Toyota Sienna Serpentine Belt Diagram: Routing & Install

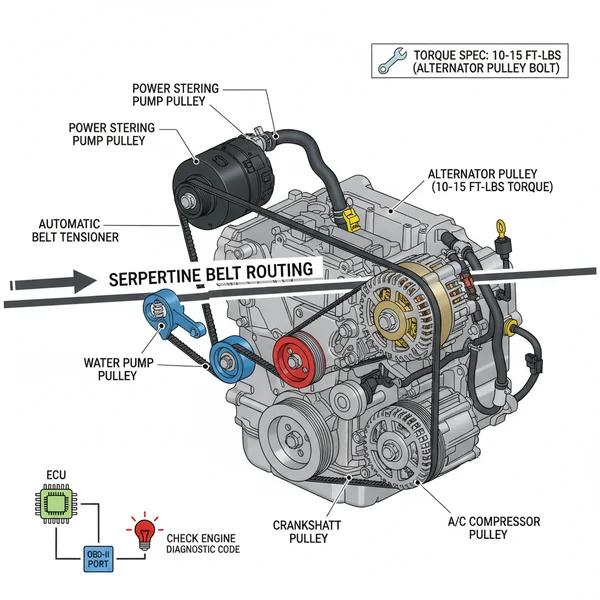

The Toyota Sienna serpentine belt diagram illustrates the precise path around the alternator, water pump, and AC compressor. Using a 14mm wrench on the tensioner allows belt removal. Proper routing is vital to prevent slippage that could trigger a check engine light or store a diagnostic code in the ECU.

📌 Key Takeaways

- Provides a visual guide for routing the 3.5L V6 accessory drive belt.

- Identifying the automatic tensioner pulley is the most critical step for belt release.

- Incorrect tension or routing can damage the water pump or alternator bearings.

- Always cross-reference the diagram with the OEM sticker found under the vehicle hood.

- Essential for DIY maintenance to prevent engine overheating or electrical failure.

Finding an accurate 2008 toyota sienna serpentine belt diagram is essential for any DIY mechanic or vehicle owner looking to maintain their minivan’s performance. The serpentine belt, also known as the accessory belt, is a single, continuous loop that powers critical engine components including the alternator, power steering pump, and air conditioning compressor. Because the 3.5L V6 engine in the 2008 Sienna is packaged tightly, understanding the exact routing path is the difference between a quick repair and hours of frustration. This guide provides a detailed breakdown of the pulley system, step-by-step installation instructions, and technical specifications to ensure your cooling and charging systems function flawlessly.

The 2008 Toyota Sienna features the 2GR-FE 3.5-liter V6 engine. Unlike older models that might have used multiple V-belts, this engine utilizes a single, long serpentine belt to drive all external accessories. The diagram for this specific model year illustrates a path that weaves through seven distinct points of contact. Understanding the layout requires identifying each pulley’s function. At the bottom of the engine sits the crankshaft pulley, which is the primary driver of the entire system. From there, the belt travels upward to interact with the alternator and the air conditioning compressor.

The routing is deceptive because it involves both “grooved” and “smooth” pulleys. Grooved pulleys interface with the ribbed side of the belt, while smooth idler pulleys or the tensioner pulley typically press against the flat backside of the belt. In the 2008 Sienna, the water pump is also driven by this belt, making its integrity vital for maintaining proper coolant flow and preventing engine overheating. If the belt is routed incorrectly, even by a single pulley, the accessories may spin in the wrong direction or the belt may slip off entirely, leading to immediate mechanical failure.

[DIAGRAM_PLACEHOLDER: 2008 Toyota Sienna Serpentine Belt Layout]

Visualizing the 7-Pulley System: 1. Alternator (Top Left) | 2. Idler Pulley (Top Center) | 3. Power Steering Pump (Top Right) | 4. Air Conditioning Compressor (Middle Right) | 5. Crankshaft Drive (Bottom Center) | 6. Automatic Tensioner (Middle Left) | 7. Water Pump (Center Interior)

The automatic tensioner is located on the front side of the engine (passenger side). It uses a heavy-duty internal spring to maintain a specific amount of pressure on the belt. When looking at the diagram, you will notice the belt loops under the tensioner and over the water pump. This specific “S-curve” is where most errors occur during installation. Because the 2008 Sienna uses a timing chain rather than a timing belt, the serpentine belt is the only external belt you need to worry about for routine accessory maintenance.

The 2008 Toyota Sienna (3.5L V6) requires a belt with a length of approximately 82.5 to 83 inches. Always verify the part number with your VIN, as slight variations in pulley diameters can occur between early and late production years.

Replacing the belt on a 2008 Sienna is a task that can be accomplished in about 45 to 60 minutes with the right tools. Because the engine is mounted transversely (sideways), space is limited between the engine and the passenger-side wheel well.

- ✓ 14mm long-handle wrench or a dedicated serpentine belt tool

- ✓ Floor jack and jack stands

- ✓ Lug nut wrench (19mm or 21mm)

- ✓ Flashlight or work lamp

Step 1: Preparation and Safety

Park the vehicle on a flat surface and engage the parking brake. Since you will be working near the engine’s rotational components, ensure the keys are out of the ignition. For the best access, loosen the lug nuts on the front passenger wheel, jack up the car, and secure it on jack stands. Remove the wheel and the plastic splash shield inside the wheel well. This provides a direct line of sight to the crankshaft and the tensioner.

Step 2: Locating the Tensioner

Identify the automatic tensioner pulley. On the 2008 Sienna, the tensioner has a 14mm bolt head cast into the assembly (often located on the arm of the tensioner rather than the center of the pulley itself). Do not attempt to loosen this bolt; instead, you will use it as a lever.

Never place your fingers between the belt and the pulleys. If the tensioner tool slips, the spring force is strong enough to cause serious injury.

Step 3: Releasing Belt Tension

Place your 14mm wrench on the tensioner nut. Rotate the wrench clockwise (toward the front of the vehicle). You will feel significant resistance as you compress the internal spring. Once the tension is released, the belt will become slack. Slip the belt off the uppermost pulley (usually the alternator) first.

Step 4: Removing and Inspecting

Slowly let the tensioner return to its original position. Feed the old belt out through the wheel well. This is the perfect time to inspect the pulleys. Spin each idler and accessory pulley by hand. They should spin smoothly without any grinding noise or lateral “wobble.” If the water pump pulley feels loose, you may have a coolant flow issue developing.

Step 5: Routing the New Belt

Using the 2008 toyota sienna serpentine belt diagram as your reference, begin “weaving” the new belt starting from the bottom. It is usually easiest to loop it around the crankshaft pulley first, then the AC compressor and power steering pump. Leave the alternator pulley (the highest one) for last, as it is the easiest to reach while holding the tensioner open.

Step 6: Final Seating

Double-check that the ribs of the belt are perfectly centered in the grooves of each pulley. Re-apply clockwise pressure to the tensioner and slide the belt over the alternator pulley. Slowly release the tensioner.

Step 7: Verification

Before starting the engine, use a flashlight to ensure the belt is not “half-on” any pulley. Reinstall the splash shield and the wheel. Lower the vehicle and tighten the lug nuts to the proper torque spec (usually 76 lb-ft for this model). Start the engine and listen for any squealing or chirping.

Take a photo of the belt routing with your phone before removing the old one. While the diagram is helpful, a real-world photo of your specific engine bay can clarify the tight clearances near the frame rail.

Common issues with the Sienna serpentine system usually manifest as audible cues. A high-pitched squeal upon startup often indicates a stretched belt or a failing tensioner. If the belt slips significantly, the alternator will fail to provide adequate power, which might cause the ECU (Engine Control Unit) to trigger a check engine light. While the belt itself doesn’t have a sensor, the resulting low voltage can cause various modules to report a diagnostic code related to “System Voltage Low.”

If you notice a “battery” light on the dashboard or a check engine light, you can use an OBD-II scanner to see if the alternator is outputting correctly. Another frequent problem is a seized AC compressor clutch. If the compressor seizes, it will create massive friction on the belt, often leading to a “burnt rubber” smell and eventual belt snapping. Use the diagram to identify if the belt is tracking straight; a misaligned belt is a sign that one of the accessory bearings is failing.

Maintaining the accessory belt is a proactive way to avoid being stranded. Most technicians recommend replacing the belt every 60,000 to 100,000 miles. However, you should inspect it annually for “glazing” (a shiny appearance on the ribs) or “cracking.” Modern EPDM (Ethylene Propylene Diene Monomer) belts do not always crack like older neoprene belts, so using a belt wear gauge is the most accurate method for assessment.

When purchasing a replacement, opt for high-quality brands like Bando (the OEM supplier for Toyota), Gates, or Continental. These brands ensure the belt length is exact, which prevents the tensioner from hitting its “stop” and causing vibration. Always keep your OBD-II scanner handy after a belt change; if the battery was disconnected or the voltage dropped during the failure, you may need to clear old codes to reset the ECU’s charging parameters.

Finally, pay attention to the water pump. Because the water pump is an external component driven by the accessory belt—and not the internal timing chain—any leak from the pump can saturate the belt in coolant. This causes the belt to slip and deteriorate rapidly. If you see pink crusty residue near the pulleys, address the coolant leak immediately to save your new belt and ensure consistent coolant flow throughout the engine block. Keeping a copy of the 2008 toyota sienna serpentine belt diagram in your glovebox is a smart move for any long-distance traveler, ensuring that even a roadside repair is manageable.

Step-by-Step Guide to Understanding the Toyota Sienna Serpentine Belt Diagram: Routing & Install

Identify the belt routing by comparing the diagram to the current belt configuration under the Sienna’s hood.

Locate the automatic tensioner pulley, usually found near the front of the 3.5L V6 engine block assembly.

Understand how to release tension by rotating the tensioner bolt counter-clockwise using a long-handled 14mm wrench.

Connect the new belt by looping it over all pulleys except the tensioner, following the diagram path exactly.

Verify that the belt ribs are centered and check the mounting bolts against the factory torque spec.

Complete the task by starting the engine to ensure no check engine light appears on the instrument cluster.

Frequently Asked Questions

What is 2008 toyota sienna serpentine belt diagram?

It is a schematic showing how the single drive belt weaves through engine pulleys like the crankshaft and alternator. It ensures the belt follows the correct path to drive accessories. Referring to it prevents installation errors that could lead to a diagnostic code being logged by the vehicle’s computer.

How do you read 2008 toyota sienna serpentine belt diagram?

Begin at the largest pulley, the crankshaft, and follow the line representing the belt. The diagram distinguishes between the smooth side and the ribbed side of the belt touching specific pulleys. This ensures the water pump and AC compressor spin in the right direction for optimal engine cooling and performance.

What are the parts of 2008 toyota sienna serpentine belt?

The system includes the multi-ribbed belt, an automatic tensioner, and pulleys for the alternator, AC compressor, power steering, and water pump. If these components fail, the ECU may detect a fault, causing the check engine light to illuminate due to improper voltage or overheating signals from various engine sensors.

Why is the tensioner important?

The automatic tensioner maintains constant pressure on the belt to prevent slipping or jumping. If the tensioner fails, the belt may squeal or snap, potentially damaging the engine. When replacing it, ensure you use the correct torque spec for the mounting bolts to avoid stripping the aluminum engine block threads.

What is the difference between serpentine and V-belts?

Serpentine belts are long, flat, and multi-ribbed, driving all accessories at once. V-belts are older, wedge-shaped, and usually drive only one or two components. Modern Sienna models use the serpentine design, which is more efficient but requires a precise routing diagram to avoid mechanical interference or catastrophic component failure.

How do I use 2008 toyota sienna serpentine belt diagram?

Print the diagram or keep it on your phone while working in the wheel well. Use it to verify that the belt ribs are seated perfectly in every pulley groove. After installation, check that no wires near the OBD-II port or other sensors were disturbed during the repair process.