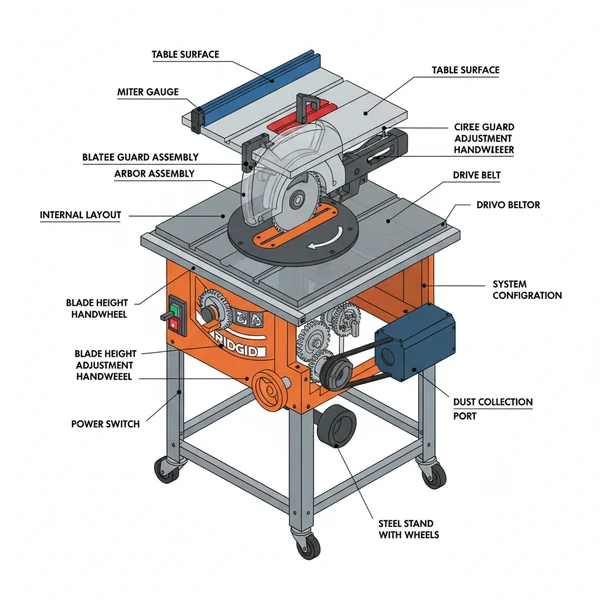

Ridgid Table Saw Parts Diagram: Repair & Assembly Guide

A Ridgid table saw parts diagram illustrates the internal structure and mechanical system of the tool. It provides a visual layout of essential parts like the motor, blade arbor, fence, and trunnions, enabling users to identify specific components for repair, routine maintenance, or ordering replacement parts for various models.

📌 Key Takeaways

- Main purpose of this diagram is to visualize the complete mechanical assembly for easier maintenance

- Most important component to identify is the specific model number to ensure part compatibility

- Safety consideration: always disconnect power before inspecting internal tool configurations

- Practical application tip: use the exploded view to sequence assembly and disassembly correctly

- Use this diagram when ordering OEM replacement components to maintain machine integrity

When you are maintaining or repairing a high-performance stationary tool, having access to a detailed ridgid table saw parts diagram is the most effective way to ensure accuracy and safety. This comprehensive guide is designed to help you navigate the complex internal architecture of your machinery, whether you are performing a routine blade alignment or a full motor replacement. By understanding the visual layout and the relationship between various mechanical assemblies, you can confidently source the correct components and execute repairs without the guesswork. Throughout this article, you will learn how to interpret exploded views, identify critical structural elements, and use these schematics to troubleshoot common mechanical failures effectively.

Understanding the Ridgid Table Saw System and Layout

The structural configuration of a Ridgid table saw is engineered for both stability and precision. When looking at a ridgid table saw parts diagram, the layout is typically divided into several major sub-systems that work in harmony. The primary structure begins with the heavy-duty cabinet or stand, which provides the foundation for the cast iron or aluminum table top. Central to this system is the trunnion assembly, a robust internal bracket that holds the motor and the arbor, allowing for height adjustments and bevel tilts.

The diagram serves as a visual breakdown of how these components interface. For instance, the arbor assembly consists of the shaft, bearings, and flanges that secure the blade. On the exterior, the fence system is represented as a separate module, including the rails, locking handle, and cursor. Understanding this configuration is vital because many Ridgid models, such as the popular contractor or job site series, utilize modular parts that may look similar but have distinct mounting points. The diagram uses numerical callouts that correspond to a parts list, ensuring that when you search for a “bearing” or a “shim,” you are obtaining the exact specification required for your specific model’s footprint.

Most Ridgid diagrams are organized by “Exploded Views.” This means the parts are shown floating in space but aligned along their axis of installation. Always look for the dashed lines in the diagram, as these indicate the specific path and order in which components like washers, spacers, and nuts must be threaded onto a shaft.

Step-by-Step Guide: How to Read and Utilize the Diagram

Interpreting a technical ridgid table saw parts diagram requires a systematic approach to avoid assembly errors. Whether you are a seasoned woodworker or a DIY enthusiast, following these steps will help you master the internal layout of your machine.

- Locate Your Model Number: Before opening the diagram, find the metal data plate on your saw’s base. Ridgid saws have variations across different production runs. Ensure your diagram matches the specific model (e.g., R4512, R4513, or R4510) to avoid ordering incompatible components.

- Identify the Major Assemblies: Divide the diagram into sections. Usually, page one covers the exterior housing and table, while subsequent pages detail the motor, internal gears, and the blade guard system. By isolating the system you are working on, you reduce visual clutter.

- Trace the Hardware Path: Look for the “stacking order.” In a table saw arbor, for example, the order of the inner flange, blade, and outer flange is critical. The diagram will show these parts in the exact sequence they should be installed on the arbor shaft.

- Cross-Reference the Part Numbers: Every numbered bubble on the diagram refers to a specific SKU. Use the legend provided with the schematic to find the official manufacturer part name. This is crucial when searching for replacements online, as generic names can be misleading.

- Analyze the Fasteners: Pay close attention to symbols representing screws, bolts, and snap rings. Often, diagrams will list the dimensions (e.g., M5 x 12mm). If you lose a screw, the diagram tells you exactly what size to buy at the hardware store.

- Verify Orientation: Many internal components, like trunnion brackets, are directional. The diagram will show the “face” of the part. If the part in your hand doesn’t match the orientation in the drawing, you may have it backwards.

Always disconnect your table saw from the power source before performing any inspection or repair based on a parts diagram. Moving parts, such as the blade and motor belt, can cause severe injury if the tool is accidentally engaged during maintenance.

When performing a repair, it is helpful to have basic tools ready. A standard set of metric and imperial hex keys, a socket set, a Phillips head screwdriver, and a pair of snap-ring pliers are usually sufficient for most Ridgid table saw teardowns. Keep a small magnetic tray nearby to hold the small components you remove, following the order shown in the schematic.

Common Issues and Troubleshooting with Schematics

A ridgid table saw parts diagram is not just for ordering new pieces; it is a primary troubleshooting tool. Many users encounter common issues that can be diagnosed simply by looking at the mechanical relationships shown in the drawing.

One frequent problem is a “stiff” height adjustment wheel. By consulting the diagram, you can identify the threaded rod and the bevel gears that facilitate this movement. Often, the diagram reveals that a build-up of sawdust in the gear teeth—or a missing retaining clip—is the culprit. Another common issue is the fence failing to lock square. The diagram illustrates the internal cam-lock mechanism. By studying the component layout, you can see if the pressure plate is worn or if the adjustment bolt simply needs tightening to restore its grip on the rail.

If you notice excessive vibration, use the diagram to locate the motor mounts and the drive belt. A cracked pulley or a loose motor mounting bolt—both clearly labeled in a standard configuration—can often be the source of the noise. If the saw fails to start, the diagram will show the location of the reset button, the power switch assembly, and the motor brushes. If the motor brushes are worn down, the diagram helps you identify exactly which housing cover to remove to reach them without dismantling the entire motor.

If your saw is several years old, some parts may be discontinued. When looking at your diagram, check for ‘superseded’ part numbers. Often, a newer, improved component has replaced the original part, and the manufacturer’s database will link the old number in your diagram to the new, available part.

Maintenance Tips and Component Best Practices

To keep your machine running according to the specifications in your ridgid table saw parts diagram, regular maintenance of each component is required. The life of your table saw depends on the health of its internal system.

- ✓ Dry Lubrication: Use a dry PTFE or graphite spray on the gears and threaded rods shown in your diagram. Avoid grease or oil, as these attract sawdust, which creates a “paste” that can jam the mechanism over time.

- ✓ Blade Path Cleaning: Periodically remove the throat plate and use compressed air to clean the trunnion area. Refer to your layout to ensure you aren’t blowing debris deeper into the motor housing.

- ✓ Check Alignment Regularly: Use the diagram to identify the trunnion mounting bolts. Every few months, verify that the blade remains perfectly parallel to the miter slots. If it’s off, these are the bolts you will need to loosen to make adjustments.

- ✓ Invest in Quality Parts: When replacing items like the arbor nut or the drive belt, stick to high-quality or OEM components. Lower-grade fasteners can strip easily, and inferior belts can cause unwanted vibration that ruins the quality of your cuts.

- ✓ Save Your Manuals: Digital diagrams are great, but keeping a printed copy of the ridgid table saw parts diagram in a plastic sleeve attached to the side of the saw ensures you always have the technical reference handy during a project.

In conclusion, a ridgid table saw parts diagram is the most valuable resource in your workshop for ensuring the longevity and precision of your tool. By understanding the structural layout and the specific function of each component, you transform from a casual user into a capable technician. Whether you are solving a complex mechanical system failure or simply performing a routine check of the configuration, the diagram provides the clarity needed to maintain a safe and efficient cutting environment. Always remember to cross-reference your model number, follow safety protocols, and use the detailed schematics to keep your Ridgid table saw performing at its peak for years to come.

Frequently Asked Questions

What is Ridgid table saw parts diagram?

A Ridgid table saw parts diagram is a technical schematic showing the exploded view of the machine’s internal structure. It labels every component, from the motor assembly to the miter gauge, helping users visualize how the entire system fits together for assembly, troubleshooting, or parts replacement tasks.

How do you read Ridgid table saw parts diagram?

To read the diagram, locate the specific assembly you are working on, such as the motor or table. Follow the leader lines from the visual component to its corresponding reference number. This number matches a parts list detailing the official name and part number for that specific configuration.

What are the parts of Ridgid table saw?

The primary parts include the motor, blade, arbor, fence, trunnions, miter gauge, and bevel adjustment gears. The diagram also details smaller hardware like washers, nuts, and bolts within the internal layout, ensuring you can identify every specific component required for a functional and safe woodcutting system.

Why is blade arbor important?

The blade arbor is a critical component because it holds the saw blade in place and transfers power from the motor. Its precise alignment within the internal structure ensures accurate cuts. Understanding its position in the system configuration is vital for maintaining safety and preventing dangerous blade wobbling or vibrations.

What is the difference between contractor and jobsite saws?

Contractor saws typically feature a larger, more stable structure and a belt-driven system, whereas jobsite saws use a compact layout with direct-drive motors. Their parts diagrams reflect these differences in configuration, with contractor saws having more heavy-duty components designed for permanent shop placement and high precision work.

How do I use Ridgid table saw parts diagram?

Use the diagram to identify faulty parts by comparing your physical saw to the visual layout. Once a component is identified, use the reference number to find the exact part number. This ensures you order the correct replacement and understand the sequence for reassembling the machine safely.