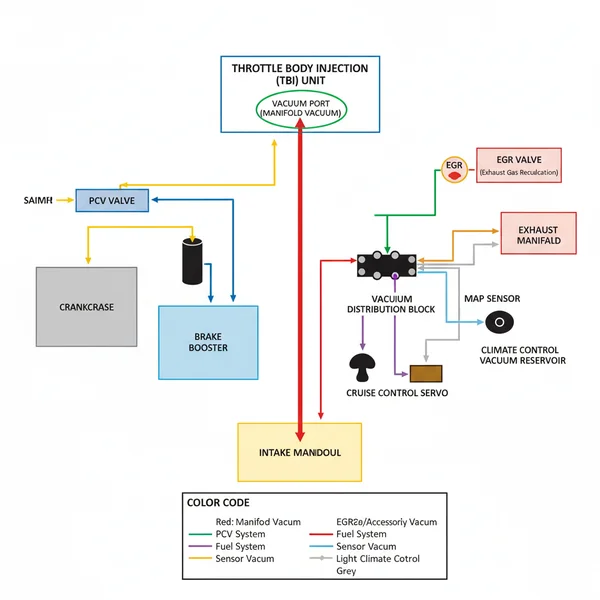

A 350 TBI 5.7 TBI vacuum diagram illustrates the precise routing of hoses between the throttle body, MAP sensor, and EGR valve. This layout ensures the vacuum system maintains proper pressure, preventing rough idling and emissions failures by outlining the correct configuration for every critical engine component and hose.

📌 Key Takeaways

- Identifies the specific routing for emission control and engine performance

- The MAP sensor is the most critical vacuum-linked component for fuel timing

- Always check for brittle or cracked hoses to prevent vacuum leaks

- Use the diagram to verify the PCV valve and EGR valve connections

- Essential for engine rebuilds or diagnosing a rough idle

Navigating the complexities of a vintage engine restoration or maintenance project requires precision, especially when dealing with the vacuum system of the legendary General Motors small-block engine. If you are working on a classic truck or passenger car, finding an accurate 350 tbi 5.7 tbi vacuum diagram is the first step toward achieving a smooth idle and optimal fuel efficiency. This comprehensive guide provides a detailed breakdown of the vacuum hose routing, component locations, and system configuration. You will learn how to identify manifold vacuum sources, understand the role of various sensors, and troubleshoot common leaks that plague these Throttle Body Injection systems. By the end of this article, you will have the knowledge needed to restore your engine’s vacuum integrity to factory specifications.

Understanding the 350 TBI 5.7 TBI Vacuum System Layout

The vacuum system in a 5.7-liter Throttle Body Injection engine is a sophisticated network designed to manage emissions, engine timing, and accessory functions. Unlike modern vehicles that rely almost entirely on electronic actuators, the TBI system uses physical pressure differentials to move valves and signal sensors. The central hub of this configuration is the throttle body itself, which sits atop the intake manifold. This unit features several vacuum ports, typically labeled with letters or numbers, each serving a specific purpose based on whether it provides constant manifold vacuum or “ported” vacuum, which only occurs when the throttle blades are open.

Most 5.7 TBI engines feature three main vacuum sources on the throttle body: a large port for the PCV valve, a medium port for the charcoal canister, and several smaller ports for the MAP sensor and EGR solenoid. Knowing which port is “timed” versus “full” is critical for proper engine timing.

The structure of the vacuum system can be divided into three primary subsystems: the emissions control loop, the engine management circuit, and the auxiliary accessories. The emissions loop includes the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission (EVAP) canister. The engine management circuit is dominated by the Manifold Absolute Pressure (MAP) sensor, which is the “brain” of the TBI system, telling the computer how much load the engine is under. Finally, the auxiliary lines handle tasks like power brakes, cruise control, and the heating and air conditioning (HVAC) door actuators. Variations in this layout occur depending on whether the vehicle is a light-duty truck, a heavy-duty van, or a passenger car, but the core principles of the 350 tbi 5.7 tbi vacuum diagram remains consistent across the platform.

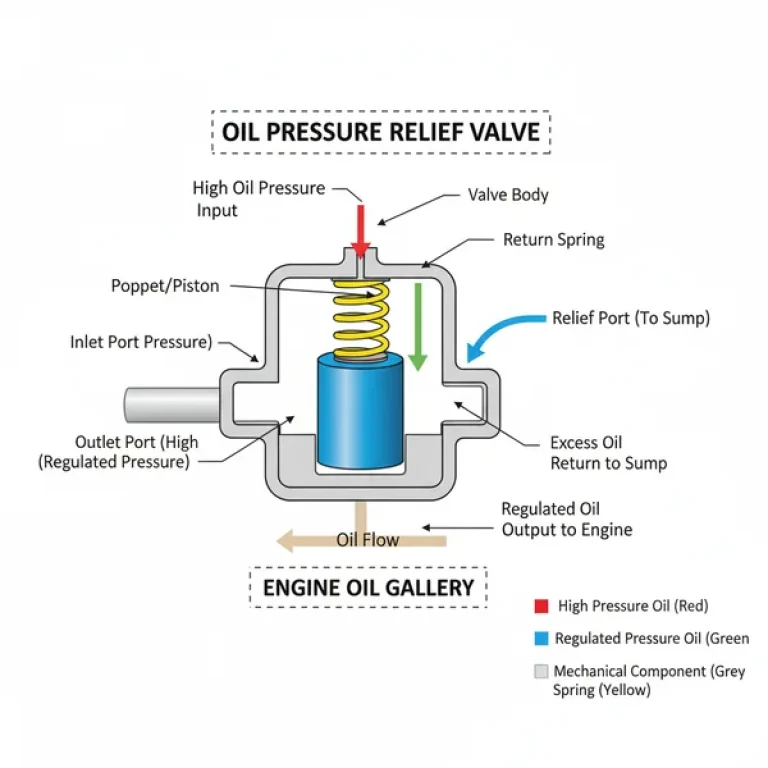

[DIAGRAM_PLACEHOLDER: A detailed 2D technical illustration of a 5.7 TBI throttle body showing ports labeled A, B, J, and T. Lines connect to a MAP sensor on the firewall, an EGR valve via a solenoid, a PCV valve in the valve cover, and a charcoal canister. Labels use high-contrast text.]

Step-by-Step Guide to Interpreting and Installing Vacuum Lines

Replacing or repairing vacuum lines on a 350 TBI engine requires a methodical approach. Because many of these engines are decades old, the original plastic lines often become brittle and crack, leading to mysterious “check engine” lights or poor performance. Follow these steps to ensure your system is configured correctly according to the 350 tbi 5.7 tbi vacuum diagram.

- Identify Your Vacuum Ports: Begin by cleaning the throttle body with a dedicated cleaner so you can see the stamped letters near the vacuum nipples. Port “A” usually goes to the EVAP canister. Port “J” is often used for the EGR solenoid. The large port at the rear or side is strictly for the Positive Crankcase Ventilation (PCV) system.

- Gather Necessary Tools and Materials: You will need several feet of high-quality vacuum hose (usually 5/32″ and 7/32″ diameters), a sharp hose cutter or utility knife, and a vacuum pump tester to verify component integrity. Avoid using generic fuel lines, as they can collapse under high vacuum pressure.

- Map the MAP Sensor: Locate the MAP sensor, typically mounted on a bracket on the passenger side of the firewall or intake manifold. This component MUST have a dedicated, leak-free line connecting directly to a manifold vacuum source. If this line leaks, the engine will run extremely rich and may blow black smoke.

- Route the EGR Circuit: The EGR valve is located at the back of the intake manifold. A line runs from the throttle body to a small electrical solenoid, and then a second line runs from the solenoid to the EGR valve. This ensures the valve only opens when the engine is warm and at cruising speeds.

- Connect the PCV and Power Brake Booster: These are the two largest vacuum consumers. The PCV valve sits in the driver-side valve cover and pulls gases into the throttle body. The power brake booster connects to a large fitting directly on the intake manifold (usually behind the TBI unit) to provide braking assistance.

- Address the Charcoal Canister: Locate the EVAP canister near the radiator support or fender well. Connect the “Tank” line to the fuel tank vapor line and the “Control” line back to the specified port on the throttle body as indicated in your 350 tbi 5.7 tbi vacuum diagram.

- Check for Accessory Leaks: If your HVAC vents only blow out of the defroster regardless of the setting, you likely have a leak in the small plastic line that runs through the firewall. Ensure this line is connected to the vacuum reservoir (the “ball”) and then to the manifold.

Never cap off the MAP sensor port. The engine computer depends on this signal to calculate fuel delivery. Running the engine with a disconnected or plugged MAP line can cause severe engine washing, where excess fuel thins the oil and damages internal bearings.

Common Issues and Troubleshooting the TBI System

Vacuum leaks are the most frequent cause of frustration for 5.7 TBI owners. Because the system relies on a specific balance of air and fuel, any “unmetered” air entering the system through a cracked hose or failed gasket will cause the computer to compensate incorrectly. Common symptoms include a high idle that won’t come down, a “hunting” idle where the RPMs surge up and down, or a hesitation when you step on the gas pedal.

To troubleshoot, use the 350 tbi 5.7 tbi vacuum diagram to trace each line. A professional method involves using a smoke machine to pump thick smoke into the intake; any wisps of smoke escaping will point directly to the leak. Alternatively, you can spray a small amount of throttle body cleaner around suspected leak areas while the engine is idling. If the RPMs change suddenly, you have found your leak. Pay close attention to the TBI base gasket, which is a notorious failure point on these engines. Over time, the heat from the engine causes the gasket to shrink or crack, allowing air to bypass the throttle blades entirely.

- ✓ Rough Idle: Often caused by a cracked PCV hose or a leaking EGR valve that is stuck open.

- ✓ Poor Gas Mileage: Likely a disconnected MAP sensor or a faulty EVAP purge solenoid.

- ✓ Brake Pedal Hardness: Indicates a failure in the large vacuum line going to the brake booster.

Maintenance Tips and Best Practices

Maintaining the integrity of your vacuum system is a low-cost way to ensure your 5.7 TBI engine lasts for hundreds of thousands of miles. One of the best upgrades you can perform is replacing the factory plastic and rubber lines with silicone vacuum hoses. Silicone is much more resistant to the extreme heat cycles found in the engine bay and will not become brittle or crack like standard rubber. While the initial cost is slightly higher, the peace of mind is well worth the investment.

When replacing lines, do them one at a time. This prevents you from getting confused about which line goes to which port. Label each new line with a small piece of masking tape corresponding to the labels on your 350 tbi 5.7 tbi vacuum diagram.

Additionally, keep the vacuum ports on the throttle body clean. Over time, carbon deposits from the PCV and EGR systems can clog the tiny orifices inside the TBI unit. Every two years, remove the vacuum hoses and use a thin wire or a specialized carb-cleaning tool to ensure the ports are clear. This ensures that sensors like the MAP and components like the EGR receive a strong, clear signal. Finally, always ensure that your air cleaner assembly is properly seated. Many TBI engines have vacuum-operated “thermac” doors in the air cleaner snorkel that help the engine warm up; if these lines are disconnected, your cold-start drivability will suffer significantly. Following the 350 tbi 5.7 tbi vacuum diagram during every tune-up will keep your classic GM powerplant running as smooth as the day it left the assembly line.

Frequently Asked Questions

What is a 350 TBI 5.7 TBI vacuum diagram?

It is a visual map showing the structure and routing of vacuum lines for the 5.7L Throttle Body Injection engine. This configuration details how vacuum pressure flows between the engine intake and components like the brake booster and EGR valve, ensuring the entire system operates efficiently and stays within emissions.

How do you read a 350 TBI 5.7 TBI vacuum diagram?

Start by identifying the main vacuum ports on the throttle body itself. Follow the lines depicted in the layout to their corresponding components, such as the MAP sensor or distributor. Lines that cross without a dot are independent, while those with a junction represent a shared vacuum source or T-fitting.

What are the parts of a 350 TBI vacuum system?

The primary components include the throttle body unit, the Manifold Absolute Pressure (MAP) sensor, the Exhaust Gas Recirculation (EGR) valve, the PCV valve, and the charcoal canister. Each component relies on specific vacuum signals to regulate fuel delivery, emissions, and idle speed within the complex engine structure.

Why is the MAP sensor component important?

The MAP sensor is a vital component because it measures the amount of vacuum in the intake manifold to determine engine load. This data allows the ECM to adjust fuel delivery. A leak in this specific vacuum line will cause poor fuel economy, stalling, and a rich-running engine condition.

What is the difference between ported and manifold vacuum?

Manifold vacuum is sourced directly from the intake and is strongest at idle, while ported vacuum is sourced above the throttle plates and increases as the throttle opens. Understanding this difference is key to the system configuration, as it dictates when components like the EGR valve activate during vehicle operation.

How do I use a 350 TBI 5.7 TBI vacuum diagram?

Use the diagram as a reference guide when replacing old, cracked hoses or troubleshooting engine codes. By comparing your engine’s physical layout to the diagram’s configuration, you can identify incorrectly routed lines, clogged ports, or missing caps that lead to performance issues and high emissions output in your vehicle.