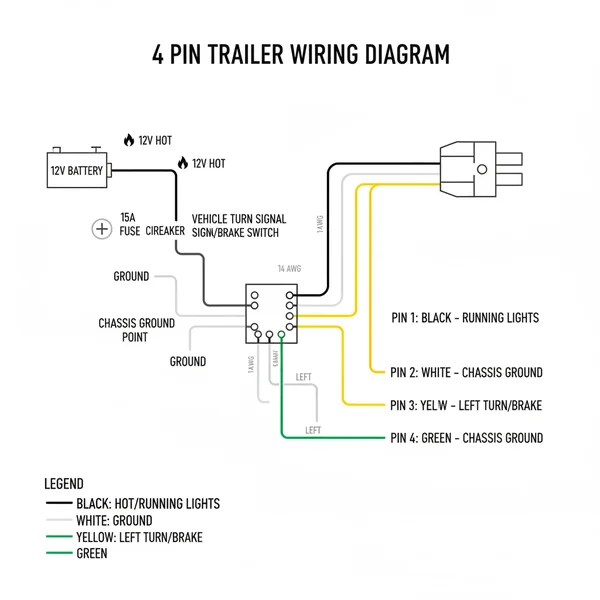

A 4 pin trailer wiring diagram provides a visual map for connecting your vehicle to a trailer. It typically includes the ground wire (white), tail lights (brown), left turn (yellow), and right turn (green). Proper grounding to a common terminal ensures the hot wire signals reach your lights without failure.

📌 Key Takeaways

- The diagram identifies color-coded circuits for brakes, turns, and tail lights

- The white ground wire is the most critical connection for circuit completion

- Always ensure a metal-to-metal connection at the common terminal for the ground

- Use a circuit tester to verify the hot wire output before connecting the trailer

- Use this diagram when installing a new harness or troubleshooting dim trailer lights

When you are preparing to tow a utility trailer, boat, or camper, ensuring your lighting system functions correctly is not just a matter of convenience; it is a critical safety requirement. A trailer wiring diagram 4 pin setup is the industry standard for light-duty towing, providing the essential signals for running lights, turn signals, and brake lights. Understanding how these four wires interact allows you to troubleshoot flickering lights, replace corroded plugs, or install a new harness from scratch. This article provides a comprehensive guide to reading a 4-pin diagram, identifying color codes, and executing a professional-grade installation to keep your towing experience safe and legal.

Understanding the 4-Pin Trailer Wiring Standard

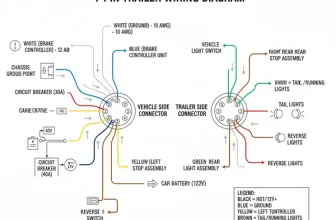

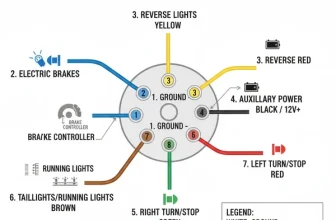

The 4-pin flat connector is the most common trailer interface found on the road today. It is designed to carry basic lighting functions without the added complexity of electric brakes or auxiliary power lines. The diagram for a 4-pin system identifies four specific circuits that must be completed between the tow vehicle and the trailer. These include the ground, the tail/running lights, the left turn/brake light, and the right turn/brake light.

In a standard trailer wiring diagram 4 pin configuration, the layout is designed for simplicity and durability. The connector usually features one shrouded male pin and three exposed female pins on the vehicle side, while the trailer side features the opposite arrangement to prevent accidental short circuits. Each pin corresponds to a specific wire color that has been standardized across the industry, ensuring that a trailer built by one manufacturer will be compatible with a vehicle hitch installed by another.

While most modern systems use flat 4-way connectors, some older or heavy-duty applications might use a 4-way round plug. These round plugs often utilize a internal brass screw to secure each traveler wire to its respective terminal. Despite the different shape, the electrical functions and color coding remain identical.

[DIAGRAM_PLACEHOLDER: A visual representation of a 4-pin flat connector. Top wire: White (Ground). Second wire: Brown (Tail/Running). Third wire: Yellow (Left Turn/Brake). Fourth wire: Green (Right Turn/Brake).]

Deep Dive into Wire Functions and Specifications

To master the trailer wiring diagram 4 pin setup, you must understand the role of each individual wire. Unlike residential wiring, which uses 120V AC power, automotive towing systems operate on 12V DC. This means the components, such as the wire gauge and insulation type, are specifically chosen to handle low voltage over moderate distances without significant power drop.

- ✓ White Wire (Ground): This is the most important wire in the system. It acts as the common terminal for all other circuits, providing a return path to the vehicle’s battery.

- ✓ Brown Wire (Tail/Running Lights): This wire carries the signal for your trailer’s side markers and rear tail lights, usually activated whenever the vehicle’s headlights are on.

- ✓ Yellow Wire (Left Turn/Brake): This is a dual-function traveler wire that handles both the flashing left turn signal and the solid left brake light.

- ✓ Green Wire (Right Turn/Brake): Similar to the yellow wire, this handles the right-side signaling and braking functions.

In terms of physical specifications, the wire gauge is a vital factor. Most 4-pin harnesses use 16-gauge or 18-gauge wire. A thicker 16-gauge wire is preferred for longer trailers to ensure that the voltage remains consistent from the vehicle’s bumper to the very back of the trailer. If the gauge is too thin, the lights may appear dim, or the wires may overheat under the constant load of the running lights.

Step-by-Step Installation and Wiring Guide

Whether you are replacing a damaged plug or wiring a new trailer, following a systematic approach ensures that you don’t cross signals or create a “hot wire” situation where a live circuit accidentally touches the metal frame of the trailer.

Step 1: Gather Your Tools and Materials

Before starting, ensure you have a high-quality 4-pin wiring kit, wire strippers, a crimping tool, heat-shrink tubing, and a multimeter. If you are using a round 4-pin connector, you may also need a small screwdriver to tighten the brass screw on the internal terminals.

Step 2: Prepare the Trailer Frame

The ground wire (white) must be securely attached to the trailer frame. Scrape away any paint or rust at the connection point to ensure metal-to-metal contact. Use a self-tapping screw and a ring terminal to create a solid common terminal point.

Step 3: Route the Main Harness

Run the 4-wire ribbon along the inside of the trailer frame. Use frame clips or UV-rated zip ties to keep the wires from sagging. Avoid routing wires near moving parts like the suspension or folding tongues, as this can pinch and sever the traveler wire paths.

Step 4: Connect the Tail Lights (Brown Wire)

The brown wire often splits into two paths—one for the left side and one for the right side. Connect these to the “running light” lead on your tail light assemblies. In the world of DC electronics, this is your primary “hot wire” for nighttime visibility.

Step 5: Connect the Left and Right Signal Wires

Connect the yellow wire to the left tail light’s turn/brake terminal and the green wire to the right tail light’s turn/brake terminal. If you are using a 4-pin round plug, ensure each wire is inserted into the correct labeled hole before tightening the brass screw.

Step 6: Insulate All Connections

Never leave bare wire exposed. Use heat-shrink tubing or waterproof butt connectors to seal every splice. Since trailers are often exposed to rain, road salt, and submersion (in the case of boat trailers), moisture is the enemy of a clean voltage signal.

Step 7: Test the Vehicle-Side Voltage

Before plugging in the trailer, use a circuit tester on the vehicle’s 4-pin plug. Check the voltage on each pin while a partner operates the lights. You should see a steady 12V DC on the brown wire and a pulsing signal on the yellow and green wires when the blinkers are engaged.

Step 8: Final Connection and Function Check

Plug the trailer into the vehicle and perform a “walk-around” test. Check the left turn, right turn, brake lights, and running lights. If the lights are dim, revisit Step 2 and ensure your ground wire connection is perfect.

Always disconnect the vehicle’s battery or unplug the harness before cutting or splicing wires. Accidental contact between a hot wire and the frame can blow vehicle fuses or damage sensitive onboard computer modules.

Common Issues and Troubleshooting

Even with a perfect trailer wiring diagram 4 pin installation, issues can arise over time. Most trailer lighting problems stem from three sources: corrosion, poor grounding, or broken wires.

One of the most frequent symptoms is “erratic behavior,” where turning on the blinker causes all the trailer lights to flash dimly. This is almost always a ground wire issue. When the white wire fails to provide a proper return path to the common terminal, the electricity tries to find a path back to the vehicle through the other light circuits or the metal hitch ball. This “feedback” causes the strange light patterns seen on the road.

Another common problem is a single light failing to work. If the right turn signal doesn’t work but the right brake light does, you likely have a broken traveler wire inside the harness or a burnt-out dual-filament bulb. Use your diagram to trace the green wire from the plug back to the light housing, looking for any nicks or breaks in the insulation.

Use a small amount of dielectric grease on the pins of your 4-way connector. This non-conductive grease blocks moisture and prevents the green corrosion (copper oxidation) that eventually destroys electrical conductivity.

Best Practices for Trailer Wiring Longevity

To ensure your wiring lasts for years, consider the environment where the trailer will be stored. UV rays from the sun can make wire insulation brittle, leading to cracks. If possible, store your trailer plug in a protective cap or tuck it inside the frame when not in use.

Maintenance is key. Every time you hook up your trailer, take ten seconds to inspect the pins on the plug. If you see dirt or debris, clean it out with a small brush. If you notice a loose wire on a round connector, use a screwdriver to re-tighten the brass screw and apply a drop of thread locker to prevent it from vibrating loose again.

When it comes to wire quality, don’t settle for the cheapest option. Look for “marine grade” tinned copper wire if you frequently launch a boat. Standard copper wire can “wick” moisture up under the insulation, causing the wire to rot from the inside out. Tinned copper is much more resistant to this type of failure. Also, ensure the wire gauge is appropriate for your trailer length; for trailers over 20 feet, stepping up to a 14-gauge ground wire can significantly improve light brightness and system reliability.

Technical Comparison: 4-Pin vs. 7-Pin Systems

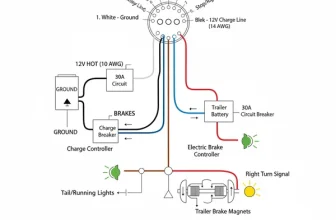

While the trailer wiring diagram 4 pin is the focus here, it is helpful to know where it sits in the hierarchy of towing. A 4-pin system is strictly for “four-way” communication: Ground, Tail, Left Signal, and Right Signal. It does not support a neutral wire in the sense of a high-voltage AC system, nor does it support electric trailer brakes.

If you upgrade to a trailer with electric brakes or an internal battery that needs charging, you will likely move to a 7-pin connector. However, many 7-pin to 4-pin adapters are available. These adapters take the four primary signals from the 7-pin vehicle socket and route them into the standard 4-pin flat configuration. Understanding the core 4-pin diagram ensures that even when using adapters, you can diagnose where a signal might be dropping out.

Summary of the 4-Pin Wiring Standard

The 4-pin trailer wiring setup remains the most user-friendly and essential electrical configuration for the DIY towers. By following the standardized color coding—White for Ground, Brown for Tail, Yellow for Left, and Green for Right—you can confidently manage any basic towing task. Remember that the integrity of your common terminal ground is the foundation of the entire system. Without a solid ground, the voltage cannot flow correctly, leading to safety hazards on the highway.

Whether you are performing a simple repair or a full-scale installation, refer back to your trailer wiring diagram 4 pin to ensure every traveler wire is correctly placed and every connection is sealed against the elements. With the right tools, a bit of patience, and a focus on quality components like the proper gauge wire and secure terminals, your trailer’s electrical system will provide years of reliable service, keeping you and other drivers safe during every journey.

Frequently Asked Questions

What is trailer wiring diagram 4 pin diagram?

A 4 pin trailer wiring diagram is a schematic illustrating the electrical connections for light-duty trailers. It defines the paths for the ground wire, tail lights, and directional signals. By following this visual guide, you can ensure the hot wire for each circuit correctly activates the brake lights and indicators.

How do you read trailer wiring diagram 4 pin diagram?

Read the diagram from left to right, identifying the color-coded paths from the vehicle plug to the trailer lights. Locate the common terminal for grounding to establish a complete circuit. Ensure you understand how each signal acts as a traveler wire from the harness to the specific rear light housing.

What are the parts of trailer wiring diagram 4 pin?

The main parts include the ground wire (white), the tail light circuit (brown), the left turn signal (yellow), and the right turn signal (green). These components connect to a common terminal or ground point on the trailer frame to ensure the hot wire signals function properly during towing operations.

Why is the ground wire important?

The ground wire is critical because it creates the return path to the common terminal, completing the electrical loop. Without a solid ground, the hot wire cannot deliver power effectively to the bulbs. Unlike household AC neutral wire setups, automotive systems rely heavily on a secure metal-to-metal frame connection.

What is the difference between 4-pin and 7-pin wiring?

A 4-pin setup provides basic lighting like tail, brake, and turn signals, while a 7-pin adds auxiliary power, reverse lights, and electric brakes. While a 4-pin system treats the frame as a neutral wire return path, a 7-pin often requires more complex traveler wire routing for additional braking functions.

How do I use trailer wiring diagram 4 pin diagram?

Use the diagram to identify which wire corresponds to each lighting function during installation or repair. Start by securing the ground wire to the common terminal, then use the schematic to route each hot wire to the correct bulb socket. This ensures the trailer signals accurately mirror the towing vehicle.