Oil Pressure Gauge Wiring Diagram: Installation Guide

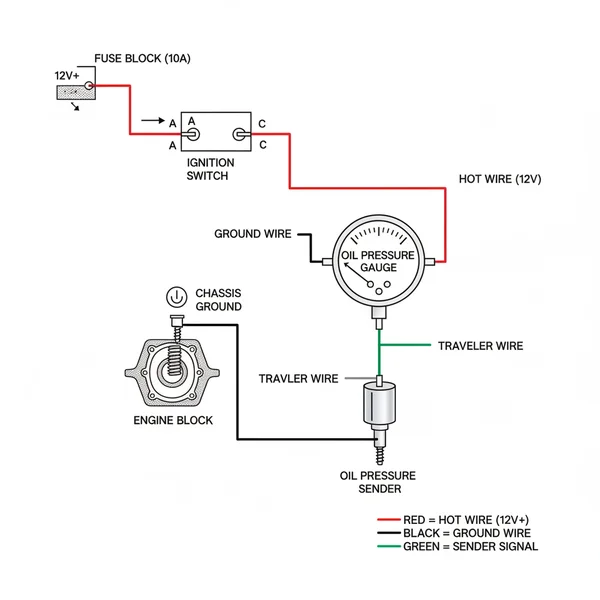

An oil pressure gauge wiring diagram shows the electrical connections between the dashboard gauge, the engine sender, and the power source. Typically, a hot wire provides fused power, a ground wire completes the circuit, and a traveler wire connects the common terminal on the sender to the gauge signal input.

📌 Key Takeaways

- Provides a visual map of the signal path from the engine to the dashboard.

- The oil pressure sender is the most critical component to identify correctly.

- A secure ground is essential to prevent erratic readings or gauge flickering.

- Route signal wires away from high-heat sources like exhaust manifolds.

- Use this diagram when troubleshooting dead gauges or installing aftermarket monitors.

Maintaining the health of your engine requires more than just regular oil changes; it demands real-time monitoring of internal conditions. If you are a DIY enthusiast or a vehicle owner looking to install an aftermarket monitoring system, understanding a precise oil pressure gauge wiring diagram is the most critical step in the process. A faulty connection can lead to inaccurate readings, potentially masking a drop in pressure that could lead to catastrophic engine failure. This guide provides a comprehensive breakdown of how to map out your electrical connections, ensuring that your gauge displays accurate data from the engine’s sending unit. You will learn the specific roles of various wires, how to troubleshoot common electrical faults, and the best practices for a professional-grade installation.

Understanding the Oil Pressure Gauge Wiring Diagram Components

An electrical oil pressure gauge system is essentially a simple DC circuit that translates physical pressure into an electrical signal. The oil pressure gauge wiring diagram typically consists of four primary connection points: power, ground, signal, and illumination. Each of these components plays a distinct role in ensuring the needle moves accurately across the scale in response to the engine’s oil pump activity. Unlike a mechanical gauge that pipes oil directly to the dashboard, an electrical gauge uses a sending unit—a pressure-sensitive resistor—to vary the voltage sent to the display.

[DIAGRAM VISUALIZATION]

(Ignition Switch) —- [Hot Wire] —- (Gauge B+ Terminal)

(Engine Block) —- [Ground Wire] —- (Gauge GND Terminal)

(Sending Unit) —- [Traveler Wire] —- (Gauge S Terminal)

(Dash Lights) —- [Illumination] —- (Gauge Lamp Terminal)

Figure 1: Typical 4-wire Electrical Gauge Configuration

The core of the system is the gauge itself, which often features a brass screw or a spade terminal on the back labeled “S” for signal. This terminal receives the traveler wire originating from the sending unit located on the engine block. In an electrical context, we use the term traveler wire to describe the dedicated signal path that carries the varying resistance values to the gauge. The common terminal on the back of the gauge often refers to the ground connection, which completes the circuit for both the internal logic of the gauge and the backlight. It is vital to distinguish between the hot wire, which provides 12V ignition power, and the signal wire to avoid damaging the sensitive internal coils of the gauge.

Most modern diagrams will also include a secondary circuit for illumination. This is usually connected to the vehicle’s parking light or dimmer switch circuit. When identifying wires, look for color-coding: red is standard for the hot wire, black for the ground wire, and often white or yellow for the signal. However, always refer to the specific manufacturer’s documentation, as these colors can vary significantly between brands like Autometer, VDO, or Bosch.

While AC systems use a neutral wire to return current to the source, DC automotive systems use the vehicle’s chassis as the return path. Therefore, your “neutral” equivalent is a robust ground wire attached to a clean, unpainted metal surface.

Step-by-Step Installation Guide

Properly interpreting and implementing an oil pressure gauge wiring diagram requires a methodical approach. Follow these steps to ensure a clean, safe, and functional installation.

- 1. Preparation and Safety: Disconnect the negative battery terminal. This prevents accidental short circuits while you are probing for power or routing wires through the firewall. Gather your tools: a wire stripper, crimping tool, digital multimeter, and heat-shrink tubing.

- 2. Mounting the Sending Unit: Locate the oil pressure port on your engine block. Remove the factory pressure switch (if applicable) and thread in the new sending unit. Use thread sealant sparingly; do not cover the bottom threads, as the sender often requires a physical connection to the block to establish a ground.

- 3. Routing the Signal (Traveler) Wire: Connect a wire to the brass screw terminal on the sending unit. Route this traveler wire through a rubber grommet in the firewall and toward the dashboard where the gauge will be mounted. Ensure it stays away from high-heat sources like exhaust manifolds or moving parts like steering columns.

- 4. Connecting Ignition Power: Identify a 12V hot wire that only receives power when the ignition is in the “On” or “Run” position. Connecting directly to the battery will drain your charge over time. Use an “add-a-circuit” fuse tap for the cleanest connection. This wire connects to the positive (+) or ‘B’ terminal on the gauge.

- 5. Establishing a Solid Ground: Connect the ground wire from the gauge’s common terminal to a clean chassis ground. A poor ground is the leading cause of “bouncy” needles or inaccurate voltage readings. Use a ring terminal and a dedicated bolt for the best results.

- 6. Wiring the Illumination: Locate the wire for your dash cluster lights. Splice the gauge’s light bulb wire into this circuit. This allows the gauge to dim and brighten along with your other factory instruments when you adjust the dashboard brightness.

- 7. Final Testing: Reconnect the battery. Turn the ignition to the “On” position; the needle should jump slightly or stay at zero. Start the engine. The needle should rise steadily as the oil pump builds pressure. Check all connections for heat or loose fittings.

Never use a neutral wire or ground from a high-amperage component like an electric cooling fan for your gauge ground. High-draw components can cause electrical interference, leading to false oil pressure readings.

Common Issues & Troubleshooting

Even with a perfect oil pressure gauge wiring diagram, issues can arise during or after installation. The most frequent problem is a gauge that “pegs” to the maximum reading as soon as the ignition is turned on. This usually indicates a short to ground in the traveler wire or a faulty sending unit. Conversely, if the needle does not move at all, it often suggests an open circuit—meaning the signal wire is disconnected or the gauge is not receiving 12V voltage from the hot wire.

Another common headache is needle flicker. This is typically caused by a loose common terminal connection or electrical noise. If you notice the gauge reading changes when you turn on your headlights, you likely have a “ground loop” or a shared ground that is overloaded. Using the diagram, re-verify that the ground wire is attached to a dedicated point on the chassis, free of paint or rust. If the troubleshooting steps fail to resolve the issue, or if you smell burning insulation, seek professional help immediately, as this indicates a significant short circuit that could lead to a vehicle fire.

Tips & Best Practices for Wiring Success

To ensure your installation lasts the life of the vehicle, follow these professional-grade tips. First, always use the correct gauge of wire. For most oil pressure gauges, 18-gauge automotive-grade primary wire is sufficient. Using wire that is too thin can lead to voltage drops, while excessively thick wire is difficult to route and crimp.

When connecting to a brass screw terminal, use a small amount of blue thread-locker on the nut to prevent it from vibrating loose over time. However, ensure the thread-locker does not insulate the electrical contact surface.

- ✓ Use Heat-Shrink Connectors: In the engine bay, moisture and oil can corrode standard crimp connectors. Heat-shrink versions provide a waterproof seal.

- ✓ Label Your Wires: Use a small piece of masking tape to label the hot wire and signal wire at both ends. This makes future diagnostics much faster.

- ✓ Protect the Loom: Run your wires through plastic split-conduit or braided looming. This protects the traveler wire from abrasion against metal edges.

- ✓ Check Sender Compatibility: Ensure your sending unit matches the gauge’s Ohmic range (e.g., 0-90 Ohms vs. 10-180 Ohms). Mixing brands often leads to incorrect readings.

By strictly adhering to a verified oil pressure gauge wiring diagram, you eliminate the guesswork associated with engine monitoring. Whether you are dealing with the brass screw on a vintage sender or the multi-pin connector of a digital display, the fundamentals of power, ground, and signal remain the same. Accurate wiring not only protects your investment but also provides the peace of mind that comes from knowing exactly what is happening inside your engine’s oil galleries at any given moment. Remember, a gauge is only as reliable as the wires that feed it; take the time to do it right the first time.

Frequently Asked Questions

What is oil pressure gauge wiring diagram?

An oil pressure gauge wiring diagram is a schematic illustrating the electrical path between the engine’s oil pressure sender and the dashboard display. It identifies where to connect power, ground, and signal lines. This ensures that the electrical resistance from the sender is accurately translated into a pressure reading for the driver.

How do you read oil pressure gauge wiring diagram?

Read the diagram by following the lines representing wires between components. Identify the 12V power source, usually labeled as a hot wire. Look for the signal path from the common terminal on the sender unit to the gauge. Symbols will indicate where the ground wire attaches to the vehicle chassis.

What are the parts of oil pressure gauge wiring?

The main parts include the gauge, the sending unit, and the connecting wires. The wiring consists of a hot wire for ignition-switched power, a ground wire for the return path, and a signal or traveler wire that carries the variable electrical signal from the engine sender to the dashboard gauge unit.

Why is common terminal important?

The common terminal on the oil pressure sender is vital because it acts as the primary junction for the signal output. This terminal sends varying resistance levels to the gauge based on oil pressure changes. Without a secure connection here, the gauge cannot receive the data necessary to display pressure levels.

What is the difference between mechanical and electric gauges?

Mechanical gauges use a physical tube to transport pressurized oil to the dash, whereas electric gauges use a wiring diagram to transmit data. Electric systems use a sender to convert pressure into electrical signals via a traveler wire, making them safer by keeping high-pressure oil out of the vehicle cabin.

How do I use oil pressure gauge wiring diagram?

Use the diagram to identify the specific pinouts on the back of your gauge. Match the colors or labels on your vehicle’s harness to the schematic. Ensure the hot wire is correctly fused and the neutral wire or ground path is established on a clean metal surface for accuracy.