Oil Pressure Gauge Wiring Diagram: Installation Guide

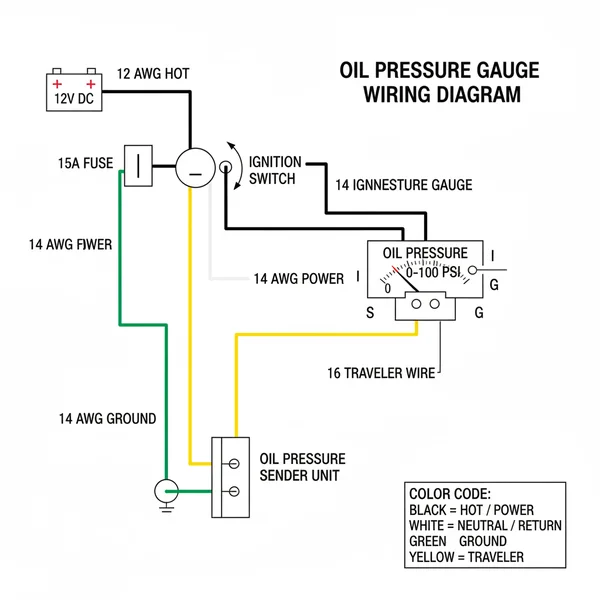

An oil pressure gauge wiring diagram illustrates the electrical path between the sender unit, power source, and display. It shows how the hot wire provides power, the ground wire completes the circuit, and the signal wire transmits pressure data. Properly identifying these connections ensures accurate engine health monitoring and prevents electrical shorts.

📌 Key Takeaways

- Visualizes connections between the engine sender and dashboard display

- The signal wire is the most critical component for data accuracy

- Ensure all connections are insulated to prevent dangerous short circuits

- Always use a fused power source when connecting the gauge’s hot wire

- Use this diagram during initial installation or when diagnosing flickering readings

Maintaining the health of your engine requires more than just regular oil changes; it demands constant monitoring of internal conditions. For many DIY enthusiasts and automotive restorers, installing or repairing an oil pressure gauge wiring diagram is a critical task that ensures you are never left guessing about your lubrication system’s performance. Whether you are dealing with a classic restoration or an aftermarket upgrade, understanding the electrical flow between the engine’s sending unit and the dashboard display is vital. This comprehensive guide will walk you through every connection, from the traveler wire to the ground terminals, ensuring you have a reliable readout every time you turn the key.

Understanding the Oil Pressure Gauge Wiring Diagram Components

An electrical oil pressure gauge system is essentially a balance of resistance and current. Unlike mechanical gauges that pipe actual oil into the cabin, an electrical system uses a sender unit to translate physical pressure into an electrical signal. The wiring diagram typically consists of four primary connections: the power supply (hot wire), the ground wire, the sender signal (traveler wire), and the illumination circuit.

The center of this system is the gauge itself, which usually features three or four terminals on the back. These are often marked with “S” for Signal, “I” or “+” for Ignition, and “G” or “-” for Ground. In many high-quality aftermarket kits, you will notice a brass screw or dedicated post for these connections to ensure a high-conductivity path. The voltage provided to the gauge must be steady, usually a switched 12-volt source, to prevent the needle from jumping or giving false readings as the alternator’s output fluctuates.

The traveler wire is the most distinct part of this diagram. It originates at the “S” terminal on the back of the gauge and travels through the firewall to the oil pressure sending unit located on the engine block. The sending unit acts as a variable resistor; as oil pressure increases, the resistance changes, which in turn alters the current flowing through the gauge, moving the needle. The common terminal in this circuit is typically the engine block itself or a dedicated ground bus, providing the return path for the electrical current.

Most modern electrical gauges use a 0-90 ohm or 240-33 ohm sweep. It is vital that your gauge and sending unit are calibrated to the same resistance range, or the oil pressure gauge wiring diagram will not result in accurate readings.

Main Diagram Breakdown: Visualizing the Connections

When looking at a standard oil pressure gauge wiring diagram, the visual layout can be broken down into the “Engine Side” and the “Cabin Side.”

- ✓ The Hot Wire (Ignition): Usually colored red, this connects to a switched 12V source so the gauge only draws power when the vehicle is on.

- ✓ The Signal/Traveler Wire: Often colored white or green, this links the gauge’s “S” post to the sender’s single terminal.

- ✓ The Ground Wire: Usually black, this runs from the “G” post to a clean, unpainted metal surface on the chassis.

- ✓ The Lighting/Neutral Wire: Often connected to the dash light circuit, allowing the gauge to dim with the rest of your cluster.

– Diagram showing a circular gauge with four terminals: S (Signal), I (Power), G (Ground), and L (Light). A wire runs from S to the Sender on the engine. A wire runs from I to the Fuse Box. A wire runs from G to the Chassis. A wire runs from L to the Dash Light switch.

In many diagrams, the brass screw on the sender is used to bite into the wire terminal, creating a secure physical and electrical bond. Because the engine vibrates significantly, this connection must be tight and protected by a rubber boot or heat-shrink tubing to prevent the traveler wire from fraying or shorting against the block.

Step-by-Step Installation and Wiring Guide

Following an oil pressure gauge wiring diagram requires a methodical approach. Before beginning, ensure you have a basic tool kit including a wire stripper, crimping tool, a multimeter for testing voltage, and 18-gauge automotive-grade wire.

Step 1: Mount the Sending Unit

Locate the oil pressure port on your engine block (refer to your vehicle’s service manual). Remove the existing plug or old sender and thread in the new unit. If your unit has a brass screw terminal, ensure it is accessible. Use thread sealant sparingly, as the threads often provide the ground path for the sender; too much sealant can insulate the unit and break the circuit.

Step 2: Establish the Ground Wire Connection

Run a black wire from the “G” or negative terminal on the back of the gauge to a solid chassis ground. A common terminal point under the dashboard is often the best choice. Ensure the contact point is free of paint, rust, or grease to maintain a low-resistance path.

Step 3: Connect the Hot Wire to Switched Power

Identify a fuse in your fuse block that only receives power when the ignition is in the “On” or “Acc” position. Connect your red hot wire to this source and run it to the “I” or “+” terminal on the gauge. Installing an inline 3-amp or 5-amp fuse is a recommended safety measure to protect the gauge internal circuitry from surges.

Step 4: Route the Traveler Wire

This is the most labor-intensive step. Connect a wire to the “S” terminal on the gauge and route it through a rubber grommet in the firewall. Avoid running this wire near high-heat sources like exhaust manifolds or high-voltage components like spark plug wires, as electromagnetic interference can cause “needle flutter.” Connect the other end to the terminal on the engine’s sending unit.

Step 5: Wire the Internal Illumination

To see the gauge at night, you need to tap into the vehicle’s dash lighting circuit. Connect a wire from the gauge’s light terminal to the wire that powers your factory instrument cluster lights. The neutral wire or return path for the light bulb usually shares the gauge’s main ground, but check your specific diagram to see if a separate ground is required for the bulb housing.

Step 6: Final Testing and Calibration

Before tidying up the wires, turn the ignition to the “On” position. The needle should jump slightly or stay at zero. Start the engine. The needle should rise as the oil pump builds pressure. Use your multimeter to check the voltage at the “I” terminal to ensure it stays near 12-14 volts while the engine is running.

Never connect the traveler wire directly to a 12V power source. Doing so will bypass the resistance of the sending unit and will likely burn out the gauge’s internal coil instantly.

Common Issues & Troubleshooting

Even with a perfect oil pressure gauge wiring diagram, issues can arise during installation or after years of use. One of the most common problems is a “pegged” needle (reading maximum pressure constantly). This usually indicates that the traveler wire has a break or has become disconnected from the sender, creating infinite resistance. Conversely, if the gauge reads zero despite the engine running smoothly, the signal wire might be shorted to the ground.

Another frequent culprit is a poor ground wire connection. If the gauge light dims when you use other accessories, or if the needle moves erratically, check the common terminal where your grounds meet. High resistance at the ground point will drop the voltage available to the gauge, leading to inaccurate readings. If you suspect the gauge is faulty, use a multimeter to check the resistance of the sender unit while the engine is off and then while it is idling; you should see a measurable change in ohms.

Tips & Best Practices for a Professional Finish

To ensure your installation lasts the life of the vehicle, consider these professional tips. First, always use heat-shrink tubing over your crimp connectors. The engine bay is a harsh environment filled with moisture and oil; unprotected connections will eventually corrode, increasing resistance and ruining your accuracy.

When routing your traveler wire, use plastic wire loom to protect it from sharp metal edges on the firewall. If your gauge uses a brass screw terminal, use a ring terminal on the end of your wire rather than just wrapping bare wire around the post. This provides a 360-degree contact surface and prevents the wire from vibrating loose.

If you are installing multiple gauges (like oil pressure, water temp, and volts), create a “daisy chain” for the hot wire and ground wire. This reduces the number of wires running to your fuse box and keeps the back of the dashboard clean and organized.

Finally, always choose high-quality components. While a cheap gauge might save money upfront, they often lack internal voltage regulation, meaning your oil pressure reading will change simply because you turned on the headlights. Spending a little more on a reputable brand ensures that the internal components can handle the heat and vibration of automotive use.

By following this oil pressure gauge wiring diagram and installation guide, you empower yourself with the data needed to protect your engine. Accurate wiring isn’t just about making the needle move; it’s about establishing a reliable line of communication between your engine’s vitals and your eyes on the road. Whether you’re navigating a trail or cruising the highway, a properly wired gauge is your first line of defense against catastrophic engine failure.

Frequently Asked Questions

What is an oil pressure gauge wiring diagram?

An oil pressure gauge wiring diagram is a visual map showing the electrical connections required to monitor engine oil pressure. It typically highlights the path from the ignition source to the gauge, then to the sending unit on the engine block, ensuring the system communicates data effectively for the driver.

How do you read an oil pressure gauge wiring diagram?

Start by identifying the power source, often labeled as the hot wire or ignition terminal. Trace the signal line from the gauge to the common terminal on the sending unit. Look for ground wire symbols indicating where the circuit returns to the vehicle chassis to complete the electrical loop.

What are the parts of an oil pressure gauge system?

The system consists of the gauge head, a sending unit sensor, a hot wire for power, and a ground wire for the return path. Some setups use a neutral wire concept for lighting circuits, while the sending unit acts as a variable resistor to change the gauge needle position.

Why is the ground wire important?

The ground wire is essential because it completes the electrical circuit. Without a solid connection to the vehicle’s chassis or battery negative, the gauge will not receive power or may provide erratic readings. A poor ground often causes the needle to peg at the maximum or minimum incorrectly.

What is the difference between mechanical and electric gauges?

Mechanical gauges use a physical tube to carry pressurized oil directly to the dashboard, whereas electric gauges use a wiring diagram to transmit signals. Electric versions are safer as they don’t bring hot oil into the cabin, relying instead on a traveler wire to send data from the engine.

How do I use an oil pressure gauge wiring diagram?

Use the diagram to match physical wires to their corresponding terminals on the back of the gauge. Identify the 12V switched source, the illumination wire, and the sender wire. Follow the schematic to ensure the common terminal is correctly linked to the engine sensor for accurate oil monitoring.