Truck Air Brake System Diagram: Maintenance and Troubleshooting

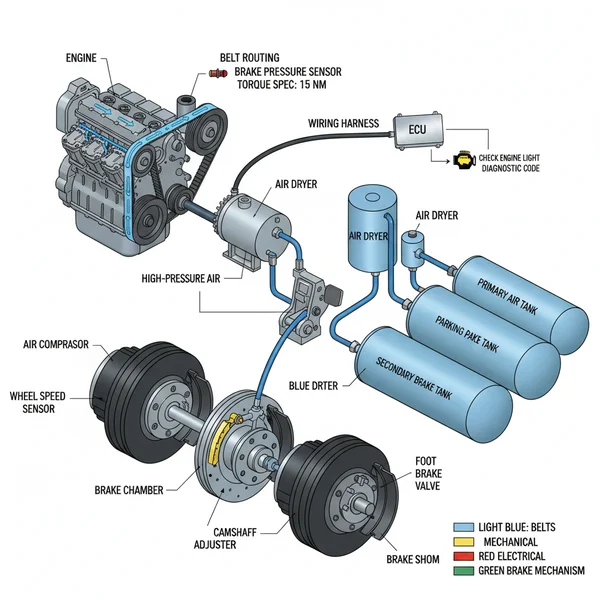

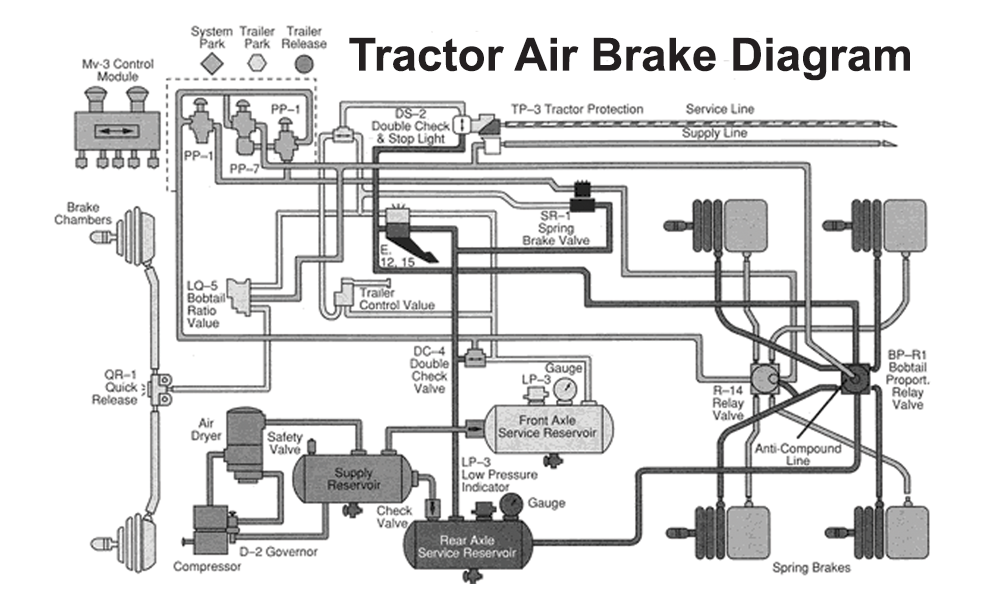

A truck air brake system diagram maps the flow of compressed air from the compressor through tanks to the brake chambers. It illustrates how the ECU manages anti-lock functions and how drivers trigger the service, parking, and emergency brakes to ensure safe stopping distances for heavy vehicles.

📌 Key Takeaways

- Visualize air flow and pressure regulation throughout the vehicle.

- The air compressor is the heart of the pneumatic pressure generation.

- Never ignore low-pressure warnings or moisture in the storage tanks.

- Use the diagram to locate specific valves for accurate leak testing.

- Essential roadmap for annual inspections or roadside emergency repairs.

Understanding the mechanical and pneumatic intricacies of heavy-duty vehicles is a prerequisite for ensuring road safety and operational efficiency. If you are a mechanic, fleet owner, or a DIY enthusiast, having a clear and accurate truck air brake system diagram is the foundation for effective troubleshooting and repair. This comprehensive guide will walk you through the entire air brake architecture, from the initial compression of air to the final application of the brake shoes. You will learn how to identify critical components, understand the logic of multi-circuit air flow, and see how modern electronics like the ECU integrate with traditional pneumatic hardware. By the end of this article, you will have a professional-level understanding of how these life-saving systems function under pressure.

Understanding the Architecture of a Truck Air Brake System Diagram

A comprehensive truck air brake system diagram is not just a collection of lines; it is a map of three distinct yet interconnected circuits: the supply circuit, the service circuit, and the parking/emergency circuit. To the untrained eye, the labyrinth of hoses can be daunting, but standardized color-coding typically simplifies the interpretation. In most modern diagrams, the supply lines are shown in red, the service lines in blue, and the secondary or auxiliary lines in green or yellow.

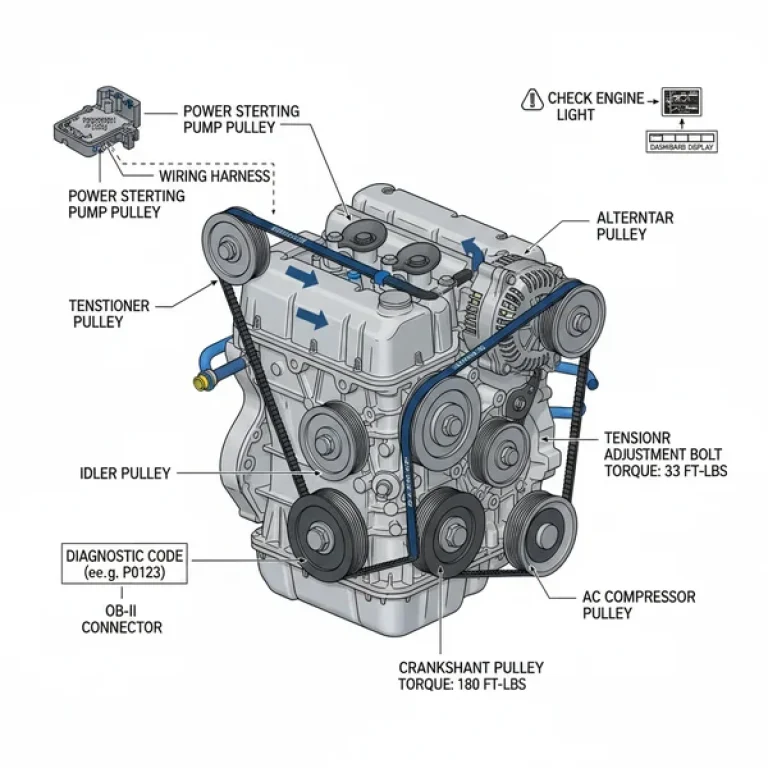

At the heart of the diagram is the air compressor. In many heavy-duty engines, this unit is gear-driven by the engine’s timing chain or timing gear assembly, while in medium-duty applications, it may be powered by an accessory belt. The diagram illustrates how the compressor takes in atmospheric air and pumps it into the system. This compressed air is then routed to the air dryer, which removes moisture and contaminants—a critical step to prevent frozen lines in winter. From the dryer, the air flows into the primary and secondary reservoirs (wet tank and dry tanks).

Modern systems are further complicated by the integration of the Electronic Control Unit (ECU). The ECU acts as the brain of the braking system, monitoring wheel speed sensors to manage Anti-lock Braking Systems (ABS) and Automatic Traction Control (ATC). The diagram will show electrical pathways connecting the ECU to various modulator valves, ensuring that pneumatic pressure is adjusted millisecond-by-millisecond to prevent wheel lockup.

Most modern trucks use a “dual air system” for safety. If one circuit fails (e.g., the primary rear circuit), the secondary circuit (front brakes) remains functional to bring the vehicle to a controlled stop.

Step-by-Step Guide: How to Read and Inspect the Air Brake System

Interpreting a truck air brake system diagram requires a systematic approach. You must follow the flow of air chronologically to understand where a potential failure might occur. Use the following steps to trace the system during an inspection or overhaul.

- Trace the Air Generation Path: Begin at the compressor. Verify if it is gear-driven via the timing chain or belt-driven. Check the coolant flow lines entering and exiting the compressor head. These lines are vital as they prevent the compressor from overheating during high-duty cycles.

- Analyze the Governor and Dryer: Locate the governor on your diagram. This component tells the compressor when to start pumping (cut-in) and when to stop (cut-out). Following this, trace the line to the air dryer. If the purge valve is leaking, the diagram helps you identify which control line signals the purge cycle.

- Map the Reservoir Distribution: Air moves from the wet tank to the primary and secondary reservoirs. Look for one-way check valves in your diagram; these are crucial because they ensure that a leak in one tank does not deplete the air in the others.

- Examine the Foot Valve (Treadle Valve): When you step on the brake pedal, you are actuating the foot valve. The diagram shows how this valve splits the air signal into two separate paths: one for the rear brakes (Primary) and one for the front brakes (Secondary).

- Locate Relay and Quick Release Valves: Because air takes time to travel long distances, relay valves are placed near the rear axles. The diagram will show a large-diameter supply line connected directly from a reservoir to the relay valve, with a smaller “signal” line coming from the foot valve.

- Inspect the Brake Chambers: The final destination is the brake chamber. Here, air pressure is converted into mechanical force. Ensure you know the difference between a service chamber and a spring brake (emergency) chamber as depicted on your schematic.

Never attempt to disassemble a spring brake chamber. These contain high-tension springs that can cause fatal injuries if released improperly. Always use a caging bolt to “cage” the spring before removal.

To perform these inspections, you will need a set of basic tools, including a high-pressure air gauge, a soapy water spray bottle (for leak detection), and a torque wrench to ensure every bolt meets the manufacturer’s torque spec. When replacing components like slack adjusters or S-cam brackets, following the exact torque spec is non-negotiable for safety.

Common Issues and Troubleshooting with Modern Diagnostics

Even with a perfect truck air brake system diagram, mechanical failures occur. One of the most common issues is a slow air pressure build-up. By referencing your diagram, you can narrow this down to a slipping accessory belt, a failing compressor, or a stuck-open purge valve in the air dryer.

Modern trucks have moved beyond purely mechanical diagnostics. If you see a check engine light or an ABS warning lamp on the dashboard, the system is telling you that the ECU has detected an abnormality. By connecting a scanner to the OBD-II port (or the heavy-duty J1939 port), you can pull a specific diagnostic code.

- ✓ Air Leaks: Use the diagram to identify “audible” leak points, such as relay valve exhaust ports or glad-hand seals.

- ✓ Brake Drag: Often caused by a seized S-cam or a failing return spring within the brake chamber, visible as the “mechanical end” of the diagram.

- ✓ ABS Faults: Triggered by the ECU when a wheel speed sensor sends an erratic signal; use the wiring portion of your diagram to check for frayed leads.

If the diagnostic code points to a “Low Pressure Sensor” or “Modulator Valve Solenoid Failure,” use your schematic to find the exact location of that sensor within the pneumatic circuit. This prevents the “parts cannon” approach, where expensive components are replaced unnecessarily.

Tips and Best Practices for System Maintenance

Maintaining a truck’s air brake system is a matter of consistency. While the truck air brake system diagram shows you where things are, a maintenance schedule tells you when to check them.

Daily reservoir draining is the single best way to extend the life of your braking system. Even with an automatic moisture ejector, manually pulling the drain cords ensures that the wet tank is truly dry.

When performing maintenance, pay close attention to the following:

- ✓ Lubrication: Use the diagram to identify grease points on slack adjusters and S-cam bushings. Proper lubrication prevents the mechanical binding that air pressure alone cannot overcome.

- ✓ Compressor Health: Ensure the coolant flow to the compressor is unobstructed. Excessive carbon buildup in the discharge line (the line from the compressor to the dryer) is a sign that the compressor is running too hot or passing oil.

- ✓ Quality Parts: When replacing lines, ensure they are DOT-approved nylon or wire-braided hoses as specified in your vehicle’s parts manual.

Cost-saving in the short term by ignoring a minor air leak or bypassing a dryer can lead to catastrophic expenses later. A small leak causes the compressor to cycle more frequently, leading to premature wear on the accessory belt or timing gears and eventually causing a total compressor failure.

Conclusion

Mastering the use of a truck air brake system diagram is an invaluable skill for anyone involved in heavy vehicle operation. By understanding the journey air takes from the atmosphere to the brake drums, you can demystify complex mechanical behaviors. Whether you are chasing a stubborn diagnostic code through the ECU and OBD-II interface or simply performing a routine check of the coolant flow through your compressor, the diagram serves as your essential roadmap.

Remember that safety is the ultimate goal. Always adhere to the recommended torque spec for every fastener and keep a watchful eye on your check engine light for early warnings. With the knowledge gained from this guide, you are now prepared to maintain, troubleshoot, and respect the incredible engineering that keeps heavy trucks stopping safely every day. Regular reference to your specific vehicle’s truck air brake system diagram will ensure that you remain a proficient and safe technician or operator.

Frequently Asked Questions

What is a truck air brake system diagram?

A truck air brake system diagram is a visual schematic representing the pneumatic circuits, valves, and reservoirs used to stop heavy-duty vehicles. It tracks compressed air from the engine-driven compressor to the brake chambers, showing how pressure is regulated and distributed across the tractor and trailer axles for safety.

How do you read a truck air brake system diagram?

To read the diagram, follow the lines representing air hoses from the supply source toward the delivery components. Look for color-coded lines indicating primary, secondary, and emergency circuits. Identifying symbols for the ECU, air dryer, and foot valves helps you understand how signal pressure initiates mechanical braking force effectively.

What are the parts of a truck air brake system?

Major parts include the air compressor, governor, air dryer, reservoirs, foot valve, and brake chambers. Electronic components like the ECU monitor wheel speed, while dash gauges provide real-time pressure feedback. S-cam or disc brake assemblies then convert this pneumatic pressure into mechanical friction to stop the heavy wheels safely.

Why is the ECU important in this system?

The ECU, or Electronic Control Unit, is the brain of the modern air brake system, specifically for ABS functionality. It monitors wheel speed sensors to prevent lock-up during hard braking. If a fault occurs, it triggers the check engine light or ABS light and stores a specific diagnostic code.

What is the difference between air brakes and hydraulic brakes?

Air brakes use compressed air to transmit force, whereas hydraulic brakes use liquid fluid. Air systems are more tolerant of small leaks and are modular, allowing trailers to be easily connected. However, air systems require compressors and dryers, whereas hydraulic systems are simpler but less effective for extremely heavy loads.

How do I use a truck air brake system diagram?

Use the diagram to trace air leaks or identify faulty valves when a diagnostic code appears via the OBD-II port. It helps locate test ports for pressure gauges and ensures that when replacing components, you follow the correct torque spec for fittings. It is an essential roadmap for maintenance.