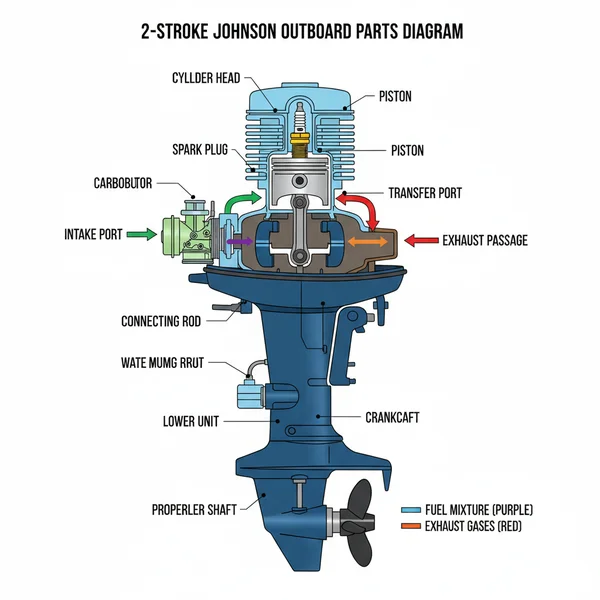

2 stroke johnson outboard parts diagram: Repair Guide

A 2 stroke johnson outboard parts diagram illustrates the internal structure of the marine engine, highlighting the fuel, cooling, and electrical system configuration. It serves as a visual guide to identify every component, such as the carburetor or propeller, ensuring accurate assembly and troubleshooting during motor repairs or routine servicing.

📌 Key Takeaways

- Provides a visual map of the engine’s internal structure and component locations.

- The carburetor and fuel lines are the most critical components for 2-stroke performance.

- Always ensure the ignition system is grounded before testing components to prevent shock.

- Cross-reference the diagram part numbers with official service manuals for precise ordering.

- Use this diagram during disassembly to record the exact layout of fasteners and seals.

Maintaining a classic marine engine requires more than just mechanical intuition; it demands a precise roadmap of every internal component. For many boaters and DIY enthusiasts, finding a reliable 2 stroke johnson outboard parts diagram is the first step toward a successful repair or a standard seasonal tune-up. These diagrams provide an essential visual guide to the intricate structure of the motor, ensuring that you can identify, source, and install parts with confidence. By understanding the specific layout and configuration of your engine, you can avoid costly mistakes and keep your vessel running smoothly on the water. This guide will walk you through the essential elements of these diagrams and how to use them effectively for your maintenance needs.

The primary function of a 2 stroke johnson outboard parts diagram is to provide an “exploded view” of the engine’s various systems. Unlike a standard photograph, an exploded view pulls individual parts away from the center of the assembly while maintaining their relative positions. This specialized layout allows you to see how a small washer or a specific gasket fits between larger components like the cylinder head and the engine block. Most diagrams are organized by major systems, such as the powerhead, the fuel system, the ignition system, and the lower unit. This categorization makes it much easier to navigate the complex internal configuration of the motor.

In a typical diagram, each component is assigned a reference number. These numbers correspond to a parts list located adjacent to the drawing, which provides the official manufacturer part name and the original equipment manufacturer (OEM) part number. The visual breakdown often uses specific line styles—such as dashed lines—to indicate where a sub-assembly fits into a larger system. You will also notice that hardware like bolts, nuts, and pins are clearly labeled, which is vital for ensuring you don’t lose track of small fasteners during a teardown. While the general structure remains similar across many horsepower ranges, the specific layout can vary significantly between a small 2-horsepower portable unit and a high-performance V6 model. For instance, the cooling system configuration in a water-cooled model will look vastly different from the simpler air-cooled vintage designs.

Always verify your engine’s model number before consulting a diagram. Johnson model numbers are typically found on a metal tag on the swivel bracket or the transom mount. The model number is the only way to ensure the parts diagram matches your specific engine’s configuration.

Reading and interpreting a 2 stroke johnson outboard parts diagram is a skill that saves time and prevents mechanical failure. Follow these steps to master the use of these technical documents for your next project:

1. Locate the Model ID: Before opening any manual, find the model and serial number on your outboard. These engines were produced in many variations over several decades, and even a one-year difference can mean a change in carburetor jets or ignition coils.

2. Select the Specific System: Don’t try to look at the whole engine at once. If your motor isn’t pumping water, navigate specifically to the “Gearcase” or “Lower Unit” section of the diagram. If the engine is coughing or stalling, focus on the “Fuel Primer” or “Carburetor” assembly.

3. Identify the Assembly Sequence: Observe the order in which parts are stacked. In a 2-stroke engine, the sequence of gaskets and seals is critical for maintaining primary compression. The diagram shows which side of a seal should face the crankshaft and where spacers are required.

4. Note the Quantities: The parts list next to the diagram will tell you the “Quantity Required.” This is helpful when ordering parts like spark plugs or leaf valves, ensuring you don’t end up one short in the middle of a rebuild.

5. Cross-Reference for Superseded Parts: Manufacturers often update part designs. If you search for an old part number from a vintage diagram and can’t find it, look for “superseded” numbers. Modern databases will often link the old reference number to the current, improved version of the component.

6. Prepare Your Workspace: Use the diagram as a template for your workbench. As you remove parts, lay them out in the exact orientation and sequence shown in the layout. This physical mirroring of the diagram prevents “leftover parts” scenarios.

7. Use the Torque Specifications: While not always on the exploded view itself, the associated service manual pages will list torque specs for the fasteners identified in the diagram. Always use a torque wrench on critical components like head bolts to prevent warping.

Working on a 2-stroke engine involves flammable fuel and high-tension electrical systems. Always disconnect the spark plug wires and the battery before performing any work. Ensure your workspace is well-ventilated to avoid the buildup of gasoline vapors.

Most issues with 2-stroke outboards fall into three categories: fuel, spark, or cooling. The 2 stroke johnson outboard parts diagram is your best tool for troubleshooting these common problems. For instance, if the engine is overheating, the diagram helps you locate the thermostat and the impeller. By looking at the system layout, you can trace the path of the water from the intake screens through the pump and into the powerhead. If you find a component that looks worn or melted compared to the “perfect” version in the diagram, you have found your culprit.

Another frequent problem is a “no-start” condition caused by a clogged carburetor. The diagram shows the intricate relationship between the float, the needle valve, and the high-speed nozzle. By studying the structure, you can determine how to disassemble the carb without damaging the delicate internal passages. Look for warning signs like cracked fuel lines or brittle gaskets; these are often the source of air leaks that lean out the fuel mixture, which can lead to catastrophic engine failure in a 2-stroke system. If you encounter a situation where the internal metal components of the powerhead are scored or broken, or if you find heavy metal shavings in the lower unit oil, it may be time to consult a professional marine technician, as these issues often require specialized boring or machining tools.

Take digital photos of the engine at each stage of disassembly. While the parts diagram shows you where things go, your photos will show you exactly how your specific wiring harness was routed or how a specific linkage was bent, which adds an extra layer of clarity during reassembly.

To ensure the longevity of your Johnson outboard, follow these best practices when using parts diagrams and performing maintenance:

- ✓ Use OEM Parts Whenever Possible: While aftermarket components are often cheaper, OEM parts are designed to the exact tolerances specified in the original engine layout, ensuring a better fit and longer life.

- ✓ Replace Gaskets Every Time: Never reuse a gasket once a component has been disassembled. The diagram identifies these as “non-reusable” items because they crush to form a seal.

- ✓ Check for Saltwater Corrosion: If you operate in salt water, pay close attention to the cooling system diagrams. Use the diagram to identify sacrificial anodes and replace them when they are 50% eroded.

- ✓ Keep a Physical Copy: Print out the relevant pages of your 2 stroke johnson outboard parts diagram. Greasy fingers and expensive tablets don’t mix well in a workshop environment.

- ✓ Organize Fasteners: Use a magnetic tray or a tackle box to store bolts and screws. Label each compartment according to the reference numbers found on the diagram to avoid confusion during the rebuild.

Maintaining your engine doesn’t have to be a guessing game. By utilizing a detailed 2 stroke johnson outboard parts diagram, you gain a professional-level understanding of your motor’s internal mechanics. Whether you are replacing a simple pull-rope or performing a full lower-unit seal replacement, these visual guides provide the clarity needed to do the job right the first time. Regular maintenance, guided by accurate technical documentation, is the most cost-effective way to ensure your outboard remains reliable for years to come. With the right tools, a bit of patience, and the correct parts layout, you can keep your classic Johnson engine running at peak performance.

Step-by-Step Guide to Understanding the 2 Stroke Johnson Outboard Parts Diagram: Repair Guide

Identify the specific engine model and year to ensure you have the correct system configuration diagram.

Locate the major assembly groups, such as the powerhead, midsection, or lower unit, on the master layout.

Understand how individual parts connect by following the exploded view lines that indicate the assembly structure.

Apply the diagram’s numerical keys to your physical engine to find the exact component requiring service or replacement.

Verify that all washers, gaskets, and small fasteners are present according to the illustrated system layout before reassembly.

Complete the repair by tightening all components to the torque specifications mentioned in the associated service manual text.

Frequently Asked Questions

What is 2 stroke johnson outboard parts diagram diagram?

A 2 stroke johnson outboard parts diagram is a technical illustration showing the engine’s internal structure. It labels every component within the motor, from the powerhead to the lower unit. This layout helps owners visualize how parts integrate into the overall system for easier maintenance and repair tasks.

How do you read 2 stroke johnson outboard parts diagram diagram?

To read the diagram, begin by identifying the specific engine section, such as the gearcase or carburetor. Follow the numbered callouts to the corresponding parts list. This systematic configuration allows you to trace assembly sequences and understand how each individual component fits within the larger mechanical structure.

What are the parts of 2 stroke johnson outboard parts diagram?

Major parts include the powerhead assembly, carburetor, fuel pump, ignition coils, and the lower unit containing the propeller and water pump. Each component plays a vital role in the engine’s combustion system, working together to provide reliable propulsion while maintaining a compact and efficient mechanical structure.

Why is the carburetor component important?

The carburetor is a critical component because it regulates the fuel-to-air ratio required for combustion. In a 2-stroke system, it also helps distribute lubricating oil mixed with fuel. A clear diagram shows the internal configuration of jets and floats, which is essential for successful cleaning or rebuilding.

What is the difference between the powerhead and the lower unit?

The powerhead is the upper section where combustion occurs, housing the pistons and crankshaft. The lower unit is the submerged portion containing the gearbox and water pump. The parts diagram clarifies the layout of the drive shaft, which connects these two sections to transmit power to the propeller.

How do I use 2 stroke johnson outboard parts diagram diagram?

Use the diagram as a reference during disassembly to ensure every component is returned to its correct position. It helps identify worn seals or missing hardware within the system configuration. By following the visual structure, you can order exact replacement parts using the provided manufacturer reference numbers.