Shifter Mercury Outboard Shift Linkage Diagram: Setup Guide

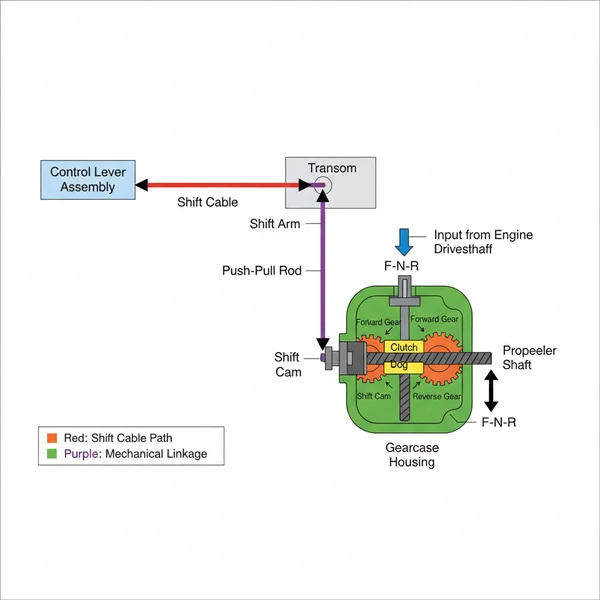

This diagram illustrates the mechanical connection between the remote control and the lower unit gear case. It details the configuration of the shift rod, cable, and bell crank, allowing boaters to visualize the linkage structure to ensure precise gear engagement and resolve shifting resistance or alignment issues.

📌 Key Takeaways

- Visualizes the mechanical path from throttle lever to gear case.

- The shift rod is the most critical component for gear selection.

- Always disconnect battery power before adjusting linkage components.

- Use the diagram to identify worn bushings or bent rods.

- Consult this layout when performing lower unit maintenance or cable replacement.

When you are tackling marine engine maintenance, having a clear and accurate shifter mercury outboard shift linkage diagram is the difference between a smooth day on the water and a frustrating afternoon stuck at the dock. For any boat owner or technician, understanding the intricate path from the helm control box down to the lower unit is essential for ensuring that your gear transitions are crisp and precise. This diagram serves as a technical roadmap, illustrating how mechanical energy is transferred through cables and rods to engage forward, neutral, and reverse gears. In this comprehensive guide, you will learn how to identify every critical component, interpret the mechanical layout of the shift system, and follow professional steps to calibrate your linkage for peak performance.

Mercury outboard shift systems vary significantly between small portable engines and high-horsepower Verado or Pro XS models. Always verify your engine’s serial number before finalizing adjustments based on a general diagram.

Understanding the Shifter Mercury Outboard Shift Linkage Diagram

The primary function of a shifter mercury outboard shift linkage diagram is to visualize the mechanical “handshake” between the remote control cables and the engine’s internal transmission. When you view a standard layout, the system is typically divided into three distinct zones: the control head (shifter handle), the mid-section cable routing, and the engine-side shift bracket.

In the engine-side portion of the diagram, you will observe the shift slide or shift cradle. This is a critical component that converts the linear horizontal push-pull motion of the throttle/shift cable into a vertical or rotational movement required by the lower unit’s shift shaft. The diagram typically uses color-coding or specific numbering to highlight the cable anchor points. For example, the shift cable is usually the bottom cable in a dual-cable setup, distinguished from the throttle cable by its specific barrel adjustment nut.

The diagram also illustrates the structure of the shift interrupt switch—a small but vital component in most Mercury configurations. This switch briefly cuts the engine’s ignition to reduce torque on the gears, allowing for a smoother transition out of gear. Without a diagram to show the proper orientation of this switch relative to the shift slide, many DIYers accidentally bypass or misalign it, leading to “stiff” shifting or engine stalling when docking.

Another key element found in the diagram is the detent ball and spring assembly. This mechanical layout ensures that when you move the shifter into the neutral position, it “clicks” and stays there securely. The configuration of the shift rod itself—often a splined shaft extending into the gearcase—is also detailed, showing how it interfaces with the cam that moves the shifter dog against the forward or reverse gears.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing the Mercury outboard shift bracket, the shift cable barrel, the shift slide, the interrupt switch, and the lower unit shift shaft interface.]

Step-by-Step Guide to Interpreting and Adjusting the Linkage

Reading a shifter mercury outboard shift linkage diagram is the first step, but applying that knowledge to a physical engine requires a methodical approach. Follow these steps to ensure your system is configured correctly and functioning within factory specifications.

- ✓ Step 1: Set the Control Box to Neutral – Before touching any linkage components, ensure your remote control handle is in the straight-up neutral position. This establishes the baseline for all subsequent measurements shown on your diagram.

- ✓ Step 2: Locate the Shift Cable Barrel – Under the engine cowling, find where the thick shift cable enters the shift bracket. The diagram will show a threaded “barrel” nut that sits in a specific cradle. This is your primary adjustment point.

- ✓ Step 3: Verify Lower Unit Alignment – Disconnect the cable and manually move the engine’s shift slide into the neutral detent. You can verify this by spinning the propeller; it should spin freely in both directions without clicking.

- ✓ Step 4: Align the Cable to the Cradle – Hold the cable end next to the shift slide pin. The barrel nut should be adjusted so that it drops perfectly into its cradle without having to pull or push the cable. This ensures the “center point” of your shifter matches the “center point” of the engine.

- ✓ Step 5: Test Full Travel Range – Move the shifter into full forward and then full reverse. Check the diagram to ensure the shift slide is reaching its maximum travel limit in both directions. If it hits the stop in forward but not in reverse, your barrel adjustment is off-center.

- ✓ Step 6: Secure the Retainer Latch – Once aligned, flip the plastic or metal retainer latch over the cable barrel. Many Mercury models use a bright orange or yellow plastic clip to signify this locking mechanism.

Never attempt to shift a Mercury outboard while the engine is off unless someone is manually turning the propeller. Shifting a stationary gearcase can bend the internal linkage or damage the shift dog because the gear teeth may not be aligned.

To perform these steps effectively, you will need a basic set of tools: a set of open-ended wrenches (usually 7/16″ or 10mm/12mm depending on the model), needle-nose pliers for cotter pins, and a high-quality marine-grade grease. Always consult the specific torque specifications if your diagram indicates that the linkage mounting bolts have been loosened.

Common Issues and Troubleshooting the Shift System

When the reality of your engine’s performance doesn’t match the smooth operation shown in the shifter mercury outboard shift linkage diagram, you likely have a mechanical discrepancy. One of the most common issues is “gear grinding” during engagement. This often occurs because the shift cable has stretched over time, meaning the shift slide isn’t moving far enough to fully lock the shift dog into the gear. By referencing the layout in your diagram, you can identify if the cable barrel needs to be turned “out” to provide more throw.

Another frequent problem is stiff shifting. If the handle requires significant force to move, the issue is rarely in the gearbox itself. Instead, look at the cable routing and the pivot points on the engine shift bracket. Saltwater corrosion often builds up on the shift rod bushing where it enters the lower unit. The diagram will show you exactly where these pivot points are located so you can apply penetrant or lubricant.

If the engine stalls whenever you shift into gear, the shift interrupt switch is the prime suspect. Using the diagram, locate the switch and the “V” shaped notch on the shift slide. If the switch is being triggered and staying depressed, it is cutting the ignition for too long. This usually points to a binding shift cable or a misaligned linkage that is fighting against the switch’s actuator arm.

If you are struggling to find neutral, look for the “Neutral Start” wires on your linkage diagram. These wires prevent the starter from engaging unless the linkage is perfectly centered. If your engine won’t even crank, your shift linkage might simply be slightly out of adjustment, triggering this safety feature.

Maintenance Tips and Best Practices for Longevity

To keep your Mercury shift system operating like new, regular maintenance of the components identified in your shifter mercury outboard shift linkage diagram is mandatory. The marine environment is incredibly harsh, particularly for the moving parts of a shift system that are exposed to both salt spray and heat.

First, always use Mercury 2-4-C Marine Grease with PTFE on all moving parts of the linkage. Every season, you should apply a small amount of grease to the shift slide, the cable ends, and the pivot pin. Avoid using heavy automotive greases, as these can thicken in cold water and make shifting difficult.

Second, inspect your shift cables for “swelling.” If the outer jacket of the cable looks cracked or expanded, moisture has entered the inner core and started to rust the steel strands. No amount of adjustment to the linkage will fix a failing cable. When replacing cables, always opt for premium high-flex cables (such as Teleflex/Seastar Xtreme series), which provide much smoother operation than standard economy cables, especially in tight routing configurations.

Third, pay attention to the lower unit shift shaft. Every time you pull the lower unit for a water pump change, inspect the splines on the shift shaft. If these splines are rounded or corroded, the linkage won’t be able to transfer torque effectively. Re-greasing these splines before reassembly is a “must-do” task that is often overlooked.

By mastering the layout and components of your shifter mercury outboard shift linkage diagram, you empower yourself to perform professional-grade maintenance and troubleshooting. This not only saves money on technician labor but also ensures that your vessel remains reliable and safe for every voyage. Whether you are adjusting a small tiller-steer motor or a complex remote-control system, precision in your shift linkage is the key to a superior boating experience.

Frequently Asked Questions

What is shifter mercury outboard shift linkage diagram?

A shifter Mercury outboard shift linkage diagram is a visual map showing how the gear selection system is organized. It details the mechanical path from the cockpit lever to the lower unit. This layout helps boaters identify specific components like cables and rods necessary for smooth gear transitions and repairs.

How do you read shifter mercury outboard shift linkage diagram?

Reading this diagram requires following the mechanical flow from the remote control input to the shift shaft. Identify the cable attachment point, then trace the movement through the internal bell crank and down to the shift rod. Understanding this structure helps you pinpoint where mechanical play or stiffness originates.

What are the parts of shifter mercury outboard shift linkage?

The system consists of several essential components including the shift cable, pivot pins, shift rod, and gear case coupler. The configuration also includes bushings and springs that maintain tension. These parts work together to translate the horizontal movement of the cable into the vertical movement required for the gear case.

Why is the shift rod component important?

The shift rod is vital because it serves as the final link that physically moves the clutch dog inside the gear case. If this component is bent or improperly indexed, the engine may fail to engage forward or reverse, potentially causing internal transmission damage or leaving you stranded on the water.

What is the difference between side-mount and top-mount linkages?

Side-mount linkages typically feature a more compact configuration integrated into a single lever housing, while top-mount systems often use a more complex layout with separate binnacle controls. While the internal components differ, both systems rely on the same fundamental principles to actuate the outboard’s shift shaft through mechanical cables.

How do I use shifter mercury outboard shift linkage diagram?

Use the diagram to identify the specific location of adjustment points and mounting hardware. By comparing the diagram’s layout to your actual motor, you can verify if parts are missing, misaligned, or worn out. It serves as a blueprint for disassembly and reassembly during routine gear system maintenance.