2 Stroke Mercury Outboard Fuel Pump Diagram: Rebuild Guide

A 2 stroke Mercury outboard fuel pump diagram illustrates the flow from the tank through the diaphragm and check valves to the carburetors. It helps identify issues like a check engine light or diagnostic code related to fuel delivery, ensuring all components meet the specific torque spec for a leak-free seal.

📌 Key Takeaways

- Visualizes the vacuum-driven pulse system of the fuel pump.

- Identifying the diaphragm and check valve orientation is vital.

- Ensuring proper torque spec prevents air leaks and fuel starvation.

- Cross-reference the diagram with ECU data during diagnostic testing.

- Use this diagram when rebuilding the pump or clearing a diagnostic code.

Navigating the complexities of marine engine maintenance can be daunting, but understanding the 2 stroke mercury outboard fuel pump diagram is the first step toward ensuring your vessel remains reliable on the open water. Whether you are dealing with a classic carbureted model or a more modern Direct Fuel Injection (DFI) system, the fuel pump serves as the heart of your engine’s combustion cycle. A clear diagram allows you to visualize the relationship between the crankcase pulses and the mechanical movement of the diaphragm. By mastering this component, you can prevent mid-lake stalls, improve throttle response, and save significantly on repair costs. This article provides a comprehensive breakdown of the fuel pump’s architecture, providing you with the technical knowledge needed to diagnose and rebuild this essential marine component.

Most 2-stroke Mercury fuel pumps operate on a pulse-driven system, utilizing the vacuum and pressure created within the engine’s crankcase to move fuel from the tank to the carburetors or fuel rail.

Decoding the 2 Stroke Mercury Outboard Fuel Pump Diagram

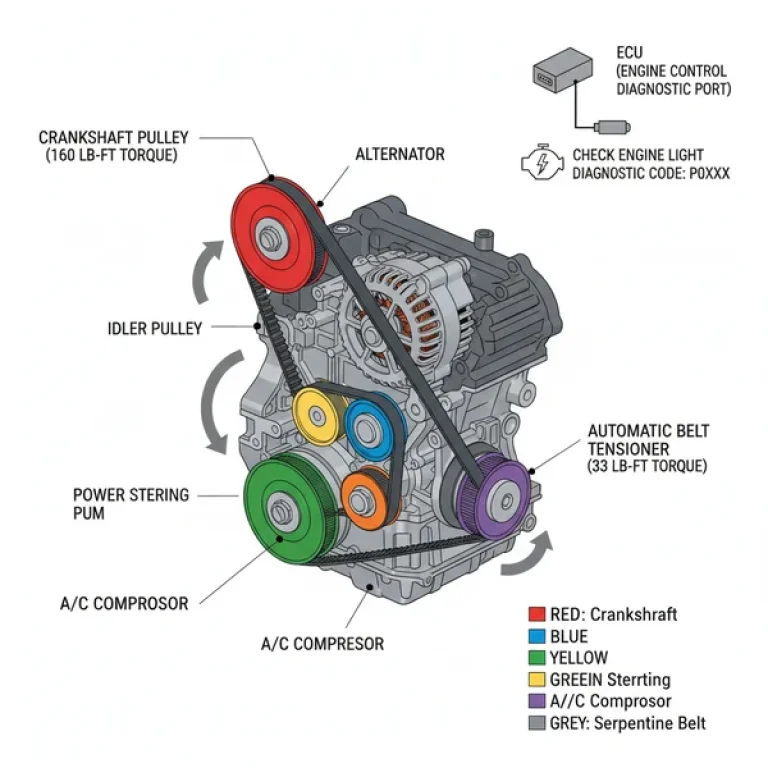

When you examine a 2 stroke mercury outboard fuel pump diagram, you are looking at a masterclass in fluid dynamics and mechanical simplicity. The diagram typically displays an “exploded view,” which separates the individual layers of the pump to show their assembly order. The most prominent feature is the pump body, usually constructed from high-grade aluminum or composite plastic. Inside this housing, you will find the diaphragm—a thin, flexible membrane that acts as the primary moving part. In the diagram, the diaphragm is often color-coded or shaded to distinguish it from the rigid gaskets that sandwich it.

Another critical element highlighted in the diagram is the check valve system. These are small, mushroom-shaped or flap-style valves that ensure fuel only flows in one direction: from the inlet to the outlet. The diagram will show the orientation of these valves; installing them backward is a common mistake that will prevent the engine from starting. Furthermore, many Mercury diagrams include the “pulse hose” connection. This is the line that connects the fuel pump to the engine block, allowing the internal piston movement to “pulse” the diaphragm. In higher-horsepower models, the diagram might also depict a boost spring, which provides additional tension to the diaphragm for higher fuel flow requirements at wide-open throttle.

[DIAGRAM_PLACEHOLDER: A technical exploded-view illustration showing a Mercury 2-stroke fuel pump. Labels include: 1. Pump Cover, 2. Check Valve Retainers, 3. Diaphragm, 4. Gasket Stack, 5. Fuel Inlet, 6. Pulse Port, 7. Mounting Bolts. Arrows indicate the direction of fuel flow and the location of the crankcase pulse entry.]

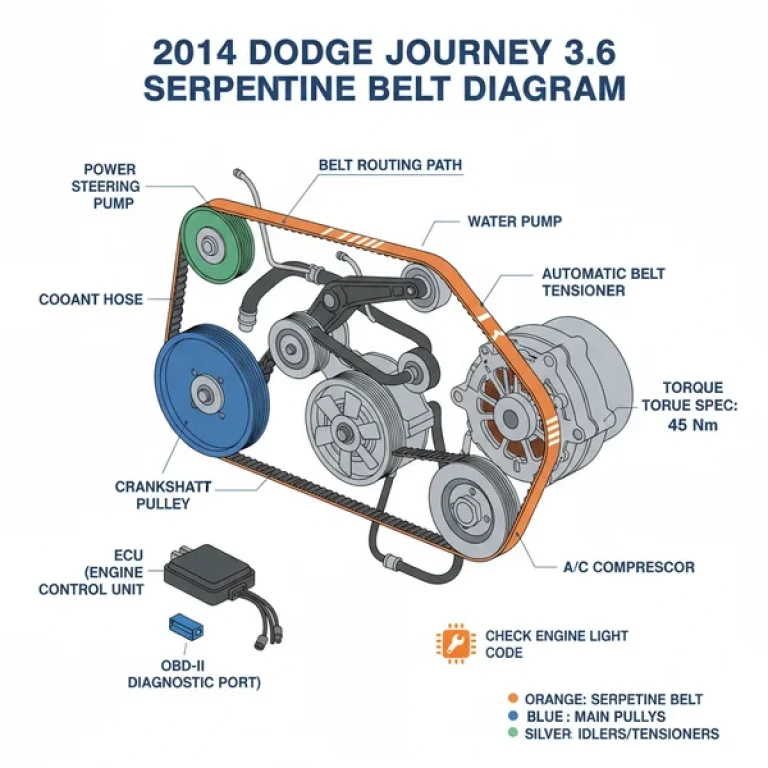

Variations in these diagrams often depend on the engine’s displacement. Smaller 2.5hp to 25hp models usually feature a square or rectangular pump integrated directly onto the side of the carburetor. Larger V6 models, such as the legendary 150hp to 200hp series, utilize a separate, pulse-driven pump mounted on the cylinder block. While these larger engines lack a traditional timing chain found in 4-stroke automotive engines, the timing of the fuel pulse is perfectly synchronized with the piston strokes, a detail that the diagram helps clarify by showing the exact port alignment on the block.

Step-by-Step Guide to Reading and Servicing the Pump

Interpreting a technical diagram is about more than just looking at pictures; it is about understanding the sequence of operation. To properly service or install a pump based on the 2 stroke mercury outboard fuel pump diagram, follow these structured steps to ensure maximum performance and safety.

- ✓ Identify the Pulse Port: Locate the port on the diagram that connects to the engine crankcase. This is the “engine” of the pump. Ensure the passage is clear of any oily residue.

- ✓ Verify Valve Orientation: Use the diagram to confirm which direction the check valves face. Usually, the “umbrella” portion faces toward the engine to allow fuel to enter the chamber but not escape back to the tank.

- ✓ Align the Gaskets and Diaphragm: This is the most common point of failure. The diagram will show a specific “stacking” order (e.g., Body > Gasket > Diaphragm > Gasket > Cover). Misplacing a single gasket can lead to a massive fuel leak or a complete lack of pressure.

- ✓ Check for Boost Springs: If your model includes a spring, ensure it is seated in the recessed cup shown in the diagram. This spring maintains the diaphragm’s “neutral” position.

- ✓ Final Torque Application: Once assembled, refer to the torque spec for the cover bolts. Over-tightening can warp the plastic housing or tear the delicate diaphragm.

Always perform fuel system work in a well-ventilated area. Gasoline vapors are heavier than air and can settle in the bilge of your boat, creating a significant explosion risk. Ensure the battery is disconnected before starting.

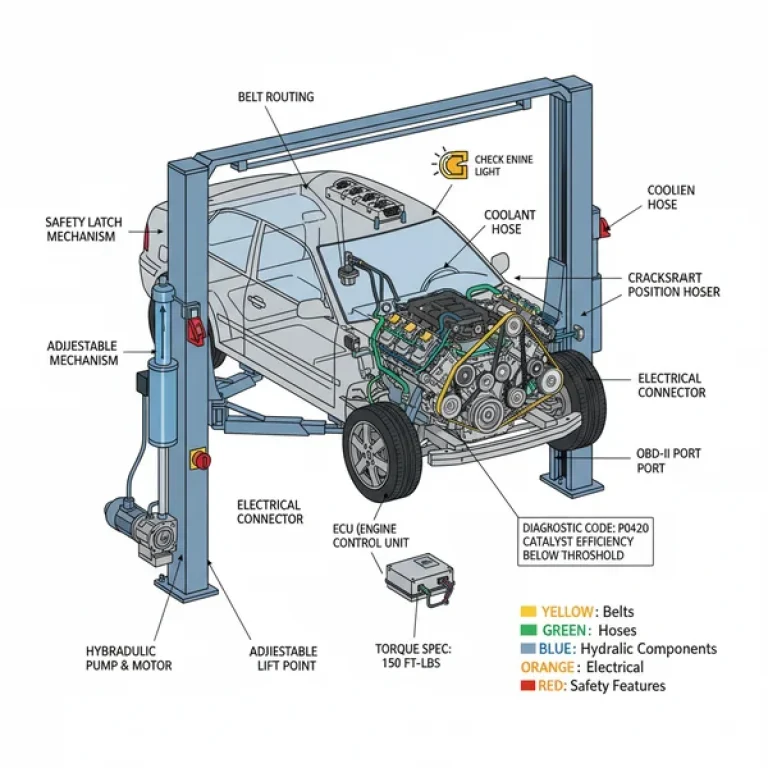

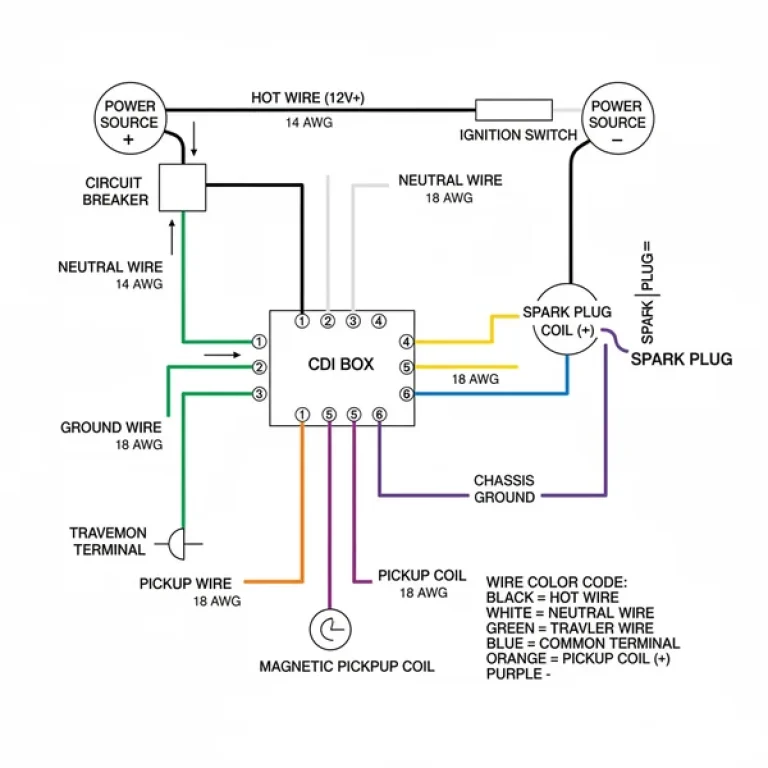

To perform this work, you will need basic hand tools: a flathead or Phillips screwdriver (depending on the bolt type), a torque wrench, and perhaps a set of needle-nose pliers for the check valves. In modern Mercury engines equipped with an ECU, the fuel delivery system might be more complex, involving an electric “lift” pump in addition to the mechanical pulse pump. In these cases, your 2 stroke mercury outboard fuel pump diagram will show electrical connectors and harness routing. If the electric side of the system fails, you might see a check engine light or hear a warning horn, requiring a scan tool to retrieve a specific diagnostic code through a system similar to OBD-II found in cars.

Common Issues and Troubleshooting

A failing fuel pump often mimics other engine problems, making the diagram an invaluable diagnostic tool. One frequent issue is a “pinhole” leak in the diaphragm. When this occurs, fuel can be sucked directly into the crankcase through the pulse line, causing the engine to run extremely “rich,” smoke excessively, or “bog” down at high speeds. By referencing the diagram, you can identify the pulse hose and inspect it for the presence of raw gasoline, which is a definitive sign of a ruptured diaphragm.

Another common problem is the “stuck” check valve. Over time, old fuel can turn into a varnish-like substance, gumming up the valves shown in your diagram. If the valves cannot open or close, the pump cannot create the pressure differential needed to move fuel. If your engine starts but dies after a few seconds, or if you find yourself constantly having to squeeze the primer bulb to keep it running, the fuel pump is the likely culprit. The diagram helps you locate exactly where these valves are seated so you can clean or replace them without disturbing the rest of the fuel system. While 2-stroke outboards do not have an accessory belt or a complex coolant flow path through the pump itself, heat soak can still affect these components, causing vapor lock in the lines if they are routed incorrectly.

Tips and Best Practices for Longevity

To keep your Mercury outboard running smoothly, preventative maintenance is far more effective than emergency repairs. The fuel pump diaphragm is a wear item; it flexes thousands of times per hour. Most marine mechanics recommend rebuilding the fuel pump every two to three years, regardless of how the engine feels. Using high-quality, ethanol-resistant components is essential. Modern pump kits are designed to withstand the corrosive nature of E10 and E15 fuels, which can quickly degrade the rubber components shown in older 2 stroke mercury outboard fuel pump diagrams.

When reassembling the pump, lightly coat the new diaphragm and gaskets with a small amount of 2-stroke oil. This helps them seal against the housing and prevents them from sticking or tearing during the next disassembly.

If you are looking to save money, purchasing a “rebuild kit” is significantly cheaper than buying a complete new pump assembly. These kits include the diaphragm, gaskets, and check valves listed in the diagram. However, always ensure you are buying OEM (Original Equipment Manufacturer) parts. Aftermarket kits often use thinner materials that may not meet the torque spec requirements of the Mercury housing, leading to premature failure. Furthermore, pay attention to the coolant flow around the engine block; if the engine is running too hot, it can accelerate the hardening of the fuel pump’s internal rubber parts. By following the 2 stroke mercury outboard fuel pump diagram and maintaining a regular service schedule, you ensure that your engine remains primed and ready for every adventure on the water.

In conclusion, the 2 stroke mercury outboard fuel pump diagram is more than just a piece of paper; it is a vital roadmap for engine health. By understanding how the pulse port, diaphragm, and check valves interact, you can troubleshoot fuel delivery issues with the confidence of a professional. Whether you are dealing with a simple mechanical pump or a complex system monitored by an ECU, the principles of fuel delivery remain the same. Keep your diagram handy, use quality parts, and your Mercury outboard will provide years of reliable service.

Frequently Asked Questions

What is 2 stroke Mercury outboard fuel pump diagram?

A 2 stroke Mercury outboard fuel pump diagram is a visual map showing how fuel travels from the supply line through the internal diaphragms to the engine. It details the arrangement of springs, gaskets, and check valves, allowing you to troubleshoot an OBD-II related fuel pressure issue or mechanical failure.

How do you read 2 stroke Mercury outboard fuel pump diagram?

To read this diagram, start at the fuel inlet and follow the arrows depicting flow. Identify symbols for the diaphragm, inlet valve, and outlet valve. Note the orientation of the pulse port, which connects to the crankcase to drive the pump, avoiding a check engine light related to fuel delivery.

What are the parts of 2 stroke Mercury outboard fuel pump?

The primary parts include the pump body, rubber diaphragms, check valves, and return springs. Modern versions may interact with the ECU via sensors. Understanding these components helps you resolve a check engine light by ensuring the mechanical side of the fuel system is pressurized and functioning correctly according to the schematic.

Why is torque spec important?

The torque spec is critical because it ensures an airtight seal between the pump layers. Over-tightening can warp the body or tear the diaphragm, while under-tightening leads to air leaks. Following these specs prevents a recurring diagnostic code and keeps the outboard running smoothly without losing fuel pressure during operation.

What is the difference between pulse and electric pumps?

Pulse pumps use crankcase pressure variations to move the diaphragm, whereas electric pumps are powered by the battery and regulated by the ECU. Most older 2-stroke Mercury models rely on pulse pumps, which are simpler but require precise manual assembly according to the provided technical diagram and specific torque spec.

How do I use 2 stroke Mercury outboard fuel pump diagram?

Use the diagram during a rebuild to ensure every gasket and valve is seated in the correct direction. If you encounter an OBD-II style diagnostic code on newer models, the diagram helps locate physical blockage points or damaged components that trigger the check engine light and lead to poor performance.