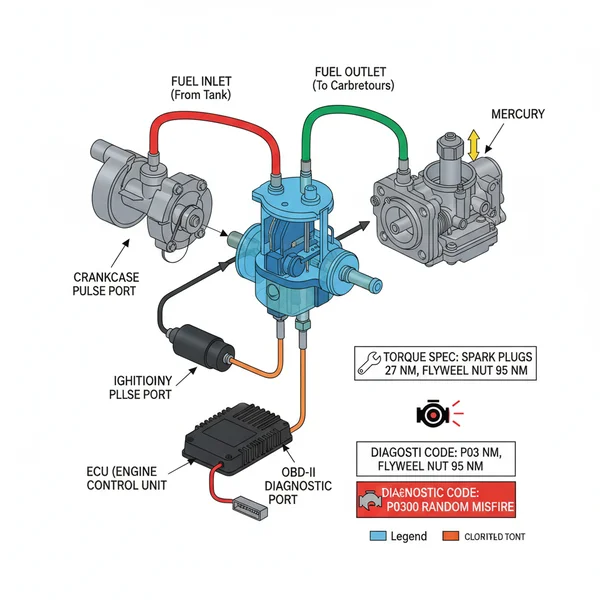

2 Stroke Mercury Outboard Fuel Pump Diagram: Repair Tips

This diagram illustrates the pulse-driven mechanism of a Mercury 2-stroke fuel pump, highlighting the diaphragm, check valves, and fuel lines. Understanding this layout helps resolve issues like a check engine light or power loss, ensuring the ECU receives proper pressure for consistent engine performance and reliable watercraft operation.

📌 Key Takeaways

- Visualizes the fuel flow path from the tank to the carburetors or injectors

- Identifies the pulse-driven diaphragm as the primary moving part

- Ensuring a vacuum-tight seal is critical for preventing lean engine conditions

- Reference the diagram to verify the correct orientation of check valves

- Use this diagram when rebuilding the pump or diagnosing fuel delivery failure

For many boaters, the mechanical fuel pump is the heart of the propulsion system, and understanding a 2 stroke mercury outboard fuel pump diagram is the first step toward independent maintenance and reliability on the water. Whether you are dealing with a classic carbureted motor or a more modern direct-injection model, the fuel pump’s role remains the same: delivering a steady, pressurized flow of gasoline to the intake system. This article provides a comprehensive breakdown of the internal components, the physics behind the pulse-driven operation, and a guide to interpreting your specific model’s layout. You will learn how to identify wear patterns and how to execute a professional-grade rebuild to keep your engine running smoothly.

Most 2-stroke Mercury fuel pumps are “pulse pumps.” They do not use a mechanical cam like an automotive engine; instead, they utilize the changing pressure in the crankcase to move a flexible diaphragm back and forth.

Understanding the 2 Stroke Mercury Outboard Fuel Pump Diagram Components

A standard 2 stroke mercury outboard fuel pump diagram typically reveals a multi-layered assembly designed to manage fluid dynamics with minimal moving parts. At the core of the diagram is the fuel pump body, usually constructed from cast aluminum or high-grade composite materials. The visual breakdown starts with the backplate, which features a “pulse port.” This port is connected directly to the engine’s crankcase. As the piston moves up and down, it creates alternating vacuum and pressure states. The diagram will show a rubber or Mylar diaphragm sandwiched between the pump body and the cover.

Key elements highlighted in the diagram include:

- ✓ The Pulse Diaphragm: The primary moving part that reacts to crankcase pressure.

- ✓ Check Valves (Flapper Valves): These are often depicted as small plastic or rubber tabs that ensure fuel only flows in one direction—from the tank to the engine.

- ✓ Gaskets and O-rings: These provide the airtight seal necessary for the vacuum to function effectively.

- ✓ The Spring and Retainer: Found in high-output models to assist the diaphragm’s return stroke.

Variations in these diagrams occur based on the engine’s horsepower. Smaller portable outboards (2.5hp to 20hp) usually feature a single-stage pump integrated into the side of the carburetor. Larger V6 models may feature dual-stage pumps or even a Vapor Separator Tank (VST) assembly. In high-performance EFI models, the 2 stroke mercury outboard fuel pump diagram will also include an electric booster pump, which is managed by the ECU (Electronic Control Unit) to maintain precise rail pressure. Unlike an automotive engine with a timing chain to coordinate fuel delivery, these 2-stroke pumps are timed naturally by the physical movement of the internal pistons.

[DIAGRAM_PLACEHOLDER: A detailed exploded-view diagram showing a Mercury pulse fuel pump with the cover plate, gaskets, diaphragm, check valves, and pulse hose connection clearly labeled.]

Step-by-Step Guide to Reading the Diagram and Servicing the Pump

Interpreting a 2 stroke mercury outboard fuel pump diagram requires a methodical approach to ensure the internal “valving” is oriented correctly. If a check valve is installed upside down, the engine will fail to prime. Follow these steps to utilize the diagram for a rebuild or inspection.

1. Identify Your Specific Serial Number

Mercury outboards are often categorized by serial number ranges rather than years. Before looking at a diagram, locate the tag on the transom bracket. This ensures the torque spec and part numbers on your diagram match your specific block.

2. Prepare the Workspace and Tools

You will need a set of metric and standard sockets, a flat-head screwdriver, a gasket scraper, and a clean, lint-free cloth. Ensure you have a specialized cleaning solvent to remove varnish from the pump housing.

3. Mapping the Flow Path

Study the arrows on the 2 stroke mercury outboard fuel pump diagram. These indicate the direction of fuel travel. Most pumps have an “IN” port (connected to the fuel line from the tank) and an “OUT” port (leading to the carburetor or fuel rail). The pulse port is usually located on the back or bottom of the pump.

4. Disassembly and Inspection

Remove the mounting bolts and carefully pull the pump away from the engine. Use the diagram as a reference to keep the layers in order. Often, the gasket and diaphragm look similar; the diagram will show that the gasket usually sits against the metal body, while the diaphragm is the flexible layer that moves.

5. Inspecting for Failure Points

Check the diaphragm for pinholes or “stretching.” In modern EFI engines, if the pump fails, it may trigger a check engine light or a specific diagnostic code on your gauges. While 2-stroke outboards do not utilize standard OBD-II ports, Mercury’s SmartCraft system provides similar digital telemetry.

6. Reassembly with Precision

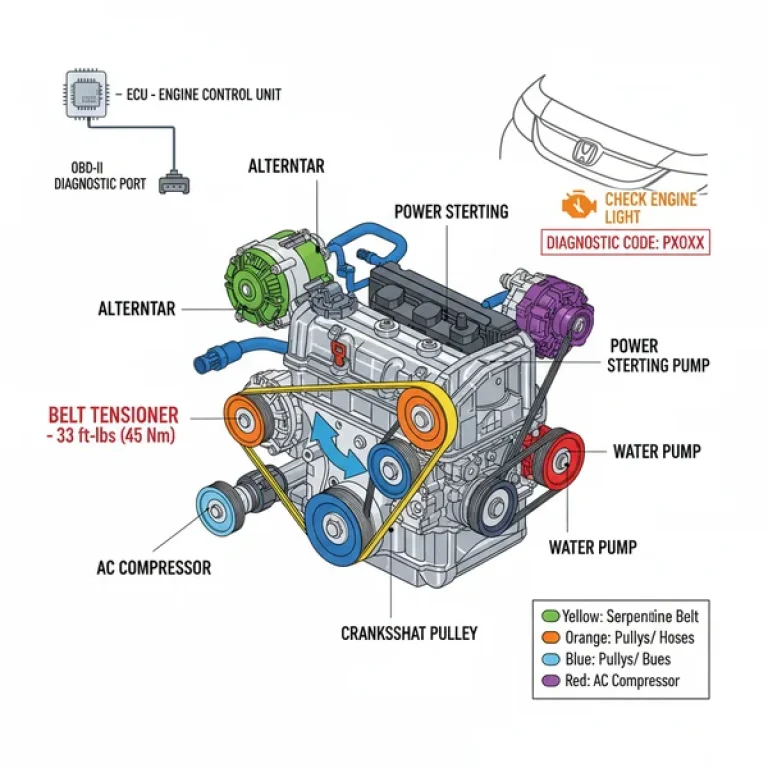

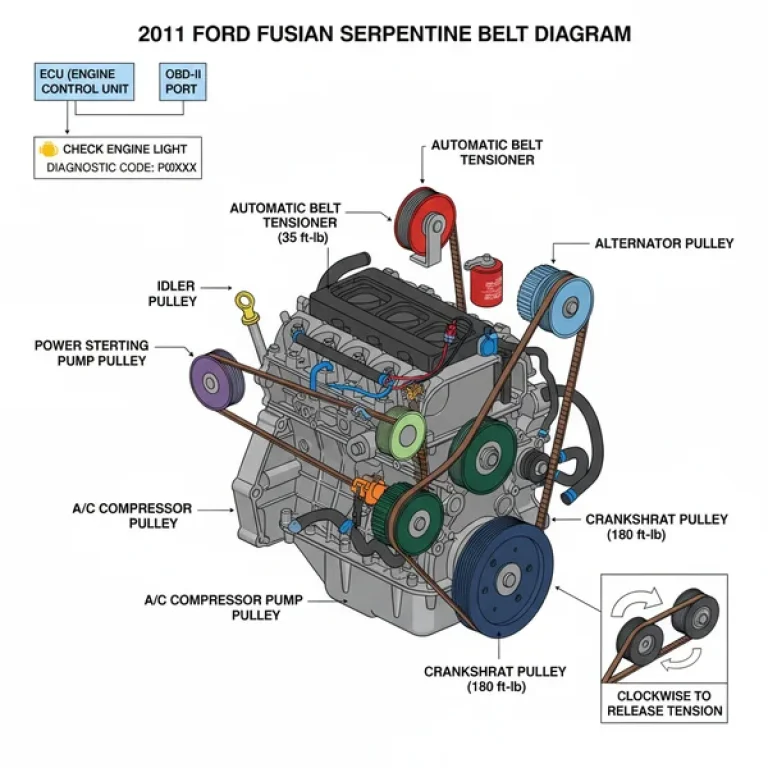

Lay the new components out exactly as shown in the diagram. Pay close attention to the orientation of the check valves. They should lay flat against their seats. If your model uses an accessory belt to drive an alternator or air compressor (common in OptiMax models), ensure the belt tension is correct and not obstructing the fuel lines.

7. Applying the Correct Torque Spec

Over-tightening the pump cover can warp the aluminum housing, leading to air leaks. Refer to your diagram or service manual for the exact torque spec, which is usually quite low (typically 25-35 inch-pounds for smaller pumps).

8. Priming and Testing

Once reassembled, use the primer bulb to force fuel through the system. Watch for leaks around the gaskets. Start the engine and observe the coolant flow (the “telltale” stream) to ensure no other systems were disturbed during the repair.

Gasoline is highly flammable. Always perform fuel pump maintenance in a well-ventilated area away from pilot lights or sparks. Have a fire extinguisher rated for chemical fires nearby.

Common Issues & Troubleshooting Using the Diagram

The most frequent issue solved by consulting a 2 stroke mercury outboard fuel pump diagram is an engine that “bogs” or dies at high RPM. This usually indicates that the pump can no longer keep up with the fuel demand. By looking at the diagram, you can see how a small tear in the pulse diaphragm would cause a loss of vacuum pressure, effectively “starving” the engine.

Another common symptom is fuel leaking into the crankcase. If the diaphragm is ruptured, the vacuum pulse will suck raw gasoline directly into the cylinder. This often leads to fouled spark plugs and a “no-start” condition. If your engine is throwing a diagnostic code related to lean fuel mixtures, the diagram can help you trace the line from the pump to the injectors to find potential air leaks or cracked pulse hoses. If the engine idles fine but stalls under load, the check valves depicted in your diagram may be hardened or “curled,” preventing them from sealing at high speeds.

Tips & Best Practices for Fuel Pump Longevity

To ensure your 2-stroke Mercury remains reliable, maintenance must go beyond just reacting to failures. The fuel pump is highly sensitive to the quality of the fuel being processed.

Always use ethanol-free fuel whenever possible. Ethanol attracts moisture and can cause the rubber diaphragms in older Mercury pumps to stiffen and crack prematurely.

Follow these best practices for optimal performance:

- ✓ Install an Inline Filter: Place a high-quality water-separating fuel filter between the tank and the pump. This prevents debris from clogging the delicate check valves shown in your diagram.

- ✓ Replace Every Three Years: Fuel pump rebuild kits are inexpensive. Making it a part of your three-year service cycle prevents mid-season breakdowns.

- ✓ Check Pulse Hoses: The hose connecting the pump to the crankcase can become brittle. A tiny crack here acts like a broken timing chain—it breaks the synchronization of the pump and stops fuel flow entirely.

- ✓ Store with Stabilizer: If the boat will sit for more than a month, use a fuel stabilizer to prevent “varnish” from coating the internal flapper valves.

When purchasing parts, always cross-reference your 2 stroke mercury outboard fuel pump diagram with OEM (Original Equipment Manufacturer) components. While aftermarket kits are available, OEM Mercury gaskets and diaphragms are specifically engineered to withstand the chemical composition of modern fuels. By maintaining this critical component, you ensure that the complex balance of air, oil, and fuel is preserved, allowing your outboard to provide years of dependable service on the water. Regardless of the complexity of your engine—whether it has a simple carb or a complex ECU-controlled rail—the principles found in the fuel pump diagram remain your best roadmap for success.

Frequently Asked Questions

What is a 2 stroke Mercury outboard fuel pump diagram?

A 2 stroke Mercury outboard fuel pump diagram is a visual blueprint mapping the internal and external components of the fuel delivery system. It identifies the diaphragm, check valves, and spring locations. This map is essential for diagnosing fuel delivery failures that might trigger a check engine light or cause stalling.

How do you read a 2 stroke Mercury outboard fuel pump diagram?

To read this diagram, start at the fuel inlet and follow the flow through the check valves and diaphragm. Locate the pulse port that connects to the crankcase. Identifying these pathways helps you interpret any diagnostic code related to lean conditions or pressure drops communicated to the ECU.

What are the parts of a Mercury fuel pump?

The primary parts include the fuel pump housing, the flexible diaphragm, check valve assemblies, and the pulse line. Additionally, modern systems include sensors that link to the ECU to monitor flow. Knowing these parts allows you to apply the correct torque spec during reassembly to prevent air or fuel leaks.

Why is the ECU important in fuel delivery?

In fuel-injected outboards, the ECU manages fuel timing based on sensor data. If the pump fails, the ECU cannot maintain the correct air-fuel ratio, resulting in poor performance. This may trigger an OBD-II style diagnostic code, signaling the operator to check the physical pump assembly for damage.

What is the difference between a pulse pump and an electric pump?

A pulse pump uses crankcase pressure variations to move the diaphragm, while an electric pump relies on a motor. Pulse pumps are standard on older 2-stroke Mercurys. However, modern EFI models use electric pumps integrated with an OBD-II diagnostic system to alert users of any delivery failures.

How do I use a fuel pump diagram?

Use the diagram to identify the sequence of internal components during a rebuild. Locate the exact position of the gasket and check valves to ensure one-way fuel flow. Referencing the diagram ensures you follow every torque spec for the housing bolts, preventing potential leaks that hinder engine ignition.