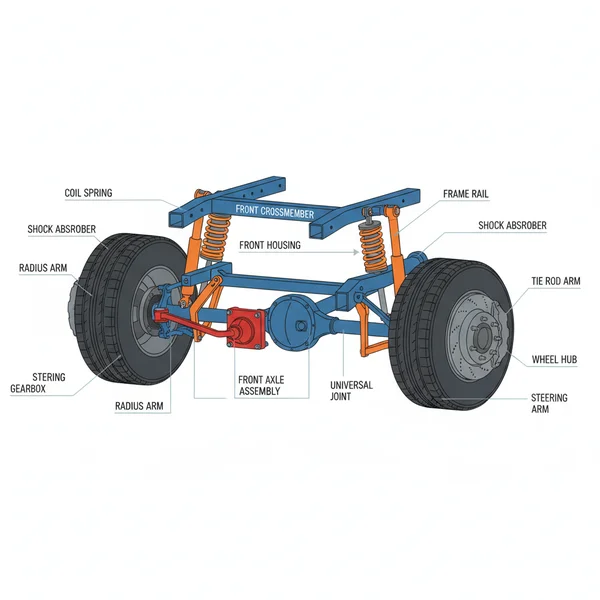

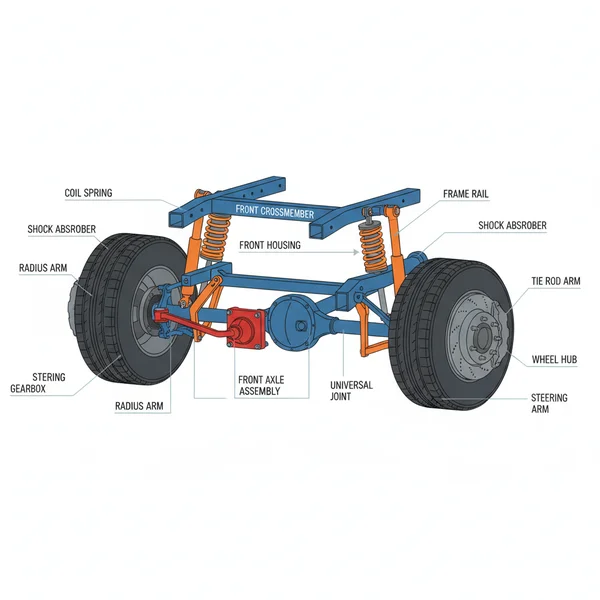

A truck front end parts diagram illustrates the complex configuration of the steering and suspension systems. This visual layout helps identify every critical component, such as tie rods, ball joints, and control arms. Understanding this structure is essential for performing repairs, ensuring vehicle stability, and maintaining overall road safety.

📌 Key Takeaways

- Identifies the relationship between steering and suspension systems

- The steering knuckle is the central pivot point to recognize

- Worn ball joints or tie rods are high-priority safety risks

- Use the diagram to verify part compatibility before purchasing

- Consult this layout during routine alignment or hardware inspections

When you are tackling a suspension repair or a steering overhaul, having access to a clear and accurate truck front end parts diagram is the difference between a successful weekend project and a vehicle stuck on jack stands. For many truck owners, the complex network of linkages, joints, and supports can be intimidating, but understanding the visual relationship between these components is essential for safety and performance. This guide provides a detailed roadmap of your vehicle’s forward architecture, explaining how each part interacts within the system. You will learn to identify key components, understand their functions, and gain the confidence to troubleshoot issues using a standardized layout.

Decoding the Truck Front End Parts Diagram

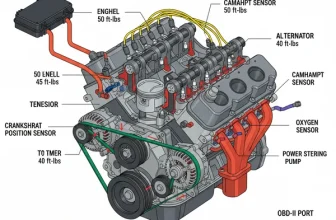

A comprehensive truck front end parts diagram serves as a blueprint for the vehicle’s steering and suspension configuration. Unlike passenger cars, trucks often utilize heavy-duty systems designed to handle significant payloads and off-road stresses. The diagram typically splits the front end into two primary categories: the steering linkage and the suspension system.

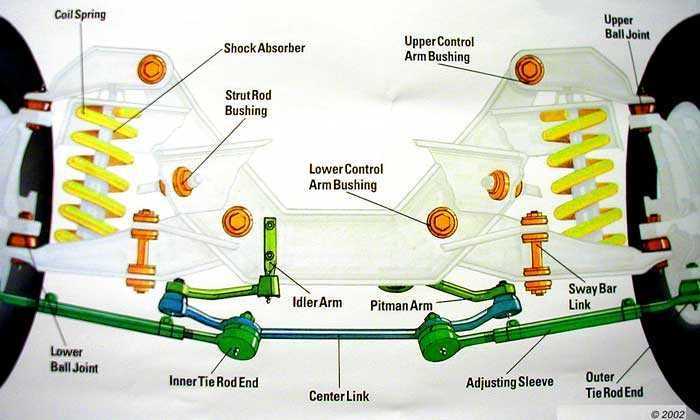

At the heart of the layout is the steering gear or rack-and-pinion, which converts your steering wheel’s rotation into lateral movement. In many heavy-duty trucks, you will find a recirculating ball system featuring a pitman arm and an idler arm connected by a center link. This structure is vital for maintaining the correct geometry of the wheels during turns. The suspension side of the diagram focuses on the control arms—usually divided into upper and lower components—which house the ball joints. These joints act as the pivot points for the steering knuckles, allowing the wheels to move up and down over bumps while still responding to steering inputs.

Color-coding in modern diagrams often distinguishes between stationary components (like the frame mounts) and dynamic components (like the tie rods and shocks). When reviewing your specific configuration, you may notice variations based on whether your truck is a four-wheel drive (4WD) or two-wheel drive (2WD) model. 4WD models will include additional elements such as the front differential, CV axles, and transfer case linkages, which add layers of complexity to the front-end structure.

Most truck front end systems are designed with “fail-safes.” For example, tie rod ends are typically threaded, allowing for precise alignment adjustments while ensuring that even if a locking nut loosens, the mechanical connection remains intact for a limited time.

Step-by-Step Guide to Interpreting and Using the Diagram

Reading a truck front end parts diagram requires a systematic approach to ensure you are identifying the correct component before beginning any mechanical work. Follow these steps to master the layout and prepare for your repair.

- Verify Your Vehicle Specifications: Before opening the diagram, confirm your truck’s make, model, and drive type. A 2500-series truck often has a completely different front-end system than a 1500-series model, frequently utilizing a solid front axle versus an independent front suspension (IFS).

- Locate the Steering Axis: Start at the steering box and follow the path to the wheels. On the diagram, find the pitman arm, which connects to the center link. From there, trace the inner and outer tie rods. This “path of motion” is the most logical way to understand how your steering input reaches the tires.

- Identify the Support Structure: Look for the upper and lower control arms. These are usually the largest triangular pieces in the diagram. Note where they connect to the frame via bushings and where they connect to the wheel hub via ball joints. This is the primary suspension system that supports the truck’s weight.

- Match Components to Physical Parts: With the diagram in hand, look under your truck. Identify the shock absorbers or struts. These are usually the most visible vertical components. Use them as an anchor point to find nearby parts like the sway bar links or the brake lines.

- Check for Fastener Details: Many professional diagrams include “exploded views” that show the specific nuts, bolts, and washers required for each joint. Note if the diagram specifies a “one-time use” torque-to-yield bolt, which must be replaced rather than reused.

- Prepare the Necessary Tools: Based on the diagram, gather your tools. You will typically need a heavy-duty jack, jack stands, a torque wrench, a pickle fork or ball joint separator, and a socket set ranging from 10mm to 32mm depending on the truck size.

- Assess the Component Condition: Use the diagram to guide your inspection. If the diagram shows a boot over a ball joint, check your truck for tears in that specific boot. If the diagram indicates a grease fitting (zerk), ensure that part of your system is properly lubricated.

- Document the Disassembly: As you remove parts shown in the diagram, lay them out in the same orientation as they appear on paper. This prevents installing a tie rod or control arm backward, which is a common mistake in front-end work.

Never work under a truck supported only by a floor jack. Always use rated jack stands placed on a level, concrete surface. Front-end components are under significant tension; releasing a ball joint without proper support can cause the suspension to spring outward violently.

Common Issues and Troubleshooting with Diagrams

When a truck begins to handle poorly, the truck front end parts diagram becomes your primary diagnostic tool. One of the most frequent issues is “steering wander,” where the truck feels loose and drifts across the lane. By referencing the diagram, you can systematically check the “play” in the tie rod ends and the idler arm. If these components show movement when the steering wheel is nudged, they are likely worn and require replacement.

Another common problem is uneven tire wear. If the inside or outside edges of your tires are wearing faster than the center, the diagram helps you locate the cam bolts on the control arms. These bolts are responsible for the “camber” and “caster” settings. Additionally, clunking sounds when driving over bumps usually point toward the sway bar links or bushings. By identifying these parts on the layout, you can use a pry bar to check for excessive movement in those specific areas. For “death wobble”—a violent shaking of the front end common in solid-axle trucks—the diagram will point you toward the track bar and the steering stabilizer, which are the primary culprits for this dangerous condition.

If you are replacing one side of the front end, always replace the corresponding part on the other side. Components like tie rods and ball joints usually have similar lifespans; if one has failed, the other is likely close behind.

Best Practices for Front End Maintenance

To ensure the longevity of the components highlighted in your truck front end parts diagram, consistent maintenance is paramount. Many aftermarket parts come equipped with grease fittings that allow you to pump fresh lubricant into the joints. This flushes out contaminants and reduces friction. If your truck is used for towing or off-roading, you should perform this “lube job” every 3,000 to 5,000 miles.

- ✓ Torque to Specification: Never “guess” how tight a bolt should be. Use a torque wrench to meet the exact foot-pounds specified in your service manual.

- ✓ Professional Alignment: Any time you replace a part found on the steering diagram, you must take the truck to a shop for a professional alignment. Even a millimeter of difference can ruin a set of tires in weeks.

- ✓ Inspect Boot Integrity: Regularly check the rubber boots on ball joints and tie rods. If the rubber is cracked, road salt and grime will enter the joint and cause rapid failure.

- ✓ Choose Quality Components: When replacing parts, opt for heavy-duty or “problem solver” versions that feature thicker housings and better sealing technology than the original equipment.

Maintaining your truck’s front end is a significant responsibility that impacts both the vehicle’s lifespan and your safety on the road. By utilizing a high-quality truck front end parts diagram, you transform a confusing mess of metal into a logical, manageable system. Whether you are performing a routine inspection or a complete system overhaul, the diagram provides the essential context needed to complete the job with precision. Remember that while DIY repairs are rewarding, steering and suspension are critical systems; if you encounter a component that is seized or if you are unsure of a specific configuration, do not hesitate to consult a professional technician. Keeping your front end in peak condition ensures your truck remains responsive, stable, and ready for whatever the road throws your way.

Frequently Asked Questions

What is truck front end parts diagram?

A truck front end parts diagram is a visual map showing the specific system of mechanical parts at the vehicle’s front. It illustrates how every component, from the steering rack to the shock absorbers, integrates into the chassis structure. This layout is vital for troubleshooting mechanical issues and maintenance.

How do you read truck front end parts diagram?

To read the diagram, start by identifying the main axle or frame rails as your reference point. Follow the interconnected lines that show the configuration of steering linkages and suspension arms. Most diagrams use numbered labels to help you locate each specific component within the overall mechanical system.

What are the parts of truck front end parts?

The primary parts include the control arms, ball joints, tie rods, and steering knuckles. These elements form the steering system and suspension structure. Additionally, you will find shocks, springs, and bushings, which are critical for the layout to function properly under heavy loads and uneven road conditions.

Why is tie rod important?

The tie rod is a critical component because it connects the steering rack to the wheel assembly. Without this vital part in the steering configuration, the driver cannot control the vehicle’s direction. It ensures the layout remains stable, allowing for precise wheel alignment and safe handling.

What is the difference between steering and suspension?

The main difference is that a steering system controls the vehicle’s direction, while the suspension system manages ride quality and weight distribution. Though they share a compact layout, the steering focuses on pivoting components, whereas the suspension structure utilizes shocks and springs to absorb road impacts.

How do I use truck front end parts diagram?

Use the diagram by matching the visual layout to the actual hardware on your truck. Identify specific parts needing replacement or inspection by comparing the diagram structure to your vehicle. This helps ensure you purchase the correct component and follow the proper installation sequence for safe repairs.