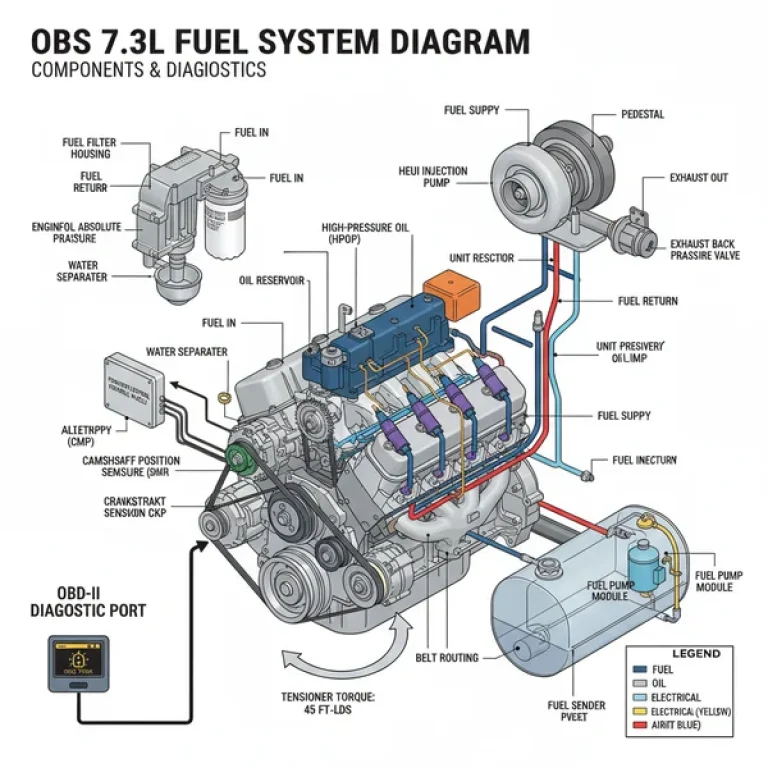

Quadrajet Vacuum Line Diagram for Chevy 305: Routing Guide

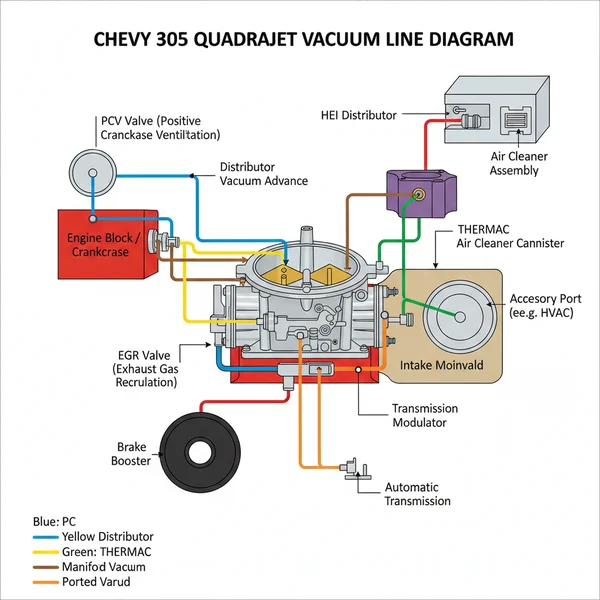

A Quadrajet vacuum line diagram for a Chevy 305 illustrates the complex configuration of hoses connecting the carburetor to emissions equipment like the PCV valve, distributor advance, and EGR valve. Properly routing this system is essential for maintaining correct idle speed, fuel efficiency, and overall engine responsiveness in classic Small Block Chevy setups.

📌 Key Takeaways

- The diagram serves as a blueprint for the engine’s pneumatic control system

- Identifying the PCV and manifold vacuum ports is the most critical step

- Always check for cracked hoses that cause vacuum leaks and poor idling

- Use color-coded silicone hoses to simplify future maintenance and identification

- Reference this diagram during a carburetor rebuild or emissions inspection

Navigating a complex quadrajet vacuum line diagram for chevy 305 can feel like solving a high-stakes puzzle, especially when your engine’s performance depends on every millimeter of hose. The Rochester Quadrajet is a masterpiece of mechanical engineering, but its efficiency is entirely dependent on a properly configured vacuum system. In this comprehensive guide, we will break down the intricate web of hoses that manage everything from your idle speed to your power brakes. You will learn how to identify specific ports, distinguish between ported and manifold vacuum, and ensure your Chevy 305 runs with the smoothness and power it was designed to deliver. Whether you are performing a restoration or troubleshooting a rough idle, this guide provides the clarity you need to master your carburetor’s configuration.

The Chevy 305 engine often utilizes different Quadrajet versions, such as the 4MV, 4MC, or the computer-controlled E4ME. While the port locations are generally similar, always verify your specific carburetor model number stamped on the side of the main body before finalizing your routing.

The Anatomy of a Quadrajet Vacuum System Layout

Understanding the structure of a Quadrajet vacuum system requires identifying the three primary types of vacuum sources: Manifold Vacuum, Ported (Timed) Vacuum, and Venturi Vacuum. Manifold vacuum is strongest at idle and is sourced from below the throttle plates. Ported vacuum, which is essential for distributor advance and EGR operation, only provides a signal once the throttle plates begin to open. Venturi vacuum is a weaker signal used primarily for sensing airflow volume. The component layout of a standard Chevy 305 Quadrajet typically features a large 3/8-inch port at the front center for the PCV (Positive Crankcase Ventilation) system and another large port at the rear for the power brake booster.

The configuration also includes several smaller ports located on the front and sides of the air horn and throttle body. A small port near the top front usually feeds the charcoal canister for fuel vapor recovery. On the passenger side, you will find the vacuum break (choke pull-off) diaphragm, which prevents the engine from flooding during a cold start by slightly opening the choke plate once the engine fires. If your 305 is equipped with an automatic transmission like the TH350, a small metal line typically runs from a vacuum T-fitting at the rear of the manifold to the transmission modulator to control shift points based on engine load.

Visualizing the system can be daunting because many lines cross over one another. Color-coding your hoses—using red for manifold vacuum, blue for ported vacuum, and yellow for emission controls—can significantly simplify the layout during installation. The following diagram represents the generalized routing found on most mid-era Chevy 305 applications, including connections for the EGR valve, thermal vacuum switches (TVS), and the air cleaner’s heat riser valve.

A high-resolution schematic showing the Rochester Quadrajet carburetor ports, including PCV, Power Brakes, Distributor Advance, EGR, and Choke Pulloff connections for a Chevy 305 engine.

Step-by-Step Guide to Interpreting and Installing Vacuum Lines

Properly implementing a quadrajet vacuum line diagram for chevy 305 requires a systematic approach. Before you begin, ensure the engine is cool and you have a clear workspace. Having a digital camera or smartphone to take “before” photos of your current configuration is highly recommended, even if you believe the current routing is incorrect.

Never attempt to route vacuum lines while the engine is running. Moving parts like the fan and hot components like the exhaust manifold pose significant safety risks. Additionally, improper routing can lead to unintended high-idle conditions.

Follow these steps to ensure a professional-grade installation:

- ✓ Step 1: Identify Vacuum Ports: Use the diagram to locate the manifold vacuum ports (active at idle) and ported vacuum ports (active off-idle). Use a vacuum gauge if you are unsure; manifold vacuum will show a steady 15-22 in-Hg at idle, while ported vacuum will show near zero.

- ✓ Step 2: Connect the PCV System: Attach a high-quality 3/8-inch vacuum-rated hose from the PCV valve in the valve cover to the large center port at the base of the Quadrajet. This is critical for engine longevity and crankcase pressure management.

- ✓ Step 3: Route the Power Brake Line: Connect the large port at the rear of the carburetor or the intake manifold directly to the brake booster check valve. Ensure this hose is reinforced to prevent collapsing under high vacuum.

- ✓ Step 4: Configure Distributor Advance: For most street-driven 305s, the vacuum advance canister on the distributor should be connected to a ported vacuum source on the carburetor. This ensures advance only occurs when the engine is under load or cruising, preventing “pinging” at idle.

- ✓ Step 5: Setup Emission Controls: Route the EGR valve through a Thermal Vacuum Switch (TVS) located on the intake manifold or thermostat housing. This prevents the EGR from opening until the engine reaches operating temperature, which avoids stalling when cold.

- ✓ Step 6: Secure and Inspect: Use small zip ties or vacuum clamps on all connections. Trace each line one final time against the quadrajet vacuum line diagram for chevy 305 to ensure no lines are pinched or touching hot exhaust surfaces.

To complete this job effectively, you will need a few basic tools: needle-nose pliers for tight spaces, a sharp utility knife for custom-cutting hose lengths, and a hand-held vacuum pump (like a Mityvac) to test individual components like the EGR valve and vacuum advance canister for leaks.

Troubleshooting Common Vacuum and Performance Issues

Even with a perfect structure, vacuum leaks are common on older Chevy 305 engines. The most frequent symptom of a vacuum issue is a “hunting” or surging idle, where the RPMs rise and fall rhythmically. If the engine hesitates or stumbles when you step on the gas, it often points to a failed vacuum break or a leak in the ported vacuum line going to the distributor. If your power brakes feel “hard” or require excessive effort, the large rear vacuum line may be cracked or the booster diaphragm itself may have failed.

The quadrajet vacuum line diagram for chevy 305 serves as a diagnostic roadmap. By capping off one port at a time while the engine is idling, you can isolate which circuit is causing the problem. If the engine smooths out when a specific port is plugged, you have found your leak. Be particularly wary of the EGR valve; if it is stuck open due to a vacuum routing error or carbon buildup, it will cause a very rough idle that mimics a mechanical engine failure. If troubleshooting does not resolve the issue, or if you find internal carburetor leaks (common in the well plugs of older Quadrajets), it may be time to consult a professional carburetor specialist.

To find hidden leaks, spray a small amount of non-flammable carburetor cleaner around the base of the carburetor and the vacuum fittings while the engine is idling. If the RPM changes, you have identified a leak location.

Maintenance Tips and Best Practices

To maintain the integrity of your system, opt for silicone vacuum hoses instead of standard rubber. Silicone is more resistant to the extreme heat generated in the engine bay of a Chevy 305 and will not crack or become brittle over time. While silicone is slightly more expensive, the long-term reliability and “set it and forget it” nature make it a cost-effective upgrade. When replacing lines, replace them one by one rather than pulling them all off at once; this prevents confusion and ensures you maintain the correct layout.

Regular maintenance should include checking the vacuum-operated air cleaner (Thermac) assembly. This component uses a small vacuum motor to pull warm air from around the exhaust manifold during warm-up. If the vacuum line to the air cleaner is disconnected or leaking, your engine may take much longer to reach operating temperature, leading to increased fuel consumption and poor driveability in cold weather. Furthermore, always ensure the charcoal canister filters are clean, as a clogged canister can create a vacuum restriction that disrupts the fuel tank’s venting system.

Finally, keep a printed copy of your quadrajet vacuum line diagram for chevy 305 inside your glove box or taped to the underside of the hood. Standard factory stickers on the radiator shroud often fade or peel away over decades of use. Having a reliable reference on hand ensures that any future repairs—or roadside emergencies—can be handled with confidence and precision. By following these best practices, your Chevy 305 will maintain its iconic performance and reliability for years to come.

Frequently Asked Questions

What is a Quadrajet vacuum line diagram for Chevy 305?

This diagram is a visual map showing the specific layout of vacuum hoses between the Rochester Quadrajet carburetor and engine peripherals. It details the system structure, indicating where manifold and timed vacuum sources connect to components like the air cleaner, vacuum advance, and EGR valve for optimal performance and emissions control.

How do you read a Quadrajet vacuum line diagram for Chevy 305?

Start by identifying the carburetor’s front and rear faces. Trace lines from labeled ports, such as the large PCV port or smaller distributor advance port, to their corresponding engine parts. Solid lines usually represent hoses, while arrows indicate the direction of vacuum flow within the engine’s configuration and pneumatic system.

What are the parts of a Quadrajet vacuum line system?

The system includes the Rochester carburetor itself, the PCV valve for crankcase ventilation, the vacuum advance on the distributor, and the EGR valve. Other key components are the charcoal canister for vapor recovery and the thermal vacuum switches often found on the intake manifold or thermostat housing for temperature-based control.

Why is the vacuum advance component important?

The vacuum advance component is crucial because it adjusts ignition timing based on engine load. By pulling timing forward during light-throttle cruising, it improves fuel economy and throttle response. Incorrect routing to this port can lead to engine overheating, poor acceleration, or a rough idle at stoplights during daily driving.

What is the difference between manifold and ported vacuum?

Manifold vacuum is sourced below the throttle plates, providing high vacuum at idle. Ported vacuum, or timed vacuum, is sourced above the throttle plates, offering no vacuum at idle but increasing as the throttle opens. Distinguishing between these in your configuration is vital for correct distributor advance and EGR valve operation.

How do I use a Quadrajet vacuum line diagram for Chevy 305?

Use the diagram as a reference during engine assembly or troubleshooting. Match each port on your specific carburetor model to the diagram’s layout. Carefully route new hoses to avoid heat sources and kinks, ensuring every component receives the correct vacuum signal required for the Chevy 305’s emissions and overall drivability.