Truck Chevy Chevy Steering Column Diagram: Repair Guide

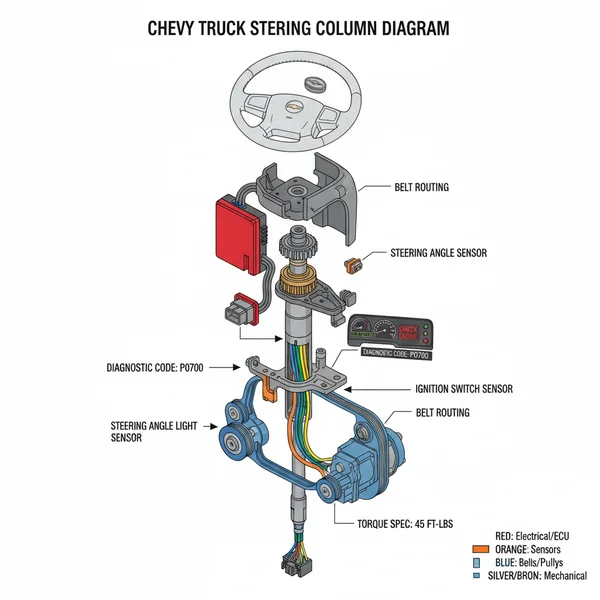

A Chevy truck steering column diagram illustrates the assembly of the steering shaft, ignition switch, turn signal switch, and tilt mechanism. It acts as a visual map for troubleshooting mechanical play or electrical faults, helping you identify specific components before disassembly to ensure proper reinstallation and steering system alignment.

📌 Key Takeaways

- Visualizes the relationship between the steering shaft and ignition system

- Identifies the clock spring as the most critical electrical component

- Always disconnect the battery to prevent accidental airbag deployment

- Check all wiring connections to the ECU to resolve electrical faults

- Use this diagram when replacing the ignition cylinder or shift linkage

When you are faced with a loose steering wheel, a failing ignition switch, or a clicking sound during turns in your pickup, a truck chevy chevy steering column diagram becomes an indispensable tool. Navigating the internal components of a steering assembly requires more than just mechanical intuition; it demands a clear visual roadmap to ensure every spring, bearing, and bolt is returned to its precise location. This article provides a comprehensive breakdown of the Chevy steering column, explaining the intricate relationship between mechanical linkages and electronic sensors. By the end of this guide, you will understand how to interpret these diagrams to perform repairs safely, identify part numbers accurately, and maintain the structural integrity of your truck’s steering system.

Understanding the Truck Chevy Chevy Steering Column Diagram

A truck chevy chevy steering column diagram typically represents an “exploded view” of the entire assembly, from the steering wheel down to the intermediate shaft that connects to the steering gear or rack. The primary purpose of this diagram is to show the sequence of assembly and the spatial relationship between complex internal parts. In most Chevy truck models, the column is a multi-layered cylinder containing the main steering shaft, the shift linkage (for automatic transmissions), and various electrical harnesses.

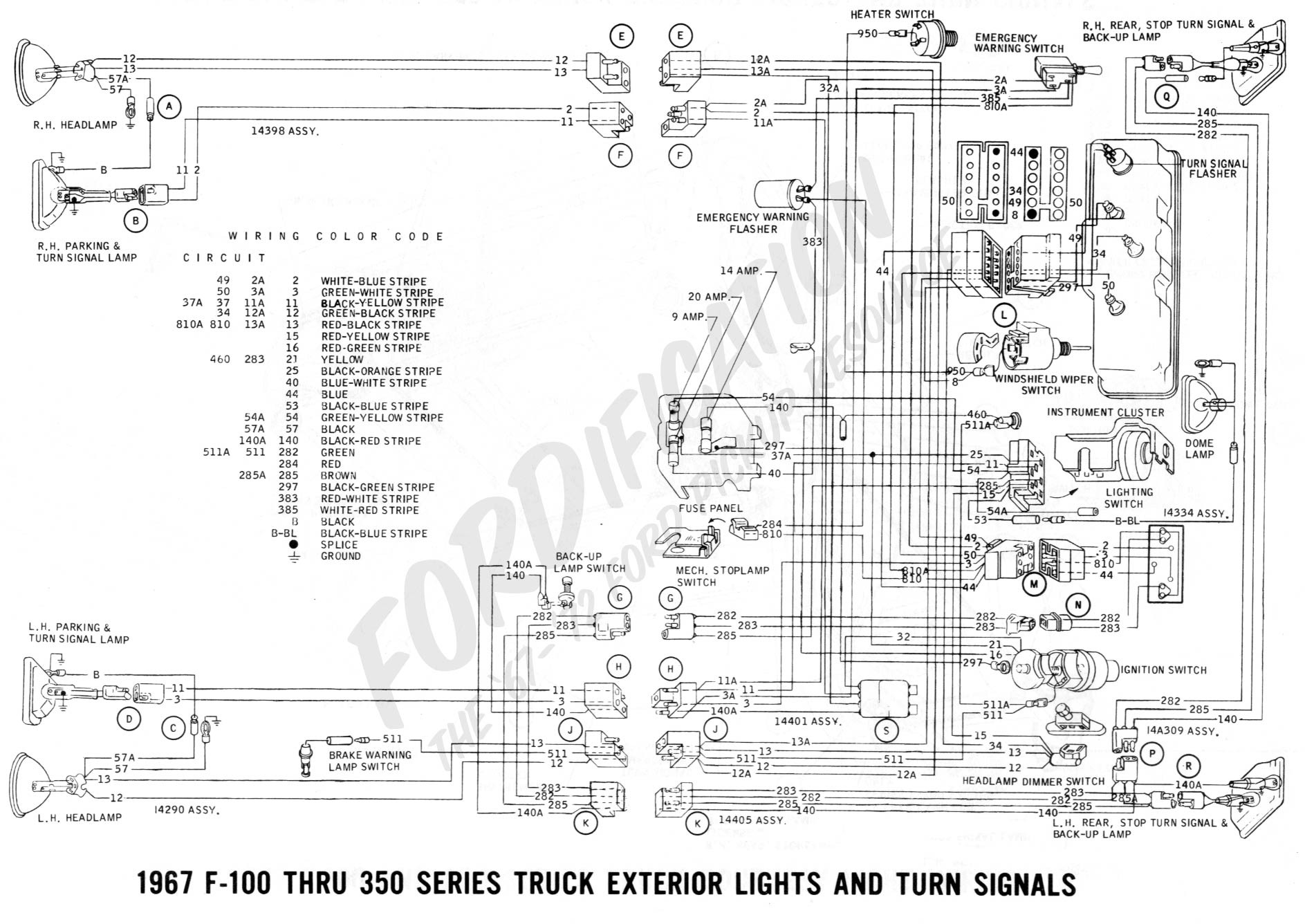

At the top of the diagram, you will find the steering wheel nut and the clock spring. The clock spring is a critical component that allows the steering wheel to rotate while maintaining a constant electrical connection for the airbag and horn. Below this, the diagram illustrates the turn signal switch assembly and the ignition lock cylinder. One of the most complex areas shown in the diagram is the tilt mechanism. This includes heavy-duty springs and pivot pins that allow the driver to adjust the wheel height.

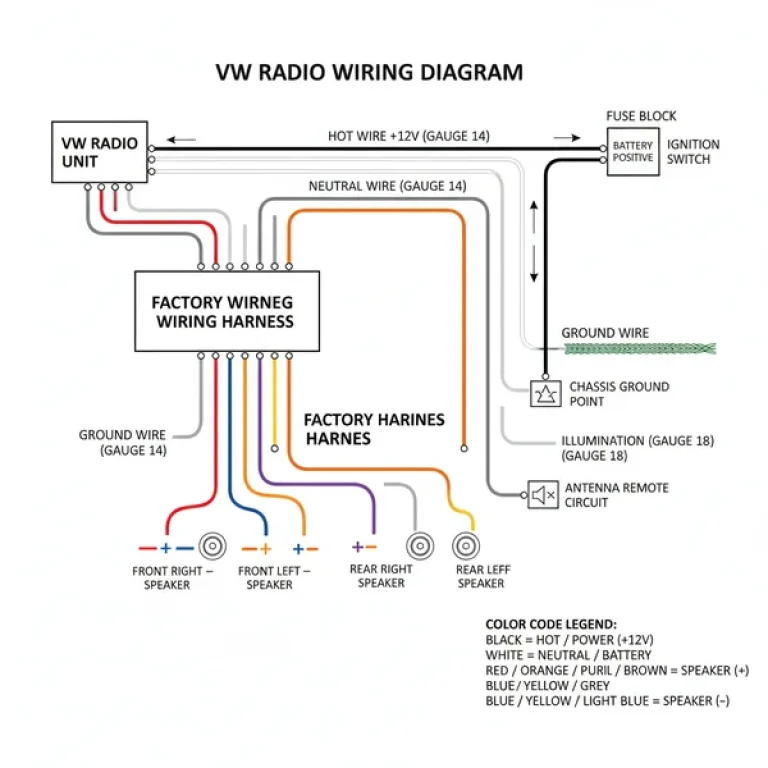

Visualizing these components helps in identifying whether a problem is mechanical, such as a worn upper bearing, or electrical, such as a pinched wire. For models equipped with column-shifters, the diagram will also detail the shift bowl and the shift lever pin. These diagrams are often color-coded in professional service manuals to distinguish between the structural housing and the moving internal shafts. Understanding these nuances is essential before you begin any disassembly, as it prevents the common mistake of removing snap rings or tension springs in the wrong order.

Step-by-Step Guide to Interpreting and Using the Diagram

Using a truck chevy chevy steering column diagram for a repair requires a systematic approach to ensure safety and precision. Follow these steps to navigate the assembly process effectively:

- Verify Your Specific Model: Before starting, ensure your diagram matches your truck’s specific configuration. Diagrams differ significantly between manual and automatic transmissions, as well as between tilt and non-tilt columns. Check for the presence of a steering angle sensor, which communicates with the ECU to manage stability control.

- Safety First (Battery and Airbag): Always disconnect the negative battery terminal and wait at least ten minutes before touching the steering column. This allows the capacitors for the airbag system to discharge. Failure to do this can result in accidental deployment and serious injury.

- Removing the Outer Shroud: Use the diagram to locate the hidden screws holding the plastic column covers together. These are often T-15 or T-20 Torx bits. Once the covers are removed, you can begin matching the physical wires to the electrical connectors shown on the diagram.

- Accessing the Steering Wheel: Use a specialized steering wheel puller tool. The diagram will show the threaded holes where the puller bolts should be inserted. Never hammer on the steering shaft, as this can collapse the energy-absorbing mechanism built into the column.

- Identifying the Ignition and Multi-Function Switch: Locate the ignition lock cylinder on your diagram. On many Chevy trucks, a small pin must be depressed while the key is in the “on” position to slide the cylinder out. The diagram helps you find this access hole, which is often obscured by the housing.

- Inspecting the Intermediate Shaft: The bottom of the diagram shows where the column exits the firewall and connects to the intermediate shaft. Check the universal joints for play. If you feel a “clunk” in the steering, the diagram will help you identify the specific pinch bolt that needs to be tightened or replaced.

- Reassembly and Torque Specs: As you put everything back together, refer to the diagram for the correct torque spec of the main steering wheel nut and the column mounting bolts. Proper tightness is vital for safety; an under-tightened nut can lead to steering failure, while over-tightening can damage the bearings.

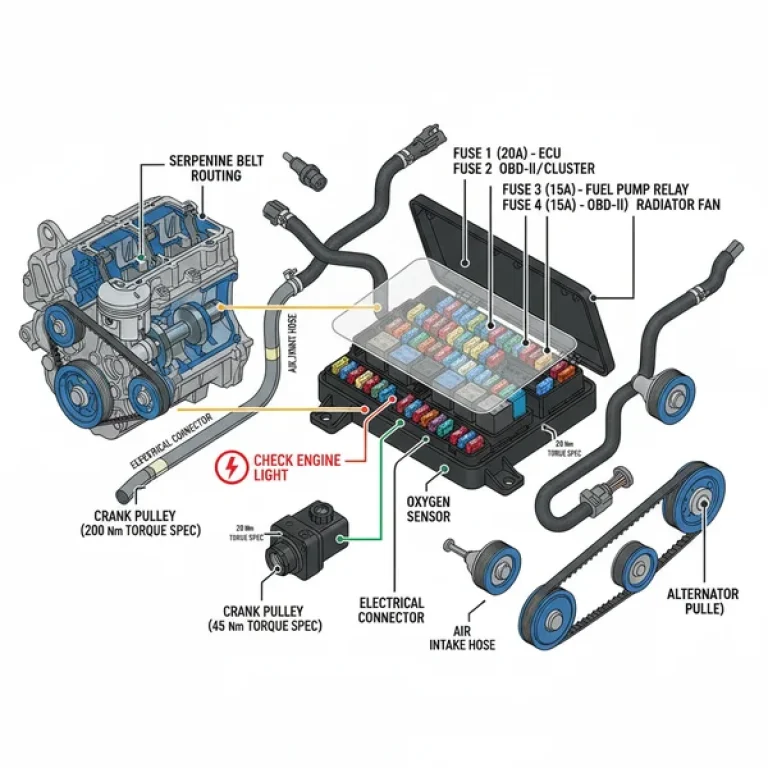

Modern steering columns are integrated with the vehicle’s Supplemental Restraint System (SRS). If you accidentally disconnect or damage the clock spring, the check engine light or SRS warning light may illuminate. Always use an OBD-II scanner to clear any soft codes and ensure the system is functioning correctly after reassembly.

Common Issues and Troubleshooting with the Steering Column

Steering column issues often manifest as physical feedback or electrical glitches. One of the most frequent complaints in older Chevy trucks is “column play” or a loose feel when driving. By consulting the truck chevy chevy steering column diagram, you can identify the four internal E-8 Torx bolts that commonly back out over time, causing the tilt mechanism to wobble.

Another common issue involves the ignition switch, which is separate from the key cylinder but sits lower on the column. If your truck fails to start or the electronics flicker, the diagram will show you how the actuator rod connects the key cylinder to the switch. If the ECU does not receive a signal from the ignition switch, it may throw a diagnostic code related to power input or immobilizer failure.

If you notice a grinding noise when turning, the upper or lower steering column bearings are likely dry or worn. The diagram indicates their location, allowing you to apply white lithium grease or replace them before they score the main shaft.

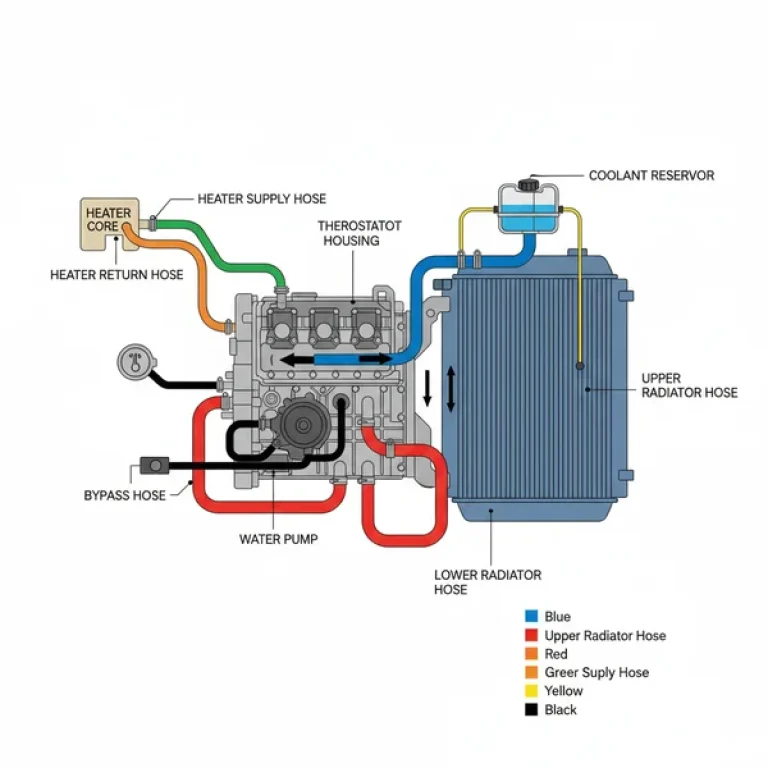

Sometimes, steering symptoms are actually related to other systems. For example, a heavy steering feel might not be a column issue but rather a problem with the power steering pump or a slipping accessory belt. Always rule out external factors, like proper coolant flow (to prevent engine overheating which can affect nearby components) or engine vibrations from a worn timing chain, before tearing into the steering column.

Tips and Best Practices for Steering Column Maintenance

Maintaining your steering column ensures long-term reliability and driver safety. Here are several pro-level tips to keep your system in top shape:

- ✓ Use Magnetic Trays: The steering column contains dozens of tiny springs, clips, and screws. Keeping them organized in the order they were removed is the best way to ensure reassembly matches the diagram.

- ✓ Mark Your Alignment: Before removing the steering wheel, use a paint pen to mark the relationship between the wheel and the splined shaft. This ensures your steering wheel isn’t crooked when you drive straight.

- ✓ Check Electrical Grounds: Many steering column issues are actually bad grounds. Ensure the wiring harness shown in the diagram is securely grounded to the metal substructure of the dashboard.

- ✓ Lubricate Pivot Points: During any teardown, lightly grease the tilt pivot pins. This prevents the “squeak” many truck owners experience during cold weather.

If you are replacing the entire column, look for high-quality OEM replacements or reputable refurbished units. Cheap aftermarket columns often have poor tolerances in the bearing seats, leading to premature failure and more time spent back under the dash.

When performing these repairs, always have your OBD-II scanner handy. Even if you don’t have a check engine light, checking for “pending codes” can alert you to a diagnostic code related to the steering angle sensor or the transmission shift solenoid before they become major problems. Combining the mechanical knowledge from the truck chevy chevy steering column diagram with modern diagnostic tools is the most effective way to keep your vehicle on the road.

In conclusion, mastering the truck chevy chevy steering column diagram is about more than just identifying parts; it is about understanding the mechanical harmony of your vehicle. Whether you are tightening the tilt housing to eliminate play or replacing a faulty clock spring to clear an airbag light, having a clear visual reference ensures the job is done right the first time. By following the torque spec guidelines and respecting the safety protocols for the electrical system, you can maintain your Chevy’s steering precision for hundreds of thousands of miles. Remember that while the steering column is a complex piece of engineering, it is manageable for any DIY enthusiast who takes the time to study the diagram and proceed with patience and care.

Frequently Asked Questions

What is truck chevy chevy steering column diagram?

This diagram is a detailed schematic showing the internal parts of a Chevrolet truck’s steering assembly, including the main shaft, bearings, and switches. It helps mechanics visualize how components like the ignition lock cylinder and shifter linkage interact within the column housing to control steering, lighting, and gear selection.

How do you read truck chevy chevy steering column diagram?

To read the diagram, start by identifying the legend for symbols and line styles. Look for callout numbers that correspond to a parts list. Trace the wiring paths that connect to the ECU and note how different circuits facilitate functions like the airbag, cruise control, and horn signals.

What are the parts of truck chevy chevy steering column?

Key parts include the upper and lower shafts, universal joints, shift lever, and electrical switches. The diagram also details sensors that communicate with the ECU. Understanding these parts is essential for diagnosing mechanical stiffness or electrical failures that might trigger a check engine light or a specific diagnostic code.

Why is the clock spring important?

The clock spring is vital because it maintains a continuous electrical connection between the steering wheel buttons and the ECU while the wheel turns. If it fails, you may see a check engine light or SRS warning. Following the diagram ensures the clock spring is centered correctly during installation.

What is the difference between tilt and non-tilt columns?

Tilt steering columns feature a pivot joint, locking pawls, and adjustment springs that non-tilt models lack. The diagram for a tilt column includes these additional mechanical levers. When repairing these units, you must follow the correct torque spec for the pivot pins to prevent steering play and wobbling.

How do I use truck chevy chevy steering column diagram?

Use the diagram as a reference during disassembly to track hardware and internal springs. If an electrical issue occurs, use an OBD-II scanner to pull a diagnostic code first. Then, use the diagram to locate the relevant wires or sensors to perform continuity tests or component replacements.