Stabilizer Bar Sway Bar Link Diagram: Component Identification

A stabilizer bar sway bar link diagram illustrates the connection between the suspension’s anti-roll bar and the control arms or struts. This visual layout helps identify the specific configuration of bushings and links within the system, ensuring the vehicle structure remains stable during turns by reducing body roll and improving handling.

📌 Key Takeaways

- Visualizing how the anti-roll bar connects to the wheels

- Identifying the sway bar links as the primary wear points

- Ensuring all bolts are torqued correctly for safety

- Using the diagram to locate specific bushing placements

- Consulting the layout during suspension repair or upgrades

When you are attempting to diagnose a noisy suspension or improve your vehicle’s handling, a stabilizer bar sway bar link diagram becomes an indispensable tool. Navigating the underside of a modern vehicle can be confusing, but understanding the specific layout of these parts allows you to pinpoint mechanical failures with precision. This article provides a comprehensive breakdown of the stabilizer bar system, showing how each component works in harmony to prevent body roll. By studying the diagram and the associated descriptions, you will learn the exact configuration of your suspension, identify worn parts, and understand the step-by-step process for performing a professional-grade replacement in your own garage.

Understanding the Stabilizer Bar System Configuration

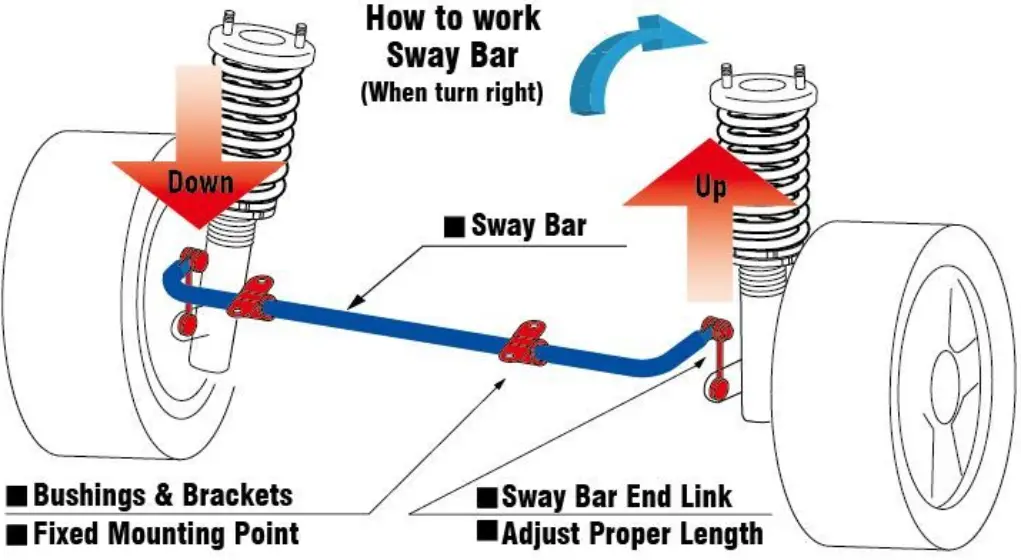

The stabilizer bar system is a relatively simple yet vital part of your vehicle’s safety and comfort layout. A stabilizer bar sway bar link diagram typically illustrates a “U-shaped” steel rod that spans the width of the vehicle’s chassis. This bar is usually made of high-tensile spring steel, designed to resist twisting forces. In a standard front-suspension configuration, the central part of the bar is attached to the vehicle’s frame or subframe using rubber or polyurethane bushings and metal brackets.

The most critical component in this layout for DIY mechanics is the sway bar link, also known as the end link. These links act as the bridge between the ends of the stabilizer bar and the vehicle’s suspension assembly, which is usually the control arm or the strut housing. The diagram highlights how these links utilize ball joints or rubber grommets at either end to allow for vertical movement of the wheels while transferring lateral force to the bar. Because the links are the most mobile part of the system, they are the component most likely to fail due to friction and road debris.

While most diagrams show a generic front-end setup, some performance vehicles or heavy-duty trucks utilize a rear stabilizer bar as well. The basic structure remains the same, though the mounting points may differ significantly between front and rear configurations.

Most diagrams use color-coding or numbered labels to differentiate between the stabilizer bar (the main structure), the bushings (the isolation points), and the links (the connectors). In high-performance systems, you might see “adjustable” links in the diagram, which allow for fine-tuning the suspension’s preload. Understanding these visual distinctions is the first step toward a successful repair.

[DIAGRAM_PLACEHOLDER – A detailed technical illustration showing a vehicle subframe with a stabilizer bar mounted via two center bushings. The ends of the bar are connected to the lower control arms via vertical sway bar links featuring ball-joint ends. Labels point to: 1. Stabilizer Bar, 2. Mounting Bushing, 3. Bracket, 4. Sway Bar Link, 5. Control Arm Connection.]

Step-by-Step Guide to Interpreting and Using the Diagram

Once you have studied the stabilizer bar sway bar link diagram, the next phase is applying that visual knowledge to physical labor. Interpreting a technical drawing requires translating a 2D image into 3D space under your car. Follow these steps to use the diagram for a successful inspection or installation.

- ✓ Identify Your Specific Suspension Type: Before starting, verify if your diagram matches your vehicle’s setup (e.g., MacPherson strut vs. Double Wishbone).

- ✓ Locate the Mounting Points: Use the diagram to find where the bar attaches to the frame. These are often hidden behind plastic covers or engine splash shields.

- ✓ Assess the Sway Bar Link Orientation: Note whether the link is vertical or angled. Installing a link upside down or on the wrong side can cause binding.

- ✓ Gather Required Tools: Based on the diagram’s fasteners, you will typically need a socket set, a wrench, and often an Allen key or hex bit to hold the stud of the ball joint in place while loosening the nut.

- ✓ Prepare the Vehicle: Lift the vehicle and support it on jack stands. Crucially, the suspension should be “loaded” or “unloaded” equally on both sides to prevent tension on the bar.

Never attempt to remove sway bar links while only one side of the vehicle is raised. This puts the stabilizer bar under extreme tension, and it can snap upward or downward with enough force to cause serious injury when the bolt is released.

To remove and replace the components according to the system layout:

1. Apply penetrating oil to all nuts and bolts shown in the layout.

2. Use a wrench to hold the inner flat of the link’s ball joint while using a socket to remove the outer nut.

3. If the link is a “stud” style, use the diagram to ensure you have the correct sequence of washers and rubber grommets.

4. Clean the mounting holes on both the stabilizer bar and the control arm to ensure a flush fit for the new component.

5. Thread the new nuts by hand to avoid cross-threading.

6. Consult your owner’s manual for torque specifications—usually ranging from 25 to 45 foot-pounds depending on the vehicle size.

7. Lower the vehicle and perform a “bounce test” by pushing down on the fenders to ensure no new noises have been introduced.

Common Issues and Troubleshooting with the Diagram

When your vehicle begins to exhibit handling problems, the stabilizer bar sway bar link diagram serves as a diagnostic roadmap. The most common symptom of a failure in this system is a metallic “clunking” or “rattling” sound that occurs when driving over small bumps or uneven pavement. By looking at the diagram, you can see that the sway bar links are the primary points of articulation; if the ball joints within these links lose their lubrication or develop play, they will bounce within their housings, creating the noise.

Another frequent issue is a “lean” or excessive body roll during cornering. This often indicates that the stabilizer bar itself has lost its effectiveness, usually because the central mounting bushings have hardened, cracked, or fallen out. By referencing the diagram’s bushing layout, you can inspect the brackets for signs of gaps between the rubber and the metal bar. If you see light through the bushing or notice the bar can be moved by hand while the vehicle is stationary, the system configuration is compromised and requires new hardware.

Finally, visual inspection often reveals “blown” grease boots on the links. The diagram shows where these protective seals should be. If they are torn, road salt and grit will enter the joint, leading to rapid failure. If your physical layout doesn’t match the clean lines of the diagram—specifically if parts appear bent or shifted—your vehicle may have suffered impact damage that requires a full bar replacement rather than just new links.

Tips and Best Practices for Maintenance

Maintaining the integrity of your stabilizer bar system configuration doesn’t have to be expensive or time-consuming. One of the best pro tips is to always replace sway bar links in pairs. Even if only one side is making noise, the other side has likely been subjected to the same amount of wear and tear. Replacing both ensures balanced handling and prevents you from having to perform the same repair twice within a few months.

When purchasing replacement parts, look for links that feature “grease zerk” fittings. Unlike factory-sealed units, these allow you to pump fresh grease into the joint during every oil change, significantly extending the life of the component beyond the standard lifespan.

When installing new bushings, avoid using petroleum-based grease on rubber components, as this can cause the rubber to degrade and swell over time. Instead, use a silicone-based lubricant or the specialized grease often provided with aftermarket polyurethane bushings. This ensures the bar can rotate smoothly within the bracket without squeaking.

Regarding component quality, it is often worth investing in “heavy-duty” aftermarket links if you frequently drive on rough roads or carry heavy loads. These parts often feature thicker rods and larger ball joints than the ones shown in a standard factory stabilizer bar sway bar link diagram. Keeping your suspension system properly tightened and lubricated will not only save you money on premature tire wear but will also ensure that your vehicle remains predictable and safe during emergency maneuvers.

In conclusion, mastering the stabilizer bar sway bar link diagram is the key to maintaining a quiet and stable ride. By understanding the relationship between the bar, the links, and the chassis, you can confidently troubleshoot noises and replace worn parts. Whether you are a novice or an experienced DIYer, following the proper system configuration and installation steps will result in a professional repair that enhances your vehicle’s performance for years to come.

Frequently Asked Questions

What is stabilizer bar sway bar link diagram?

A stabilizer bar sway bar link diagram is a technical illustration showing the layout of a vehicle’s anti-roll system. It details how the bar connects to the suspension via links, identifying every critical component. This visual guide is essential for understanding the mechanical configuration required to keep the car level.

How do you read stabilizer bar sway bar link diagram?

To read this diagram, start by identifying the main stabilizer bar running across the chassis. Follow the lines to the sway bar links at each end, which connect to the struts or control arms. Note the location of bushings and brackets that secure the structure to the frame.

What are the parts of stabilizer bar sway bar link?

The primary parts shown in the diagram include the main stabilizer bar, end links with ball joints or bushings, mounting brackets, and rubber insulators. Each component plays a vital role in the system, working together to transfer force and maintain vehicle balance during cornering or over bumps.

Why is sway bar link important?

The sway bar link is a crucial component because it acts as the bridge between the stabilizer bar and the suspension system. It transmits energy from the wheels to the bar, allowing the system to resist body roll. Without a functional link, the vehicle’s handling and stability are compromised.

What is the difference between stabilizer bar and sway bar link?

The stabilizer bar is a long metal rod that spans the width of the vehicle to control lean. In contrast, the sway bar link is the smaller connecting structure that attaches the bar to the wheel assembly. Both are parts of the same system but serve different mechanical purposes.

How do I use stabilizer bar sway bar link diagram?

Use the diagram to identify the correct placement and orientation of parts during maintenance. It provides a clear layout for assembly, ensuring that bushings and links are installed in the right configuration. This helps prevent installation errors that could lead to noise or poor suspension performance.