Paccar MX 13 Fuel System Diagram: Component Troubleshooting

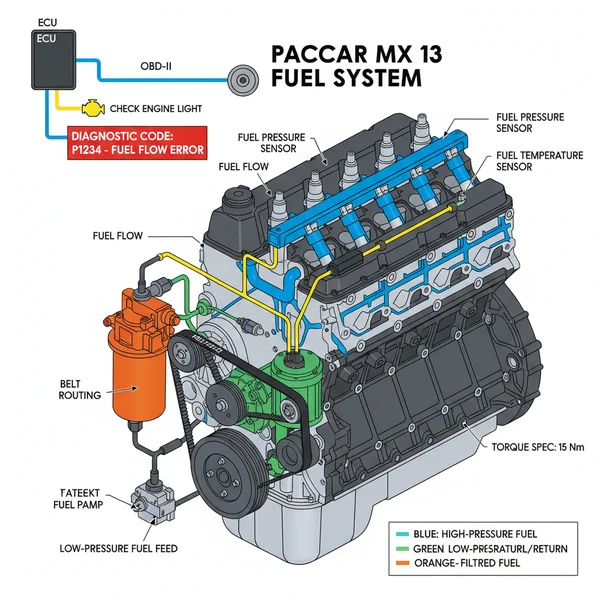

The Paccar MX 13 fuel system diagram illustrates the high-pressure common rail path, starting from the fuel tanks through the filtration module to the injectors. It helps technicians locate the fuel pump, supply lines, and pressure sensors required to diagnose performance issues and ensure the engine operates within factory specifications.

📌 Key Takeaways

- Visualizes the flow from low-pressure lift pumps to high-pressure rails

- The high-pressure fuel pump is the central component for power delivery

- Ensure all fittings meet the specific torque spec to prevent leaks

- Use the diagram to trace fuel restrictions causing engine hesitation

- Consult the diagram when diagnosing complex fuel-related fault codes

Maintaining a heavy-duty diesel engine requires more than just mechanical intuition; it demands a precise understanding of how every component interacts within the engine’s architecture. When you are faced with a loss of prime, a drop in rail pressure, or a mysterious performance lag, having a clear paccar mx 13 fuel system diagram is your most valuable asset. This specialized diagram serves as a roadmap, guiding you through the complex journey fuel takes from the chassis-mounted tanks to the high-pressure common rail. By understanding this flow, you can pinpoint failures more accurately, reduce downtime, and ensure your engine operates at peak efficiency. In this comprehensive guide, we will break down the MX-13 fuel system into its core components, explain the high-pressure delivery logic, and provide the diagnostic steps needed to keep your truck on the road.

Deciphering the Fuel System Architecture

The Paccar MX-13 engine utilizes a sophisticated high-pressure common rail (HPCR) system designed to meet stringent emissions standards while maximizing torque. The paccar mx 13 fuel system diagram typically illustrates a two-stage process: the low-pressure suction side and the high-pressure delivery side. The diagram begins at the fuel tanks, following the supply lines into the fuel filter module. This module is a centralized hub that houses the primary water separator and the secondary micron filter.

Visually, the diagram identifies the mechanical transfer pump, which is responsible for pulling fuel from the tanks. From there, the flow is directed into the engine block, where two integrated high-pressure pump units—often referred to as fuel injection pumps (FIPs)—take over. These pumps are driven by the engine’s internal gear train, a system that relies on precise synchronization similar to a timing chain to ensure the pressure pulses align with the injector firing order. The diagram will often color-code these paths: blue or green for low-pressure suction, and red for high-pressure delivery (reaching upwards of 36,000 PSI).

Another critical element found on the diagram is the fuel rail itself, which acts as a pressurized reservoir for all six injectors. You will also see the return circuit, which carries excess fuel back to the cooling plate on the ECU and eventually back to the tank. This return flow is vital for cooling the electronic components and the injectors themselves.

The MX-13 fuel system is highly sensitive to debris. The fuel filter module not only cleans the fuel but also manages the fuel temperature through an internal thermostatic valve, ensuring optimal viscosity before the fuel reaches the high-pressure pumps.

How to Read and Navigate the MX-13 Fuel Path

Interpreting a paccar mx 13 fuel system diagram requires a systematic approach. To successfully diagnose or repair the system, you must follow the flow in the exact order the fuel travels. This prevents you from overlooking simple issues, like a cracked suction line, before assuming a high-pressure pump has failed.

- ✓ Step 1: Inspect the Low-Pressure Suction Side – Start at the fuel tanks. Use the diagram to identify the supply lines. Check for any signs of “wetness” or crimped lines that could introduce air into the system. Air is the enemy of the MX-13, as it causes cavitation in the high-pressure pumps.

- ✓ Step 2: Locate the Fuel Filter Module – This is the large assembly on the driver’s side of the engine. Use your diagram to identify the primary filter (with the water bowl) and the secondary filter. Ensure the manual priming pump is seated correctly and not leaking air.

- ✓ Step 3: Trace the Transfer Pump Flow – The mechanical transfer pump is located behind the fuel module. It creates the initial pressure (roughly 70-110 PSI) needed to feed the high-pressure pumps. If your OBD-II scanner shows low “gallery pressure,” this pump or its bypass valve is the likely culprit.

- ✓ Step 4: Analyze the High-Pressure Pump Interaction – The MX-13 uses two pump units submerged in the engine block. According to the diagram, these are actuated by the camshaft. They compress the fuel and send it to the common rail. Check for leaks at the high-pressure lines connecting these pumps to the rail.

- ✓ Step 5: Monitor the Rail Pressure Sensor and PRV – At the end of the fuel rail, the diagram will show a Pressure Relief Valve (PRV) and a Rail Pressure Sensor. These components report back to the ECU. If the PRV is hot to the touch while the engine is running, it indicates an internal leak, venting pressure back to the tank.

- ✓ Step 6: Verify the Return Circuit and ECU Cooling – Follow the return lines from the injectors and the rail. These lines pass through a cooling plate behind the ECU. If the coolant flow in the engine is restricted, the fuel return temperature can rise, causing the ECU to derate the engine to protect the electronics.

Never loosen a high-pressure fuel line while the engine is running or immediately after shutdown. The MX-13 common rail retains pressure exceeding 30,000 PSI, which can cause fatal skin penetration. Always wait at least 10 minutes for pressure to bleed down naturally.

To perform these steps effectively, you will need a few specialized tools. A high-quality OBD-II diagnostic tool capable of reading Paccar-specific SPN and FMI codes is essential for viewing real-time ECU data. Additionally, a fuel pressure test kit with the correct M14 adapters allows you to verify the mechanical transfer pump’s health. Finally, always have a torque wrench ready to meet the strict torque spec required for the high-pressure fuel lines; over-tightening can deform the flare and cause permanent leaks.

Troubleshooting Common Fuel System Failures

When the check engine light illuminates on your dashboard, the ECU is usually reacting to a deviation in the fuel system’s expected performance. Common diagnostic codes for the MX-13 often revolve around “Fuel Rail Pressure – Data Valid But Below Normal Operating Range.”

One frequent issue is air entering the suction side. If the paccar mx 13 fuel system diagram shows a line from the tank to the filter module, any tiny pinhole in that line will suck air into the system. This often presents as a hard start or a rough idle. Another common failure is the Pressure Relief Valve (PRV) “popping.” This happens when a pressure spike occurs, and the valve stays open, preventing the rail from reaching the pressure required for high-load operation.

If you encounter a diagnostic code related to fuel delivery, use the diagram to check the “easy” components first. Verify that the accessory belt isn’t slipping, as it sometimes shares space near the fuel lines, and ensure the fuel heater in the filter module is receiving power. If the issue persists, the diagram will help you locate the specific high-pressure pump unit that may be failing by allowing you to perform a “cylinder cutout” test via your diagnostic software.

Maintenance Tips and Best Practices

The longevity of your Paccar MX-13 is directly tied to the cleanliness of your fuel. Because the tolerances within the high-pressure pumps and injectors are measured in microns, even the smallest speck of dirt can cause a catastrophic failure.

Always pre-fill your fuel filters with clean, filtered diesel before installation. However, only fill through the outer “dirty” holes of the filter, never the center “clean” hole. This ensures the fuel passes through the filter media before reaching the engine, protecting your high-pressure components from “new filter” debris.

To keep your system in top shape, adhere to the following best practices:

– Stick to OEM Filters: While aftermarket filters are cheaper, they often lack the water-separation efficiency required by the MX-13.

– Respect the Torque Spec: Fuel line vibration is a major cause of cracking. Always use a torque wrench to tighten rail lines to the manufacturer’s specification (usually 20-30 Nm depending on the specific line).

– Monitor Coolant Flow: Since the fuel return line cools the ECU, ensure your cooling system is flushed and the accessory belt driving the water pump is in good condition.

– Check for “Diesel in Oil”: If you notice your oil level rising, consult your paccar mx 13 fuel system diagram to locate the injector O-rings. A failed O-ring can allow fuel to leak directly into the crankcase, which thins the oil and can lead to engine bearing failure.

By combining a high-quality paccar mx 13 fuel system diagram with disciplined maintenance habits, you can demystify one of the engine’s most complex systems. Whether you are performing a routine filter change or diagnosing a complex rail pressure fault, the diagram is your first line of defense against costly repairs and unnecessary downtime. Keep your ECU updated, listen to your check engine light, and always prioritize cleanliness whenever the fuel system is opened for service.

Step-by-Step Guide to Understanding the Paccar Mx 13 Fuel System Diagram: Component Troubleshooting

Identify the main fuel supply line originating from the chassis fuel tanks.

Locate the fuel filtration module to check for water separation and filter integrity.

Understand how the ECU modulates the high-pressure pump to maintain rail pressure.

Connect an OBD-II scanner to check for any active or pending diagnostic codes.

Verify that every high-pressure fitting meets the manufacturer’s specific torque spec.

Complete the inspection by clearing any check engine light indicators after successful repairs.

Frequently Asked Questions

What is a Paccar MX 13 fuel system diagram?

It is a technical illustration showing the layout of fuel delivery components in a heavy-duty diesel engine. This visual tool maps the flow from the chassis tanks through the fuel module, high-pressure pump, and injectors, allowing technicians to understand how the ECU manages fuel timing and pressure levels.

How do you read a Paccar MX 13 fuel system diagram?

Start by identifying the fuel flow direction, usually indicated by arrows from the tank to the return line. Look for color-coded paths that distinguish between low-pressure suction, medium-pressure gallery, and high-pressure injection stages. Match the numbered labels in the diagram to the corresponding component legend provided in the manual.

What are the parts of the Paccar MX 13 fuel system?

Core components include the fuel filtration module, electric lift pump, high-pressure fuel pump, and common rail. It also features high-precision fuel injectors and various sensors that send data to the ECU. These parts work together to maintain consistent pressure for optimal combustion and low emissions during operation.

Why is the fuel pressure sensor important?

This sensor monitors real-time pressure within the common rail and reports data to the ECU. If pressure deviates from the set parameters, the system may trigger a check engine light or enter limp mode. Accurate sensor readings are vital for maintaining engine power and meeting strict emission standards.

What is the difference between the low-pressure and high-pressure sides?

The low-pressure side draws fuel from the tanks and filters it to remove contaminants before reaching the pump. The high-pressure side, driven by the mechanical pump, pressurizes the fuel up to 36,000 PSI. Understanding this distinction is crucial when using an OBD-II scanner to read a diagnostic code.

How do I use a Paccar MX 13 fuel system diagram?

Utilize the diagram as a roadmap during physical inspections to verify that all lines and connectors are properly routed. It is essential for pinpointing the exact location of sensors when a diagnostic code appears. Use it to ensure every bolt and fitting is tightened to the correct torque spec.