3 Wire Speed Sensor Wiring Diagram: Troubleshooting Guide

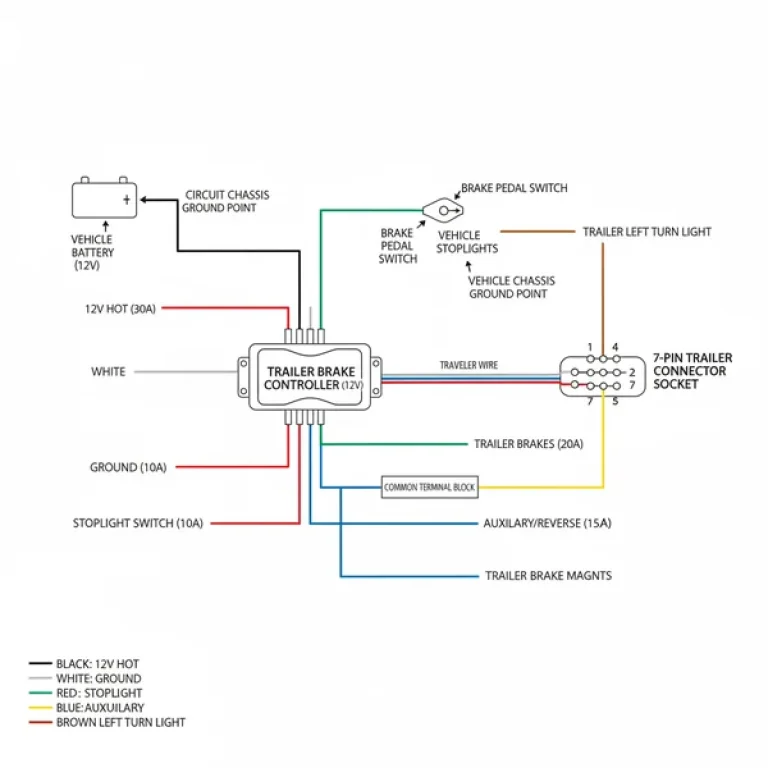

A 3 wire speed sensor wiring diagram illustrates the electrical connections between the sensor and the ECU. These typically consist of a power supply (hot wire), a ground wire, and a signal or traveler wire. Identifying the common terminal and ensuring proper voltage flow is essential for measuring rotational speed or vehicle velocity.

📌 Key Takeaways

- Visualizes connections for power, ground, and signal output.

- Identify the signal wire (traveler) to ensure data reaches the controller.

- Always verify voltage before connecting to prevent sensor damage.

- Use a multimeter to check continuity across the common terminal.

- Essential for diagnosing speedometer failure or transmission issues.

Understanding a 3 wire speed sensor wiring diagram is essential for anyone looking to repair, upgrade, or install electronic speedometers and tachometers in automotive or industrial applications. Whether you are working on a modern vehicle’s transmission or a custom industrial motor, knowing how to interpret the power, ground, and signal connections is the difference between a functional system and a short-circuited component. In this comprehensive guide, we will break down the complexities of 3-wire sensor configurations, providing you with the technical clarity needed to complete your project safely. You will learn how to identify the specific purpose of each wire, how to integrate them with your control module or gauge, and the best practices for ensuring long-term signal integrity. By the end of this article, you will have a professional-grade understanding of the 3 wire speed sensor wiring diagram and the confidence to troubleshoot any connectivity issues that arise during the installation process.

Decoding the 3 Wire Speed Sensor Wiring Diagram

The core of any 3 wire speed sensor wiring diagram is the identification of the three distinct paths that allow the sensor to communicate with the vehicle’s computer or a standalone gauge. Most 3-wire sensors operate on the Hall Effect principle, which requires a constant power source to

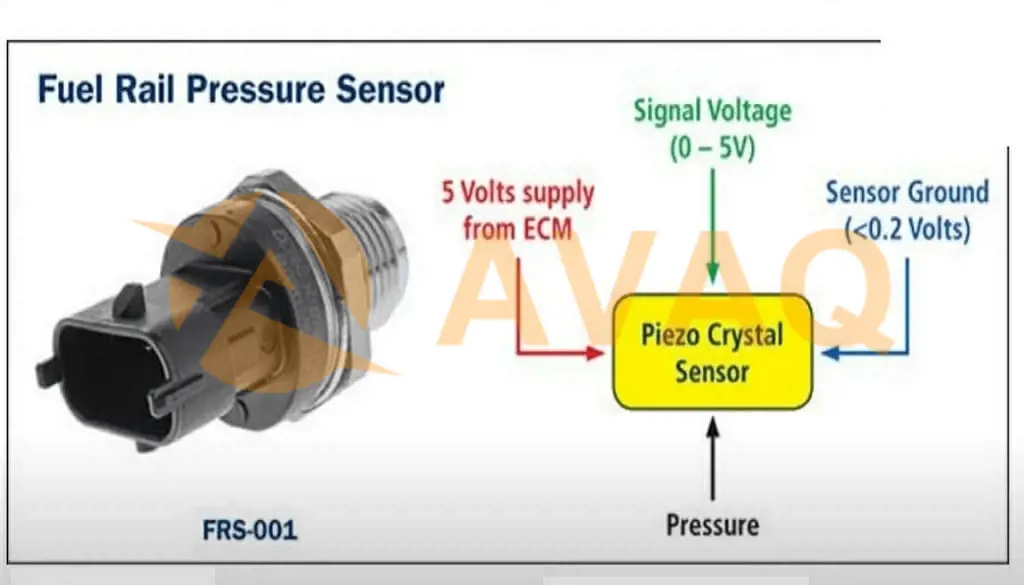

When you look at the diagram, you will notice three primary lines. The first is the power supply, often referred to as the hot wire in general electrical terms, which provides the necessary voltage for the internal circuitry. This is typically a 5V or 12V DC source provided by the Engine Control Unit (ECU). The second line is the ground wire, which completes the circuit. In some industrial terminal blocks, this might connect to a common terminal to ensure all sensors share the same reference point. The third and perhaps most critical line is the signal wire. This acts as the traveler wire of the system, carrying the pulsed data from the sensor back to the gauge or controller. On many diagrams, these are color-coded: red or orange for power, black or green for ground, and white, blue, or yellow for the signal output.

[DIAGRAM_PLACEHOLDER – A visual schematic showing a Speed Sensor connected to a Power Source, Ground, and a Signal Output/Gauge. Labels: VCC (Power), GND (Ground), SIG (Signal Output). Connections shown via three distinct colored paths.]

Variations in these diagrams can occur depending on the specific application. For instance, in heavy-duty machinery, you might find that the wires are shielded to prevent electromagnetic interference. In these cases, the diagram will show a fourth “drain” or shield wire that is grounded at only one end. Additionally, while most automotive sensors use high-quality plastic connectors, industrial versions might use a brass screw terminal set for more permanent installations. Understanding these variations ensures that regardless of the hardware you are using, you can map the connections back to the fundamental 3-wire logic: Supply, Return, and Data.

Most 3-wire speed sensors are Hall Effect sensors. They require a stable DC voltage to operate and produce a digital signal. This differs from 2-wire sensors (Variable Reluctance), which are passive and produce an analog AC signal. Never swap these sensor types without a converter.

Step-by-Step Installation and Wiring Guide

Interpreting a 3 wire speed sensor wiring diagram is the first step, but the physical installation requires precision and attention to detail. Follow these steps to ensure a successful integration of your sensor into your electrical system.

Step 1: Gather Your Tools and Materials

Before beginning, ensure you have a digital multimeter, wire strippers, high-quality crimping tools, and heat-shrink tubing. You should also verify the wire gauge required for your specific sensor. Most speed sensors use 18 to 22 AWG (American Wire Gauge) wire. Using a gauge that is too thin can lead to signal degradation, while too thick can make the connector assembly difficult.

Step 2: Disconnect the Power Source

Safety is paramount. Before touching any part of the electrical system, disconnect the negative terminal of the battery or the main power supply to the control panel. This prevents accidental shorts that could destroy the sensitive internal components of the sensor or the ECU.

Step 3: Identify the Sensor Pinout

Refer to your specific 3 wire speed sensor wiring diagram to identify which pin on the sensor corresponds to which function. Do not assume that the wire colors on the sensor match the wire colors on your vehicle’s harness. Check the manufacturer’s datasheet. Usually, Pin 1 is the voltage supply (VCC), Pin 2 is the ground (GND), and Pin 3 is the signal output (OUT).

Step 4: Establish the Ground Connection

Connect the ground wire from the sensor to a clean, unpainted metal surface on the chassis or to the dedicated common terminal on your wiring block. A poor ground is the most common cause of “jumpy” or erratic speed readings. Ensure the connection is tight and protected from corrosion.

Step 5: Connect the Power Supply (Hot Wire)

Locate the power source indicated in your diagram. For most automotive applications, this is a “switched” 12V or 5V source, meaning it only receives power when the ignition is in the ‘on’ position. If your installation involves an industrial terminal, you may be securing this wire to a brass screw terminal labeled with the appropriate voltage level.

Applying 12V to a sensor designed for 5V will result in immediate internal failure. Always verify the required voltage on the sensor’s specification sheet before connecting the hot wire.

Step 6: Route the Signal Wire

The signal wire, or traveler wire, must be routed from the sensor to the gauge or ECU input. Avoid routing this wire parallel to high-voltage components like spark plug wires or heavy power cables for electric motors, as this can introduce electrical noise into the signal. Use cable ties to secure the wire every 6 to 12 inches.

Step 7: Final Connection and Testing

Once all wires are connected, double-check your work against the 3 wire speed sensor wiring diagram. Reconnect the power. Set your multimeter to DC voltage and check the signal wire while the target (tone wheel or gear) is moving slowly. You should see the voltage pulse between 0V and your supply voltage. If the pulse is present, the wiring is correct.

Troubleshooting Common Wiring Issues

Even with a perfect 3 wire speed sensor wiring diagram, issues can occur due to environmental factors or component failure. The most frequent problem users encounter is a “dead gauge,” where the speedometer stays at zero despite the vehicle being in motion. The diagram helps solve this by allowing you to systematically test each of the three circuits.

First, check the voltage between the power and ground wires at the sensor plug. If there is no voltage, the issue lies in the power supply or a blown fuse, not the sensor itself. Second, check the ground wire continuity. If the resistance to the chassis is high, the sensor cannot complete its circuit. Third, examine the signal wire. If you have power and ground but no pulsing signal while the wheels are turning, the sensor internal Hall Effect chip may have failed.

- ✓ Erratic Readings: Often caused by a loose ground or electrical interference. Check the common terminal connections.

- ✓ No Signal: Check for a broken traveler wire or an incorrect air gap between the sensor and the gear.

- ✓ Sensor Overheating: Usually indicates the voltage supply is too high (e.g., 12V into a 5V sensor).

If you observe physical damage to the wire insulation or if the sensor housing is cracked, it is best to seek professional help or replace the unit entirely, as these sensors are sensitive to moisture ingress.

Tips & Best Practices for Longevity

To ensure your 3 wire speed sensor wiring remains reliable over years of service, follow these professional best practices. First, always use heat-shrinkable butt connectors or solder with adhesive-lined heat shrink. Traditional “twist and tape” methods are prone to failure in the vibrating, high-moisture environment of an engine bay or factory floor.

To significantly reduce electromagnetic interference (EMI), twist the power, ground, and signal wires together in a “braid” pattern (about 1 twist per inch) before routing them through the vehicle. This helps cancel out external noise.

Maintenance is also key. Periodically inspect the area where the sensor is mounted. Speed sensors work by detecting metal teeth on a gear; if metal shavings or road debris build up on the sensor face, the signal can become distorted. Cleaning the sensor tip with a soft cloth during routine oil changes or machine inspections can prevent future headaches.

Regarding cost-saving, while it is tempting to buy the cheapest sensor available online, stick to reputable brands. Quality components often feature better internal voltage regulators and superior weather sealing. Investing a bit more upfront in a high-quality sensor and the correct gauge of wire will save you the cost and labor of repeated replacements. Finally, always document any changes you make to the wiring colors. If you use a different color wire than what is shown on the original 3 wire speed sensor wiring diagram, note it down in the vehicle’s manual or on a label near the connection point to assist future troubleshooting.

In conclusion, mastering the 3 wire speed sensor wiring diagram allows you to take control of your equipment’s data and performance. By understanding the relationship between the hot wire, the signal traveler, and the neutral or ground path, you ensure that your speed readings are accurate and your electrical system remains robust. Whether you are tightening a brass screw on a terminal block or crimping a connector for a custom gauge, these principles will serve as your roadmap to a professional installation.

Frequently Asked Questions

What is 3 wire speed sensor wiring diagram?

This diagram is a visual schematic used to map the connections of Hall-effect or magnetic sensors. It identifies the hot wire providing power, the ground wire for circuit completion, and the signal traveler wire. Mechanics use it to ensure the sensor communicates pulses correctly to the vehicle’s computer or speedometer.

How do you read 3 wire speed sensor wiring diagram?

Start by identifying the color-coded paths leading from the sensor to the common terminal. Look for the power supply line (hot wire) and the neutral wire or ground. Trace the signal path, often referred to as the traveler wire, to understand how frequency data is transmitted to the processing unit.

What are the parts of 3 wire speed sensor wiring?

The system consists of the sensor housing, an internal magnetic or optical element, and three distinct wires. These include the voltage input (hot wire), the return path (ground wire), and the output signal. The wiring often meets at a common terminal or plug that connects directly into the main wiring harness.

Why is ground wire important?

The ground wire is critical because it provides a stable reference point for the electrical circuit. Without a clean ground, the sensor cannot complete the circuit back to the neutral wire or chassis. This lack of stability causes electrical noise, leading to erratic speed readings or total sensor signal failure.

What is the difference between 2 wire and 3 wire sensors?

A two-wire sensor generates its own AC voltage using a magnet and coil, whereas a three-wire sensor requires an external hot wire for power. The three-wire version uses a traveler wire to send a digital square-wave signal, offering higher precision at lower speeds compared to the passive two-wire variety.

How do I use 3 wire speed sensor wiring diagram?

Use the diagram to perform diagnostic tests with a digital multimeter. By identifying which lead is the hot wire and which is the signal traveler wire, you can check for 5V or 12V reference signals. This ensures the common terminal receives the correct data to calculate speed accurately.